Professional Documents

Culture Documents

Pollution Problems: Table 1 Noise Level Caused by Various Construction Equipments

Pollution Problems: Table 1 Noise Level Caused by Various Construction Equipments

Uploaded by

Justin NgCopyright:

Available Formats

You might also like

- Arema Manual RailwayDocument2 pagesArema Manual RailwayBewok Giay15% (13)

- Environmental Impact Assessment For Highway ProjectsDocument8 pagesEnvironmental Impact Assessment For Highway Projectssaurabh514481% (32)

- Omega - Installation ManualDocument25 pagesOmega - Installation ManualCreaciones VilberNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Guide To Trench ExcavationsDocument43 pagesGuide To Trench ExcavationsmlakkissNo ratings yet

- Storm Water Drainage SystemDocument23 pagesStorm Water Drainage Systemankitbalyan100% (3)

- Levelling, Lining and Tamping MachinesDocument6 pagesLevelling, Lining and Tamping MachinesAnonymous Byopfd100% (2)

- Brosur Produk Precast WIKA BetonDocument40 pagesBrosur Produk Precast WIKA BetonRofik Susetyo Nugroho100% (4)

- Construction Phase: 1. Impact On SoilDocument11 pagesConstruction Phase: 1. Impact On SoilAnanditaKarNo ratings yet

- EIA Proposed Property Development Scheme Project On "Plot P" of Avalon Golf Estate at Bois SecDocument10 pagesEIA Proposed Property Development Scheme Project On "Plot P" of Avalon Golf Estate at Bois Secmelvin_12No ratings yet

- Peir Nts Section 6 AstDocument14 pagesPeir Nts Section 6 AstthamestunnelNo ratings yet

- Case StudyDocument3 pagesCase StudyathiraiNo ratings yet

- Individual Assignment On Structure-Borne Sound-VibrationDocument2 pagesIndividual Assignment On Structure-Borne Sound-VibrationMuhd NasrulNo ratings yet

- Road-Tunnels TP06 Road Tunnel Portal EmissionsDocument16 pagesRoad-Tunnels TP06 Road Tunnel Portal EmissionsALARP (Arnold Dix)No ratings yet

- 2 Druid StreetDocument4 pages2 Druid StreetthamestunnelNo ratings yet

- Sachin Bhardwaj Eia AssignmentDocument7 pagesSachin Bhardwaj Eia Assignmentsachin bhardwajNo ratings yet

- PEIR NTS Section 10 DormayDocument14 pagesPEIR NTS Section 10 DormaythamestunnelNo ratings yet

- Track Design To Control Railway Induced Vibration - CrossrailDocument8 pagesTrack Design To Control Railway Induced Vibration - CrossrailmetropodikasNo ratings yet

- AssignmentDocument19 pagesAssignmentMisango EmmanuelNo ratings yet

- Sustainable Construction AssignmentDocument10 pagesSustainable Construction AssignmentchillichilliNo ratings yet

- Transportation Activities Affecting The EnvironmentDocument6 pagesTransportation Activities Affecting The EnvironmentZia MohammadNo ratings yet

- Components of Sewer Sanitary Project CostDocument48 pagesComponents of Sewer Sanitary Project CostRamilArtates100% (1)

- Peir Nts Section 8 BeDocument14 pagesPeir Nts Section 8 BethamestunnelNo ratings yet

- Sewerage ImpactsDocument7 pagesSewerage ImpactsWajeeha UmerNo ratings yet

- 4-Albert Embankment ForeshoreDocument4 pages4-Albert Embankment ForeshorethamestunnelNo ratings yet

- Environmental Impact Assessment and Cost Benefit AnalysisDocument9 pagesEnvironmental Impact Assessment and Cost Benefit AnalysisBose RajNo ratings yet

- Peir Nts Section 13 FpsDocument13 pagesPeir Nts Section 13 FpsthamestunnelNo ratings yet

- Mine ManagementDocument7 pagesMine ManagementBranden OxfordNo ratings yet

- Peir Nts Section 23 EpsDocument12 pagesPeir Nts Section 23 EpsthamestunnelNo ratings yet

- Applied Acoustics: Aglaia Badino, Davide Borelli, Tomaso Gaggero, Enrico Rizzuto, Corrado SchenoneDocument14 pagesApplied Acoustics: Aglaia Badino, Davide Borelli, Tomaso Gaggero, Enrico Rizzuto, Corrado SchenoneEdwin HernandezNo ratings yet

- The Crossrail ProjectDocument11 pagesThe Crossrail ProjectArindom100% (1)

- Method Statement For Construction of Access BridgeDocument12 pagesMethod Statement For Construction of Access BridgeSepthy14No ratings yet

- Sustainability of Vibration Mitigation Methods Using Meta-Materials Exposed To Adverse Weather ConditionsDocument20 pagesSustainability of Vibration Mitigation Methods Using Meta-Materials Exposed To Adverse Weather ConditionsSHNo ratings yet

- Cut and Fill - WikipediaDocument9 pagesCut and Fill - WikipediaVineet YadavNo ratings yet

- Air Quality Impact: Construction PhaseDocument6 pagesAir Quality Impact: Construction PhaseChristina NgNo ratings yet

- A Review of Offshore Windfarm Related Underwater Noise SourcesDocument63 pagesA Review of Offshore Windfarm Related Underwater Noise SourcesJohn Williamson100% (2)

- Murton - Assessment of GR Bibr Eff From Constr and OperationDocument60 pagesMurton - Assessment of GR Bibr Eff From Constr and OperationMax ShashkinNo ratings yet

- The HONG-KONG-ZHUHAI MACAO Bridge - The HONG-KONG Link RoadDocument9 pagesThe HONG-KONG-ZHUHAI MACAO Bridge - The HONG-KONG Link RoadFerga VanessaNo ratings yet

- Metro Project CCDocument15 pagesMetro Project CCJanhavi KamdarNo ratings yet

- Current State of Practice in Railway Track VibratiDocument11 pagesCurrent State of Practice in Railway Track VibratiSajid IqbalNo ratings yet

- PEIR NTS Section 16 KirtlingDocument14 pagesPEIR NTS Section 16 KirtlingthamestunnelNo ratings yet

- Impact of Traffic Vibration On HeritageDocument10 pagesImpact of Traffic Vibration On HeritageMohamad HabibiNo ratings yet

- EVR Quarry BDocument11 pagesEVR Quarry BdumindaNo ratings yet

- Attachment To Project Site - ContractsDocument3 pagesAttachment To Project Site - ContractsMichael KpeglahNo ratings yet

- The Environmental Impacts For A One Way Road Construction ProjectDocument8 pagesThe Environmental Impacts For A One Way Road Construction ProjectMadhushiWijeratnaNo ratings yet

- Peir Nts Section 26 AmpsDocument13 pagesPeir Nts Section 26 AmpsthamestunnelNo ratings yet

- Construction Project Working Site of Environmental Pollution and CountermeasuresDocument4 pagesConstruction Project Working Site of Environmental Pollution and CountermeasuresArshi KhanNo ratings yet

- EIA-Water, Land and NoiseDocument11 pagesEIA-Water, Land and NoiseRyan Rhys NyambzNo ratings yet

- Aqua Silencer MailDocument1 pageAqua Silencer MailHARI KUMAR SNo ratings yet

- Final Writing Test: Topic: What Are The Causes of Air Pollution in Ha Noi ?Document2 pagesFinal Writing Test: Topic: What Are The Causes of Air Pollution in Ha Noi ?Cường KèoNo ratings yet

- Keller 39 03E Vibration Mitigation RailwayDocument4 pagesKeller 39 03E Vibration Mitigation RailwayDanielSierraNo ratings yet

- 2-Putney Bridge ForeshoreDocument4 pages2-Putney Bridge ForeshorethamestunnelNo ratings yet

- Toxic WasteDocument3 pagesToxic WastenithansaNo ratings yet

- STONE Falbe HansenDocument6 pagesSTONE Falbe HansenAyman ShamaNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Manual for Climate Change Adaptation Measures for Transport Infrastructure in Central Asia with a Focus on UzbekistanFrom EverandManual for Climate Change Adaptation Measures for Transport Infrastructure in Central Asia with a Focus on UzbekistanNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Paper Crawer CraneDocument10 pagesPaper Crawer CraneJustin NgNo ratings yet

- Building Construction CAP 123B PDFDocument28 pagesBuilding Construction CAP 123B PDFJustin NgNo ratings yet

- Brazilian TestDocument11 pagesBrazilian TestJustin Ng100% (1)

- Malaysian FYPDocument138 pagesMalaysian FYPJustin NgNo ratings yet

- Brazilian TestDocument11 pagesBrazilian TestJustin NgNo ratings yet

- Uclt Siding & PolDocument36 pagesUclt Siding & PolSSE TRD JabalpurNo ratings yet

- Indian RailwaysDocument28 pagesIndian RailwaysGurpreet KaurNo ratings yet

- Coal MachineriesDocument7 pagesCoal Machineriesdudealok100% (2)

- Time Table 2016Document8 pagesTime Table 2016C&W controller MughalsaraiNo ratings yet

- Trans Flux MotorDocument46 pagesTrans Flux MotorkoppulabroNo ratings yet

- Jeffrey Russell - DR Stephen Goh - Aurecon Paper PDFDocument14 pagesJeffrey Russell - DR Stephen Goh - Aurecon Paper PDFAnubhav Hem Kumar JainNo ratings yet

- Micropower, Rail-to-Rail Input and Output Operational Amplifiers OP196/OP296/OP496Document16 pagesMicropower, Rail-to-Rail Input and Output Operational Amplifiers OP196/OP296/OP496Ram NiwasNo ratings yet

- Project Report: Tourism Products of IrctcDocument36 pagesProject Report: Tourism Products of Irctcish rehNo ratings yet

- Lalitpur YardDocument1 pageLalitpur YardAjayNo ratings yet

- Advanced Grammar in Use - 3121st EditionDocument2 pagesAdvanced Grammar in Use - 3121st EditionasddsaNo ratings yet

- Underground StructuresDocument12 pagesUnderground StructuresmctrtNo ratings yet

- X1-3 X2-3 X3-3 X4-3 X5-3 X6-3 X7-3 X8-3 X9-3: X10-1 X10-2 X10-4 X10-5 X10-6 X10-7 X10-8 X10-9 X10-10 1Document5 pagesX1-3 X2-3 X3-3 X4-3 X5-3 X6-3 X7-3 X8-3 X9-3: X10-1 X10-2 X10-4 X10-5 X10-6 X10-7 X10-8 X10-9 X10-10 1Edgar Tejeda VieraNo ratings yet

- London AllRail v41Document1 pageLondon AllRail v41NJNo ratings yet

- ISBT Plan, Indore - DM V1.1 PDFDocument11 pagesISBT Plan, Indore - DM V1.1 PDFDevalMishraNo ratings yet

- Route 066Document2 pagesRoute 066api-224803686No ratings yet

- Zone F (South Delhi - I) ReportsDocument66 pagesZone F (South Delhi - I) ReportsSwati Sharma100% (2)

- Mexico City's Suburban Land Use and Transit Connection - The Effects of The Line B Metro ExpansionDocument10 pagesMexico City's Suburban Land Use and Transit Connection - The Effects of The Line B Metro ExpansionLutfi PrayogiNo ratings yet

- Dabbawalas of MumbaiDocument12 pagesDabbawalas of MumbaicshanglooNo ratings yet

- ABUS Product Overview PDFDocument15 pagesABUS Product Overview PDFNguyen Duc CuongNo ratings yet

- Answer Keys: Division of City Schools-Manila Gen. Emilio Aguinaldo Integrated School Punta, Sta. AnaDocument7 pagesAnswer Keys: Division of City Schools-Manila Gen. Emilio Aguinaldo Integrated School Punta, Sta. AnaJennina Bordeos MazoNo ratings yet

- 27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFDocument20 pages27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFLungisaniNo ratings yet

- Blue Label V-BeltDocument5 pagesBlue Label V-BeltMiguelAguirreNo ratings yet

- The Graph Below Shows The Different Modes of Transport Used To Travel To and From Work in One European City in 1960Document2 pagesThe Graph Below Shows The Different Modes of Transport Used To Travel To and From Work in One European City in 1960ngocNo ratings yet

- SM Sakai Sv505-1Document410 pagesSM Sakai Sv505-1LU YO89% (9)

- PUNE-Planning PrinciplesDocument24 pagesPUNE-Planning Principles7007Neeraj BhirudNo ratings yet

Pollution Problems: Table 1 Noise Level Caused by Various Construction Equipments

Pollution Problems: Table 1 Noise Level Caused by Various Construction Equipments

Uploaded by

Justin NgOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pollution Problems: Table 1 Noise Level Caused by Various Construction Equipments

Pollution Problems: Table 1 Noise Level Caused by Various Construction Equipments

Uploaded by

Justin NgCopyright:

Available Formats

Long Valley is the largest remaining fresh water wetland in Northern New Territories.

The habitat supports a high diversity of birds as well as flora and fauna. With its high ecological value, therefore, when the Kowloon-Canton Railway Corporation (KCRC) proposed the alignment of the Spur Line traversing the Long Valley, hot argument against the proposal arose. While much emphasis has been put on the ecological impacts on the Long Valley that the project would possibly bring, the issue of pollution that would likely be created seemed to have been overlooked. In this report, we are going to analyze the air and noise pollution problems associated with the Spur Line proposal within the Long Valley area. Pollution Problems In the following paragraphs, discussion on the air and noise pollution problems will be divided into two main parts, namely the construction phase and the operational phase. It is worth noticing that during the construction phase, air pollution would be of greater concern over noise pollution, whereas for the operational phase noise pollution problems would dominate instead. Air Pollution Construction Phase In general, for most types of construction works, construction dust is the major problem contributed to air pollution. However, this is not the case for the Spur Line project in the Long Valley since the earth within this wetland area is of high moisture content. Therefore, dust impacts associated with excavation works would be relatively insignificant. However, dust nuisance may be caused by vehicles entering and leaving the construction site. Dust particles may attach to the tyres and undercarriages of the vehicles and be carried away from the site, which then become deposited on public roads outside the construction area. Vehicles carrying refuse, earth, construction debris, etc. may also give rise to particulates contributing to air pollution problems both in and out of the construction site. Operational Phase No major adverse impact is anticipated due to the operation of the Spur Line as the trains are operated by electricity which leads to no atmospheric emission. However, minor air-related impact may arise during operation. Minute metallic particles would be produced during wheel/rail interaction. These fine particles are liable to be carried away and dispersed by wind, and would finally settle in the Long Valley area (atmospheric deposition). This may pose health risk on the birds as the metallic particles may dissolve in water or become mixed with birds feed and thus ingested, resulting in poisoning of birds. Besides, as metals are non-biodegradable, they would accumulate in the birds body. Excessive bioaccumulation of metals is liable to have adverse effects on birds including mortality and deformities as well as changes in reproduction.

Noise Pollution Construction Phase

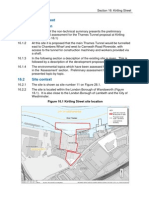

Table 1 Noise Level caused by Various Construction Equipments

Construction Equipments Adopted Dump Trucks Bulldozers Water Pumps (Electric) Generators, silenced

Sound Level (dB) 117.0 112.0 92.8 103.0 118.0 115.0 106.0 108.0 100.0 114.0 100.0 108.0 112.0 117.0

Site Formation for Temporary Works Area

Total: Bore Piling Machines & Oscillators Concrete Lorries Wood Saw Generators, silenced Vibratory Pokers Welding Machine Batching Plant Gantry Hoist Total:

Alignment Construction

During the construction period of the Spur Line, two construction activities, namely the site formation and the alignment construction, are expected to have potential construction noise impacts to the Long Valley. In particular, construction processes of concrete delivery and the

CIVE1001Environmental EngineeringProjectPage 1

concreting activities, which would adopt a large number of Power Mechanical Equipments (PME) such as dump trucks, bulldozers, bore piling machines, vibratory pokers and gantry hoist etc., are of major concern. The sound levels caused by various construction equipments are listed in the above table (Table 1). However, the overall noise impact is anticipated to be acceptable owing to the fact that the duration of such noisy activities is relatively short (usually within a month) with the introduction of some mitigation measures. Operational Phase The potential noise impacts due to the operation of the Spur Line include the airborne noise originating from the propulsion system and wheel/rail interaction, structure radiated or reradiated noise resulting from wheel/rail interaction (which is transmitted through the viaduct structure), and the noise from the roof-mounted air-conditioning system on the top of the carriage. Such noise pollution is liable to have adverse effects on the birds inhabiting in the Long Valley, especially the sensitive species like flock-feeding water birds. Birds, as a result of the operational noise impacts imposed by the Spur Line, may be driven away from the vicinity of Long Valley, which is therefore comparable to habitat loss. It is also suspected that noise may also interfere with breeding behavior of birds.

Mitigation Measures In order to reduce the pollution problems caused, mitigation measures should be incorporated. The following are some suggested mitigation measures: Air Pollution Construction Phase Tyres and undercarriages of vehicles should be washed and cleaned before leaving the site. A paved wash bay could be constructed for such purpose. However, washings from the wash bay should be directed to pass through a silt trap to filter out the silt in order to prevent water pollution. Vehicles carrying refuse, earth, construction debris, etc. should be covered completely before they leave the construction site. Spraying water over the loads may also help reducing the possible dust nuisance. Noise Pollution Construction Phase Noise mitigated machines should be adopted. Devices such as silencers, mufflers and acoustic shields should be incorporated to reduce the noise generated. Noise barrier of minimum height of 2.5 m should be provided around active parts of the construction site as well. If possible, avoid operating too many machines at the same time. Regular maintenance of construction equipments should be carried out. Operational Phase Floating Slab Track (FST) could be installed to reduce vibration transmitted to the viaduct structure, thereby reducing the structure radiated noise involved as trains pass. Regular lubrication should be carried out in order to minimize the squealing noise produced at the wheel rail interface at tight curves, points and crossings. Barrier walls with sound absorber should be installed in order to minimize the spreading of noise.

Construction of Spur LineJustified or Not? At present, as claimed by the KCRC, the average number of cross-border passengers at Lo Wu is 250,000 on weekdays and exceeds 300,000 on holidays, with an annual growth of 18 to 20 per cent since 1996. Such a high volume of commuter flow is about to stretch the operation of Lo Wu to its limit. In order to ease the border congestion problem at the East Rail crossing to the Mainland at Lo Wu, the KCRC therefore proposed the construction of the Spur Line. Besides relieving the congestion problem, the Spur Line also aims at providing a second rail crossing into the Mainland as well as providing access to rail transport for the proposed Kwu Tung Strategic Development Area. If decision was to be made by only considering the possible air and noise pollution problems, we believe that the construction of the Spur Line is justified, provided that suitable and adequate mitigation measures are incorporated during both the construction and operational phases.

CIVE1001Environmental EngineeringProjectPage 2

You might also like

- Arema Manual RailwayDocument2 pagesArema Manual RailwayBewok Giay15% (13)

- Environmental Impact Assessment For Highway ProjectsDocument8 pagesEnvironmental Impact Assessment For Highway Projectssaurabh514481% (32)

- Omega - Installation ManualDocument25 pagesOmega - Installation ManualCreaciones VilberNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Guide To Trench ExcavationsDocument43 pagesGuide To Trench ExcavationsmlakkissNo ratings yet

- Storm Water Drainage SystemDocument23 pagesStorm Water Drainage Systemankitbalyan100% (3)

- Levelling, Lining and Tamping MachinesDocument6 pagesLevelling, Lining and Tamping MachinesAnonymous Byopfd100% (2)

- Brosur Produk Precast WIKA BetonDocument40 pagesBrosur Produk Precast WIKA BetonRofik Susetyo Nugroho100% (4)

- Construction Phase: 1. Impact On SoilDocument11 pagesConstruction Phase: 1. Impact On SoilAnanditaKarNo ratings yet

- EIA Proposed Property Development Scheme Project On "Plot P" of Avalon Golf Estate at Bois SecDocument10 pagesEIA Proposed Property Development Scheme Project On "Plot P" of Avalon Golf Estate at Bois Secmelvin_12No ratings yet

- Peir Nts Section 6 AstDocument14 pagesPeir Nts Section 6 AstthamestunnelNo ratings yet

- Case StudyDocument3 pagesCase StudyathiraiNo ratings yet

- Individual Assignment On Structure-Borne Sound-VibrationDocument2 pagesIndividual Assignment On Structure-Borne Sound-VibrationMuhd NasrulNo ratings yet

- Road-Tunnels TP06 Road Tunnel Portal EmissionsDocument16 pagesRoad-Tunnels TP06 Road Tunnel Portal EmissionsALARP (Arnold Dix)No ratings yet

- 2 Druid StreetDocument4 pages2 Druid StreetthamestunnelNo ratings yet

- Sachin Bhardwaj Eia AssignmentDocument7 pagesSachin Bhardwaj Eia Assignmentsachin bhardwajNo ratings yet

- PEIR NTS Section 10 DormayDocument14 pagesPEIR NTS Section 10 DormaythamestunnelNo ratings yet

- Track Design To Control Railway Induced Vibration - CrossrailDocument8 pagesTrack Design To Control Railway Induced Vibration - CrossrailmetropodikasNo ratings yet

- AssignmentDocument19 pagesAssignmentMisango EmmanuelNo ratings yet

- Sustainable Construction AssignmentDocument10 pagesSustainable Construction AssignmentchillichilliNo ratings yet

- Transportation Activities Affecting The EnvironmentDocument6 pagesTransportation Activities Affecting The EnvironmentZia MohammadNo ratings yet

- Components of Sewer Sanitary Project CostDocument48 pagesComponents of Sewer Sanitary Project CostRamilArtates100% (1)

- Peir Nts Section 8 BeDocument14 pagesPeir Nts Section 8 BethamestunnelNo ratings yet

- Sewerage ImpactsDocument7 pagesSewerage ImpactsWajeeha UmerNo ratings yet

- 4-Albert Embankment ForeshoreDocument4 pages4-Albert Embankment ForeshorethamestunnelNo ratings yet

- Environmental Impact Assessment and Cost Benefit AnalysisDocument9 pagesEnvironmental Impact Assessment and Cost Benefit AnalysisBose RajNo ratings yet

- Peir Nts Section 13 FpsDocument13 pagesPeir Nts Section 13 FpsthamestunnelNo ratings yet

- Mine ManagementDocument7 pagesMine ManagementBranden OxfordNo ratings yet

- Peir Nts Section 23 EpsDocument12 pagesPeir Nts Section 23 EpsthamestunnelNo ratings yet

- Applied Acoustics: Aglaia Badino, Davide Borelli, Tomaso Gaggero, Enrico Rizzuto, Corrado SchenoneDocument14 pagesApplied Acoustics: Aglaia Badino, Davide Borelli, Tomaso Gaggero, Enrico Rizzuto, Corrado SchenoneEdwin HernandezNo ratings yet

- The Crossrail ProjectDocument11 pagesThe Crossrail ProjectArindom100% (1)

- Method Statement For Construction of Access BridgeDocument12 pagesMethod Statement For Construction of Access BridgeSepthy14No ratings yet

- Sustainability of Vibration Mitigation Methods Using Meta-Materials Exposed To Adverse Weather ConditionsDocument20 pagesSustainability of Vibration Mitigation Methods Using Meta-Materials Exposed To Adverse Weather ConditionsSHNo ratings yet

- Cut and Fill - WikipediaDocument9 pagesCut and Fill - WikipediaVineet YadavNo ratings yet

- Air Quality Impact: Construction PhaseDocument6 pagesAir Quality Impact: Construction PhaseChristina NgNo ratings yet

- A Review of Offshore Windfarm Related Underwater Noise SourcesDocument63 pagesA Review of Offshore Windfarm Related Underwater Noise SourcesJohn Williamson100% (2)

- Murton - Assessment of GR Bibr Eff From Constr and OperationDocument60 pagesMurton - Assessment of GR Bibr Eff From Constr and OperationMax ShashkinNo ratings yet

- The HONG-KONG-ZHUHAI MACAO Bridge - The HONG-KONG Link RoadDocument9 pagesThe HONG-KONG-ZHUHAI MACAO Bridge - The HONG-KONG Link RoadFerga VanessaNo ratings yet

- Metro Project CCDocument15 pagesMetro Project CCJanhavi KamdarNo ratings yet

- Current State of Practice in Railway Track VibratiDocument11 pagesCurrent State of Practice in Railway Track VibratiSajid IqbalNo ratings yet

- PEIR NTS Section 16 KirtlingDocument14 pagesPEIR NTS Section 16 KirtlingthamestunnelNo ratings yet

- Impact of Traffic Vibration On HeritageDocument10 pagesImpact of Traffic Vibration On HeritageMohamad HabibiNo ratings yet

- EVR Quarry BDocument11 pagesEVR Quarry BdumindaNo ratings yet

- Attachment To Project Site - ContractsDocument3 pagesAttachment To Project Site - ContractsMichael KpeglahNo ratings yet

- The Environmental Impacts For A One Way Road Construction ProjectDocument8 pagesThe Environmental Impacts For A One Way Road Construction ProjectMadhushiWijeratnaNo ratings yet

- Peir Nts Section 26 AmpsDocument13 pagesPeir Nts Section 26 AmpsthamestunnelNo ratings yet

- Construction Project Working Site of Environmental Pollution and CountermeasuresDocument4 pagesConstruction Project Working Site of Environmental Pollution and CountermeasuresArshi KhanNo ratings yet

- EIA-Water, Land and NoiseDocument11 pagesEIA-Water, Land and NoiseRyan Rhys NyambzNo ratings yet

- Aqua Silencer MailDocument1 pageAqua Silencer MailHARI KUMAR SNo ratings yet

- Final Writing Test: Topic: What Are The Causes of Air Pollution in Ha Noi ?Document2 pagesFinal Writing Test: Topic: What Are The Causes of Air Pollution in Ha Noi ?Cường KèoNo ratings yet

- Keller 39 03E Vibration Mitigation RailwayDocument4 pagesKeller 39 03E Vibration Mitigation RailwayDanielSierraNo ratings yet

- 2-Putney Bridge ForeshoreDocument4 pages2-Putney Bridge ForeshorethamestunnelNo ratings yet

- Toxic WasteDocument3 pagesToxic WastenithansaNo ratings yet

- STONE Falbe HansenDocument6 pagesSTONE Falbe HansenAyman ShamaNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Manual for Climate Change Adaptation Measures for Transport Infrastructure in Central Asia with a Focus on UzbekistanFrom EverandManual for Climate Change Adaptation Measures for Transport Infrastructure in Central Asia with a Focus on UzbekistanNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Paper Crawer CraneDocument10 pagesPaper Crawer CraneJustin NgNo ratings yet

- Building Construction CAP 123B PDFDocument28 pagesBuilding Construction CAP 123B PDFJustin NgNo ratings yet

- Brazilian TestDocument11 pagesBrazilian TestJustin Ng100% (1)

- Malaysian FYPDocument138 pagesMalaysian FYPJustin NgNo ratings yet

- Brazilian TestDocument11 pagesBrazilian TestJustin NgNo ratings yet

- Uclt Siding & PolDocument36 pagesUclt Siding & PolSSE TRD JabalpurNo ratings yet

- Indian RailwaysDocument28 pagesIndian RailwaysGurpreet KaurNo ratings yet

- Coal MachineriesDocument7 pagesCoal Machineriesdudealok100% (2)

- Time Table 2016Document8 pagesTime Table 2016C&W controller MughalsaraiNo ratings yet

- Trans Flux MotorDocument46 pagesTrans Flux MotorkoppulabroNo ratings yet

- Jeffrey Russell - DR Stephen Goh - Aurecon Paper PDFDocument14 pagesJeffrey Russell - DR Stephen Goh - Aurecon Paper PDFAnubhav Hem Kumar JainNo ratings yet

- Micropower, Rail-to-Rail Input and Output Operational Amplifiers OP196/OP296/OP496Document16 pagesMicropower, Rail-to-Rail Input and Output Operational Amplifiers OP196/OP296/OP496Ram NiwasNo ratings yet

- Project Report: Tourism Products of IrctcDocument36 pagesProject Report: Tourism Products of Irctcish rehNo ratings yet

- Lalitpur YardDocument1 pageLalitpur YardAjayNo ratings yet

- Advanced Grammar in Use - 3121st EditionDocument2 pagesAdvanced Grammar in Use - 3121st EditionasddsaNo ratings yet

- Underground StructuresDocument12 pagesUnderground StructuresmctrtNo ratings yet

- X1-3 X2-3 X3-3 X4-3 X5-3 X6-3 X7-3 X8-3 X9-3: X10-1 X10-2 X10-4 X10-5 X10-6 X10-7 X10-8 X10-9 X10-10 1Document5 pagesX1-3 X2-3 X3-3 X4-3 X5-3 X6-3 X7-3 X8-3 X9-3: X10-1 X10-2 X10-4 X10-5 X10-6 X10-7 X10-8 X10-9 X10-10 1Edgar Tejeda VieraNo ratings yet

- London AllRail v41Document1 pageLondon AllRail v41NJNo ratings yet

- ISBT Plan, Indore - DM V1.1 PDFDocument11 pagesISBT Plan, Indore - DM V1.1 PDFDevalMishraNo ratings yet

- Route 066Document2 pagesRoute 066api-224803686No ratings yet

- Zone F (South Delhi - I) ReportsDocument66 pagesZone F (South Delhi - I) ReportsSwati Sharma100% (2)

- Mexico City's Suburban Land Use and Transit Connection - The Effects of The Line B Metro ExpansionDocument10 pagesMexico City's Suburban Land Use and Transit Connection - The Effects of The Line B Metro ExpansionLutfi PrayogiNo ratings yet

- Dabbawalas of MumbaiDocument12 pagesDabbawalas of MumbaicshanglooNo ratings yet

- ABUS Product Overview PDFDocument15 pagesABUS Product Overview PDFNguyen Duc CuongNo ratings yet

- Answer Keys: Division of City Schools-Manila Gen. Emilio Aguinaldo Integrated School Punta, Sta. AnaDocument7 pagesAnswer Keys: Division of City Schools-Manila Gen. Emilio Aguinaldo Integrated School Punta, Sta. AnaJennina Bordeos MazoNo ratings yet

- 27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFDocument20 pages27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFLungisaniNo ratings yet

- Blue Label V-BeltDocument5 pagesBlue Label V-BeltMiguelAguirreNo ratings yet

- The Graph Below Shows The Different Modes of Transport Used To Travel To and From Work in One European City in 1960Document2 pagesThe Graph Below Shows The Different Modes of Transport Used To Travel To and From Work in One European City in 1960ngocNo ratings yet

- SM Sakai Sv505-1Document410 pagesSM Sakai Sv505-1LU YO89% (9)

- PUNE-Planning PrinciplesDocument24 pagesPUNE-Planning Principles7007Neeraj BhirudNo ratings yet