Professional Documents

Culture Documents

Water Level Sensor

Water Level Sensor

Uploaded by

John Gary Recto VillanuevaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Level Sensor

Water Level Sensor

Uploaded by

John Gary Recto VillanuevaCopyright:

Available Formats

Water Level Sensor

Dexter S. De Guzman, ECE Department, Adamson University de_guzman_dexter@yahoo.com

Abstract- This project entitled Water Level Sensor aims to determine the level of water in standpipes, wells, tanks or wherever possible that water is being stored and especially in places which are flood-prone area, through the connections of the grounds of the circuit and with the use of the AND and NOT gate and displays the output with the 7-segment display common cathode. This project was given to engineering student especially students taking up Electronic Devices and Circuits to apply, observe and learn basics in electronics. Applying their knowledge in circuits by following the given circuit and learning how to do it in EAGLE software or PCB Wizard and transferring it to the PCB board.

Keywords AND, NOT gate, 7 segment display common cathode, Electronics Devices and Circuits, Eagle, PCB Wizard. I. INTRODUCTION

sodium. When water is boiled and the steam is allowed to condense in a reservoir. The pure liquid that remains, devoid of minerals, is called distilled water. And distilled water or purified water cant conduct electricity because of the absence of the impurities or of the minerals. Salt water, on the other hand, is considered a good conductor of electricity because it contains ions in it. Tap water, although it doesn't taste salty, can also conduct electricity because it isn't pure. The water from the kitchen sink often has traces of minerals such as calcium, Ca2+, and magnesium, Mg2+ and can help conduct electricity. However, what needs to be noted here is that not all water is the same nor will it conduct electricity at the same rate. Therefore this device cant be use on industry for measuring purified water. And thats only the exception. II. PROCEDURE

This project Water Level Sensor is a water indicator which tells the user if a certain container is low, half, and full. And in accordance with the full is an alarm where if the operator is distant he/she can still be informed about the status of the water level. This device can be used in a wide range of applications. Basically Plain water contains dissolved minerals like calcium, magnesium, iron and

A. GATHERING INFORMATION So first we get first the schematic diagram of the device, how does it looks, what are the components, how does it work etc. We should now gather information how to etch, drill, and solder to make our own designs. We also need to study basic programs to do the design.

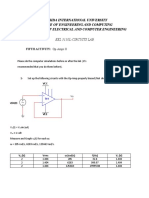

Basically it works when the points are connected as shown in this figure.

Figure 1.1 B. MAKING A DESIGN Since the schematic design is given we need now to follow the circuit and design our own.

Fig. 1.3 (The Design in PCB Wizard-Real World)

Fig. 1.4 (The Design in PCB Wizard-ArtWork) Figure 1.2 (The Schematic Design Given) Designing my own circuit in my case im more used to PCB Wizard and Livewire software program that is also used for designing PCB layouts, where you can manually and let the software place the connections for you, and i used manual to reduce jumpers. The Design is shown: C. IMPLEMENTATION OF THE DESIGN Due to trials and errors I find it more easy and effective using a laser copy of the circuit to a bond paper and then ironing it to the PCB board where by 20 mins the Ink that was on the Paper will be transferred to the PCB but before taking out the paper it should be immersed to water to let the paper unstick to the PCB board. Unlike using Pre-synthesized PCB it more detailed

and difficult to use beacuse of the proper and time of exposing it to light and Acetate paper should be used and much more expensive as I experienced. D. Etching. After the circuit design was transferred to the board, make sure there is no broken line because you dont want to have a broken connection thats why it should be checked thoroughly. Do not put the ferric chloride to a metal container it should be plastic, after pouring the ferric, immerse the PCB and slightly shake or move the container so that it will take the uncovered part of the copper quickly. After all the uncovered part was etched and the remaining part was the drawing of the circuit, rinse the PCB to a clean water and then use a sand paper to remove the inked marked and reveal the copper connections.

components will not be working or will not work properly.

Fig 1.5

Fig 1.6 Figure 1.5 and 1.6 shows the after installation of the components. As shown, The IC and the Displays where given sockets to protect them from direct etching and also to replace them easily. F. TROUBLESHOOTING When it comes to troubleshooting the lines should be checked if their connected to other line or if not connected/open. Checked your circuit if its working, if not look for possible problems, IC and the 7 segment since these two are sensitive. And also check the biasing of the IC and the

E. INSTALLING THE COMPONENTS. Installing the components is the most exciting part, first you need to drill the holes where your IC, 7 segment display, resistor, source, jumper, buzzer and switch located. After that you need to place each component one by one to their respective places and then soldering the components with a soldering lead. Integrated Circuits and the 7 segment display are pretty sensitive and soldering should not be overdone beacuse if does the

buzzer and the switch and also the 7 segment display. III. OBSERVATIONS

months or years and apply what we learn to build better and more creative ideas for the applications of theorems that we are studying through years. REFERENCES

1. http://humantouchofchemistry.com/do es-distilled-water-conductelectricity.htm

I observed that on making PCB Designs, it is more easy if you can manual your work since there is less connections you can also put it to organized manner where all components goes together just like the resistor, IC, and the 7 segment display. And one more advantage I think is that you will not get confused where the inputs and outputs are located and during troubleshooting, you will know where part of the circuit is malfunctioning and more importantly you will understand how the system of your circuit works and by that, it is easy to analyze. I also observed that ironing method is more easy and more effective than using acetate and exposing it to light, with that you will not be sure if the lines are drawn correctly and completely.

2. http://en.wikipedia.org/wiki/State_of _matter#

IV.

CONCLUSIONS

I conclude that this Water Level Sensor can be used for future experiments and can be improved to help people especially in the event of rainfall or typhoons to tell ahead of time or at the current time the level of water running into our seas, damns, or just in our streets. It will help a lot to communities which are floodprone area beacause it will display an output where you can say its still safe or not safe and if you need to evacuate the area etc. I also concluded that this Water Level Sensor project made me know and familiarize more on making electronic designs which we can improve in the coming days, weeks,

You might also like

- Florida International University College of Engineering and Computing Department of Electrical and Computer EngineeringDocument9 pagesFlorida International University College of Engineering and Computing Department of Electrical and Computer EngineeringAneelaMalikNo ratings yet

- ASTON Kartika GrogolDocument2 pagesASTON Kartika GrogolAngga Ciro Bams100% (1)

- Arduino Water Level Sensor, Controller + IndicatorDocument8 pagesArduino Water Level Sensor, Controller + IndicatorMozammeer DeenmahomedNo ratings yet

- Acknowledgement: Cherthala, For Giving Us Valuable Suggestions and SupportDocument36 pagesAcknowledgement: Cherthala, For Giving Us Valuable Suggestions and SupportJithinRajNo ratings yet

- Nebosh IGC Element 5. Rish Assessment (Notes)Document6 pagesNebosh IGC Element 5. Rish Assessment (Notes)kkalvi96% (25)

- Sterility Testing - Pics PDFDocument15 pagesSterility Testing - Pics PDFdepardieu1973100% (2)

- WL705 Ultrasonic Water Level SensorDocument1 pageWL705 Ultrasonic Water Level SensorEdward YaoNo ratings yet

- Design and Implementation of Liquid Level Detector Using Ultrasonic SensorDocument6 pagesDesign and Implementation of Liquid Level Detector Using Ultrasonic SensorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Young's ModulusDocument7 pagesYoung's ModulusNgatno100% (1)

- VFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedDocument5 pagesVFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedelengineerNo ratings yet

- F-03 Self-cleaningFiltersManual & AutomaticAIRPELDocument4 pagesF-03 Self-cleaningFiltersManual & AutomaticAIRPELdevang asher100% (1)

- Lecture 5 - Power SuppliesDocument48 pagesLecture 5 - Power SuppliesNimsiri AbhayasingheNo ratings yet

- Ccs CatalogDocument35 pagesCcs CatalogRicardo Betancourt MaldonadoNo ratings yet

- Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerDocument26 pagesIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerKunal PandeyNo ratings yet

- Sensor Devices Mechanical SensorsDocument41 pagesSensor Devices Mechanical Sensorsdesaivilas60100% (1)

- Preconstruction MeetingDocument32 pagesPreconstruction MeetingMar OlacsNo ratings yet

- Case Study On Comparison of Wireless Technologies in Industrial ApplicationsDocument4 pagesCase Study On Comparison of Wireless Technologies in Industrial ApplicationsM PATHANNo ratings yet

- Spray-Type Deaerating Heaters: TABLE 12.2Document2 pagesSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiNo ratings yet

- Main Pivot Pin Dia CalculationDocument2 pagesMain Pivot Pin Dia Calculationjdutia83100% (1)

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- 722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)Document16 pages722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)rianafrian2611No ratings yet

- Water Level SensorDocument3 pagesWater Level Sensorx-robotNo ratings yet

- SprayAdvantage 2018 CatalogDocument226 pagesSprayAdvantage 2018 CatalogJoe100% (1)

- Automatic Water Level Controller Cum IndicatorDocument46 pagesAutomatic Water Level Controller Cum IndicatorPrasanna Dhayalamoorthy50% (2)

- EE 334 Lecture 2 DiodeDocument14 pagesEE 334 Lecture 2 Diodedreamworld1341No ratings yet

- Load Line Analysis PDFDocument2 pagesLoad Line Analysis PDFVikas GaurNo ratings yet

- Basic Construction and Working of A DC GeneratorDocument7 pagesBasic Construction and Working of A DC GeneratorGlen Howell PanesNo ratings yet

- Portable Water Quality Analysis Using ArduinoDocument6 pagesPortable Water Quality Analysis Using ArduinoRajesh SNo ratings yet

- Synchronous MotorDocument6 pagesSynchronous MotorSelvasundar KumarNo ratings yet

- GrinderDocument5 pagesGrinderfikahNo ratings yet

- Chap 15 CLX Math, Comparison, and Move InstructionsDocument20 pagesChap 15 CLX Math, Comparison, and Move Instructionsjameesng69No ratings yet

- Manuscript 123Document46 pagesManuscript 123Datuzuharto Sultan100% (1)

- Pivot PinDocument1 pagePivot Pinsourajpatel001100% (1)

- Catalogo Geral 2013 SchneiderDocument216 pagesCatalogo Geral 2013 SchneiderGersel RodriguesNo ratings yet

- Meta MEC Adjustable MCCBDocument16 pagesMeta MEC Adjustable MCCBECATOnlineNo ratings yet

- Experimental Study of Solar Power Grass PDFDocument6 pagesExperimental Study of Solar Power Grass PDFBemn BayuNo ratings yet

- Types of DiodeDocument3 pagesTypes of DiodeRyan HarrisNo ratings yet

- Electric and Magnetic LoadingDocument14 pagesElectric and Magnetic LoadingViggnesh Venkatakrishnan100% (1)

- Water Level Controller Using Microcontroller and BuzzerDocument65 pagesWater Level Controller Using Microcontroller and Buzzermohit73% (11)

- EE131.1 LabDocument40 pagesEE131.1 LabMarc MontillaNo ratings yet

- Catalog - Essential Guide of Control Panel PDFDocument172 pagesCatalog - Essential Guide of Control Panel PDFMircea MurarNo ratings yet

- Edge Baffle AsslyDocument4 pagesEdge Baffle AsslyVikram TambeNo ratings yet

- Chapter 4 PLC ProgrammingDocument100 pagesChapter 4 PLC ProgrammingMuhd Izwan Ikhmal RosliNo ratings yet

- Application of Chain Drive and Its Selection Method in AutomobileDocument18 pagesApplication of Chain Drive and Its Selection Method in AutomobileSumedh sonawaneNo ratings yet

- Document'S Code Attachment 10.3 Revision 0: ClientDocument4 pagesDocument'S Code Attachment 10.3 Revision 0: ClientrfriosEP100% (1)

- NPN TransistorDocument1 pageNPN TransistorsphinxNo ratings yet

- 18 SG With Round Rotor DesignDocument45 pages18 SG With Round Rotor DesignAnonymous 2eBal0sNo ratings yet

- Project ReportDocument9 pagesProject ReportAnika Chawla100% (5)

- PLCDocument19 pagesPLCassaultquirasNo ratings yet

- Guided Problem Solving No. 1: Transmission Media and Antenna Systems ECE Department, TUP ManilaDocument1 pageGuided Problem Solving No. 1: Transmission Media and Antenna Systems ECE Department, TUP ManilaJesmar EnerioNo ratings yet

- Design and Monitoring of Water Level System Using Sensor TechnologyDocument3 pagesDesign and Monitoring of Water Level System Using Sensor TechnologyIJSTENo ratings yet

- Design and Construction of Automatic Hand DryerDocument6 pagesDesign and Construction of Automatic Hand DryerSamuelNo ratings yet

- Ideal Transformer - Electrical4uDocument3 pagesIdeal Transformer - Electrical4usauravNo ratings yet

- PLC Unit 2-1 PDFDocument44 pagesPLC Unit 2-1 PDFMahesh ShendeNo ratings yet

- Chapter 3 Signal Conditioning CircuitDocument30 pagesChapter 3 Signal Conditioning CircuittcsNo ratings yet

- Chinhoyi University of Technology: - School of Engineering Sciences and - CUME 206Document33 pagesChinhoyi University of Technology: - School of Engineering Sciences and - CUME 206Cornelius DhliwayoNo ratings yet

- Touch Sensor DLD ProjectDocument6 pagesTouch Sensor DLD ProjectThe Alone RayNo ratings yet

- Unit-03 - Part-2 FiltersDocument57 pagesUnit-03 - Part-2 Filtersr55088299No ratings yet

- TRANSMISSION LINES Part 2 3Document53 pagesTRANSMISSION LINES Part 2 3Em ReyesNo ratings yet

- Single Phase TransformerDocument22 pagesSingle Phase Transformerkssrao13No ratings yet

- Touch Sensor ProjectDocument23 pagesTouch Sensor ProjectamiferariNo ratings yet

- (Hazmi) Task 5 - Fabrication PCBDocument9 pages(Hazmi) Task 5 - Fabrication PCBAtzroulnizam AbuNo ratings yet

- 3 - Project Work - R1Document25 pages3 - Project Work - R1Sujesh ChittarikkalNo ratings yet

- Concept of C ProgrammingDocument74 pagesConcept of C ProgrammingAbhishek KumarNo ratings yet

- ch9 Text Bank Consumer BehaviorDocument60 pagesch9 Text Bank Consumer BehaviorHiba AhmedNo ratings yet

- Radar EquationDocument15 pagesRadar EquationLintang AnggitiadewiNo ratings yet

- BA4911Document17 pagesBA4911Maicon Bruno AlbaNo ratings yet

- BSC 6600Document11 pagesBSC 6600Naldo Baskara ArmandNo ratings yet

- Aisi Type 403 (Chemical Composition)Document7 pagesAisi Type 403 (Chemical Composition)MiguelPacheecoAgamezNo ratings yet

- 72 Generations UKDocument10 pages72 Generations UKszymonmaj712No ratings yet

- CPK60DWS DriverGuideE V100Document18 pagesCPK60DWS DriverGuideE V100Matías BlancoNo ratings yet

- Internship Research Project Guidelines - 2020-23Document7 pagesInternship Research Project Guidelines - 2020-23today.sureshjk6No ratings yet

- Amafilter MVDCDDocument3 pagesAmafilter MVDCDFaiz ElninoNo ratings yet

- ReadmeDocument2 pagesReadmeVictor MilhomemNo ratings yet

- Panasonic CS-C95KEDocument16 pagesPanasonic CS-C95KEJuana LasernaNo ratings yet

- JEE (Main + Advanced) : Leader Course (Score-I) & Enthusiast Course (Score-Ii)Document34 pagesJEE (Main + Advanced) : Leader Course (Score-I) & Enthusiast Course (Score-Ii)anwa1No ratings yet

- Metrosils For High Impedance RelaysDocument4 pagesMetrosils For High Impedance RelaysPramod B.WankhadeNo ratings yet

- Deadlands - Classic - Huckster Basics, Tricks and HexesDocument6 pagesDeadlands - Classic - Huckster Basics, Tricks and HexesDaniel McallisterNo ratings yet

- EU - Type Examination Certificate: II 2G Ex Ia IIC T5/T6 GB II 2D Ex Ia IIIC T100°C/T85°C DB IP6XDocument4 pagesEU - Type Examination Certificate: II 2G Ex Ia IIC T5/T6 GB II 2D Ex Ia IIIC T100°C/T85°C DB IP6XHabibulla BavajiNo ratings yet

- Exam Possible QuestionsDocument2 pagesExam Possible Questionsoilkgas31No ratings yet

- PWD P4Document39 pagesPWD P4RupaliNo ratings yet

- Year:: Gift Mae M. Raymundo BSHM 1-C 1 YearDocument3 pagesYear:: Gift Mae M. Raymundo BSHM 1-C 1 YearGift Mae Noguit Mijares-RaymundoNo ratings yet

- Welcome To Our Presentation: Topic: Teacher Role in Group DiscussionDocument18 pagesWelcome To Our Presentation: Topic: Teacher Role in Group DiscussionDuy NguyễnNo ratings yet

- Nut 1661818Document1 pageNut 1661818phantomboyz_aipNo ratings yet

- Inverse Laplace TransformDocument12 pagesInverse Laplace TransformjmciurcaNo ratings yet

- MG University B Tech (Scheme & Syllabi) 2002-2003Document562 pagesMG University B Tech (Scheme & Syllabi) 2002-2003hotchapgopu50% (4)

- 0 chtp6 03 IMDocument40 pages0 chtp6 03 IMking100% (1)

- Chapter9 PDFDocument28 pagesChapter9 PDFSayantan RoyChowdhuryNo ratings yet

- Dna ExtractionDocument3 pagesDna ExtractionCetura VillaruzNo ratings yet

- 32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyDocument139 pages32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyEcus ElectronicsNo ratings yet