Professional Documents

Culture Documents

Contactor Vol 4 No 5 PDF

Contactor Vol 4 No 5 PDF

Uploaded by

Mudassir KhalilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contactor Vol 4 No 5 PDF

Contactor Vol 4 No 5 PDF

Uploaded by

Mudassir KhalilCopyright:

Available Formats

The CONTACTOR

Dehydration Using TEG

Published Quarterly by Optimized Gas Treating, Inc. Volume 4, Issue 5, September 2010

Glycol dehydration is a process that presents some unique challenges from technical and computational standpoints. In the first place, modern designs almost invariably use tower internals consisting of structured packing rather than the more traditional bubble cap trays. Structured packing offers lower pressure drop and considerably higher capacity than trays. Structured packing is well suited to handling the very low L/G ratios common in dehydration. However, until now estimating height of packing used rules of thumb, not science. Mass transfer rate based modeling, on the other hand, uses science and therefore it offers greater reliability of design. The other challenge of dehydration using any glycol is thermodynamic. The dehydration of streams having very high concentrations of acid gases is hard to model reliably because the thermodynamics of vaporliquid phase equilibrium involves water, one of natures most perversely-nonideal chemical species. Interactions between water and the acid gases CO2 and H2S, as well as with most hydrocarbons in the gas phase must be taken into account for a thermodynamic model to be reliable. Furthermore, in the liquid phase, aqueous glycol solutions themselves are quite nonideal because both water and glycol are polar molecules. Optimized Gas Treating, Inc. has recently released a new glycol dehydration model, currently for TEG, and being extended to MEG and DEG. This note addresses the efficacy of the model in terms of (1) how well it reflects known phase behavior and (2) how closely it predicts known plant performance data using both bubble cap trays and packed columns without recourse to HETP or HTU estimates and other rules of thumb. This latest addition makes ProTreat the premier simulation tool not just for gas treating with single and mixed amines, but for acid gas removal with DMPEG and for dehydration.

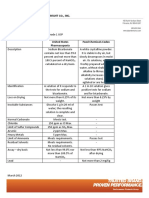

Phase Equilibrium The concern here is with the accurate calculation of equilibrium water content of high- and low-pressure gases containing very high levels of CO2 and/or H2S. ProTreats dehydration model uses the Peng-Robinson equation of state (EOS) for the vapor phase and currently offers a 4-suffix Margules equation activity coefficient model based on the data of Bestani & Shing for the liquid phase. A similar model based on the less conservative data of Parrish et al. is planned for a future release. There are two important aspects to thermodynamic modeling: water content of the treated gas, and the hydrocarbon, acid gas, and especially the BTEX content of the water-laden glycol. Table 1 compares ProTreat model results with GPSA Data Book entries for saturated water content. Generally, ProTreat reproduces measured values of water content to within the accuracy of the data. The EOS Table 1 Saturated Water Content of Gases

GPSA Ref. Ex 20-1 Ex 20-2 Fig 20-9 Mole Percent (Dry Basis) CH4 CO2 H2S 100 80 0 0 20 100 0 0 0 Temp (oF) 150 160 100 Pres (psia) 1,000 2,000 500 750 1,000 2,000 3,000 850 1,125 1,500 2,000 2,000 1,000 2,000 1,000 2,000 1,500 1,367 1,000 1,100 1,900 1,500 2,000 H2O lb/MMscf Meas'd ProTreat 220 216 172 188 132 125.3 110 102.5 125 100.7 215 215.1 238 247.8 88 96.9 81 99.2 128 148.6 139 184.2 40.6 41.1 286 283.9 40.6 45.1 282 292.5 172 188.5 111 103.5 247 252.6 292 293.4 81 81.2 442 264.4 109.2 95 164.6 234.5

5.31

94.69

100

Fig 20-16

89 89 80 80 80 92 72.5 83 30 9 5.31 5.31

11 11 20 20 20 0 0 0 60 10 94.69 94.69

0 0 0 0 0 8 27.5 17 10 81 0 0

100 160 100 160 160 130 160 160 100 100 77 122

See Clinton, Hubbard & Shah, LRGCC, Norman, OK, 2008 See Parrish et al., Proceedings 65th Annual Convention, GPA, 1986

2010 by Optimized Gas Treating, Inc., 12337 Jones Rd., Suite 410, Houston, TX 77070, USA, Phone/Fax +1 281 970 2700, Web: www.ogtrt.com

(Peng-Robinson) that performs these saturated water calculations applies a large number of interaction parameters (kijs) for the interactions between water and the various gases as well as between the gases themselves. Other components whose solubility in TEG is pertinent are the acid gases and hydrocarbons, especially the BTEX components. Vapor-liquid equilibrium constants (K-values) for benzene, toluene, ethyl benzene and o-xylene are available in GPA RR-131and the data there have been used to fit the ProTreat solubility model for these species. The data indicate that at typical contactor conditions approximately 1030% of the aromatics in the gas stream may be absorbed in the TEG solution. ProTreat results conform closely to the conclusions of RR-131 (as they should, because ProTreats solubility model has been regressed to the actual measured BTEX solubilities). Process Simulation The GPSA Data Book contains a nice example of dehydration with TEG (Example 20-11). The gas is water saturated at 600 psia with other details noted in Figure 1. Two cases are detailed, both requiring two theoretical stages. One uses bubble cap trays which at a tray efficiency of 25 to 30%, translates into 6 to 8 actual trays. The other case uses 10-ft of an unspecified structured packing. ProTreat has provision for a separate

Table 2 shows the effect of the actual tray count on the water content of the dehydrated gas. Table 2 Water Content vs. Tray Count

Number of Trays 5 6 7 8 Water lb/MMscf 8.5 6.7 5.7 5.1

ProTreat simulation indicates 6 trays are adequate to reduce the water content from 88.7 lb/MMscf to the target level of < 7 lb/MMscf. Tower diameter for 70% flood is 3-0. Table 3 shows that the crimp size of the structured packing does indeed make a difference and that packing with a finer crimp is needed to meet the dehydration goal with a 10-ft bed. Its not enough just to specify structured packing because performance depends on the mass transfer characteristics of the tower internals. The absorber diameter in this case is about 2-3, consistent with the well-established fact that under otherwise identical conditions, columns with structured packing have higher hydraulic capacity than their trayed equivalent. Table 3 Effect of Crimp Size

Packing Type FLEXIPAC 2Y FLEXIPAC 1.6Y Water lb/MMscf 8.5 6.5

The beauty of ProTreats mass transfer rate based approach to simulation is that you never have to worry about tray efficiencies, artificial residence times, HETPs, HTUs, and other rules of thumb. ProTreat doesnt use rules of thumbit uses science and good sound engineering to predict performance. These results were all obtained without any correction factors whatsoever. They are true predictions in every sense of the word. Stahl column, shown immediately below the stripper in Figure 1 but the stripper can also be simulated without this column if desired. Two condenser outlet streams allow wet stripping gas withdrawal from the system (Stream 19), and removal of a specifiable portion of condensed water (Stream 20), with the remainder returned as reflux. To learn more about this and other aspects of gas treating, plan on attending one of our seminars. Visit www.ogtrt.com/seminars.cfm for details. ProTreat and The Contactor are trademarks of Optimized Gas Treating, Inc.

2010 by Optimized Gas Treating, Inc., 12337 Jones Rd., Suite 410, Houston, TX 77070, USA, Phone/Fax +1 281 970 2700, Web: www.ogtrt.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- LAB: What Is The Solubility Curve of Sugar?: ObjectiveDocument3 pagesLAB: What Is The Solubility Curve of Sugar?: ObjectiveLaisha Hernandez0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cigre Guidelines For Life Management Techniques For Power Transformers PDFDocument125 pagesCigre Guidelines For Life Management Techniques For Power Transformers PDFJorge Bejarano100% (2)

- Cambridge Lower Secondary Checkpoint: Science 1113/02Document16 pagesCambridge Lower Secondary Checkpoint: Science 1113/02lol67% (6)

- Chem7-Structure, Bonding and PropertiesDocument6 pagesChem7-Structure, Bonding and PropertiesNor Ashikin Ismail0% (1)

- 4.inter Phase Mass Transfer PDFDocument11 pages4.inter Phase Mass Transfer PDFMohit SathwaraNo ratings yet

- United States Pharmacopoeia Food Chemicals CodexDocument3 pagesUnited States Pharmacopoeia Food Chemicals CodexДима ВараваNo ratings yet

- Solid Liquid Extraction - 1 - 19 Sept 2020 PDFDocument11 pagesSolid Liquid Extraction - 1 - 19 Sept 2020 PDFshubhamNo ratings yet

- Benzene Recovery 1Document12 pagesBenzene Recovery 1Student 80No ratings yet

- Chapter 6 Chemical EquilibriumDocument40 pagesChapter 6 Chemical EquilibriumMaame Ama FrempongNo ratings yet

- BS 3958-1 PDFDocument10 pagesBS 3958-1 PDFAnitha Mj100% (2)

- Food Chemistry Pratical ManualDocument57 pagesFood Chemistry Pratical ManualDocumentos Tecnicos100% (1)

- Thermodynamics of ZnFeS Sphalerite A CVM ApproachDocument22 pagesThermodynamics of ZnFeS Sphalerite A CVM ApproachElvis StansvikNo ratings yet

- EBatistil - Scientific Report On VitaminsDocument16 pagesEBatistil - Scientific Report On VitaminsEssielve BatistilNo ratings yet

- Sample Paper 1 (Solutions Only) - IsC Chemistry 2024Document17 pagesSample Paper 1 (Solutions Only) - IsC Chemistry 2024Dia SureshNo ratings yet

- Solutions - Class Notes - Lakshya NEET 2025Document24 pagesSolutions - Class Notes - Lakshya NEET 2025Dipanshu MundNo ratings yet

- Solvent Fractionation Method With Brix For Rapid Characterization of Wood Fast Pyrolysis LiquidsDocument4 pagesSolvent Fractionation Method With Brix For Rapid Characterization of Wood Fast Pyrolysis LiquidsAnkit KumarNo ratings yet

- Sample Alumunium SulphateDocument8 pagesSample Alumunium SulphateCandra BayuNo ratings yet

- White: Photoreactive Resin For Form 1, Form 1+, Form 2Document8 pagesWhite: Photoreactive Resin For Form 1, Form 1+, Form 2Ivan SimicNo ratings yet

- Trickle Bed ReactorDocument23 pagesTrickle Bed ReactorgautamahujaNo ratings yet

- DexpanthenolDocument2 pagesDexpanthenolMulayam Singh YadavNo ratings yet

- AP Chem 2013S Mod C Notes - AnsDocument44 pagesAP Chem 2013S Mod C Notes - AnsWTSENo ratings yet

- Starch Microspheres With EPCLDocument9 pagesStarch Microspheres With EPCLancutauliniuc@yahoo.comNo ratings yet

- Solid DispersionDocument11 pagesSolid DispersionkavitaNo ratings yet

- Glucopon 225 DK: Technical InformationDocument4 pagesGlucopon 225 DK: Technical InformationrotulcmNo ratings yet

- 01 YardleyDocument20 pages01 YardleyHEBERT JHON RAFAEL AGUILARNo ratings yet

- CHEM 43.1 Exercise 4Document7 pagesCHEM 43.1 Exercise 4paradoxcomplexNo ratings yet

- Activity 7 LIPIDS PDFDocument3 pagesActivity 7 LIPIDS PDFPrincess Pilove GawongnaNo ratings yet

- ISC 2014 Chemistry Theory Paper 1 Solved PaperDocument23 pagesISC 2014 Chemistry Theory Paper 1 Solved PaperMd Saif UddinNo ratings yet

- ProteinDocument5 pagesProteinSyifaAnandaNo ratings yet

- 8.8 Preparing SaltsDocument6 pages8.8 Preparing Saltswama ojhaNo ratings yet