Professional Documents

Culture Documents

Is 8091.2008 - Safe Plant Layout

Is 8091.2008 - Safe Plant Layout

Uploaded by

Prakash Kumar KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 8091.2008 - Safe Plant Layout

Is 8091.2008 - Safe Plant Layout

Uploaded by

Prakash Kumar KumarCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

01 ' 5

Jawaharlal Nehru

Step Out From the Old to the New

1 +, 1 +

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS 8091 (2008, Reaffirmed 2008): Industrial Plant

Layout--Code of Safe Practice (First Revision). ICS 13.100

: 91.040.20

IS 8091 : 2008

9fRJTP:r !{PtCh

a:f)c:ltf1ICh Cf)f 1CWII - W8Jf qe&fa f(f6dl

Indian Standard

INDUSTRIAL PLANT LAYOUT - CODE OF SAFE

PRACTICE

JUTre 2008

( First Revision)

ICS 91.040.20

BIS 2008

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Price Group 7

Occupational Safety and Health and Chemical Hazards Secrjonal Committee, CHD 8

FOREWORD

This Indian Standard (First Revision) was adopteu by lhe Bureau of Indian Standards, after the draft finalized

by the Occupational Safety and Health and Chemical Hazards Sectional Committee had been approved by the

Chemical Division Council

This standard was originally published in 1976. In view of the experiences gained over the period of about last

three decades. Committee felt to revise the standard and to widen its scope to accommodate the outside facilities

for which there was a separate standard IS 8089 : lY76 -Code of safe practice for layout of outside facilities in an

industrial plant'. After the publication of this standard, IS 8089 shall be withdrawn.

There is no ISO Standard on this subject.]n the fonnulation of this standard, assistance has been derived from the

following publications:

a) Accident Prevention Manual for Industrial Operations, 1969, Ed. 6 Nationa) Safety Council, Chicago,

USA

b) Loss Prevention in the Process Industries -- Frank P Lees, 2nd edition

The composition of the Committee n:sponsihlc for formulation of this standard is given at Annex C.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final value,

Qbserve<l or calculated. expressing the resllit of a test. or analysis, shaH be rounded off in accordance with

IS 2 : 1960 'Rules for rounding off numerical values (revised),. The number of significant places retained in the

rounded off value should be the same as that of the specified value in this standard.

IS 8091 : 2008

Indian Standarli

INDUSTRIAL PLANT LAYOUT - CODE OF SAFE

PRACTICE

( First Revision)

1 SCOPE

This standard covers the code of safe practice for layout

and building structures inside as well as outside

fadlities in an industrial plant.

2 REFERENCE

The following standard contains provision, which

through reference in this text constitutes provision of

this standard. At the time of publication, the edition

indicated was valid. All standards are subject to revision

to agreements based on this sumdard arc

encouraged to investigate the possibility of applying

the most recent edition of the standard indicated below:

Title IS No.

2825 : 1969 Code for unfired pressure vessels

3 INTRODUCTION

3.1 Design for Safety

Plant layout is concerned with the spatial arrangement

of processing equipment, storage vessels, their

interconnecting pipe work, workplace and warehouse.

This is an important aspect in (he design of chemical

and process plants, since a good layout will ensure that

the plant functions correctly, safely and efficiently. It

considers the design constraints arising from safety,

environment, construction, maintenance, and operation

wilh an economical balance.

Access to the plant and supply of maintenance,

construction and emergency are all affected

by the plant layout. Numerous accidents, occupational

diseases, ex.plosions, and fires are preventable if

suitable measures and code of standards are taken into

consideration right from the carliest planning, dc:.;ign,

and the initial project stage.

3.1.1 Efficiency and safety in industrial operations can

be greatly increased by careful planning of the location,

design, and layout (of a new plant or of an existing

one) in which major alterations are to be made.

3.1.2 Plant layout will be based OIl factors like:

a) New site development or addition to

previously developed site.

b) Type and quantity of products to be produced,

c) Possible future expansion,

d) Operational convenience and accessibility.

e) Type of process and product control,

f) Economic distribution of utilities and services.

g) Type of building and building code require-

h) Guidelines related to health and safety,

j) Waste-disposable problems.

k) Space available and space requirement,

m) Auxiliary equipment, and

n) Roads and railroad.

3.1.3 The guidelines relate 10 safety, health, welfare

and provisions related to hazardous processes which

can be incorporated in the plant layout and have a

statutory binding 011 the industry.

3.2 Building, Equipment and Processes

3.2.1 Major factors determining the size, shape and

type of buildings and structures are the nature of the

processes and materials. maintenance, mechanical

handling equipment. requirement for gravity flow,

equipment needing specially strong foundations; access

for construction; commissioning, operation; space for

future expansion, escape and fire fighting, containment

of accidents; environmental impact, and working

conditions. These can vary greatly.

.12.2 CaLastrophcs resulting in large loss of life and

heavy property damage are often due to inadequate

planning-stage consideration of the physical and

chemical properties of dangerolls substances and their

processing methods. Hence, code of practice should

be strictly followed. ZoningIDivision criteria should

be considered at the planning stage. HAZOP and fisk

assessment should be undertaken. After this analysis,

the best possibJe layout will emerge with major

emphasis on safety.

3.2.3 High hazard processes should be located in small

isolated huildings of limited occupancy. or in areas cut

off by fire-resistant materiaJs appropriate to the hazard

involved. Buildings can be designed so that internal

explosions will produce minimum damage and

IS 8091 : 2008

minimum broken glass. Lower hazard operations can

jWilify larger units.

3.2.4 Even less serious injuries resulting from poor

housekeeping facilllles and congestion of workplaces

can be reduced substantialJy by preplanning for safety.

Layout of equipm.ent and buildings shall be such that

production lines do nOl cross, and that operators have

enough working space. This saves lime, increases

production, and helps prevent accidents. Pipe rack

layour should also consider extra space to

accommodate future modified lines and approaching

space between overhead Jines for ease of access during

attending leaks etc. Safety standards should be followed

strictly especially, for staircases in building. crane gang

ways. railing and fencing as provided in Factories Act.

1948. Spatial arrangement of processing equipment.

storage vessels and their interconnecting pipelines

should be given utmos{ importance.

Personnel facilitie.s. such as lunchrooms and

ht'ii]llh !5crvicC'i and disaster services are for

rea .. ons of health and treatment of injuries. They can

be planned and located for maximum effecti,,eness.

.-\s fat as possihle, fire slation and medical facility like

ambulance should be located adjacent to each other,

so that in case of emergency call, both the fIre tender

and ambulance wi)) rush together, to the emergency

spot.

4 SITE PLANNING

4.1 Safety is a prime consjdcration in plant siting.

Seleclion of a site consideration of a number

of factors, such as possible hazards to the community

and their relationships to climate and terrain. space

requlrements, type and size of buildings. necessary

facilities, availability of raw material, cooling water,

transportation, market. labour supply, population

density near the site and means of effluent disposal.

Ground water survey can he undertaken to ensure the

availahility of water for indus-trial requirement. or the

factors listed, those of direct concern to the safety

professional are given below. While the safety

professional is not direcl1y responsible for specialized

plant and process engineering and design, still it is his

tlulY 10 keep the engineers and architects as safety

consciolls as possible, and to anticipate potential safety

hazards and try to have Lhem designed out oflhe system

hefore the construction stage begins.

4.2 Location, Climate and Terrain

4.2.1 Location

As far as safety of the public is concerned, the most

important feature is the distance between the site and

built-up areas. Sites range from rural to urban, with

population den:-;ities varying from virtually uro to

2

high. Separation between a hazard and the public is

beneficial in mitigating the effects of a major accident.

An area of low population density around the site will

help reduce causalities. Plants producing or using

highly flammable or toxic substances in bulk should

be located so as not to cause damage to a city or town.

either generally or in case of disaster or some

unexpected happening.

4.2.2 Climate

Study of the climate of the area may be required. It

may reveal that, if a certain site is selected, the

prevailing winds will Cause noxious fumes or dusts to

settle on a neighboring community or plant, thereby

doing severe harm to peopJe or property or creating a

nuisance. The prevailing winds may also determine the

best location for processing equipment in relation to

administration offices; especiaJly their air-condjtioning

air intakes; drainage and waste disposal problems shaH

also be anticipated. Winter conditions or winterization

should he considered to protect the plant against severe

winter conditions. The behavior of airborne emissions

of aU types should be carefully considered. Although

the prevailing wind it'; the main factor other possible

troublesome wind conditions should be taken into

account. The effect of weather conditions such as

inversions should also be considered. Location of air

intake towers for air separation units should take into

account, the wind directions, nare header locations (as

hydrocarbon emissions from flare stacks Can be sucked

into the process causing severe accidents), and also

the cooHng tower locations to avoid corrosion of

equipment and reduce moisture ingress into the

etc.

4.2.3 In a hurricane, floor or seismic prone area, plans

and specifications should include suitable protective

measures. and safety factors shaH be designed into the

operation.

NOTF. .- National Building I.:odcs give: data on climaCic

changes and seismic zones with [actor of safety to be taken

while designing the building and equipment foundations.

4.2.4 Terrain

rf sir.e pl call for bridges over steams, ditches, and other

hazards, be sure they are adequately protected by

industrial fence or by handrails 1 m high and intermediate

rails. A typical layout is given in Fig. 1.

4.3 Space Requirements

4.3.1 Size of a site is determined by both present space

and possible future expansion. In the past

the growlh of business and population have resulted in

serious crowding, and the resulting congestion of

buildjngs and other facilities has increased fIre. accident

and health hazards.

IS 8091 : 2008

FIG. 1 TYPlCAL LAYOUT OF A BRIDGE

Site Scrvict?$

rht site central service8 such as. the boiler house, power

station, sw ilch station, pumping stations. utilities

etc .. should he placed in suitable localiuns.

They should not ht; pUl OUl of action by events as fire

or floor and, if possible not by other accidents such as

explosion. and that they should not constitute sources

of ignition for t1ammables. For example, factors in

siting the boiler house are that it should not constitute

a source of ignition. {hat emissions from stack should

not give rise to nuisance.

4.3.3 New developments may figure in the size of the

plant sileo Some companies anticipating increased use

of air transportation, are allowing space for l<!nding

fields or heliports as they acquire new property. Plans

for such installations should include all necessary

safety precautions,

4.3.4 Fire prevention codes specify minimum distance

between buildings according to their size, type and

occupancy. Laws governing storage of explosives and

of highly, tlammable materials specify minimum

distances between manufacturing and storage facilities

for various quantitIes of, such materials, as well as

minimum distance between the above from adjoining

property.

4.3.5 Ample space for outdoor storage areas is essential.

When the area for storing such materials as steel, pipe.

ami timber adjacent to shops proves insufticient, space

has to be provided elsewhere. This necessitates added

handling and transportation and increases both cost and

accident risk.

4.3.6 Parking lots are best located inside the plant fence

for convenience. protection, and safety. Since a

considerable area may be necessary to accommodate

3

employees and visitor cars, space requirements are

important. in site planning.

4.3.7 The sile layout must accommodate the systems

for handling the liquid e.ffluents, gaseous emissions,

solid wastt:&, water and fire water. For liquid

eft1uents. one arrangement is to have three separate

systems: an open sewer system for clean storm water

and two closed sewer systems, one fordomeslic sewage

and one. for aqueous effluent from the plant and for

contaminated storm water. Process effluents are

collected in a common sewer, and closely controlled.

The traditional sewer is the gravity flow rype. This

should have gradient and be self-cleaning. Measure:-.

should be taken to avoid flooding on process and

storage plots. Drains should be designed to handle the

corrosive materials. and mix.tures of materials, which

may be discharged into tlfem. In some cases.,

well-located disposal area for solid waste shall also be

provided when a site is being laid out. Separate bins

for paper, wood, and metal be provided inside the

premises, adjacent to road. in hazard free zone, for ease

of lifting the material into a vehicle. Gaseous emissions

should be burned or discharged from a tall stack so

that fumes do not affect to the site or the public. A

Ilare stack ma.y have to he located to a distant site,

because flare stack radiate intense heat. light, and can

be very noisy.

4.3.8 Scale relief models of the site in addition to maps

can be of much help to the planner in predesign, and

will help in spotting potential safety problems.

5 PLANT LAYOUT

5.1 General

5.1.1 Size, shape, location, construction. and layout of

buildings and other facilities should permit the most

IS 8091 : 2008

dt'icient utilization of materials, processes, and

methods.

5.1.2 Some materials and processes may favour gravity

How and the construction of a multistorey building,

for example. in the case of mills for one treatment In

processes, where material charging is to be done

through trolleys or drums, which arc required to be

carried from one floor to other, elevators may be

provlded, to avoid accidents in lifting them.

5.1.3 Other lIses, such as automobile assembly plants.

may favour a one-storey building because floor loads

will be heavy and excessive handling of materials by

venical and inclined conveyors would be required in a

mullistorey building.

5.2 Location of Buildings and Structures

5.2.1 The segregation of raw materials storage.

processing and storage fur finished products

warrantH thorough l'>tudy in laying out a plant to

minimize tire hazards. Storage of volatile

flammahle in an area apart from processing

buildings reduces the fire hazards. Tn the event of fire,

control is more easily achieved. Moreover, the cost of

separate storage eventually may be less than the

investment for storage in a processjng building. The

site should aim to contain an accident at source, to

prevent escalation and avoid creating hazard to

vulnerable targets.

Analytical laboratories should be in a safe area, but

otherwise as close as possible to the plants served. So

sbould workshops and general stores. The stores also

require ready access for stores materials.

5.2.2 Ample space should be provided between

segregated units, from such flame sources as boilers,

and from shops, streets. and adjoining property. The

codes of local. state and central authorities should be

followed in planning the location of the units of a planl.

S.2.3 Wherever storage of is involved,

magazines. should be located and constructed in

accordance with the recommendations of the

Derartment of Explosives.

5.2.4 The type of retardant required in relation to the

horizontal distance bctween building of frame. brick

and fire-resistant construction, and minimum

separation distances between buildings shaH be as

required by government regulations.

5.2.5 Many plants use and store flammable liquids

having nash points below 93C. Plans and layouts 1n

such plauLs should conform strictly to specifications

for handling and storing flammable liquids stipulated

by Department of Explosives.

4

In large petrochemicals complex/refineries, multitire

station loc.:atiom; for a minimum distance from aU plants

should be considered.

Statutory specifications shall be met in storing

flammable liquids outside the bui ldings in

underground or aboveground tanks. The amount of

liquid that can be stored in an underground tank

depends upon the proximity of the tank to any

buHding, depth in the ground in relation to the

building, and flash point of the liquid. Standards for

tanks inc] ude type and thickness of material,

provisions for relieving excessive internal pressure,

grounding, insulation, piping, and other

appurtenances, and similar details (see IS 2825).

5.2.6 The required distance between the line of

adjointng property, which may be built upon, and the

location of an aboveground tank depends upon the

content, construction, tIre extinguishing equipment.

and greatest dimension (diameter or height) of the tank.

5.2.7 Tanks shall be built of &teeJ unless the properties

of rhe flammable or combustible liquid are such that

some other material has to be used for its corrosion

resj Slance.

5.2.8 The djstance between occupied buildings and

plant buildings will be governed by the need to reduce

the dangers of explosion, fire and toxicity. In particular,

evacuation routes should not be blocked by poor plant

layout Administration buildings should be situated in

safe area on the public side of the security point. The

main office block should always be near the main

entrance and other administration buildings should be

ncar this enlralll'C if possible. Other buildings such as

medical centers, canteens, etc, should be in a safe area

and the latter should have ready access for food

supplies. Consideration should be given to siting of

occupied buildings outside the main fence. In all cases

occupied huildings should be sited downwind of

hazardous plant areas.

5.2.9 Conlrol Facililies

The control building should protect its occupants

the hazards of fire. explosion and toxic reJease.

The control huilding s.hould be situated on the edge of

the plant to allow an escape route. Recommended

minimum distances between the plant and the control

building tend to lie in the range 20 - 30 m. Depending

upon hazard studies. distance between the control room

building should be increased. [t should not be so near

the plant that its occupants are at once put at risk by

serious leak of tlammable, roxic. or corrosive materials.

The control building should contain only the essential

process concro] functions, only one storey above

ground. The building should be orie.nted to present

minimum area to probable centers of explosion, with

a strong construction, constructed in ductile materials

(Ductile material inClude steel and reinforced

concreter).

The control room should not be used as a center to

control emergencies, nor it should be used as an

emergency assembly point. There should be a separate

emergency control centre for controlling the incident

by the incident controller, having necessary

arrangements for positive pressure inside.

5.2.10 Water drift from cooling towers can cause

corrosion of plants. air intake towers. increase vibration

in centrifugal air compressors, so the towers should be

sited to minimize this. The entrainment of effluents

from stack and of corrosive vapors from plants into

cooling towers, or air separation units should be

avoided, as should the siting of buildings near the tower

int.:1.kes. The positioning of natural dri:l.ught cooling

towers should also take into account resonance caused

by wind hetween the towers. Another problem is

recycling of' air from the discharge of one tower to the

.. uction of another, which is countered by placing

towers cross-wise to the. prevailing wind. Further

guidance i:-; available in standard references.

5.2.11 Escape

A minimum of two escape routes should be provided

for any workspace, except where the fire risk is very

small. No workplace should be more than 12-45 m.

depending on degree of risk, from an exit, and a dead

end shouJd not exceed 8 m.

Escape routes across open mesh areas should have :-iolid

tlooring. Escape stairways should be in straight flights

preferabJy be on the olltside of buildings. Fixed ladders

may be used for escape from structures if the number

of people does not exceed 10. Escape routes should be

at least 0.7 m and preferably 1.2 m wide to allow the

passage of 40 per minute on the flat and 20

persons per minute tlown stairways. The escape times

of personnel should be estimated. paying particular

attention to people on tall items such as distillation

columns or cranes.

The main switchgcIJT and emergency controls should

have good access, preferably on an escape rome, so

that the operator does not have to risk his life to effect

shutdown.

5.2.12 Fire Fighting

Access is essenilal for fire fighting. This is provided

by the suggested plot size of 100 m x 200 m with

approaches preferably on all four sides and by spacing

bet\\Ieen plots and buildings of 15 m. Some basic

principles are that it should be possible to get fire-

fighting equipment sufficiently dose the site of the tIre.

5

IS 8091 : 2008

Hydrant points should be pOSitioned so that hoses can

reach any i1re on the plot. Hydrant spacing of 48 m,

65 m. and 95 m are suitable for high, medium, and

low risk plots, respectively. Plants over 18 m high

should be provided with dry riser mains and those over

60 m high or of high risk should be equipped with wet

riser malns. The inlets on the ground floor to dry riser

mains and the outlets on all floors to both types of

mains should be accessible. Fire equipment should be

located so that it is not likely to be disabled by the

accident itself. The site layout should contribute to the

containment of any fire, which may occur, and to

combating the fire. Feature of the site layout relevant

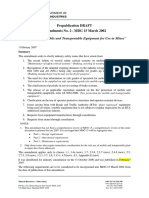

to fire hazards are illustrated in the Fig. 2 and Fig. 3

and described in Annex A.

5.2.13 Compressors should be located in different

buildings with acoustic enclosure, to reduce noise.

5.3 Flow Sheet

5.3.1 A detailed flow sheet is a useful guide in the

layout or plant, particularly those m:ing dangerou" and

harmful materials and complicated processes. The

nature uf the materials and processes in each

manufacturing stage can he studied and provision made

to eliminate or control hazards. A typical flow sheet

and layout showing a hazardous operation is given in

Fig. 4.

5.3.2 A comprehensive risk assessment study can be

done which is based on consequence analysis and

engineering judgment can lead to a set of conclusion

and risk mitigation to arrive at a safe process tlowsheet

(HAZOP). Auto-Cad computer applications can be

used to plan the layout and now sheet.

5.4 I,ayaut of Equipment

5.4.1 Various methods are used to determine the safest

and most efficient layout of production machines and

equipment. 'Ole two-dimensional method consists of

templates made to scale and fitted into a plan of {he

site or floor area.

Now-a-days, l:omputer aided design (CAD) method

are widely used. One type of Code gives visualization

or the 2D or in 3D forms. Typically such CAD

packages not only give 3D display, but hold a large

amount of information about the plant such as

coordinates of the main items and branches, the piping

routes, the materials list etc.

5.4.2 The most effective method is to use three-

dimensional models, made to scaJe and set up a scaled

floor plan. The models can be rearranged until the safest

and most efficient layout has been devised.

5.4.3 Layout studies show Lhe most suitable locations

for spray-painting. welding and similar work generally

IS 8091 : 2008

ACCESS ROAD 6m WIDE

PROCESS AREA

ROAD 4.5m WIDE

_J

(j)

C(

W

I-

w

:r.:

o

STACK

w

o

E

t.D

o

<i

o

cr

L cP __

ROAD 4.5m WlDE

o

UJ

a:

u:::

O

cnWC/)8_

ctJ !

_ 9?__ ___ __

CW. S;TCH

HOUSE

CONTROl! SWITCH

BUILDING HOUSE COMPRESSOR

HOUSE

m - METRES

FIG. 2 COMPACT BLOCK LAYOUT SYSTEM IN THE PROC!:'.SS AREA OF A PETROCltEMICAL PLANT WITH

4.5 m METRE ROADS

ill

Z

-<

\3 STACK

MAIN PROCESS

AREA

ill

a:;

\

---l

If)

(JJ

ill

U

U

AREA

PROCESS

I./}

IJJ

W

U

U

.:(

W

0::

u::

RECOVERED

OIL COMPOUND

(j) .:{

(I) W

\J.J Z

U <J;

U 0:::

'<i U

w

0::

u:

U)

a:;

W

1-

w

I

FiRE ACCESS

MAIN PROCESS

AREA

SUBSIDIARY

PROCESS AREA

u

w

0::

u::

FIG. 3 BLOCK LAYOUT SYSTEM IN THE PROCESS AREA OF A PETROCllfiMICAL PLANT WITH 6 m ROADS

6

/1'

/LABORATORY

I

rANK CAR UNLOADING

STATIONS

IS 8091 : 2008

FOAM STATION

FIC!. 4 COMlilNATION FLOW SHEF.T AND LAYOUT SHOWrNG A PLANT HAVING HAZARDOUS OPRATIONS

requiring segregation as they related to other

operations.

NOTE - Results to be obtained through layout studies are

shown in Annex B.

5.4.4 By using the three-dimensional method (3D)

model of the space occupied by each item of

equipment, congested areas can be anticipated and

avoided. These pile-up areas mean frequent handling

of materials, many unnecessary movements. and result

in bad housekeeping, which, may be in itself a prolific

source of accidents.

This 3D envelope should include space for:

a) Operations access,

b) Maintenance access, and

c) Piping connections.

Preparing a scale model showing details of the plant

layout will help in determining the best location for

cquipments and facilities. 1L will also easily locate

errors in a plant layout.

5.4.5 Insufficient headroom at aisles, platforms,

pipelines, overhead conveyors, other parts of the

structure, and other installations is disclosed in studying

the models. A vertical distance of at least 2.2 ill is

generally specified between passage stairways and

overhead structures to provide ample clearance.

Overhead cranes and conveyors require at least 60 em

of vertical and horizontal clearance.

7

5.4.6 Trucks and other vehicles require enough room

for movement without endangering men and

equipment and need space to back and turn near

machines. Aisles should be wide enough to permit

trucks to pass without colliding. For one-way traffic,

aisles should be not less than 1 m wider than the widest

vehicles. Aisles for two-way traffic should be not less

than 1 m wider than twice the width of the widest

vehicle. These minimum widths are exceeded

considerably in some new buildings where, because

of anticipated heavy traffic, aisles from 4 to 6 m wide

have been specified. Considerations to be taken into

account of bigger capacity tankers, before constructing

loading bays and gales. Adequate radius should be

provided near the loading by for easy movements of

the tankers. Separate routes must be made for tanker

lllQvements inside the tank farm (not from inside the

plant roads).

5.4.7 Safe layout of aisles requires that there should

be no blind corners and that adequate radius be

provided to anow for vehicle turns. A 2 m radius is

large enough for small industrial trucks.

5.4.8 Aisles should be clearly defined with approved

markings of either traffic paint or striping material.

Plastic buttons that are glued or fastened with me.tal

fasteners to the floor, are used by many because of

their durability; Aisles should also be clearly identified

around every machine in a workshop.

IS 8091 : 2008

5.4.9 Parking areas for both hand and power trucks

should be deSignated. Large plants often provide

garages with room for both storage and maintenance.

S.4.10 If building plans include ramps for use by

pedestrians and trucks, a I-m wide section should be

reserved as a walkway. and it should be clearly defined

with approved markings of traftic paint. Sharp turns

into aisles at the top and bottom of ramps are hazardous

and should be avoided. Provide an abrasive coating

where slippery-floor conditions may exist.

5.4.11 If the process materials are corrosive, this aspect

should be taken into account in the plant layout.

Foundations of both the buildings and machines,

I::specially those constructed in concrete. may be

attacked by leakage of corrosive materials. Additional

(hickness of concrete, and corrosion resistant asphalt,

bricks, and can be used. Floors should be

sloped so that spill agcs arc drained away from

v llinerable equipme.nt. walkways and trafflc lanes. Pipe

flanges. which may drip corrosive substances. ShOllld

Tlul be locmed over walkways.

5.4.12 Operators cabins must be located inside the plant

ttl low hazard, low noise area for better communication

and coordination in daily activities and during

emergencies.

5.5 Electrical Equipment

5.5. t Electrical substalions should be located in arcas

where non-namcproof equipment can be llsed, except

where they are an integral part of the plant. Complete

metal enclosed unit substations have been developed

for industrial plants and arc grounded. Such rooms,

however, are not proof against the haz.ards of oil-filled

transformers. This equipment may give otT flammable

vapours under certain conditions. which may form an

explosive mixture with the atmosphere in the room.

Non-tl;1mmable transformers should be installed with

the atmosphere in the room. Non-flammable

transformers should he instalkd in conlined areas anu

ncar llammahLe materials. Transformers should be

located outside the substation building.

Substalian of individual plant should be located nearer

(0 lhe control room for better coordination betwee.n

the process and electrical department, and also for ease

in eady detection of any untoward incidents. like tire.

High voltage and low voltage MeC panels should be

clearly demarcated, and all MCC should be easily

identified by numbering, and with list of motor drives

under them.

In case of any electromagnetic waves emitted from

cellular phones/walkie-talkie affects particular MCC.

it should be located in a separate room with a c,1Ulion

board.

8

5.5.2 Short-circuit protective devices should be large

enough to carry the load and xhould be rated to open

without any danger from the maximum shortcircuit

current. Circuit breakers, fuses and safety switches that

fail under short-circuit current may explode and cause

serious damage and injuries.

5.5.3 The potential of every grounding system should

be measured with a meter to determine whether or not

the system is capable of conducting the necessary

amounl of return.

5.5.4 When direct currenl voltage is supplied from

batteries isolate the battery room from the work area.

Battery room should be well ventilated. no smoking

should be permitted.

5.5.5 In an up-la-date industrial electrical system,

sections may be deenergized for maintenance and other

work without shutting down the entire system. In

addilion, a1l electrical installations should conform to

the local regulations.

5.5.6 Major switching apparatus should have metal

enclosures connected to the grounding system, and

cable circuits likewise should be enclosed in rigid

COl1dllit or interlocked armor cable. Metal enclosed

plug-in-busways should provide an easy method of

connecting and disconnecting machine tools.

5.5.7 Ungrounded portable electric tools and

equipment constitute a common source of fatalities in

industry. The hazard can be largely eliminated if plans

include a three-wire system. of which one is a ground

wire, and jf the equipment is provided with three-

conductor cables.

5.6 Ventilation, Heating and Air Conditioning

5.6.1 Ventilating. heating and air conditioning are

needed both for persona) comfort and very often to

meet process conditions. Personal comfort is very

important becallse it affects employees efficiency. All

efforts should be made not only to make general office

and plant conditions comfortable, but also to eliminate,

or at least reduce. poor conditions, which can contribute

Lo excessive employee fatigue or discomfort. If

machinery or processes radiate heal or generate bad

fumes. extra ventilation should be supplied to the work

area. \Vhere the ventilation rate is set by the need to

remove a contaminant. the number of air changes per

unit time is an appropriate measure.

5.6.2 Boilers. fans, and air-conditioning equipment are

usually kept separate from the general work areas

because their adjustment is very fine. It is important to

make certain that boilers receive adequate air and that

comhustion by-products are exhausted safely. In

locating incinerators, too. he sure that a negative

pressure in a building does. not cause an

incinerator stack to serve as an air source.

5.6.3 Maintenance should be considered. Not only shall

authorized employees have easy access to [he

machinery, but also there shall be sufficient space

around the equipment to replace parts as needed. There

shall be room behind to pun the tubes if necessary.

5.6.4 The control room an oLher workplace should be

maintained aL poSiltVe air pressure to avoid ingress of

dust and fumes from the outside.

5.7 Inside Storage

5.7.1 Industrial buildings seldom have enough storage

room. Sufficient space for raw materials and finished

products may be estimated on the basis of max.imum

production requirements with allowances for shortages,

seasonal shipping, and quantity purchases.

5.7.2 Modern mechanical handling and Slacking

equlpmcnt permils cxtcll:'iivc lise 1.11' verlicill SPi\Ct:

through dnuble and triple decking. If this method is

anticipated in lhe future, basic live tloor requirements

in [he initial building design shall allow for the

increase il1 m

2

load. Systematic optimization hased

approach and certain available software packages can

be used for increasing space efficiency.

5.7.3 Plans for storage of supplies, the finished product.

and empty or full pallets should permit ease of access,

stability of piling or stacking, and proper functioning

of the emergency sprinkler system. Design density

(l/min/m2) and area of application are dependent on

type of material and the height to which it is piled.

When piling hcight exceeds 3.5 m, double-check the

sprinlcle.r system's ability to put out any fire.

Space for storing 5upplie,s, tools, and in frequently used

equipment ncar working areas is seldom included in

plans for departmental layouts. The result is that such

j tcm" often are left in unsafe positions and locations.

To discourage employees from Jeaving long maLcrials

and parts against walls or other places where they can

fall, potable ladders. (Cols. such as pry bars. and

machine. parts, such as shafts should have definite

slorage plal:cs.

5.7.4 Space should be provided for racks, bins and

shelves. Materials that project from such places should

be stored above eye level. Metal baskets or special racks

provided with drip pans can be used for storing machine

parts covered with cutting oils.

5.7.5 Closets should be built for the storage of sanitary

supplies, sllch as deodorants and soaps.

5.7.6 Waste storage may take considerable room,

especially if the waste is bulky or is produced in large

quanlilies. In huildings with basements, chutes to

9

IS 8091 : 2008

basement storage bins help prevent accumulations in

working area:). To dispose of smalJ quantities of sharp

edged wasre, boxes with handles that are protected from

contaCt with sharp materials, or similar safe containers

may be specified.

5.S Receiving and Dispatching

5.8.1 Receiving and dispatching facilities should fit in

with overall material flow within the company or plant.

and should aid efficient flow of materials into and out

of production areas. Se.parate material gate should be

provided. like liquid movement. solid logistic

movement, etc, thar shaH ensure aU entries related to

ex.cise and taxation. Receiving and dispatching areas

should be designed to keep building heating and

cooling losses at a minimum.

5.8.2 Self-leveling dock boards, truek levelers, and

can facilitate loading and unloading. Storesl

Load otTice should be near to the material gate to have

inward of the goods.

5.8.3 Separate truck siding should be provided near

the material gale for parking of trucks after their

movement of loading of finished goods or raw materials

unloading. Parking fucility should also be provided for

tankers, \.vhich are in queue for loading/unloading. In

such case, proper communication (like pubic address

system, walkytalky, hot Hnes. etc) between parking

fucility and the load ofi1ce should be provided with

security posts to control the vehicular movement.

Facilities of toilets and canteen should be provided so

as to avoid movement of drivers in the work premises.

5.8.4 Dispatch of all finished goods should be done

from a separate location in the factory without

interfering the movement in work premises. Proper

barricade, with security gate should be made to avoid

any unauthorized entry of vehicle in the plant prern.ises.

5.9 RaHway Sidings

5.9.1 This commonly used rcceiving and dispatching

facility requires planning, especiaUy if bulk receiving

of raw, process and maintenance materials is an

economic advantage. Tank wagons containing

hazardous materials, such as chlorine, caustics, acids.

and other volatile. flammable. explosive and toxic

materials, require proper consideration for pressure

piping. breakaway piping, valves, pumps, derails, etc:

5.9.2 Each side track should be guarded away from

main line. public thoroughfares, and proper clearance

between main plants and wagons observed.

Guidelines provided by the railways should be followed

while making a layout for a railway siding. making

provision for the following:

a) Gateways;

IS 809 J : 2008

L)) Barriers and turn

c) Track clearances; and

d) Crossings, etc.

5.10 Roads and Footpaths

5.10.1 The engineer should always be alert to

opportunities where he can assist the civil engineer in

designing for maximum safety. Roads in plant yards and

grounds are sources of frequent accidents unless they

are carefully laid out. substantially constructed, and well

surfaced and drained nnd kept in good condition.

5.10.2 Heavy duty motor truck hauJjng requires road

tip to 16 m wide for two-way traffic with ample radii

at c.urves. Gradients. in general. are limited to a

ma-ximum of 8 percent. A s.light crown is necessary

for drainage, with ditches to carry off water.

5.10.3 Road should be located at least 11 m from

buildings, especially at entrances. At loading docks an

of oU ann ;0\ half lruck length is desirable to

facilitllte bacKing.

5.10.4 The regulation and control of traffic. signs, road

hl}'OUl.. and should conform to local and state

practices.

S.10.5 Traffic signs ilnd signals regulating speed and

movements at hazardous locations are essential. Stop

signs are specified for railway crossings and entrances

to main thoroughfares, and 'SOUND YOUR HORN'

signs are necessary at sharp curves (blind corners)

where view is obstructed and at entrances to buildings.

Mirrors mounted to afford views around sharp turn or

corners of buildings are of great help in preventing

accidents if roads have to be built close to buildings.

Barricades and 'MEN WORKING' signs are needed

for construction and repair work. Speed limit boards

and speed breakers with appropriate indications shall

be installed before entrance/exit of plants, sharp curves,

blind comers and also before such places where

speeding vehicles would pose a particular hazard to

pedestrian lraffie and/or other vehicles moving in the

area. If roads are llsed at night, trattic signs should be

made of reflective or lumin()us materials. Separate

gates should be used for allowing shift buses

employee's entrance/exit and other vehicles.

S.l(}.6 Good footpaths between outside facilities

prevent injury from employees stepping on round

stones or Into holes and ruts on rough ground. As far

as possible, footpaths should be the shortest distance

from one building to another to discourage short

cutting. A footpath that has to be next to railway tracks

should be separated from them by a fence or railing,

Warning signs should be installed at railway crossings

and other hazardous places.

10

5.10;7 Concrete is preferred for footpaths, especially

in principal areas like entrances and between main

huildings. Crushed rock surfaced with gravel or asphalt

makes a good footpath for less used locations. Also

pedestrian's footpaths/railway can be made on both

sides of main road clearly defined with approved

markings of (raffie paints.

5.10.8 Foo{parhs shQuld be kept in good condition.

especially where they cross railway rracks, and should

be cleared of ice and snow.

5.11 Parking Areas

5.11.1 To reduce travel in the plant grounds, a desirable

location for a parking area is between an entrance and

the locker room. The entire parking area should be

fenced. The parking stalls shall be laid out so that

driving in. parking. opening of car doors and driving

away is not obstructed. 1Ypicallayou LS of parking stalls

of staggered and non-staggered types arc indicated in

Fig. 530 and ')b respectively. The surface of the parking

area should be smooth and hard. to eliminate the

frequent injuries that wouLd occur from falls un stony

or rough ground. G(H}d drainage is essential.

5.11.2 The use of while lines 10 to 15 em wide to

designate stalls reduces confusion and the number of

backing acc.idents. Standard staHs are 5 m wide and 6

m long. The centre-to-centre distance between parked

cars varies according to the method of parking. Be sure

that parking does not encroach on approaches [0

comers, bus stops. loading zones, and clearance spaces

for islands. DIiveways should be a minimum of 8 In

for two-way traffic and there should be no obstructions

to viewing.

5. n.3 Angle parking has both advantages and

The smaller the angle, the fewer the

number of cars that can be parked in the same area.

Aisle widths can be narrower but traffic is usual1y

restricted to one way. On the other hand, angle parking

is easier for customers and it does not require a lot of

room for sharp tums.

S.H.4 The area allowed per car in parking lots varies

from 20 m

2

to more than 30 m

2

, if aisles are induded.

Luge, economically laid out areas may approach the

20 m? fjgure; smaIJer poorly configured parking areas

may have a higher percentage of aisle space and may

approach 30 m

2

car. A large commercial attended

parking area is considered efficient if the layout keeps.

the space requirements to 24 m

2

per car.

5.11.S Separate entrances for incoming and outgoing

cars facilitate ()(derly traffic movements. Entrances

should be designated with suitable signs. Speed signs

and signs limiting areas to employees or visitors should

be installed, as circumstances require. These signs

a) STAGGERED

NOTES

-- --

777

b) NON-STAGGERED

IS 8091 : 2008

1 In both patterns, vehicles have to reverse inlo parking space.

2 For parking areas with restricted lane widths, a slope angle of 30 degrees

is stJggesled. Depending upon the adequacy of lane width any angle up to 45

degree is recommended.

FIG. 5 TYPICAL LAYOUTS OF PARK1NO STAl.LS

should eonfonn to recommended and would

be similar to other street find highway signs.

S.I1.6 Traft1e at exit to heavily travelled streets st)()Uld

be controlled by a traffic ljght, or, there should

bt.: acceleration or mt.:rging lime.

5.11.7 If lhe area is used at night, adequate lighting

should be provided for safely and for the prevent.ion

of thefl, about 100 lux/m

2

at a height of t m should he

an adequate level.

5.12 AdditionaJ Facilities

Consideration offoJlowing suitable additional fL"lcililies

should also he horne in mind at the designing stage:

a) Smoking room should be provided in process

plants where smoking is prohihitr.;d.

h) Greater use should he made of mech<lnical

handling devices, such as conveyors, bucket

elevators, etc, in Qrder to reduce transport by

rait i.Hld road to an optimum extent

c) Secrionali7jng arrangement should be made

in electrical supply line to r.;quipmcnL

d) Planning and erection of equipment should

take into consider<ltion facilities for repaIrs

and preventive maintenance work.

e) Eguipme,nt layout/installation should also

consider the case of removal of the equipment

(by cranes), especially when located on higher

floors.

f) As far as possible, bridging of fhe platforms

of adjacent columns (distillation, scruhhers,

evaporators, etc) should be done, for ease of

operation especially during shutdown and

start up.

ANNEXA

(Clause 5.2.12)

SITE LAYOUT RELEVANT TO FIRE HAZARD

A-I Figure 2 shows a compact Jayout, which minimizes

Innd usage and pipe work, for petrochemical plant

consisting of a major process with several stages allll a

number of subsidiary processes.

There arc two main process areas and at right angles

to these is an area with a row of fired heaters, and

associated reactors, steam boilers and a stack.

This layout has several weaknesses. The lack of

firebreaks in the main process blocks would allmv a

fire to propagate right along these, particularly if \vind

is hlowing along them. There is entry to the plant area

II

from the 6 m roads from opposite corners, which allows

for all wind directions. But the only access for vehicles

lu lhL; pr()(:t:ss plots is the 4.5 m roads. In the case of a

major tire, appliances might well get trapped by an

escalation of the fire. Clearance is also not adequate.

The Jayout also likely to cause difficulties in

maintenance work.

A-2 The aHernativl: layout shown in Fig. 3 avoids these

problems. The process areas are divided by firebreaks.

There are more entry points on the site and dead cnd.o;

are eliminated. The crane access areas provide

:.tudilional clearances for fired heaters.

IS 8091 ; 2008

ANNEXB

(Clause 5.4.3)

RESULTS OF LAYOUT STUDIES

B-1 Results to be obtained through layout studies are

sho\l,In in Fig. 6.

8-2 Here the new layout reduced unit travel from 772 to

246 m of which 63 mare conveyorized. The saving in

OLD LAYOUT

FLOW STARTS AND

i ENDS AT ELEVATOR

TOO

GRIR

TRAN8:FORMFR

STORAGE

dis.tancc amounted to about 76 percent. The reduction

is particularly significant to the safety professional

because the largest number of injuries in most

industries occurs in material handling.

PRODUCTION FLOW OF HERMETIC UNIT

NEW LAYOUT

FLOW STARTS

l

AND ENDS AT

ELEVATOR

---y'-----J-.,......,..--.I'......,.,

REAR SECTION

c::::::J

E::::3 E::3

HEAVY UNIT

ASSEMBLY

TEST LABORATORY

MATERIAL STORES

TOOL GRIB

BLACK DIP

ASSEMBLY

POTTING SECTION

CONVEYOR

-....,-_ ......

I

SECOND ASSEMBLY

GONVEY-"O_R __ -,

!

BELT I

CONV1:Y.QBj

I DISPATCH

OFFICE

HEADER

ASSEMBLY

FIG. 6 THE OLD AND NEW LAYOUT OF TRANSFORMER MANUFACTURiNG OPERATION

12

ANNEX C

( Foreword)

CO?\-'lMITTEE COMPOSITION

IS 8091 : 2008

Occupational Safety and Health and Chemical Hazards Sectional Committee, CHD 8

Organization

Na[ional Safety COllncil, Navi Mumbai

Authori{y of India, New Delhi

Atomic Energy Regulatury Buard. Mumbai

Bhabh:l Atomic Research Centre, Mumbai

Central Boiler Board, New Delhi

Centml Leather Rese<'lrcn Institu[e, Chennai

Ce.nlral Mining Research Instltute, Dhanbad

Wilrehoming Corporation, New Delhi

Cl:"nLury Rayon.

Confederation of Indian Industries, New Delhi

C')[1S'.1I1h'.r Ecl\lc(llion and Rest;':(lfch Centre. Ahmedabad

Dep<lrlment of Explosives. Nagpur

Departmenl of Industrial Policy and Promotion. New Delhi

Department of Space (lSRO). Sriharikota

Directorate General Factory Advice Service and Labour Institute,

Mumhai

Directorate General of Health Services, New Delhi

Dire-.:tordte General of Mines Safety, Dhanbad

Directorate of Industrial Safety and Health. Mumbai

Dire-.:torate of Standardization, Ministry of Defence, New Delhi

Employees State Insurance Corporation. New Delhi

Aeronautics Limited. BangalorC!

Hindustan Lever Limited. Mumbflj

Indian Associa[ion of Health, Bangl1lore

Indian Chemical Association. Mumhai

Indian Institute ot Chemical Technology, Hyderahad

Indian InSiitllte ot Safety and Environment. Chennai

Indian Petrochemical Corporation Ltd, Vadodara

Illdian Toxicological Research Centre, Lucknow

I"linistry ()f Defence (DGQA), New Delhi

Minislry (.f Defelice (R&D), Kanpur

l3

J

SHRI K. C. GUPTA (Chairman)

SHIU A. N. KHER.A

SHRI M.

SHRI P. K. GHOSH

DR B. N. RATHI

S HRI S. SOUNDARARAJAN (AlraMle)

REPRESENTATlVE

SHRI G. SWAMINATHAN

SHRi J. K. P A.NOEY

REPRBSl:iNTAJI Vii,

SHIH H. G. UlT.l.MCHANDANl

SIIIU S. K. MISHRA (AltenuJle)

SHRI A, K.

ANlK AlMeR ... (Alfernate)

UK C. J. SH!SJ-l()l)

8. Yl:.l.LORE (Alternate)

REPRESENTATIVE

DR D. R. ClI,\WLA

SHIU P. N. SA,NKAR.I\.N

SHRI V. K. SRIVASTAVA (Alternate)

DR A. K. \1AlUMDAR

SIlRl S, P. -RANA (Alternate)

REPRESENTATiVE

DIRECTOR OF M[NES

DEPUTY DIRECTOR OP MINES SAFETY (HQ) (Allernate)

SHRI V. L. JOSHI

SHRI P. S. AHUJA

LT-COL TEllNDER SlNGJ-l (Al/ernale)

RF.PRESENTATIVE

SHRI S. V. SVRESH

SHRI B. B. D.we

SHRl ADl'ITA JHAV ...II (Alfemme)

REPRESENTA!!\- E

SHIU V. N. DAS

SHill A. A. PANI't\'ANI (Alrernate)

Smu S. VESKATESWARA RAO

DR M. RMENDRAN

DR G. {Alternate)

SHRI P. VIJAYRAGliAVAN

SHil.l M. R. PAm. (Alternate)

DR VIRENDRA MISHRA

DR V. P. SHARMA (Alternate)

M. S. SULTA:'<IA

SHJl.1 SUJIT (Altemate)

DR A. K.

DR RAIJNDRA SIN{]H (Allemale)

IS 809 t : 2008

Organ izat/on

Minislry of Environment & Forests, New Delhi

Ministry of Home Affair .... New Delhi

National Institute of Occupational Health, Ahmedabad

National Safety Council. Navi Mumbai

NOCll. Mumbai

Office of the Development Commissioner (SSl), New Delhi

Oil Industry Safety Directorate (Ministry of Petroleum & Natural

Gas). Delhi

Ordnance Factory Board, Kolkata

Safety Appliances Manufacturers Association. Mumbai

tEL CtJ,emical Complex, New Delhi

SOlltnern Petrocnemical Industries Corporation Ltd. Chcnnai

Authority of India Ltd. Rllnchi

1:11a AIG Management Services Ltd. Mumbai

SIS Directorate General

Represenlalive( s)

SHRl OM PR .... KASH

SHRI D. K. SHAMI (Alternate)

DR H. R. R...st;l()HAN

DR A. K (Alternate)

SHRl P. M. RAO

SKRI D. BISWAS (Alternate)

DR B. V. BAPAT

51'111.1 V. R. NARt.1I (Alternate)

S.HRJ MATH1JRA PRASAD

SHRIMATI SVNITA KUMAR (Alternafe)

SHRI S. K. CHAKRABARTI

SURl V. K. SRJVASTAVA (Alternate)

DR D. S. S. GANGULY

SHRI R. SRINIVASAN (Alremote)

SHRJ M. KANT

StiRI Knm MI\RU (Altemate)

SH1I.l R.ucEv MAII.WAii

SIfRI NAVDEEP SINGH BIRDIe (Altemate)

Smu V. J,\YARAMAN

SHRI S. MURL'OANI\NOAhl (Alternate)

SHRJ V. K. JAIN

SHiU URMISH D. SUAH

DR U. C. SRIVASTAVA, Scientist 'F' & Head (CHD)

[Representing Director General (Ex.officio))

Member Secretat}'

SHRI V. K. DIUNDI

SCIentist 'E' (CHD), BIS

14

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

I

j

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act. 1986 to promote

harmoniolls development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of SIS. This does not preclude the free use, in the course of

implementing the standard. of necessary details, such as symbols and sizes; type or grade designations.

Enquiries relating to copyright be addressed to the Direclor (Publications). SIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendmenls is reaffirmed when such review indicates that no changes are

if the review indicates that changes are needed. it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

'BIS Catalogue' and 'Standards : Monthly Additions.

This Inct.m Standard has been developed from Doc: No. CHD 8 (1238).

Amendments Issued Since Publication

Amend No. Date of Issue

BUREAU OF INDIAN STANDARDS

Headquarters :

Manak Bhavan. 9 Bahadur Shah Zafar Marg. New Delhi 110 002

Telephones: 2323 0131, 23233375,23239402

Re gional Offices :

Central Manak Bhavan. 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

Northern

Southern

Western

1114 C.l.T. Scheme VII M\ V. I. P. Road, Kankurgachi

KOLKATA 700 054

sea 335-336, Sector 34-A. CHANDIGARH 160022

C.I.T. Campus. IV Cross Road, CHENNAI 600 113

Manakaiaya, E9 MIDC. Marol, Andheri (East)

MUMBAI 400 093

Text Affected

Telegrams: Manaksanstha

(Common all offices)

Telephone

{

23237617

23233841

{

23378499.23378561

23378626.23379120

{

2603843

2609285

{

2254 1216. 2254 1442

2254 25 19. 2254 2315

{

2832 9295, 2832 7858

2832 7891. 2832 7892

Branches AHMEDABAD. BANGALORE. BHOPAL. COIMBAIDRE. FARIDABAD.

GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

PARWANOO. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM .. VISAKHAPATNAM.

Printed at Prabl\at Offset Press. New De.lhi-2

You might also like

- RISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeDocument10 pagesRISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeemmyNo ratings yet

- Practical Manual - Plant PathologyDocument85 pagesPractical Manual - Plant PathologyPrakash Kumar Kumar100% (1)

- Design of Strap FootingDocument3 pagesDesign of Strap FootingPrakash Kumar KumarNo ratings yet

- Practical Manual - Insect Ecology & IPMDocument81 pagesPractical Manual - Insect Ecology & IPMPrakash Kumar Kumar67% (15)

- Practical Manual - Crop DiseasesDocument82 pagesPractical Manual - Crop DiseasesPrakash Kumar Kumar86% (7)

- Three Phase Horizontal SeparatorDocument6 pagesThree Phase Horizontal SeparatorHani KirmaniNo ratings yet

- Copper and Copper Alloys PDFDocument31 pagesCopper and Copper Alloys PDFShaikh Mohd Qaisar100% (1)

- Indian Standard - Industrial Plant Layout-Code of Safe PracticeDocument29 pagesIndian Standard - Industrial Plant Layout-Code of Safe PracticeDineshKumarNo ratings yet

- Is.8091.200 Safety Facilities LayoutDocument20 pagesIs.8091.200 Safety Facilities Layoutconsultor9010No ratings yet

- Industrial Plant LayoutDocument18 pagesIndustrial Plant Layoutamit singhNo ratings yet

- Safety Systems For The Oil and Gas Industrial Facilities - Design, Maintenance Policy Choice, and Crew SchedulingDocument15 pagesSafety Systems For The Oil and Gas Industrial Facilities - Design, Maintenance Policy Choice, and Crew SchedulingEsron Hadinata Lumban GaolNo ratings yet

- Twelve Steps To Engineering Safe Onshore Oil and Gas FacilitiesDocument9 pagesTwelve Steps To Engineering Safe Onshore Oil and Gas FacilitiesMario Alejandro Mosqueda ThompsonNo ratings yet

- Iarjset 2022 9575Document9 pagesIarjset 2022 9575MagiNo ratings yet

- Integration of Internal Design Management and Requirements For Medical Cyclotron FacilitiesDocument10 pagesIntegration of Internal Design Management and Requirements For Medical Cyclotron FacilitiesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Oisd RP 233Document66 pagesOisd RP 233Arunashish MazumdarNo ratings yet

- SPE - DescriptionDocument5 pagesSPE - DescriptionJuan VelasquezNo ratings yet

- Mahindra - STANDARD FOR ON-SITE WORKERS HOUSING QUARTERS - 10.-Volume-IX-Standard-for-onsite-workers-housing-quartersDocument20 pagesMahindra - STANDARD FOR ON-SITE WORKERS HOUSING QUARTERS - 10.-Volume-IX-Standard-for-onsite-workers-housing-quartersAshwanth BhuvanrajNo ratings yet

- Manajemen K3Document15 pagesManajemen K3Triadi Dju Mengi UlyNo ratings yet

- Logical Sequence ApproachDocument22 pagesLogical Sequence ApproachV. BalasubramaniamNo ratings yet

- Kumbirai Answer Madenyika UB10930SME17914: Safety EngineeringDocument11 pagesKumbirai Answer Madenyika UB10930SME17914: Safety EngineeringKumbirai Answer MadenyikaNo ratings yet

- Pdis 102Document66 pagesPdis 102Dhirendra PatelNo ratings yet

- Code of Practice ExcavationDocument35 pagesCode of Practice Excavationsrobinson123No ratings yet

- Design Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Document36 pagesDesign Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Anuj DeoNo ratings yet

- Chapter 1 For PrintingDocument38 pagesChapter 1 For PrintingRitsuko ijuinNo ratings yet

- Y. H. P. Manurung, M. A. Mohamed, D. Andud, A. Z. Abidin, S. Saidin, K. Kasim, D. P. IshakDocument15 pagesY. H. P. Manurung, M. A. Mohamed, D. Andud, A. Z. Abidin, S. Saidin, K. Kasim, D. P. IshakFatman Fatin FaudiNo ratings yet

- Mper 2017 0006Document14 pagesMper 2017 0006Abde LazizeNo ratings yet

- Design Appraisal For The Construction of A Water Off-Take Channel Following Construction Design and Management RegulationsDocument4 pagesDesign Appraisal For The Construction of A Water Off-Take Channel Following Construction Design and Management RegulationsKhalid Abdel Naser Abdel RahimNo ratings yet

- Project Report - Group 6 - OshDocument26 pagesProject Report - Group 6 - OshsyahirabdullahNo ratings yet

- MDG 15 Amendments No 2Document13 pagesMDG 15 Amendments No 2Bouchard EugeneNo ratings yet

- Std-180, Lightning ProtectionDocument33 pagesStd-180, Lightning Protectionnaraengandhi50% (2)

- COMAH and Safety Case RegulationsDocument16 pagesCOMAH and Safety Case RegulationsAdeel RazaNo ratings yet

- Sensing Technology Applications in The MDocument16 pagesSensing Technology Applications in The MHajar BnouachirNo ratings yet

- GDN 180 PDFDocument33 pagesGDN 180 PDFb_913664038No ratings yet

- Defence in Depth Concept EmpfsicherheitskonzepteDocument22 pagesDefence in Depth Concept EmpfsicherheitskonzeptehoimingwNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Rafi Steel PVL Safety CultureDocument7 pagesRafi Steel PVL Safety CultureIJRASETPublicationsNo ratings yet

- BCE03-4 Summary 1Document22 pagesBCE03-4 Summary 1Djfj DuudNo ratings yet

- Ingles Forma de InformeDocument10 pagesIngles Forma de InformeAlexLopezNo ratings yet

- MS-CVL-009 Erection of Hollowcore Slabs 1Document12 pagesMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanNo ratings yet

- Lightning ProtectionDocument35 pagesLightning ProtectionAbhi CoolNo ratings yet

- Science and MaterialDocument6 pagesScience and MaterialStevenNo ratings yet

- Characterization of Operational Safety in Offshore Oil WellsDocument16 pagesCharacterization of Operational Safety in Offshore Oil WellsNelson Choueri JuniorNo ratings yet

- Trussed Rafter Assoc Instalation Guide 175Document41 pagesTrussed Rafter Assoc Instalation Guide 175rammirisNo ratings yet

- Eqpt IsolationDocument68 pagesEqpt IsolationDobrescu CristianNo ratings yet

- Risk and Reliability Assessment of Smoke Control Systems in The BuildingsDocument8 pagesRisk and Reliability Assessment of Smoke Control Systems in The BuildingsIJRASETPublicationsNo ratings yet

- D 12 PDFDocument85 pagesD 12 PDFMoon180No ratings yet

- Chapter 3.2 Occupational HSDocument7 pagesChapter 3.2 Occupational HSRina FebrianaNo ratings yet

- Study On Work Permit SystemDocument16 pagesStudy On Work Permit SystemIJRASETPublicationsNo ratings yet

- Process STD 601Document13 pagesProcess STD 601madx44100% (1)

- Safety Audit During Tunnel ConstructionDocument13 pagesSafety Audit During Tunnel ConstructionIJRASETPublications0% (1)

- Chapter 9.safetyDocument47 pagesChapter 9.safetyMuhamad Baihakhi ShamsudinNo ratings yet

- Inherent SafetyDocument16 pagesInherent Safetykirandevi1981No ratings yet

- Engineering Design For Process SafetyDocument6 pagesEngineering Design For Process Safetytoalok4723No ratings yet

- Advance Safety SeminarDocument34 pagesAdvance Safety Seminarpp3986No ratings yet

- Revised Paper Abs-61 9974912844Document9 pagesRevised Paper Abs-61 9974912844syasyaff880No ratings yet

- Piling Works Industry Standard Web PDFDocument24 pagesPiling Works Industry Standard Web PDFAriyaan PabitraNo ratings yet

- Standard Layout of An IndustryDocument14 pagesStandard Layout of An Industrynadimduet1No ratings yet

- TR5 5622Document40 pagesTR5 5622gustinugrahaNo ratings yet

- Safety, Health and Working Environment of Construction ProjectsDocument10 pagesSafety, Health and Working Environment of Construction ProjectsBhavya PatelNo ratings yet

- Designers Manufacturers Suppliers ADocument6 pagesDesigners Manufacturers Suppliers AVu ThanhNo ratings yet

- Code of Practice-FormworkDocument32 pagesCode of Practice-FormworkChung Yiung YungNo ratings yet

- Report 6 - 216716973 FINAALDocument11 pagesReport 6 - 216716973 FINAALGerhard vd WesthuizenNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationFrom EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Human Factors Engineering Aspects of Instrumentation and Control System DesignFrom EverandHuman Factors Engineering Aspects of Instrumentation and Control System DesignNo ratings yet

- Watershed Note DDP IwmpDocument4 pagesWatershed Note DDP IwmpPrakash Kumar KumarNo ratings yet

- Surveying RTP MODDocument106 pagesSurveying RTP MODPrakash Kumar KumarNo ratings yet

- Elimination of Rohs Substances in Electronic Products: Nemi Rohs/Pb-Free SummitDocument17 pagesElimination of Rohs Substances in Electronic Products: Nemi Rohs/Pb-Free SummitPrakash Kumar KumarNo ratings yet

- Indian ClimateDocument7 pagesIndian ClimatePrakash Kumar Kumar100% (1)

- Concrete PropertiesDocument32 pagesConcrete PropertiesPrakash Kumar KumarNo ratings yet

- Practical Manual ENGLDocument58 pagesPractical Manual ENGLPrakash Kumar KumarNo ratings yet

- Practical Manual - Field Diagnosis in AgricultureDocument127 pagesPractical Manual - Field Diagnosis in AgriculturePrakash Kumar KumarNo ratings yet

- Effect of Aggregate Size Distribution On Concrete Compressive StrengthDocument5 pagesEffect of Aggregate Size Distribution On Concrete Compressive StrengthPrakash Kumar KumarNo ratings yet

- State Level Energy Conservation Awards-2011Document1 pageState Level Energy Conservation Awards-2011Prakash Kumar KumarNo ratings yet

- Specification Package PlantDocument30 pagesSpecification Package PlantPrakash Kumar KumarNo ratings yet

- Pastel Yellow Blue and Green Simple Human Illustrative Sponsorship Deck Pitch PresentationDocument13 pagesPastel Yellow Blue and Green Simple Human Illustrative Sponsorship Deck Pitch PresentationMrs VxnillxsNo ratings yet

- Applied Triz in High-Tech Industry: Valery Krasnoslobodtsev, Richard LangevinDocument13 pagesApplied Triz in High-Tech Industry: Valery Krasnoslobodtsev, Richard LangevinOprisor ValerianNo ratings yet

- Imperial Assault Game Log Lite V4.3Document33 pagesImperial Assault Game Log Lite V4.3Sherif NasratNo ratings yet

- PHD Research ProposalDocument5 pagesPHD Research ProposalZeeshan AhmadNo ratings yet

- QP 06 Calibration of IMTEDocument3 pagesQP 06 Calibration of IMTEShanmuga PrakashNo ratings yet

- Opc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Document15 pagesOpc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Abdul RashidNo ratings yet

- Journal of CatalysisDocument13 pagesJournal of CatalysisNur KhasanahNo ratings yet

- tp6140 PDFDocument72 pagestp6140 PDFangel aguilarNo ratings yet

- Viamo sv7 Leaflet - MCAUS0294EA - Low 1804Document2 pagesViamo sv7 Leaflet - MCAUS0294EA - Low 1804MedisonicFlorAtalayaNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

- VT Ratio Measurement With 12KVDocument9 pagesVT Ratio Measurement With 12KVmanikandanNo ratings yet

- Transaction Codes For Payroll AccountingDocument3 pagesTransaction Codes For Payroll AccountingDHL123No ratings yet

- Eryigit Goldberg 120sDocument2 pagesEryigit Goldberg 120sElom Djadoo-ananiNo ratings yet

- PDF To WordDocument2 pagesPDF To WordRamdas NagareNo ratings yet

- Tutorial - Week02 - chpt12 - With AnswersDocument4 pagesTutorial - Week02 - chpt12 - With AnswersmakoNo ratings yet

- For Transportation Industry: Transforming The Way Your Fleet OperatesDocument78 pagesFor Transportation Industry: Transforming The Way Your Fleet OperatesImran RusyanaNo ratings yet

- Ga and OylDocument3 pagesGa and Oyljuad87No ratings yet

- Atlas Copco Boomer L2D Component and Signallists RCS4Document34 pagesAtlas Copco Boomer L2D Component and Signallists RCS4Hai Van100% (4)

- 420 Holiday: Pre 420 Sale! Pre 420 Sale! Pre 420 Sale!Document12 pages420 Holiday: Pre 420 Sale! Pre 420 Sale! Pre 420 Sale!liz6085No ratings yet

- VAFS-T Series-1Document14 pagesVAFS-T Series-1Ditya GufronoNo ratings yet

- Toyota Safety Sense C: The Three Most Common Accident TypesDocument3 pagesToyota Safety Sense C: The Three Most Common Accident TypesMUHAMMAD WAQASNo ratings yet

- 250 kVA Transformer Manufacturing and Transformer TestingDocument84 pages250 kVA Transformer Manufacturing and Transformer TestingPronoy Kumar100% (2)

- Bellal Hossain: Career ObjectiveDocument2 pagesBellal Hossain: Career ObjectiveNusrat JahanNo ratings yet

- FlowLabEOC2e CH03Document2 pagesFlowLabEOC2e CH03tomekzawistowskiNo ratings yet

- Dassmonarch InstallDocument8 pagesDassmonarch InstalljdslattenNo ratings yet

- Inquiry Training Model: Lesson Plan Template - 1Document9 pagesInquiry Training Model: Lesson Plan Template - 1jishnunairbNo ratings yet

- Kingsland C.E. Primary School Spring Term 2014 Information For Parents in Class 2Document4 pagesKingsland C.E. Primary School Spring Term 2014 Information For Parents in Class 2KingslandCEPrimaryNo ratings yet

- Motorpact™ 200/400/450 A Vacuum Contactors Contactores en Vacío Motorpact™ de 200, 400 y 450 A Contacteurs Sous Vide Motorpact 200/400/450 ADocument76 pagesMotorpact™ 200/400/450 A Vacuum Contactors Contactores en Vacío Motorpact™ de 200, 400 y 450 A Contacteurs Sous Vide Motorpact 200/400/450 AEduardo Castañares VillarroelNo ratings yet