Professional Documents

Culture Documents

Inspection Procedure For KEC Remediation Project

Inspection Procedure For KEC Remediation Project

Uploaded by

goyalmanojCopyright:

Available Formats

You might also like

- Sample Projects For Project Management AssignmentDocument28 pagesSample Projects For Project Management Assignmentmanoj kumar Das93% (15)

- Ac 193Document46 pagesAc 193Tiago Castelani100% (1)

- Checklist Control PanelDocument2 pagesChecklist Control PanelSaravana Kumar83% (23)

- Gurgaon MSME LIST PDFDocument90 pagesGurgaon MSME LIST PDFSaptarshi RoyNo ratings yet

- Section-02 Testing RequirementDocument24 pagesSection-02 Testing RequirementChaitanya Shakya0% (1)

- Ac 133Document7 pagesAc 133thirumalaichettiar100% (2)

- Inspection Surveillance ExpeditingDocument4 pagesInspection Surveillance ExpeditingPrasanna RajaNo ratings yet

- Tsec ManualDocument88 pagesTsec ManualNeeraj SinghNo ratings yet

- CV of Welding InspectorDocument4 pagesCV of Welding Inspectorramesh77c100% (2)

- JLL Quality Test Reports & Checklists - CivilDocument55 pagesJLL Quality Test Reports & Checklists - CivilN.PrabhuNo ratings yet

- Stat Prod Range enDocument23 pagesStat Prod Range enhjyujyagghjafhgjhgafNo ratings yet

- MSCRM Interview Questions and AnswersDocument11 pagesMSCRM Interview Questions and Answersadikesa100% (1)

- CV Aravind API InspectorDocument12 pagesCV Aravind API Inspectorநான் மகான் அல்லNo ratings yet

- Quality Management System SystemDocument4 pagesQuality Management System SystemMario YañezNo ratings yet

- TIC Information 12 Dec 2023Document43 pagesTIC Information 12 Dec 2023Sayan KeawponwongNo ratings yet

- Thamilvendhan Vetrinambi: QA/QC Inspector - (Welding)Document2 pagesThamilvendhan Vetrinambi: QA/QC Inspector - (Welding)Paul PhiliphsNo ratings yet

- KP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection WorksDocument1 pageKP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection WorksUtku Can KılıçNo ratings yet

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- General QuestionnaireDocument9 pagesGeneral Questionnairehemant1284No ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- Inspection and Test Procedure FR1672A - ApprvdDocument10 pagesInspection and Test Procedure FR1672A - ApprvdSavvas KatemliadisNo ratings yet

- 01-Pre-Commissioning Tests For SEC Transmission Electrical EquipmentsDocument38 pages01-Pre-Commissioning Tests For SEC Transmission Electrical EquipmentsThameemul BuhariNo ratings yet

- BV PSPC Pres 03122012Document31 pagesBV PSPC Pres 03122012Ahmed Algunaid احمد الجنيدNo ratings yet

- Jawad+Ahsan + ResumeDocument3 pagesJawad+Ahsan + ResumeAndiappan PillaiNo ratings yet

- Aramco-Candidate QuestionDocument5 pagesAramco-Candidate Questionnafis2u100% (1)

- Srihari Katari 11 Jan 2022Document50 pagesSrihari Katari 11 Jan 2022Abhishek DevarajNo ratings yet

- KEPIC 감사 보고서Document36 pagesKEPIC 감사 보고서J.H LeeNo ratings yet

- Quality Assurance and Quality ControlDocument4 pagesQuality Assurance and Quality ControlRuli DarmawanNo ratings yet

- SR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Document8 pagesSR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Sreenath KooliyattuNo ratings yet

- Jawed Ahsan: +92-318-2990934 Cell #Document4 pagesJawed Ahsan: +92-318-2990934 Cell #Nomi ANo ratings yet

- 22 66 KV LA R4 Jan 11 PDFDocument17 pages22 66 KV LA R4 Jan 11 PDFDin CuyNo ratings yet

- QM and Process Flow Chart BKT SideDocument3 pagesQM and Process Flow Chart BKT SideDebashis SarkarNo ratings yet

- 5657-Jawad Hanif CV TakreerDocument6 pages5657-Jawad Hanif CV TakreerkanchithalaiNo ratings yet

- QC Welding Inspector NotesDocument26 pagesQC Welding Inspector NotesSohail Aziz Ahmad MalikNo ratings yet

- VT-2 Codes and StandardsDocument29 pagesVT-2 Codes and StandardsMirza Safeer Ahmad100% (1)

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- QSP 23 - Quality Assurance (R0) 010105Document10 pagesQSP 23 - Quality Assurance (R0) 010105ukali_csNo ratings yet

- Audit ReportDocument9 pagesAudit ReportVIVEK100% (1)

- George Morris: Mechanical Engineer Having Rich Experience of Above 3years in Oil and Gas Construction ObjectiveDocument6 pagesGeorge Morris: Mechanical Engineer Having Rich Experience of Above 3years in Oil and Gas Construction Objectivedavidgeorge143No ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- Japan2010 Workshops SingaporeDocument32 pagesJapan2010 Workshops Singaporethanh huyền hồNo ratings yet

- Piping QC Inspector Resume 2020Document5 pagesPiping QC Inspector Resume 2020Omprakash Yadav100% (1)

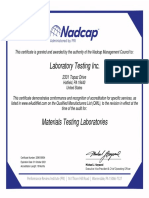

- Laboratory Testing Inc.: 2331 Topaz DriveDocument4 pagesLaboratory Testing Inc.: 2331 Topaz Driveamirkhakzad498No ratings yet

- ACL-CPIS-01 (Control of Purchased Services)Document3 pagesACL-CPIS-01 (Control of Purchased Services)Mo ZeroNo ratings yet

- Application For The Post of Suitable Position For Mechanical QA/QC INSPECTORDocument4 pagesApplication For The Post of Suitable Position For Mechanical QA/QC INSPECTORAhmed Imtiaz RaoNo ratings yet

- Inspection DocumentsDocument6 pagesInspection DocumentsTulen CabuldinNo ratings yet

- PDF Quality AssuranceDocument14 pagesPDF Quality AssuranceNaveen ThakurNo ratings yet

- 9171-5.6.1 SAT ProcedureDocument1 page9171-5.6.1 SAT ProcedureArdeleanu-Simion StefanNo ratings yet

- Concrete Mech AnchorsDocument30 pagesConcrete Mech AnchorscustomerxNo ratings yet

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- Measurement of LengthDocument2 pagesMeasurement of LengthCedric MercadoNo ratings yet

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- Quality Control Checklist: Structural Steel Painting - Localized ChecklistDocument4 pagesQuality Control Checklist: Structural Steel Painting - Localized ChecklistDilhara WickramaarachchiNo ratings yet

- PMI Procedure Rev.00Document13 pagesPMI Procedure Rev.00Abdul Khaliq50% (6)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Iso Work InstructionsDocument115 pagesIso Work InstructionsEkondroNo ratings yet

- General Technical Specifications For CS & SS Pipes and Pipe FittingsDocument10 pagesGeneral Technical Specifications For CS & SS Pipes and Pipe FittingsrajaNo ratings yet

- SFT-ECAS - OP - 24c Factory Inspection Report (RoHS) Final Draft 21st Jan, 18Document15 pagesSFT-ECAS - OP - 24c Factory Inspection Report (RoHS) Final Draft 21st Jan, 18Duong N. KhoaNo ratings yet

- B31.3 Process Piping Course - 13 Inspection, Examination and TestingDocument19 pagesB31.3 Process Piping Course - 13 Inspection, Examination and TestingLuong AnhNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

- Magnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryFrom EverandMagnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- CSC 99Document16 pagesCSC 99goyalmanojNo ratings yet

- NORMS AND TECHNICAL SPECIFICATIONS OF TESTING INSTRUMENTS - Rev 2021Document86 pagesNORMS AND TECHNICAL SPECIFICATIONS OF TESTING INSTRUMENTS - Rev 2021goyalmanoj100% (1)

- JD - AC Design - ReNew PowerDocument2 pagesJD - AC Design - ReNew PowergoyalmanojNo ratings yet

- TechnicalSpecification For HG Fuse & LADocument12 pagesTechnicalSpecification For HG Fuse & LAgoyalmanojNo ratings yet

- Low Voltage Ride-Through (LVRT) Testing of Distributed Generation SourcesDocument2 pagesLow Voltage Ride-Through (LVRT) Testing of Distributed Generation SourcesgoyalmanojNo ratings yet

- RFP-TD-4022-Consultancy Services For GIS StationDocument120 pagesRFP-TD-4022-Consultancy Services For GIS StationgoyalmanojNo ratings yet

- D8 N R T General Duty1Document9 pagesD8 N R T General Duty1robert0126No ratings yet

- A5000 User Manual PDFDocument72 pagesA5000 User Manual PDFTandin IgorNo ratings yet

- FiverrDocument13 pagesFiverrdevilsharmaNo ratings yet

- Armalite AR 10 Rifle ManualDocument53 pagesArmalite AR 10 Rifle Manualparatrpr2003No ratings yet

- BP344Document53 pagesBP344DaneKerenCometaNo ratings yet

- Group 4 Presentation OM ERP and MRP IIDocument22 pagesGroup 4 Presentation OM ERP and MRP IICindi NabilaNo ratings yet

- Lead Free Series S-FBV-1 2-Piece, Full Port, Stainless Steel Ball Valves Specification SheetDocument2 pagesLead Free Series S-FBV-1 2-Piece, Full Port, Stainless Steel Ball Valves Specification SheetWattsNo ratings yet

- Mill PostsDocument158 pagesMill PostsPham LongNo ratings yet

- Introduction To Chemical Process Design EngineeringDocument4 pagesIntroduction To Chemical Process Design Engineeringankur2061100% (1)

- AhlDocument25 pagesAhlHassaan DarNo ratings yet

- Atestat Harley Davidson A Way of LifeDocument33 pagesAtestat Harley Davidson A Way of Lifesweet_oannyNo ratings yet

- Fluid and Filter: Change RecommendationsDocument8 pagesFluid and Filter: Change RecommendationsJIMJEO100% (2)

- Implementation of Total Productive Maintenance (TPM) With Measurement of Overall Equipment Effectiveness (OEE) and Six Big Losses in Vapour Phase Drying Oven Machines in PT. XYZDocument7 pagesImplementation of Total Productive Maintenance (TPM) With Measurement of Overall Equipment Effectiveness (OEE) and Six Big Losses in Vapour Phase Drying Oven Machines in PT. XYZInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Data PreparationDocument28 pagesData PreparationnaveengargnsNo ratings yet

- Travelling Salesman ProblemDocument27 pagesTravelling Salesman ProblemrafsantetoNo ratings yet

- Master Catalog Final PDFDocument89 pagesMaster Catalog Final PDFak100% (1)

- Samsung Investor Presentation Foundry 2019 v1Document19 pagesSamsung Investor Presentation Foundry 2019 v1xellosdexNo ratings yet

- Using Value Stream Mapping ToDocument12 pagesUsing Value Stream Mapping ToAlexanderHFFNo ratings yet

- FD100 分Document17 pagesFD100 分Hadi FaisalNo ratings yet

- Internal Audit Check Sheet Ok 2016Document11 pagesInternal Audit Check Sheet Ok 2016manttupandeyNo ratings yet

- Fort St. John RCMP Building Construction - Tender Awards, January 2021Document14 pagesFort St. John RCMP Building Construction - Tender Awards, January 2021AlaskaHighwayNewsNo ratings yet

- Cellular BeamsDocument83 pagesCellular BeamsStephen Hicks100% (3)

- Om 0017Document198 pagesOm 0017praveen4_40% (1)

- 2018 04 ATR Converted FreightersDocument2 pages2018 04 ATR Converted FreightersLuis ParraNo ratings yet

- Frnc5user PDFDocument2 pagesFrnc5user PDFValiNo ratings yet

- Case Study For NRDocument10 pagesCase Study For NRsaanidhya1115No ratings yet

Inspection Procedure For KEC Remediation Project

Inspection Procedure For KEC Remediation Project

Uploaded by

goyalmanojOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Procedure For KEC Remediation Project

Inspection Procedure For KEC Remediation Project

Uploaded by

goyalmanojCopyright:

Available Formats

Inspection Procedure for KEC Remediation Pr S.No. ITP Clause No.

Stage Activity

1.a.1 1.b.1

Raw material Identification

1.a 1.b 1.c 1.d 1.e 1.f

Raw Material

Raw material test Certificates

1.c.1 1.d.1 1.e.1 1.f.1

Raw Material Testing

Inprocess Inspection (Fabrication) 2 2 3 Inprocess Inspection Inprocess Inspection (Galvanizing)

Dimensional Inspection (after Galvanizing)

Final Inspection

Finished Good (FG) Inspection 3 5 Final Inspection

Dispatch Clearance

Dispatch Clearance

Inspection Procedure for KEC Remediation Project Scope of Inspection KEC When raw material enters KEC's works they issue ME No. for each lot and offer the same to SNC for visual, dimensional inspection and mechanical testing Scope of Inspection SNC KEC segregates pieces from lot as per sampling plan for SNC visual and dimensional inspection, SNC witnesses the same after satisfactory inspection, SNC identifies the samples for mechanical and chemical testing. SNC reviews raw material test certicates for chemical and mechanical properties as per ITP and code requirements Document of Reference

ITP, ASTM A6

KEC prepares raw material visual, dimensional inspection reports and submit copy of their reviewed raw material test certifcates for SNC review

ITP, ASTM A6, ASTM A36, ASTM A572 GR. 50

SNC witnesses Mechanical testing ( Tensile and impact* ) on samples KEC performs Chemical, identified during raw material Mechanical and Ultrasonic testing identification stage. SNC also (on plates above thickness 38 witnesses Ultarsonic tests on mm) plates (above 38 mm thk) as per ASTM 435 SNC reviews documents for these KEC performs 100% inspection of stages and performs audits to components in Black stage, ensure that KEC is following Machine operator inspects inspection procedures properly or 1st,2nd and last piece. not KEC performs galvanizing inspection of pieces on sampling basis, they performs visual, Coating thickness check and adhesion test on sampling basis SNC reviews documents for these stages and performs audits to ensure that KEC is following inspection procedures properly or not SNC performs visual and dimensional inspection of pieces as per sampling plan after galvanizing. Pieces are randomly picked from finished yard

ITP, ASTM A6, ASTM A36, ASTM A572 GR. 50, ASTM A435 (for Plate UT)

KEC drawings, ITP, Specification, ASTM A123

Drawings, ITP

KEC offers materials for final inspection to SNC for identification of samples for Galvanizing test (mass of zinc coating, adhesion test, coating thickness check),Mechanical testing and visual, dimensional check KEC performs mechnical, chemical and galvanizing test on SNC identified samples KEC performs dimensional inspection on pieces identified during FG inspection sampling

SNC identifies list of items for mechanical, chemical testing and galvanizing tests and also identifes items critical items to be inspected KEC drawings, ITP, Specification, for visual, dimensional check ASTM A123 SNC witnesses Mechanical testing and galvanizing test on samples identified during FG inspection. SNC witnesses/performs visual, dimensional, adhesion test and coating thickness checks on items identified during FG inspection sampling At this stage SNC verfies that all the stage inspection activities as per ITP completed or not . If all the activities completed as per ITP requirements and documents review is also completed then SNC will give Dispatch clearance to KEC as per their request.

Drawings, ITP

KEC submits all the stage inspection documents I,e, raw material test certificate correlation sheet, mechanical testing reports, galvanizing test records, dimensional check records, BNA test records as per ITP for SNC review

ITP, Specification

Remark

*Impact testing is done shoe base plate only

You might also like

- Sample Projects For Project Management AssignmentDocument28 pagesSample Projects For Project Management Assignmentmanoj kumar Das93% (15)

- Ac 193Document46 pagesAc 193Tiago Castelani100% (1)

- Checklist Control PanelDocument2 pagesChecklist Control PanelSaravana Kumar83% (23)

- Gurgaon MSME LIST PDFDocument90 pagesGurgaon MSME LIST PDFSaptarshi RoyNo ratings yet

- Section-02 Testing RequirementDocument24 pagesSection-02 Testing RequirementChaitanya Shakya0% (1)

- Ac 133Document7 pagesAc 133thirumalaichettiar100% (2)

- Inspection Surveillance ExpeditingDocument4 pagesInspection Surveillance ExpeditingPrasanna RajaNo ratings yet

- Tsec ManualDocument88 pagesTsec ManualNeeraj SinghNo ratings yet

- CV of Welding InspectorDocument4 pagesCV of Welding Inspectorramesh77c100% (2)

- JLL Quality Test Reports & Checklists - CivilDocument55 pagesJLL Quality Test Reports & Checklists - CivilN.PrabhuNo ratings yet

- Stat Prod Range enDocument23 pagesStat Prod Range enhjyujyagghjafhgjhgafNo ratings yet

- MSCRM Interview Questions and AnswersDocument11 pagesMSCRM Interview Questions and Answersadikesa100% (1)

- CV Aravind API InspectorDocument12 pagesCV Aravind API Inspectorநான் மகான் அல்லNo ratings yet

- Quality Management System SystemDocument4 pagesQuality Management System SystemMario YañezNo ratings yet

- TIC Information 12 Dec 2023Document43 pagesTIC Information 12 Dec 2023Sayan KeawponwongNo ratings yet

- Thamilvendhan Vetrinambi: QA/QC Inspector - (Welding)Document2 pagesThamilvendhan Vetrinambi: QA/QC Inspector - (Welding)Paul PhiliphsNo ratings yet

- KP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection WorksDocument1 pageKP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection WorksUtku Can KılıçNo ratings yet

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- General QuestionnaireDocument9 pagesGeneral Questionnairehemant1284No ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- Inspection and Test Procedure FR1672A - ApprvdDocument10 pagesInspection and Test Procedure FR1672A - ApprvdSavvas KatemliadisNo ratings yet

- 01-Pre-Commissioning Tests For SEC Transmission Electrical EquipmentsDocument38 pages01-Pre-Commissioning Tests For SEC Transmission Electrical EquipmentsThameemul BuhariNo ratings yet

- BV PSPC Pres 03122012Document31 pagesBV PSPC Pres 03122012Ahmed Algunaid احمد الجنيدNo ratings yet

- Jawad+Ahsan + ResumeDocument3 pagesJawad+Ahsan + ResumeAndiappan PillaiNo ratings yet

- Aramco-Candidate QuestionDocument5 pagesAramco-Candidate Questionnafis2u100% (1)

- Srihari Katari 11 Jan 2022Document50 pagesSrihari Katari 11 Jan 2022Abhishek DevarajNo ratings yet

- KEPIC 감사 보고서Document36 pagesKEPIC 감사 보고서J.H LeeNo ratings yet

- Quality Assurance and Quality ControlDocument4 pagesQuality Assurance and Quality ControlRuli DarmawanNo ratings yet

- SR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Document8 pagesSR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Sreenath KooliyattuNo ratings yet

- Jawed Ahsan: +92-318-2990934 Cell #Document4 pagesJawed Ahsan: +92-318-2990934 Cell #Nomi ANo ratings yet

- 22 66 KV LA R4 Jan 11 PDFDocument17 pages22 66 KV LA R4 Jan 11 PDFDin CuyNo ratings yet

- QM and Process Flow Chart BKT SideDocument3 pagesQM and Process Flow Chart BKT SideDebashis SarkarNo ratings yet

- 5657-Jawad Hanif CV TakreerDocument6 pages5657-Jawad Hanif CV TakreerkanchithalaiNo ratings yet

- QC Welding Inspector NotesDocument26 pagesQC Welding Inspector NotesSohail Aziz Ahmad MalikNo ratings yet

- VT-2 Codes and StandardsDocument29 pagesVT-2 Codes and StandardsMirza Safeer Ahmad100% (1)

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- QSP 23 - Quality Assurance (R0) 010105Document10 pagesQSP 23 - Quality Assurance (R0) 010105ukali_csNo ratings yet

- Audit ReportDocument9 pagesAudit ReportVIVEK100% (1)

- George Morris: Mechanical Engineer Having Rich Experience of Above 3years in Oil and Gas Construction ObjectiveDocument6 pagesGeorge Morris: Mechanical Engineer Having Rich Experience of Above 3years in Oil and Gas Construction Objectivedavidgeorge143No ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- Japan2010 Workshops SingaporeDocument32 pagesJapan2010 Workshops Singaporethanh huyền hồNo ratings yet

- Piping QC Inspector Resume 2020Document5 pagesPiping QC Inspector Resume 2020Omprakash Yadav100% (1)

- Laboratory Testing Inc.: 2331 Topaz DriveDocument4 pagesLaboratory Testing Inc.: 2331 Topaz Driveamirkhakzad498No ratings yet

- ACL-CPIS-01 (Control of Purchased Services)Document3 pagesACL-CPIS-01 (Control of Purchased Services)Mo ZeroNo ratings yet

- Application For The Post of Suitable Position For Mechanical QA/QC INSPECTORDocument4 pagesApplication For The Post of Suitable Position For Mechanical QA/QC INSPECTORAhmed Imtiaz RaoNo ratings yet

- Inspection DocumentsDocument6 pagesInspection DocumentsTulen CabuldinNo ratings yet

- PDF Quality AssuranceDocument14 pagesPDF Quality AssuranceNaveen ThakurNo ratings yet

- 9171-5.6.1 SAT ProcedureDocument1 page9171-5.6.1 SAT ProcedureArdeleanu-Simion StefanNo ratings yet

- Concrete Mech AnchorsDocument30 pagesConcrete Mech AnchorscustomerxNo ratings yet

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- Measurement of LengthDocument2 pagesMeasurement of LengthCedric MercadoNo ratings yet

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- Quality Control Checklist: Structural Steel Painting - Localized ChecklistDocument4 pagesQuality Control Checklist: Structural Steel Painting - Localized ChecklistDilhara WickramaarachchiNo ratings yet

- PMI Procedure Rev.00Document13 pagesPMI Procedure Rev.00Abdul Khaliq50% (6)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Iso Work InstructionsDocument115 pagesIso Work InstructionsEkondroNo ratings yet

- General Technical Specifications For CS & SS Pipes and Pipe FittingsDocument10 pagesGeneral Technical Specifications For CS & SS Pipes and Pipe FittingsrajaNo ratings yet

- SFT-ECAS - OP - 24c Factory Inspection Report (RoHS) Final Draft 21st Jan, 18Document15 pagesSFT-ECAS - OP - 24c Factory Inspection Report (RoHS) Final Draft 21st Jan, 18Duong N. KhoaNo ratings yet

- B31.3 Process Piping Course - 13 Inspection, Examination and TestingDocument19 pagesB31.3 Process Piping Course - 13 Inspection, Examination and TestingLuong AnhNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

- Magnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryFrom EverandMagnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- CSC 99Document16 pagesCSC 99goyalmanojNo ratings yet

- NORMS AND TECHNICAL SPECIFICATIONS OF TESTING INSTRUMENTS - Rev 2021Document86 pagesNORMS AND TECHNICAL SPECIFICATIONS OF TESTING INSTRUMENTS - Rev 2021goyalmanoj100% (1)

- JD - AC Design - ReNew PowerDocument2 pagesJD - AC Design - ReNew PowergoyalmanojNo ratings yet

- TechnicalSpecification For HG Fuse & LADocument12 pagesTechnicalSpecification For HG Fuse & LAgoyalmanojNo ratings yet

- Low Voltage Ride-Through (LVRT) Testing of Distributed Generation SourcesDocument2 pagesLow Voltage Ride-Through (LVRT) Testing of Distributed Generation SourcesgoyalmanojNo ratings yet

- RFP-TD-4022-Consultancy Services For GIS StationDocument120 pagesRFP-TD-4022-Consultancy Services For GIS StationgoyalmanojNo ratings yet

- D8 N R T General Duty1Document9 pagesD8 N R T General Duty1robert0126No ratings yet

- A5000 User Manual PDFDocument72 pagesA5000 User Manual PDFTandin IgorNo ratings yet

- FiverrDocument13 pagesFiverrdevilsharmaNo ratings yet

- Armalite AR 10 Rifle ManualDocument53 pagesArmalite AR 10 Rifle Manualparatrpr2003No ratings yet

- BP344Document53 pagesBP344DaneKerenCometaNo ratings yet

- Group 4 Presentation OM ERP and MRP IIDocument22 pagesGroup 4 Presentation OM ERP and MRP IICindi NabilaNo ratings yet

- Lead Free Series S-FBV-1 2-Piece, Full Port, Stainless Steel Ball Valves Specification SheetDocument2 pagesLead Free Series S-FBV-1 2-Piece, Full Port, Stainless Steel Ball Valves Specification SheetWattsNo ratings yet

- Mill PostsDocument158 pagesMill PostsPham LongNo ratings yet

- Introduction To Chemical Process Design EngineeringDocument4 pagesIntroduction To Chemical Process Design Engineeringankur2061100% (1)

- AhlDocument25 pagesAhlHassaan DarNo ratings yet

- Atestat Harley Davidson A Way of LifeDocument33 pagesAtestat Harley Davidson A Way of Lifesweet_oannyNo ratings yet

- Fluid and Filter: Change RecommendationsDocument8 pagesFluid and Filter: Change RecommendationsJIMJEO100% (2)

- Implementation of Total Productive Maintenance (TPM) With Measurement of Overall Equipment Effectiveness (OEE) and Six Big Losses in Vapour Phase Drying Oven Machines in PT. XYZDocument7 pagesImplementation of Total Productive Maintenance (TPM) With Measurement of Overall Equipment Effectiveness (OEE) and Six Big Losses in Vapour Phase Drying Oven Machines in PT. XYZInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Data PreparationDocument28 pagesData PreparationnaveengargnsNo ratings yet

- Travelling Salesman ProblemDocument27 pagesTravelling Salesman ProblemrafsantetoNo ratings yet

- Master Catalog Final PDFDocument89 pagesMaster Catalog Final PDFak100% (1)

- Samsung Investor Presentation Foundry 2019 v1Document19 pagesSamsung Investor Presentation Foundry 2019 v1xellosdexNo ratings yet

- Using Value Stream Mapping ToDocument12 pagesUsing Value Stream Mapping ToAlexanderHFFNo ratings yet

- FD100 分Document17 pagesFD100 分Hadi FaisalNo ratings yet

- Internal Audit Check Sheet Ok 2016Document11 pagesInternal Audit Check Sheet Ok 2016manttupandeyNo ratings yet

- Fort St. John RCMP Building Construction - Tender Awards, January 2021Document14 pagesFort St. John RCMP Building Construction - Tender Awards, January 2021AlaskaHighwayNewsNo ratings yet

- Cellular BeamsDocument83 pagesCellular BeamsStephen Hicks100% (3)

- Om 0017Document198 pagesOm 0017praveen4_40% (1)

- 2018 04 ATR Converted FreightersDocument2 pages2018 04 ATR Converted FreightersLuis ParraNo ratings yet

- Frnc5user PDFDocument2 pagesFrnc5user PDFValiNo ratings yet

- Case Study For NRDocument10 pagesCase Study For NRsaanidhya1115No ratings yet