Professional Documents

Culture Documents

Interpretation: VIII-79-04

Interpretation: VIII-79-04

Uploaded by

rtrajan_mech5408Copyright:

Available Formats

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Asme 2019 Sec VIII Div 1 Key ChangesDocument80 pagesAsme 2019 Sec VIII Div 1 Key Changesjay velNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Vapor Release Triggers California Blaze: IL Fire District Protects Local EconomyDocument40 pagesVapor Release Triggers California Blaze: IL Fire District Protects Local EconomyManish ChandaniNo ratings yet

- CaseStudy#03-Hyatt Regency Walkway Collapse PDFDocument5 pagesCaseStudy#03-Hyatt Regency Walkway Collapse PDFMalik ZainNo ratings yet

- RB211 Bleed ValvDocument10 pagesRB211 Bleed Valvyasser_nasef5399100% (1)

- AttentionDocument1 pageAttentionrtrajan_mech5408No ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- VIII 59 85 - UW 11a5bDocument2 pagesVIII 59 85 - UW 11a5bisrar khanNo ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- 864 37 PDFDocument1 page864 37 PDFrtrajan_mech5408No ratings yet

- InterpretationsDocument705 pagesInterpretationsAxe ProneNo ratings yet

- Interpretation: VIII-78-14: F Due To A Lower Seasonal Atmospheric Temperature?Document1 pageInterpretation: VIII-78-14: F Due To A Lower Seasonal Atmospheric Temperature?rtrajan_mech5408No ratings yet

- Asme Section Viii, Division 1 InterpretationsDocument1,148 pagesAsme Section Viii, Division 1 InterpretationsajitNo ratings yet

- Interpretation: VIII-78-65Document1 pageInterpretation: VIII-78-65rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-138Document1 pageInterpretation: VIII-78-138rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-23Document1 pageInterpretation: VIII-78-23rtrajan_mech5408No ratings yet

- 864 32 PDFDocument1 page864 32 PDFrtrajan_mech5408No ratings yet

- Interpretation: VIII-78-11Document1 pageInterpretation: VIII-78-11rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-38: F For Section VIII, Division 1Document1 pageInterpretation: VIII-78-38: F For Section VIII, Division 1rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-17Document1 pageInterpretation: VIII-77-17rtrajan_mech5408No ratings yet

- As MeDocument235 pagesAs Meshashi_uitNo ratings yet

- Sec II Part A Interpretations PDFDocument247 pagesSec II Part A Interpretations PDFRamu Nallathambi100% (1)

- Interpretation: VIII-78-94Document1 pageInterpretation: VIII-78-94rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-52Document1 pageInterpretation: VIII-78-52rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-145Document1 pageInterpretation: VIII-78-145rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-76Document1 pageInterpretation: VIII-77-76rtrajan_mech5408No ratings yet

- 08-Div.1-Volume 60aDocument50 pages08-Div.1-Volume 60aThanh NguyenNo ratings yet

- Interpretation: VIII-78-101Document1 pageInterpretation: VIII-78-101rtrajan_mech5408No ratings yet

- Of "User" or "Designated Agent") .: Interpretation: VIII-77-12Document1 pageOf "User" or "Designated Agent") .: Interpretation: VIII-77-12rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-48Document1 pageInterpretation: VIII-78-48rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-135Document1 pageInterpretation: VIII-78-135rtrajan_mech5408No ratings yet

- Asme Q&aDocument57 pagesAsme Q&amsraja7767% (3)

- Interpretation: VIII-78-142Document1 pageInterpretation: VIII-78-142rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-21Document1 pageInterpretation: VIII-77-21rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-75Document1 pageInterpretation: VIII-78-75rtrajan_mech5408No ratings yet

- 864 28 PDFDocument1 page864 28 PDFrtrajan_mech5408No ratings yet

- BPVC VIII InterpretationDocument4 pagesBPVC VIII InterpretationUtw InspeçõesNo ratings yet

- ASME General 100 QuestionsDocument54 pagesASME General 100 Questionsatulpatil99100% (2)

- ASME IIA - Intrprt 61Document6 pagesASME IIA - Intrprt 61ditoNo ratings yet

- Asme Section Ii, Part B InterpretationsDocument70 pagesAsme Section Ii, Part B InterpretationsnvmohankumarNo ratings yet

- 864 34 PDFDocument1 page864 34 PDFrtrajan_mech5408No ratings yet

- Interpretation: VIII-77-27Document1 pageInterpretation: VIII-77-27rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-55Document1 pageInterpretation: VIII-78-55rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-53Document1 pageInterpretation: VIII-77-53rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-69Document1 pageInterpretation: VIII-78-69rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-41: F The Stress Values Can Be Used Provided Heat Treatment Is Carried Out AsDocument1 pageInterpretation: VIII-78-41: F The Stress Values Can Be Used Provided Heat Treatment Is Carried Out Asrtrajan_mech5408No ratings yet

- Interpretation: VIII-77-50Document1 pageInterpretation: VIII-77-50rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-06Document1 pageInterpretation: VIII-77-06rtrajan_mech5408No ratings yet

- Asme Ix Int Vol26Document17 pagesAsme Ix Int Vol26Julio CastilhosNo ratings yet

- PP 2001 11Document4 pagesPP 2001 11Ashish YadavNo ratings yet

- Lesson 10 UG77 UG120 New2Document16 pagesLesson 10 UG77 UG120 New2AyyappanNo ratings yet

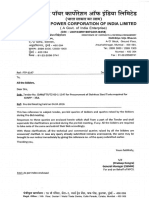

- 8559 Finalresponsetoprebidqueriesftp114720.04.2016 PDFDocument90 pages8559 Finalresponsetoprebidqueriesftp114720.04.2016 PDFAbhijeet SahuNo ratings yet

- Interpretation: VIII-77-84: F Used For Section VIII, Division 1 Construction?Document1 pageInterpretation: VIII-77-84: F Used For Section VIII, Division 1 Construction?rtrajan_mech5408No ratings yet

- ASME Code News (Questions and Answers)Document4 pagesASME Code News (Questions and Answers)dj22500No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Aviation Weather Services Handbook: FAA AC 00-45HFrom EverandAviation Weather Services Handbook: FAA AC 00-45HRating: 3 out of 5 stars3/5 (5)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- FMC Network Uae Jafza List - November 2013Document489 pagesFMC Network Uae Jafza List - November 2013rtrajan_mech5408No ratings yet

- Interpretation: 'VIII-78-149Document1 pageInterpretation: 'VIII-78-149rtrajan_mech5408No ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-138Document1 pageInterpretation: VIII-78-138rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-142Document1 pageInterpretation: VIII-78-142rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-107Document1 pageInterpretation: VIII-78-107rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-145Document1 pageInterpretation: VIII-78-145rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-112Document1 pageInterpretation: VIII-78-112rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-135Document1 pageInterpretation: VIII-78-135rtrajan_mech5408No ratings yet

- AttentionDocument1 pageAttentionrtrajan_mech5408No ratings yet

- Interpretation: VIII-78-65Document1 pageInterpretation: VIII-78-65rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-75Document1 pageInterpretation: VIII-78-75rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-91Document1 pageInterpretation: VIII-78-91rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-85Document1 pageInterpretation: VIII-78-85rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-101Document1 pageInterpretation: VIII-78-101rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-94Document1 pageInterpretation: VIII-78-94rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-73Document1 pageInterpretation: VIII-78-73rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-82Document1 pageInterpretation: VIII-78-82rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-79Document1 pageInterpretation: VIII-78-79rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-55Document1 pageInterpretation: VIII-78-55rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-62Document1 pageInterpretation: VIII-78-62rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-69Document1 pageInterpretation: VIII-78-69rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-52Document1 pageInterpretation: VIII-78-52rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-58Document1 pageInterpretation: VIII-78-58rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-48Document1 pageInterpretation: VIII-78-48rtrajan_mech5408No ratings yet

- Analisis Motor de Traccion (Ingles) PDFDocument28 pagesAnalisis Motor de Traccion (Ingles) PDFVictorDjChiqueCastillo100% (1)

- Sample Project Report On Financial Analysis at B D K LTD HubaliDocument102 pagesSample Project Report On Financial Analysis at B D K LTD HubalihareeshngvNo ratings yet

- HOSS ProductDescriptionDocument6 pagesHOSS ProductDescriptionmath62210No ratings yet

- Department of Urban Planning SPA Delhi PDFDocument25 pagesDepartment of Urban Planning SPA Delhi PDFrehanNo ratings yet

- SOLDSPX06Document16 pagesSOLDSPX06Shafayet UddinNo ratings yet

- mc707 CheatsheetDocument1 pagemc707 CheatsheetJorge GómezNo ratings yet

- Designing AV Automation For The Mediasite Rich Media RecorderDocument26 pagesDesigning AV Automation For The Mediasite Rich Media RecorderjohnemeryisiNo ratings yet

- BS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test CubesDocument10 pagesBS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test Cubesmykel_dpNo ratings yet

- ALTIVAR 28 Quick Reference GuideDocument1 pageALTIVAR 28 Quick Reference Guidesuperpuma86100% (1)

- Steam Peeler - OrbitDocument2 pagesSteam Peeler - OrbitMoaz TajammalNo ratings yet

- Design of PLC Based Speed Control of DC Motor Using PI ControllerDocument4 pagesDesign of PLC Based Speed Control of DC Motor Using PI ControllerTricia Mae EvangelistaNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- Road-Tunnels TP06 Road Tunnel Portal EmissionsDocument16 pagesRoad-Tunnels TP06 Road Tunnel Portal EmissionsALARP (Arnold Dix)No ratings yet

- Presented by - ASHUTOSH SINGHAL (1312231041)Document21 pagesPresented by - ASHUTOSH SINGHAL (1312231041)askarNo ratings yet

- FFDVFDocument1 pageFFDVFshamirNo ratings yet

- 6 Requirements of Good Quality BricksDocument1 page6 Requirements of Good Quality BricksRamaprasad VarmaNo ratings yet

- Cmmi Documentation For Maturity Level 2Document8 pagesCmmi Documentation For Maturity Level 2Hamid HamidNo ratings yet

- About GenpactDocument2 pagesAbout GenpactPatrick AdamsNo ratings yet

- Google Code of Jam - Qualification RoundDocument10 pagesGoogle Code of Jam - Qualification RoundVivek ShahNo ratings yet

- Unveiling The Ultimate Electrical Switch: Revolutionize Your Home With This Game-Changing Device!Document4 pagesUnveiling The Ultimate Electrical Switch: Revolutionize Your Home With This Game-Changing Device!saanvisingh861No ratings yet

- 132 KV Twrkifaf SSDocument4 pages132 KV Twrkifaf SSsahmeduNo ratings yet

- Manual Basic X11Document436 pagesManual Basic X11hrimagesNo ratings yet

- Fundamental of Smart GridDocument3 pagesFundamental of Smart GridGhayas Ud-din DarNo ratings yet

- Equivalencias Volvo & RTDocument512 pagesEquivalencias Volvo & RTHernan HernanNo ratings yet

- DebugDocument11 pagesDebugAlqubsNo ratings yet

- 360 Fluids ReferenceDocument2 pages360 Fluids ReferencecesarecontoNo ratings yet

Interpretation: VIII-79-04

Interpretation: VIII-79-04

Uploaded by

rtrajan_mech5408Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interpretation: VIII-79-04

Interpretation: VIII-79-04

Uploaded by

rtrajan_mech5408Copyright:

Available Formats

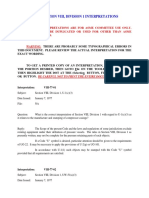

Interpretation: VIII-79-04 Subject: Section VIII, Division 1, UG-11, Weld Caps Date Issued: January 4, 1979 File: BC78-745

Question: May weld caps, as called out in UG-11(a)(1), produced per SA-234 or SA-403 and marked in accordance with UG-93 and UG-94 and complying with ANSI B16.9 be used as a formed end closure head on a pressure vessel? Reply: The Preface of Material Specifications SA-234 arid SA-403 outline that these materials are intended for Section III construction. They are not intended for Section VIII construction. It is suggested that ASTM Standards A403 and A234 could be used and would meet the intent of UG-11(a)(1) of Section VIII, Division 1.

Interpretation: VIII-79-05 Subject: Section VIII, Divisions 1 and 2, UG-120(c), UG-116(i), AS-120, and AS-310; Partial Data Reports Date Issued: January 5, 1979 File: BC78-749 Question (1): A vessel Manufacturer at site "A" receives fabricated parts from his facility at site "B". Under these conditions may these parts be furnished without parts stamping of Partial Data Reports U-2 or A-2 under the provisions of Section VIII, Divisions 1 and 2? Reply (1): Yes, provided the Quality Control System of the vessel Manufacturer outlines the method of control, including applicable documentation and procedure, to be used to produce the vessel and the Manufacturer does have a contract with the same inspection agency at Location A and B. Question (2). May the Partial Data Report U-2 or A-2 Form be used under Section VIII, Divisions 1 and 2 to document more than one part to be incorporated into a vessel? Reply (2): Section VIII, Divisions 1 and 2 do not prohibit the documentation of more than one part on a Partial Data Report U-2 or A-2 Form.

Interpretation: VIII-79-06 Subject: Section VIII, Division 1, Table UNF-23.3; Maximum Allowable Stress Values in Tension for Nonferrous Boltings Date Issued: January 9, 1979 File: BC78-734 Question: In general, allowable stress values for bolting, are lower than those for plates, pipe, and tubes, or rods and bars of same materials. Maximum allowable stress values in tension for high nickel boltings have been revised in Table UNF-23. May we assume that the reason why these revisions have been made although material specifications have not been revised, is reliable technical data on these materials have been developed and come to be available after previous issuance of the Code? Reply: The requirements of Appendix P, UA-500(4)(b) of Section VIII, Division 1 explains the reasoning for the stress criteria in Table UNF-23 for bolting material. Note that the higher stress values

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Asme 2019 Sec VIII Div 1 Key ChangesDocument80 pagesAsme 2019 Sec VIII Div 1 Key Changesjay velNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Vapor Release Triggers California Blaze: IL Fire District Protects Local EconomyDocument40 pagesVapor Release Triggers California Blaze: IL Fire District Protects Local EconomyManish ChandaniNo ratings yet

- CaseStudy#03-Hyatt Regency Walkway Collapse PDFDocument5 pagesCaseStudy#03-Hyatt Regency Walkway Collapse PDFMalik ZainNo ratings yet

- RB211 Bleed ValvDocument10 pagesRB211 Bleed Valvyasser_nasef5399100% (1)

- AttentionDocument1 pageAttentionrtrajan_mech5408No ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- VIII 59 85 - UW 11a5bDocument2 pagesVIII 59 85 - UW 11a5bisrar khanNo ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- 864 37 PDFDocument1 page864 37 PDFrtrajan_mech5408No ratings yet

- InterpretationsDocument705 pagesInterpretationsAxe ProneNo ratings yet

- Interpretation: VIII-78-14: F Due To A Lower Seasonal Atmospheric Temperature?Document1 pageInterpretation: VIII-78-14: F Due To A Lower Seasonal Atmospheric Temperature?rtrajan_mech5408No ratings yet

- Asme Section Viii, Division 1 InterpretationsDocument1,148 pagesAsme Section Viii, Division 1 InterpretationsajitNo ratings yet

- Interpretation: VIII-78-65Document1 pageInterpretation: VIII-78-65rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-138Document1 pageInterpretation: VIII-78-138rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-23Document1 pageInterpretation: VIII-78-23rtrajan_mech5408No ratings yet

- 864 32 PDFDocument1 page864 32 PDFrtrajan_mech5408No ratings yet

- Interpretation: VIII-78-11Document1 pageInterpretation: VIII-78-11rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-38: F For Section VIII, Division 1Document1 pageInterpretation: VIII-78-38: F For Section VIII, Division 1rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-17Document1 pageInterpretation: VIII-77-17rtrajan_mech5408No ratings yet

- As MeDocument235 pagesAs Meshashi_uitNo ratings yet

- Sec II Part A Interpretations PDFDocument247 pagesSec II Part A Interpretations PDFRamu Nallathambi100% (1)

- Interpretation: VIII-78-94Document1 pageInterpretation: VIII-78-94rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-52Document1 pageInterpretation: VIII-78-52rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-145Document1 pageInterpretation: VIII-78-145rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-76Document1 pageInterpretation: VIII-77-76rtrajan_mech5408No ratings yet

- 08-Div.1-Volume 60aDocument50 pages08-Div.1-Volume 60aThanh NguyenNo ratings yet

- Interpretation: VIII-78-101Document1 pageInterpretation: VIII-78-101rtrajan_mech5408No ratings yet

- Of "User" or "Designated Agent") .: Interpretation: VIII-77-12Document1 pageOf "User" or "Designated Agent") .: Interpretation: VIII-77-12rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-48Document1 pageInterpretation: VIII-78-48rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-135Document1 pageInterpretation: VIII-78-135rtrajan_mech5408No ratings yet

- Asme Q&aDocument57 pagesAsme Q&amsraja7767% (3)

- Interpretation: VIII-78-142Document1 pageInterpretation: VIII-78-142rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-21Document1 pageInterpretation: VIII-77-21rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-75Document1 pageInterpretation: VIII-78-75rtrajan_mech5408No ratings yet

- 864 28 PDFDocument1 page864 28 PDFrtrajan_mech5408No ratings yet

- BPVC VIII InterpretationDocument4 pagesBPVC VIII InterpretationUtw InspeçõesNo ratings yet

- ASME General 100 QuestionsDocument54 pagesASME General 100 Questionsatulpatil99100% (2)

- ASME IIA - Intrprt 61Document6 pagesASME IIA - Intrprt 61ditoNo ratings yet

- Asme Section Ii, Part B InterpretationsDocument70 pagesAsme Section Ii, Part B InterpretationsnvmohankumarNo ratings yet

- 864 34 PDFDocument1 page864 34 PDFrtrajan_mech5408No ratings yet

- Interpretation: VIII-77-27Document1 pageInterpretation: VIII-77-27rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-55Document1 pageInterpretation: VIII-78-55rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-53Document1 pageInterpretation: VIII-77-53rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-69Document1 pageInterpretation: VIII-78-69rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-41: F The Stress Values Can Be Used Provided Heat Treatment Is Carried Out AsDocument1 pageInterpretation: VIII-78-41: F The Stress Values Can Be Used Provided Heat Treatment Is Carried Out Asrtrajan_mech5408No ratings yet

- Interpretation: VIII-77-50Document1 pageInterpretation: VIII-77-50rtrajan_mech5408No ratings yet

- Interpretation: VIII-77-06Document1 pageInterpretation: VIII-77-06rtrajan_mech5408No ratings yet

- Asme Ix Int Vol26Document17 pagesAsme Ix Int Vol26Julio CastilhosNo ratings yet

- PP 2001 11Document4 pagesPP 2001 11Ashish YadavNo ratings yet

- Lesson 10 UG77 UG120 New2Document16 pagesLesson 10 UG77 UG120 New2AyyappanNo ratings yet

- 8559 Finalresponsetoprebidqueriesftp114720.04.2016 PDFDocument90 pages8559 Finalresponsetoprebidqueriesftp114720.04.2016 PDFAbhijeet SahuNo ratings yet

- Interpretation: VIII-77-84: F Used For Section VIII, Division 1 Construction?Document1 pageInterpretation: VIII-77-84: F Used For Section VIII, Division 1 Construction?rtrajan_mech5408No ratings yet

- ASME Code News (Questions and Answers)Document4 pagesASME Code News (Questions and Answers)dj22500No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Aviation Weather Services Handbook: FAA AC 00-45HFrom EverandAviation Weather Services Handbook: FAA AC 00-45HRating: 3 out of 5 stars3/5 (5)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- FMC Network Uae Jafza List - November 2013Document489 pagesFMC Network Uae Jafza List - November 2013rtrajan_mech5408No ratings yet

- Interpretation: 'VIII-78-149Document1 pageInterpretation: 'VIII-78-149rtrajan_mech5408No ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-138Document1 pageInterpretation: VIII-78-138rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-142Document1 pageInterpretation: VIII-78-142rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-107Document1 pageInterpretation: VIII-78-107rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-145Document1 pageInterpretation: VIII-78-145rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-112Document1 pageInterpretation: VIII-78-112rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-135Document1 pageInterpretation: VIII-78-135rtrajan_mech5408No ratings yet

- AttentionDocument1 pageAttentionrtrajan_mech5408No ratings yet

- Interpretation: VIII-78-65Document1 pageInterpretation: VIII-78-65rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-75Document1 pageInterpretation: VIII-78-75rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-91Document1 pageInterpretation: VIII-78-91rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-85Document1 pageInterpretation: VIII-78-85rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-101Document1 pageInterpretation: VIII-78-101rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-94Document1 pageInterpretation: VIII-78-94rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-73Document1 pageInterpretation: VIII-78-73rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-82Document1 pageInterpretation: VIII-78-82rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-79Document1 pageInterpretation: VIII-78-79rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-55Document1 pageInterpretation: VIII-78-55rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-62Document1 pageInterpretation: VIII-78-62rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-69Document1 pageInterpretation: VIII-78-69rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-52Document1 pageInterpretation: VIII-78-52rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-58Document1 pageInterpretation: VIII-78-58rtrajan_mech5408No ratings yet

- Interpretation: VIII-78-48Document1 pageInterpretation: VIII-78-48rtrajan_mech5408No ratings yet

- Analisis Motor de Traccion (Ingles) PDFDocument28 pagesAnalisis Motor de Traccion (Ingles) PDFVictorDjChiqueCastillo100% (1)

- Sample Project Report On Financial Analysis at B D K LTD HubaliDocument102 pagesSample Project Report On Financial Analysis at B D K LTD HubalihareeshngvNo ratings yet

- HOSS ProductDescriptionDocument6 pagesHOSS ProductDescriptionmath62210No ratings yet

- Department of Urban Planning SPA Delhi PDFDocument25 pagesDepartment of Urban Planning SPA Delhi PDFrehanNo ratings yet

- SOLDSPX06Document16 pagesSOLDSPX06Shafayet UddinNo ratings yet

- mc707 CheatsheetDocument1 pagemc707 CheatsheetJorge GómezNo ratings yet

- Designing AV Automation For The Mediasite Rich Media RecorderDocument26 pagesDesigning AV Automation For The Mediasite Rich Media RecorderjohnemeryisiNo ratings yet

- BS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test CubesDocument10 pagesBS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test Cubesmykel_dpNo ratings yet

- ALTIVAR 28 Quick Reference GuideDocument1 pageALTIVAR 28 Quick Reference Guidesuperpuma86100% (1)

- Steam Peeler - OrbitDocument2 pagesSteam Peeler - OrbitMoaz TajammalNo ratings yet

- Design of PLC Based Speed Control of DC Motor Using PI ControllerDocument4 pagesDesign of PLC Based Speed Control of DC Motor Using PI ControllerTricia Mae EvangelistaNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- Road-Tunnels TP06 Road Tunnel Portal EmissionsDocument16 pagesRoad-Tunnels TP06 Road Tunnel Portal EmissionsALARP (Arnold Dix)No ratings yet

- Presented by - ASHUTOSH SINGHAL (1312231041)Document21 pagesPresented by - ASHUTOSH SINGHAL (1312231041)askarNo ratings yet

- FFDVFDocument1 pageFFDVFshamirNo ratings yet

- 6 Requirements of Good Quality BricksDocument1 page6 Requirements of Good Quality BricksRamaprasad VarmaNo ratings yet

- Cmmi Documentation For Maturity Level 2Document8 pagesCmmi Documentation For Maturity Level 2Hamid HamidNo ratings yet

- About GenpactDocument2 pagesAbout GenpactPatrick AdamsNo ratings yet

- Google Code of Jam - Qualification RoundDocument10 pagesGoogle Code of Jam - Qualification RoundVivek ShahNo ratings yet

- Unveiling The Ultimate Electrical Switch: Revolutionize Your Home With This Game-Changing Device!Document4 pagesUnveiling The Ultimate Electrical Switch: Revolutionize Your Home With This Game-Changing Device!saanvisingh861No ratings yet

- 132 KV Twrkifaf SSDocument4 pages132 KV Twrkifaf SSsahmeduNo ratings yet

- Manual Basic X11Document436 pagesManual Basic X11hrimagesNo ratings yet

- Fundamental of Smart GridDocument3 pagesFundamental of Smart GridGhayas Ud-din DarNo ratings yet

- Equivalencias Volvo & RTDocument512 pagesEquivalencias Volvo & RTHernan HernanNo ratings yet

- DebugDocument11 pagesDebugAlqubsNo ratings yet

- 360 Fluids ReferenceDocument2 pages360 Fluids ReferencecesarecontoNo ratings yet