Professional Documents

Culture Documents

Manual 2

Manual 2

Uploaded by

Rafat ThongCopyright:

Available Formats

You might also like

- Quarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)Document18 pagesQuarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)AC Balio100% (5)

- 5008S Fresenuis Service ManualDocument318 pages5008S Fresenuis Service ManualEslam Karam100% (10)

- Protection CDG 13Document2 pagesProtection CDG 13david wyethNo ratings yet

- New Scientist International Edition - August 07 2021Document62 pagesNew Scientist International Edition - August 07 2021Thảo HoàngNo ratings yet

- Project Name: Dcu Test Report For Motor Protection RelayDocument4 pagesProject Name: Dcu Test Report For Motor Protection RelayArul Kumar100% (1)

- TL Epr-Measurement For PDFDocument6 pagesTL Epr-Measurement For PDFKatukuri RaviNo ratings yet

- MRTPDocument20 pagesMRTPStephen Crawford100% (1)

- Capacitor Bank Controller Installation 7Document8 pagesCapacitor Bank Controller Installation 7Rafat ThongNo ratings yet

- Mit 161Document24 pagesMit 161Santosh Gairhe100% (1)

- NGRDocument2 pagesNGRAchint RajputNo ratings yet

- Loss of Field or Excitation Protection of Alternator or GeneratorDocument4 pagesLoss of Field or Excitation Protection of Alternator or Generatorsiddhant103No ratings yet

- MiCOM P122CDocument8 pagesMiCOM P122Cকুররাতুল আইনNo ratings yet

- 33 HT Panel ReportDocument30 pages33 HT Panel ReportVishakha PandeyNo ratings yet

- Test Results For Songea 5mva TransformerDocument6 pagesTest Results For Songea 5mva TransformerNuru TwahaNo ratings yet

- L&T Mm30743 Motpro RelayDocument31 pagesL&T Mm30743 Motpro Relayanvesh_jadavNo ratings yet

- Automatic Slip RegulatorDocument4 pagesAutomatic Slip RegulatorRajesh ThulluriNo ratings yet

- REJ 601-Panel N0-4Document3 pagesREJ 601-Panel N0-4Siva NandhamNo ratings yet

- Volt::Ch: Voltech Engineers Pvt. LTDDocument32 pagesVolt::Ch: Voltech Engineers Pvt. LTDstalin63100% (1)

- Ground Fault Tripping of Large MotorsDocument5 pagesGround Fault Tripping of Large Motorsclide_050793No ratings yet

- SA2003-000019 A en Trip Circuit Supervision With RXMB 1 Auxiliary RelayDocument1 pageSA2003-000019 A en Trip Circuit Supervision With RXMB 1 Auxiliary RelayErmin FazlicNo ratings yet

- Prok ManualDocument8 pagesProk ManualaymaanfkNo ratings yet

- Micom p211 Io 01 enDocument8 pagesMicom p211 Io 01 enKopi143No ratings yet

- Difference Between 2 Wire RTD, 3 Wire RTD, and 4 Wire RTD'sDocument5 pagesDifference Between 2 Wire RTD, 3 Wire RTD, and 4 Wire RTD'sbilalNo ratings yet

- Maintenance Procedure: Preventive Mantenance of HT MotorDocument5 pagesMaintenance Procedure: Preventive Mantenance of HT Motorsanjay sharmaNo ratings yet

- NGR PanelDocument17 pagesNGR PanelnikerNo ratings yet

- CTMM RelayDocument3 pagesCTMM RelayshiyasNo ratings yet

- Trip Circuit Supervisory Relay: Type: ATSR31ADocument3 pagesTrip Circuit Supervisory Relay: Type: ATSR31ADarius Balakauskas100% (1)

- Testing Maintenance Troubleshooting ACBDocument16 pagesTesting Maintenance Troubleshooting ACB322399mk7086100% (1)

- Relay: Type: 1. 2. 3Document5 pagesRelay: Type: 1. 2. 3SLDC DDNo ratings yet

- Mpr300 CatalogueDocument4 pagesMpr300 CatalogueSanthosh Reddy BNo ratings yet

- Relay Coordination Chapter3Document13 pagesRelay Coordination Chapter3Chân Gà NướngNo ratings yet

- Pre-Commissioning Test Report For Numerical Relay: ProjectDocument3 pagesPre-Commissioning Test Report For Numerical Relay: ProjectHari haranNo ratings yet

- Protection MannualDocument121 pagesProtection Mannualgeetha_yagantiNo ratings yet

- JVS Manual JRP 011Document12 pagesJVS Manual JRP 011Tamilventhan_sNo ratings yet

- VDT - 877 - Annexure-IADocument176 pagesVDT - 877 - Annexure-IAprati121100% (1)

- VCB - TestDocument1 pageVCB - TestThức VõNo ratings yet

- Megawin Switchgear: Numerical Over Current ProtectionDocument4 pagesMegawin Switchgear: Numerical Over Current ProtectionRock hackNo ratings yet

- Alternator Protection PDFDocument33 pagesAlternator Protection PDFfhfghNo ratings yet

- Restricted Earth Fault ProtectionDocument15 pagesRestricted Earth Fault ProtectionKuntal SatpathiNo ratings yet

- Vaj CortecDocument6 pagesVaj CortecvenkateshbitraNo ratings yet

- Setting Sheet For Rex 521Document6 pagesSetting Sheet For Rex 521mad_sam282729No ratings yet

- Effect of High and Low VoltageDocument2 pagesEffect of High and Low VoltageBhupinder SinghNo ratings yet

- Installation and Commissioning Procedure FOR Exide Plante Type Standby Batteries Complete With First Charge Instructions and Maintenance PracticeDocument24 pagesInstallation and Commissioning Procedure FOR Exide Plante Type Standby Batteries Complete With First Charge Instructions and Maintenance PracticeSaran KumarNo ratings yet

- Maximum Demand ControllerDocument4 pagesMaximum Demand ControllerDIWAKAR NNo ratings yet

- Operation, Erection & Maintenance For Power TrafoDocument50 pagesOperation, Erection & Maintenance For Power TrafoJagdeep KumarNo ratings yet

- MPR300Document4 pagesMPR300KUNALJAY100% (1)

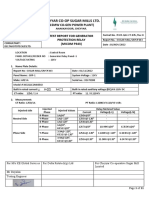

- Cheyyar Co-Op Sugar Mills LTD.: (15Mw Co-Gen Power Plant)Document11 pagesCheyyar Co-Op Sugar Mills LTD.: (15Mw Co-Gen Power Plant)Vijay PitchaiahNo ratings yet

- MM30 743Document4 pagesMM30 743sigmasurat100% (1)

- Relay TerminalsDocument3 pagesRelay Terminalssundars_sriNo ratings yet

- Lecture Notes - 19Document32 pagesLecture Notes - 19Bhaskar1411No ratings yet

- HWX SparesDocument6 pagesHWX SparesMohan SaravanaNo ratings yet

- Panel and APFC SpecDocument34 pagesPanel and APFC SpecreddyloginNo ratings yet

- Transformer ProtectionDocument22 pagesTransformer ProtectionRuben MaychelNo ratings yet

- Why LT Motors Are Delta Connected and HT Motors Are Star Connected - 4Document2 pagesWhy LT Motors Are Delta Connected and HT Motors Are Star Connected - 4Shah JayNo ratings yet

- 25ref RelayDocument8 pages25ref Relaysikander843562No ratings yet

- Schneider Protection RelayDocument8 pagesSchneider Protection Relayeugene oneillNo ratings yet

- Distance Protection Relay of LineDocument11 pagesDistance Protection Relay of LineYahya DarNo ratings yet

- ABB Test Report For Bcu Relay: P A N e LD e T A Il SDocument3 pagesABB Test Report For Bcu Relay: P A N e LD e T A Il SJayamkondanNo ratings yet

- SPR, RCS-9627CN, NoDocument5 pagesSPR, RCS-9627CN, NoAmaresh NayakNo ratings yet

- Genesis Mit 114 RelaysDocument32 pagesGenesis Mit 114 RelaysVijay Suryavanshi100% (3)

- Easun MIT114Document32 pagesEasun MIT114chandraprakashhh0% (1)

- MJT 315 - or Rev 1-1 PDFDocument32 pagesMJT 315 - or Rev 1-1 PDFashish_muley100% (1)

- Easun Reyrolle Limited: Application and Commissioning Manual Mit161 RelayDocument24 pagesEasun Reyrolle Limited: Application and Commissioning Manual Mit161 RelaySumonto MajiNo ratings yet

- Notes On Tripping RelaysDocument7 pagesNotes On Tripping RelaysSenthil KumarNo ratings yet

- Polyphase SystemsDocument11 pagesPolyphase SystemsRafat ThongNo ratings yet

- C57 109-1985Document10 pagesC57 109-1985mjimenezg100% (1)

- S 2807914Document4 pagesS 2807914Rafat ThongNo ratings yet

- Advc2 3002rev1 0Document6 pagesAdvc2 3002rev1 0Rafat ThongNo ratings yet

- ABB Hard To Find Information On Distribution Systems Part IIDocument27 pagesABB Hard To Find Information On Distribution Systems Part IIRafat ThongNo ratings yet

- TechRef Overhead Line Models PDFDocument29 pagesTechRef Overhead Line Models PDFRafat ThongNo ratings yet

- TechRef Load PDFDocument26 pagesTechRef Load PDFRafat ThongNo ratings yet

- TechRef Imeas PDFDocument9 pagesTechRef Imeas PDFRafat ThongNo ratings yet

- TechRef CableConstants PDFDocument21 pagesTechRef CableConstants PDFRafat ThongNo ratings yet

- Conversion TablesDocument2 pagesConversion TablesKumarNo ratings yet

- Certification No. 1118: DLMS User AssociationDocument1 pageCertification No. 1118: DLMS User AssociationRafat ThongNo ratings yet

- Trinetics Switches Ultravac Ii200Document4 pagesTrinetics Switches Ultravac Ii200Rafat ThongNo ratings yet

- DLL Mother TongueDocument41 pagesDLL Mother TongueMarxPascualBlancoNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet

- Ozone Therapy Is Safest Known TherapyDocument35 pagesOzone Therapy Is Safest Known Therapyherdin2008100% (1)

- 12 Abm Bangelyns Group1Document64 pages12 Abm Bangelyns Group1G-VALDEZ, SHELAHNo ratings yet

- FracShield Composite Frac PlugDocument3 pagesFracShield Composite Frac PlugJOGENDRA SINGHNo ratings yet

- OpenFOAM编程指南Document100 pagesOpenFOAM编程指南Feishi XuNo ratings yet

- UNHCR Hygiene Promotion GuidelinesDocument112 pagesUNHCR Hygiene Promotion GuidelinesBrandie ShackelfordNo ratings yet

- Qsi540-600Document74 pagesQsi540-600Lorenzo RossiNo ratings yet

- MT2OL-Ia6 2 1Document136 pagesMT2OL-Ia6 2 1QUILIOPE, JUSTINE JAY S.No ratings yet

- About BITS CmdletsDocument3 pagesAbout BITS CmdletsvashsauNo ratings yet

- How To Improve Battery Life of Your Galaxy Note 10 and Note 10Document18 pagesHow To Improve Battery Life of Your Galaxy Note 10 and Note 10rainpcruzNo ratings yet

- EC Physical Sciences Grade 11 November 2022 P1 and MemoDocument25 pagesEC Physical Sciences Grade 11 November 2022 P1 and MemokhulntandoNo ratings yet

- Statement of PurposeDocument3 pagesStatement of PurposeehsanNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- Alere G1 Glucose Meter ManualDocument55 pagesAlere G1 Glucose Meter ManualSundar Rajan33% (6)

- Manual C28 Plus enDocument28 pagesManual C28 Plus enSveto SlNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- REVISING EXERCISES 1baDocument3 pagesREVISING EXERCISES 1baAlvaro LorcaNo ratings yet

- WRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkDocument2 pagesWRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkFatmah El WardagyNo ratings yet

- Mic 2 Mkii Installation Instructions and Reference Handbook 4189320057 UkDocument70 pagesMic 2 Mkii Installation Instructions and Reference Handbook 4189320057 Ukkamel kamelNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Worksheet Research-Title FINALDocument3 pagesWorksheet Research-Title FINALJierroe EvangelistaNo ratings yet

- Free CV Template 31Document1 pageFree CV Template 31Aaron WilsonNo ratings yet

- The Design of An Annular Combustion Chamber: October 2017Document11 pagesThe Design of An Annular Combustion Chamber: October 2017ko koNo ratings yet

- MTCNA Lab Guide INTRA 1st Edition - Id.en PDFDocument87 pagesMTCNA Lab Guide INTRA 1st Edition - Id.en PDFreyandyNo ratings yet

- Support/downloads or Scan Above QR Code For Detailed Policy WordingDocument10 pagesSupport/downloads or Scan Above QR Code For Detailed Policy Wordingraj VenkateshNo ratings yet

- Suntrust VeronaDocument12 pagesSuntrust Veronalyanca majanNo ratings yet

Manual 2

Manual 2

Uploaded by

Rafat ThongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual 2

Manual 2

Uploaded by

Rafat ThongCopyright:

Available Formats

1

FEBRUARY 2002

APPLICATION AND COMMISSIONING MANUAL

MIT121 / 131 RELAY

EASUN REYROLLE LIMITED

2

ISSUE NO : 1

st

Issue

Date of Issue : 14 - 02 - 2002

Department : SPBD - TMS

3

CONTENTS

PAGE

APPLICATION 4 - 6

INSTALLATION 7 - 14

COMMISSIONING 15- 22

DRAWINGS 23 -24

4

APPLICATION

1. INTRODUCTION

The MIT121 / MIT131 is micro-controller based numerical TRUE RMS single pole

directional over current protection with voltage polarization and the relay will

operate depending on the direction of fault current and relay setting.

Moreover, supervisory components and self-monitoring features give high

confidence of serviceability.

M I T 121 Single pole directional over current protection Relay

M I T 131 Single pole directional over current protection Relay with DC

transient free High set.

1.1 MULTIPLE CHARACTERISTICS

MIT121 / MIT131 relay is suitable for various inverse characteristics and

also for definite time lag characteristic, any one of them can be selectable at site.

Standard Inverse characteristic - SI 3 theoretical operating time is 3

seconds at 10 times current setting at time multiplier setting (TMS) 1.000.

Standard Inverse characteristics - SI 1 theoretical operating time is 1.3

seconds at 10 times current setting at TMS 1.000.

Very Inverse characteristic - VI curve is suited to networks where there is a

significant reduction in fault current as the distance from the source increases. The

operating time is shorter for large fault currents and increases at a greater rate as

the fault current decreases. This permits the use of the same time multiplier

setting for several relays in series.

Extremely Inverse characteristic - EI is very much useful to grade the relay

with the fuse and applications where short duration transients over currents occur.

e.g. motor starting or reacceleration.

Long time Inverse characteristic - LTI is generally used for Standby Fault

protection for Neutral / Ground Earthing Resistor. The same characteristics can be

used to guard against overheating / over loading protection, when it matches with

thermal characteristics of the motor, generator, transformer or capacitor banks.

Definite Time Lag characteristic - DTL is used for grading the system where

source impedance determines fault current level and the fault current does not

vary to a considerable amount down the length of the line.

5

1.2 DIRECTIONAL ELEMENT

The directional element detects the direction of the fault. If the fault

direction is with in the directional element boundary the IDMTL element starts

timing.

1.3 DC TRANSIENT FREE HIGHSET

On transmission lines or transformer feeders where the source impedance is

small compared with the protection circuit, to reduce the tripping time at high fault

level the highset instantaneous over current element is used in addition to the

inverse time over current element. The MIT 131 relay is provided with highset over

current elements. Depending upon the point on wave switching of the fault and

the X/R ratio of the system, the initial current may have DC offset. The highset

over current unit being instantaneous one, it should not over reach due to initial

DC offset current though it may exceed the highset pick-up value. The MIT 131

relay is provided with the DC transient free highset instantaneous elements, which

will not over reach for DC transient condition.

1.4 RESET TIME DELAY

The increasing use of plastic cables, both, conventionally buried types and

aerial bundled conductor types have given rise to the number of "pecking" or

"flashing" intermittent faults on distribution systems. At the fault position, the

plastic melts and temporarily reseals the faulty cable for a short time, after which

the insulation falls again. The same phenomenon has occurred in joint boxes

where an internal flashover temporarily reseals.

The behavior of different types of over current relays under flashing fault

condition is compared in Fig.1. The repeating process often caused

electromechanical disc relays to "ratchet up and eventually trip the faulty circuit

provided that the reset time of the relay was longer than the time between

successive flashes. Early electronic IDMTL relays with instantaneous reset features

were not at all effective in dealing with this condition and only tripped after the

flashing fault had developed into a solid permanent fault.

To overcome this the MIT relay has a reset time setting which can be user

programmed to be either instantaneous or delayed from 1 to 60 seconds.

On the other hand, on overhead line networks, particularly where reclosers

are incorporated in the protected system, instantaneous resetting is desirable to

ensure that, on multiple shot reclosing schemes, correct grading between the

source relays and the relays associated with the reclosers is maintained.

6

FAULT

CURRENT

ELECTROMECHANICAL

SLOW RESET

STATIC

INSTANTANEOUS RESET

NUMERICAL (MIT)

DELAYED RESET

TRIP

TRIP

TRIP

Fault becomes

permanent

Flashing Faults

Figure 1 Flashing Fault Protection

1.5 LIGHTLY LOADED SYSTEMS

The lower range of the current setting is available in the MIT relay setting

makes the relay suitable for lightly loaded system. The setting can be changed to

higher value when the system load is upgraded.

1.6 PARALLEL OR RING FEEDER PROTECTION

The directional element can be set for Forward or Reverse direction with

wide range of required MTA suitable for protection of Parallel or Ring Feeder

Protection.

1.7 RELAY CHARACTERISTIC

a. Phase fault 90 connection 45 lead

The recommended connection for phase fault is 90 i.e. R phase relay is

polarised with YB voltage. 45-lead characteristic gives MTA when current leads

the voltage by 45. Refer Fig. 4 for connection diagram.

Other connection and characteristic angles are also possible by selecting

appropriate input and MTA angle.

b. Earth fault Characteristic

The relay should be polarised with open delta voltage for directional

determination and the relay MTA angle can be selected based on type of

grounding. Normally 15 lag MTA & 45 lag MTA settings are recommended for

resistive grounding and solid grounding respectively.

7

INSTALLATION

1.1 UNPACKING

On receipt, remove the relay from the carton box in which it was received

and inspect it for obvious damage. It is recommended that the relay is not

removed from the relay case. To prevent the possible ingress of dirt, the sealed

polythene bag should not be opened until the relay is to be used.

If damage has been sustained, please inform Easun Reyrolle Ltd., for

necessary action.

1.2 STORAGE

When the relay is not required for immediate use, it should be returned to

its original carton and stored in a clean dry place.

1.3 HANDLING

The relays electronic circuits are protected from damage by static discharge

when the relay is housed in its case. When relay is withdrawn from the case, static

handling procedures should be observed:

Before removing the relay from its case the operator must first ensure that

he is at the same potential as the relay, by touching the case.

The relay must not be handled by any of the relay terminals at the rear of

the chassis.

Ensure that anyone else handling the relay is at the same potential.

As there are no user serviceable parts and adjustable user settings inside the

relay, there should be no requirement to remove any modules from the chassis.

If any modules are removed or tampered with, then the guarantee will be

invalidated.

1.4 MOUNTING

Mount the relay using 2 nos. mounting straps and 1no earth strap. Ensure

that an earth wire is connected to the earth strap from the earth terminal 23.

Terminal 23 should be directly connected to the system ground.

Only settings or trip details can be accessed via the pushbuttons when the

cover is fitted. To change the settings the front cover has to be removed. Sealing

arrangement is provided in one of the four knurling screws fitted on the cover.

Sealing can be done using a sealing wire. Thus mechanical interlock is provided to

avoid unauthorized setting change.

8

2. EQUIPMENT

2.1 CURRENT TAP SELECTION

MIT relays are suitable for 1A or 5A application. However the relays are

internally wired for either 1A or 5A as per the customer requirement. Internal

wiring are to be changed (Faston crimp connections) for changing the relay rating

from one to other.

To ensure the current rating of the relay, check the connection of CT wires

connected to the bottom TB (Terminal Block) at the rear of the chassis as per the

following table:

For 1A

Phase Terminal No.

of TB

Ferrule No. of

CT wire(Black)

Phase 9 9A

For 5A

Phase Terminal No.

of TB

Ferrule No. of

CT wire(Black)

Phase 9 9B

Following are the steps to change the current rating of the relay from 1A to 5A.

1) Identify 9

th

terminal from number strip on bottom terminal block at the rear

of the chassis.

2) The black colour wire 9A is inserted to 9

th

terminal of TB.

3) First, carefully lift the PVC boot of the wire by means of a tool (like nose

pliers) to expose terminal 9A.

4) Hold the crimp by means of the same tool at the crimp point and lift to

remove from the fixed terminal. Remove the 9B wire from the terminal

parking rack (fixed on terminal block) and insert the crimp of 9B wire on to

the terminal No.9 by means of the tool. Insert "9A" wire back to the terminal

parking rack.

5) Ensure proper insertion of 9B wire by pulling the wire by hand and the

wire should not come off the terminal.

6) Push the boot of 9B wire, to completely cover the crimp.

9

Same procedure in reverse is to be followed to change from 5A to 1A using

appropriate wire numbers

2.2 VOLTAGE INPUT

MIT directional relays are suitable for AC 110 V application. V phase

Terminal No. 11 & V neutral Terminal No. 12.

2.3 HUMAN MACHINE INTERFACE (HMI)

The user friendly HMI provided on the front panel has following features:

1. Six digit, 7 segment LED display (First two digits are Red colour and other four

digits are Green colour). First two digits (Red) displays the main menu when

selected for setting mode. Remaining four digits (Green) displays Sub menu or

"Trip" indication respectively.

2. Green LED - Protection healthy indication

3. Yellow LED (STARTER) - Starter indication

4. Yellow LED (DIRECTION) - Direction is favorable for tripping indication

5. Red LED (TRIP) - Trip indication,

6. Red LED (in Key) - Sub Menu

7. Key - Up scrolling

8. Key - Down scrolling

9. Key - Sub menu

10. Key - Enter / Reset / Cancel / To check Version

3.0 SETTING INSTRUCTIONS

3.1 HOW TO OPERATE HMI

Remove the front cover by unscrewing the four knurling screws.

Apply DC supply. Terminals 22, 24 and 23 are for positive, negative and earth

respectively as per relay rating. When the relay powers up it takes few seconds

to complete the self-check routing.

10

Ensure Protection Healthy LED (Green) is ON and indication appears on

the LED display unit. Wait until the indication goes off.

Press or key is displayed

Represents MIT 121 relay

Represents MIT 131 relay

Press key repeatedly scrolls down the Factory setting Main menu in the

following order on the display.

- Characteristics setting is Standard Inverse 3.0 Sec

- Current setting is 100%

- Time multiplier setting is 1.000

- Directional is OFF

- Reset time delay is 0 Sec

- Highset is OFF

3.2 SELECT CHARACTERISTICS

Pressing key repeatedly get Main menu, press Submenu

Key, 3mm LED in the Key Lit to indicate that the Sub menu is activated.

Pressing key repeatedly the Sub menu will scroll down in the following

order on the display.

- Standard Inverse 3.0 Sec characteristics

- Standard Inverse 1.3 Sec characteristics

- Very Inverse characteristics

- Extremely Inverse characteristics

- Long Time Inverse characteristics

- Definite Time Lag characteristics

11

By pressing or key choose the desired characteristic and press key.

Now the Submenu LED goes OFF and the Main menu appears on the LED

display.

3.3 CURRENT SETTING

Setting range: 5% to 250% insteps of 5%

Pressing key repeatedly get Main menu (represents the

current setting has been set to 100%), press key (Submenu LED On) to

get the Sub menu. Pressing or key changes the current setting in 5%

increment or decrement. Upon selecting the desired setting, once again

press the key (Sub menu LED goes OFF) to return to the main menu.

3.4 TIME SETTING / TIME MULTIPLIER SETTING

If characteristic is selected as Definite Time Lag, the Time setting range is

00.00 Sec to 20.00 Sec in steps of 0.01Sec.

If characteristic is selected as Inverse, the Time Multiplier setting range is

0.025 to 1.000 in steps of 0.025

For Inverse Characteristics

Pressing key repeatedly get Main menu (represents Time

Multiplier setting has been set to 1.000), press key (Submenu LED On) to

get the Sub menu. Pressing or key changes the time setting by 0.025

increment or decrement. Upon selecting the desired setting, once again

pressing key (Sub menu LED goes OFF) to return to the main menu.

For Definite Time Lag Characteristics

Pressing key repeatedly get main menu (represents Time

setting has been set to 3.00 Secs), press key (Submenu LED On) to get

the Sub menu. Pressing or key changes the time setting by

0.01Seconds increment or decrement. Upon selecting the desired setting,

once again press the key (Sub menu LED goes OFF) to return to the

main menu.

3.5 DIRECTIONAL SETTING

Directional setting: Forward, Reverse, OFF

Pressing key repeatedly get main menu (represents directional

has been set to off), press key (Submenu LED On) to get the Sub menu.

Pressing the key repeatedly the Sub menu will scroll down in the following

order on the display.

12

- Direction setting is OFF

- Direction setting is Forward

- Direction setting is Reverse

Upon selecting the desired directional setting, once again press the key

(Sub menu LED goes OFF) to return to the main menu.

3.5.1 CHARACTERISTICS ANGLE SETTING

Characteristics Angle setting range: 1 to 90 lead insteps of 1

0

1 to 90 lag insteps of 1

The Characteristics angle menu will not appear in the display when the

Directional setting is chosen to "OFF"

Pressing or repeatedly get main menu (represents

Characteristics angle has been set to 45 lead). Press key (Submenu LED

On) to get the sub menu. Pressing or key continuously, changes the

Characteristics angle setting by 1 increments or decrements.

When the angle setting reach to (represents Characteristics

angle has been set to 90 lead) and still pressing the key the menu will be

changed to (represents Characteristics angle has been set to 90

lag) and further continuous key pressing the Lag angle will be

decremented by 1, when reaching (represents Characteristics

angle has been set to 1 lag) and pressing key the setting changes to

(represents Characteristics angle has been set to 0)

Upon selecting the desired characteristics angle setting, once again press

the key (Sub menu LED goes OFF) to return to the main menu.

3.6 RESET TIME

Setting range: 0 Sec to 60 Sec in steps of 1 Sec.

Pressing key repeatedly get Main menu (represents reset time

has been chosen as 0 sec). Press key (Submenu LED On) to get

Submenu. Pressing or key, changes reset time delay by 1 second for

each pressing. After selecting the desired setting, once again press the

key (Sub menu LED goes OFF) to get back the main menu. The

recommended setting is 0sec.

13

3.7 HIGHSET (FOR MIT 131 VERSION ONLY)

Setting range: 50% to 2500% in steps of 50% .

From Main menu, Press key (Submenu LED On) to get

Submenu. Pressing or key, changes highset value by 50% increments.

After selecting the desired setting, once again press the key (Sub menu

LED goes OFF) to return to the main menu.

When we select High set mode, automatically Directional High set mode will

enable. In this mode we can select Directional High set is ON or OFF.

3.8 ACCEPTANCE OF SETTINGS (ENTER)

For the relay to accept the above setting changes press X key once, now

the display goes off and the settings are updated. By pressing any key

again

Indication will appear

Ensure all the chosen settings are as per requirements. In case of any

changes required use Sub menu key and then do the changes and finally

press enter X key once.

ENSURE TO PRESS 'X' KEY TO ACCEPT THE CHANGES

3.8 TO CHECK THE RELAY VERSION

Press X key four times, example of relay version display is as follows:

- Represent M I T 121 relay version 1

- Represent M I T 131 relay version 1

To get back the main menu, press or key.

4. TO CANCEL SETTING WHILE CHANGING (CANCEL)

While the particular setting is being changed (using or key) with

Submenu LED ON, by pressing key, the original setting is restored

14

5. TRIP INDICATION AND RESETTING OF TRIP INDICATION (RESET)

When the relay operates, RED " TRIP" LED indicates tripping. To find which

element operated press or key. There is possibility for the following

display after the trip,

Indicates Over current trip.

Indicates Highset trip.

Once the fault is cleared, press key twice to reset the trip

indication.

The trip indication and settings will be retained in Non - volatile memory

during auxiliary DC power supply failure.

6. CT RATING

Pull out the relay from relay box and ensure the required current

transformer tapping (1Amp/5Amp) is inserted into live terminal 9. 1Amp

tapping is ferruled with 9A and 5Amp tapping is ferruled with 9B. Terminal

No.10 is common for both 1Amp and 5Amp.

15

COMMISSIONING

1. REQUIRED TEST EQUIPMENT'S

500V insulation test sets.

Variable secondary injection current source rated 10A or greater.

Variable voltage source.

Phase shifting transformer and phase angle meter.

Time interval meter.

Primary injection equipment.

A DC supply with a nominal voltage within the working range of the relays

DC auxiliary supply ratings.

2. INSPECTION

Ensure that all connections are tight and in accordance with the relay wiring

diagram and the scheme diagram. Check if the relay is correctly

programmed and the relay is fully inserted into the case.

3. APPLYING SETTINGS

The relay settings for the particular application should be applied before any

secondary testing is started.

4. PRECAUTIONS

Before testing commences, the equipment should be isolated from the

current transformers and the CT's to be short-circuited, in line with the local

site procedures. The tripping and alarm circuits should also be isolated,

where practical. Also, ensure that trip links are removed.

Ensure that correct DC auxiliary voltage and polarity is applied. See the

relevant scheme diagrams for the relay connections.

5. TESTS

5.1 INSULATION

Connect together all relay C.T. terminals and measure the insulation

resistance between these terminals and all of the other relay terminals

connected together and to earth.

Connect together all relay V.T. terminals and measure the insulation

resistance between these terminals and all of the other relay terminals

connected together and to earth.

16

Connect together the terminals of the DC auxiliary supply (only +ve and

-ve) and measure the insulation resistance between these terminals and all

of other terminals connected together and to earth.

Connect together all the output relay terminals and measure the insulation

resistance between these terminals and all of other terminals connected

together and to earth.

Satisfactory values for the various readings depend upon the amount of

wiring concerned. Where considerable multi-core wiring is involved a

reading of 2.5 to 3.0 megohms can be considered satisfactory. For short

lengths of wiring higher values can be expected. A value of 1.0 megohm

should not be considered satisfactory and should be investigated.

5.2 SECONDARY INJECTION

Select the required relay configuration and settings for the application. Note

that the MIT relay can be connected either as 1A or 5A rated device. The

user should check this before commencing secondary testing. Please refer

Sec. 2.1. in Installation

a. Pick up and Reset

The test checks the accuracy of the current settings for the relays main

over current characteristics. Apply single-phase current into the current

inputs. Slowly increase the current until the starter LED (yellow) operates

and record the pick up current in Table 1. Reduce the current until the LED

goes off and record this as the reset level.

Check that all the pick up current levels are measured within 104% 4% or

10m A of the applied setting. Check that the reset levels are 94% of

pick-up.

POLE PICK-UP

SETTING

MEASURED

PICK-UP

PICK-UP

ERROR

MEASURED

RESET

RESET

ERROR

PHASE

TABLE 1

b. IDMTL / DTL Characteristics

This test checks the accuracy of the main time delay characteristics (IDMTL

/ DTL). Select the relay current setting, characteristics and time multiplier

setting as required and then inject a level of current which is a multiple of

the relay setting.

17

A time interval meter should be connected to the correct output contact

terminals. The timer should be started by the source and stopped by the

relay trip contacts. A secondary injection timing test circuit is illustrated in

Fig. 2. The secondary injection test equipment should be made 'OFF', once

the relay contact is closed

Table 2 shows theoretical value of each characteristic with time multiplier

set to 1.000. Record the actual results in Table 3 and check that the

measured times lie within 5% of the theoretical value.

CURVE 2xIs 5 x Is 10 x Is 20 x Is

SI 3 10.03 4.28 2.97 2.27

SI 1 4.39 1.87 1.3 1.0

EI 26.67 3.33 0.81 0.20

VI 13.50 3.38 1.50 0.71

LTI 120.00 30.0 13.33 6.32

DTL * * * *

TABLE 2

* USER SETTING

2xIs 5xIs 10xIs 20xIs Pole Characteristic

(SI3,SI1,EI,VI

LTI,DTL)

Delay Error

(5%)

Delay Error

(5%)

Delay Error

(5%)

Delay Error

(5%)

Phase

TABLE 3

c. Highset

Program the current settings for the highset characteristics to the required

level. Inject a level of current below the setting of the relay, then increase

the current until the output operates. Record the pick up level in Table 4.

and confirm that it occurs within 100% 4% or 10 mA of applied setting.

When the highset setting is above the continuous thermal rating of the

relay, care should be taken, such that the duration of the applied current

should not damage the relay. Refer catalogue for thermal rating.

18

POLE HIGHSET

SETTING

MEASURED

PICK-UP

ERROR

Phase

TABLE 4

D. Output relays

1.Starter - C/O

This contact to be used whiles testing the pick up and reset value of the

relay.

2.IDMTL 1N/O contacts

This contact to be used while testing the IDMTL characteristics.

3.Highset 1 N/O contacts

This contact to be used while testing the highset characteristic.

4. Alarm - 1 N/o contact

5. Trip - 1 N/o contact

6. Protection Unhealthy - 1 N/C contact

5.3 DIRECTIONAL TESTING

The following test deal specifically with directional functionality. Note that

the directional response for each characteristic (e.g. IDMTL, Highset etc.) is

programmable, and may be selected as either non-directional, forward or

reverse on the requirement of the scheme. The 'Directional Control' settings

should now be correctly programmed.

Firstly remove the voltage fuses and check that the magnitude and phase

sequences of the system voltages are correct.

5.3.1 DIRECTIONAL POLARITY CHECK

This test checks for correct polarity of the directional circuits. Using the

phase sequence indicator, first check that the phase sequence of the

voltage in the relay is correct and see by inspection that the phasing of the

connections is correct. Check the magnitudes of the voltage transformer

voltage.

19

Pass a single phase load current of about 25% or more of the current rating

of the relay as per table no 5 and see that the directional elements operate

or restrain depending upon the direction of flow of the primary current.

If the flow of current is such that the relay should operate, see that in fact

it does operate, then reverse the connections to the current coils and see

that the relay restrains.

If the flow of current is such that the relay should restrain, see that in fact it

does restrain, then reverse the connections to the current coils and see that

the relay operates.

This test is based on the assumption that the load current has a normal

power factor.

I phase I neutral V phase V neutral

Phase 9 10 11 12

Table 5. Terminal Details for directional polarity test

5.3.2 CHECK THE OPERATING ANGLE OF THE DIRECTIONAL ELEMENT

The maximum torque angle of a directional relay is defined as the phase

angle between the current in the current coil and the voltage applied to the

voltage coil at which the relay develops maximum torque.

The available maximum torque angles are: -

1 to 90 lead in steps of 1

0

1 to 90 lag in steps of 1

Energize the voltage coil with rated voltage and the current coil with rated

current. Set the phase shifting transformer at the phase angle for maximum

torque. Set the indicator on the phase shifting transformer to zero; then

adjust the control to give lagging and leading phase angles until the Starter

LED drop off. The angle at which this occurs should be to the actual MTA,

88 lagging or leading with respect

5.4 PRIMARY INJECTION

Primary injection tests are essential to check the ratio and polarity of the

current transformers as well as the secondary wiring.

Using the circuit shown in Fig. 3 check the current transformer ratio. Inject

a current of sufficient magnitude .The secondary current is

Is = Primary current / CT ratio

20

5.5 PUTTING INTO SERVICE

After completing all tests satisfactorily, the relay should be put back into

service as follows:

1. Make a final check of the secondary wiring and tightness of all terminal

connections.

2. Insert the DC supply fuse.

3. Check the relay healthy indication/display.

4. Replace the relay cover.

5. Insert the trip links.

6. Perform trip test by secondary injection.

7. Remove all test connections

21

Fig. 2 - Secondary injection timing test circuit (Terminals are shown for 1A rating)

Fig. 3 - Primary Injection Test Circuit (Terminals are shown for 1A rating)

A

TIME

INTERVAL

METER

START

STOP

240 V A.C

SUPPLY

+

ve

-ve D.C SUPPLY

MIT121

10

9A

22 24

3 4

23

Use good quality switch

+ve -ve

D.C

A

PRIMARY

TEST SOURCE

MIT 121

9A

10

22 24

23

I

I

22

A

240 V A.C

SUPPLY

MIT121

V

Phase

Angle

Meter

Phase Shifting

Transformer

11

12

9A

10

22

24

DC

Auxiliary

Supply

+VE

-VE

Fig. 5 Directional Test Circuit

23

A B

C

P2

MIT121(A)

S1

S2 S2 S2

S1 S1

Voltage Transformer

MIT121(B) MIT121(C)

Case earth

Case earth Case earth

OC OC OC

10

9

6 5

10

9

6 5

10 9

6 5

Line current

transformers

Relays will operate

for a fault in this

direction

B C

A

Phase Rotation

Fig. 7 Directional over current, 45 Leading Power factor (using 90 connection)

P1

B

C

A

M I T 1 2 1

23

EARTH

22

24

AUXIL IARY

SUPPLY

+ VE

- VE

ALARM

1

2

TRIP

3

4

20

21

19

STARTER

PROTECTION

UNHEALTHY

18

13

12

Voltage

I nput

11

10

Current

I nput

9 9

9 B

A

Note :

1. CT circuit is shown connected to Relay 1A

tap. For 5A tap remove wire and connect

wire to terminal number 9. Unused current terminal

is to be fitted in the parking rack.

2. Terminal No.23 (Earth) is to be connected

directly to Earth bar.

9 A

9 B

1

2

3

4

5

6

7

8

11

12

13

18

19

20

21

22

23

24

CASE TERMI NALS VIEWED FROM REAR

(- )Ve (+) Ve

Earth

10

9

CT SHORTING CONTACT

6

6

6

6

WIRING DIAGRAM FOR MIT 121 RELAY

DAT E

DRAWN

CHECKED

APPROVED

EASUN REYROLLE LIMITED,

HOSUR, INDIA.

Drawing No. :- 8431W20121

R

E

V

No.

Sig. DATE Sig. DATE Sig. DATE

SUPERSEDES

No. No.

R. Ezhilmaran

01. 06.2001

23

EARTH

AUXILIARY

SUPPLY

+ VE

- VE

Note :

1. CT circuit is shown connected to Relay 1A

tap. For 5A tap remove wire and connect

wire to terminal number 9. Unused current terminal

is to be fitted in the parking rack.

2. Terminal No.23 (Earth) is to be connected

directly to Earth bar.

9 A

9 B

1

2

3

4

5

6

7

8

11

12

13

18

19

20

21

22

23

24

CASE TERMINALS VIEWED FROM REAR

(-)Ve (+) Ve

Earth

10

9

CT SHORTING CONTACT

17

16 14

WIRING DIAGRAM FOR MIT 131 RELAY

DATE

DRAWN

CHECKED

APPROVED

EASUN REYROLLE LIMITED,

HOSUR, INDIA.

Drawing No. :- 8431W20131

R

E

V

No. Sig. DATE Sig. DATE Sig. DATE

SUPERSEDES No. No.

R.Ezhilmaran

16.08.2001

M I T 131

ALARM

1

2

TRIP

3

4

20

21

19

STARTER

12

Voltage

Input

11

10

Current

Input

9 9

9 B

A

PROTECTION

UNHEALTHY

18

13

14

16

HIGHSET

OPERATED

IDMTL

OPERATED

COMMON

23

22

24

8

8

24

You might also like

- Quarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)Document18 pagesQuarter 3 - Module 1-W1&W2: Computer Systems Servicing (CSS)AC Balio100% (5)

- 5008S Fresenuis Service ManualDocument318 pages5008S Fresenuis Service ManualEslam Karam100% (10)

- Protection CDG 13Document2 pagesProtection CDG 13david wyethNo ratings yet

- New Scientist International Edition - August 07 2021Document62 pagesNew Scientist International Edition - August 07 2021Thảo HoàngNo ratings yet

- Project Name: Dcu Test Report For Motor Protection RelayDocument4 pagesProject Name: Dcu Test Report For Motor Protection RelayArul Kumar100% (1)

- TL Epr-Measurement For PDFDocument6 pagesTL Epr-Measurement For PDFKatukuri RaviNo ratings yet

- MRTPDocument20 pagesMRTPStephen Crawford100% (1)

- Capacitor Bank Controller Installation 7Document8 pagesCapacitor Bank Controller Installation 7Rafat ThongNo ratings yet

- Mit 161Document24 pagesMit 161Santosh Gairhe100% (1)

- NGRDocument2 pagesNGRAchint RajputNo ratings yet

- Loss of Field or Excitation Protection of Alternator or GeneratorDocument4 pagesLoss of Field or Excitation Protection of Alternator or Generatorsiddhant103No ratings yet

- MiCOM P122CDocument8 pagesMiCOM P122Cকুররাতুল আইনNo ratings yet

- 33 HT Panel ReportDocument30 pages33 HT Panel ReportVishakha PandeyNo ratings yet

- Test Results For Songea 5mva TransformerDocument6 pagesTest Results For Songea 5mva TransformerNuru TwahaNo ratings yet

- L&T Mm30743 Motpro RelayDocument31 pagesL&T Mm30743 Motpro Relayanvesh_jadavNo ratings yet

- Automatic Slip RegulatorDocument4 pagesAutomatic Slip RegulatorRajesh ThulluriNo ratings yet

- REJ 601-Panel N0-4Document3 pagesREJ 601-Panel N0-4Siva NandhamNo ratings yet

- Volt::Ch: Voltech Engineers Pvt. LTDDocument32 pagesVolt::Ch: Voltech Engineers Pvt. LTDstalin63100% (1)

- Ground Fault Tripping of Large MotorsDocument5 pagesGround Fault Tripping of Large Motorsclide_050793No ratings yet

- SA2003-000019 A en Trip Circuit Supervision With RXMB 1 Auxiliary RelayDocument1 pageSA2003-000019 A en Trip Circuit Supervision With RXMB 1 Auxiliary RelayErmin FazlicNo ratings yet

- Prok ManualDocument8 pagesProk ManualaymaanfkNo ratings yet

- Micom p211 Io 01 enDocument8 pagesMicom p211 Io 01 enKopi143No ratings yet

- Difference Between 2 Wire RTD, 3 Wire RTD, and 4 Wire RTD'sDocument5 pagesDifference Between 2 Wire RTD, 3 Wire RTD, and 4 Wire RTD'sbilalNo ratings yet

- Maintenance Procedure: Preventive Mantenance of HT MotorDocument5 pagesMaintenance Procedure: Preventive Mantenance of HT Motorsanjay sharmaNo ratings yet

- NGR PanelDocument17 pagesNGR PanelnikerNo ratings yet

- CTMM RelayDocument3 pagesCTMM RelayshiyasNo ratings yet

- Trip Circuit Supervisory Relay: Type: ATSR31ADocument3 pagesTrip Circuit Supervisory Relay: Type: ATSR31ADarius Balakauskas100% (1)

- Testing Maintenance Troubleshooting ACBDocument16 pagesTesting Maintenance Troubleshooting ACB322399mk7086100% (1)

- Relay: Type: 1. 2. 3Document5 pagesRelay: Type: 1. 2. 3SLDC DDNo ratings yet

- Mpr300 CatalogueDocument4 pagesMpr300 CatalogueSanthosh Reddy BNo ratings yet

- Relay Coordination Chapter3Document13 pagesRelay Coordination Chapter3Chân Gà NướngNo ratings yet

- Pre-Commissioning Test Report For Numerical Relay: ProjectDocument3 pagesPre-Commissioning Test Report For Numerical Relay: ProjectHari haranNo ratings yet

- Protection MannualDocument121 pagesProtection Mannualgeetha_yagantiNo ratings yet

- JVS Manual JRP 011Document12 pagesJVS Manual JRP 011Tamilventhan_sNo ratings yet

- VDT - 877 - Annexure-IADocument176 pagesVDT - 877 - Annexure-IAprati121100% (1)

- VCB - TestDocument1 pageVCB - TestThức VõNo ratings yet

- Megawin Switchgear: Numerical Over Current ProtectionDocument4 pagesMegawin Switchgear: Numerical Over Current ProtectionRock hackNo ratings yet

- Alternator Protection PDFDocument33 pagesAlternator Protection PDFfhfghNo ratings yet

- Restricted Earth Fault ProtectionDocument15 pagesRestricted Earth Fault ProtectionKuntal SatpathiNo ratings yet

- Vaj CortecDocument6 pagesVaj CortecvenkateshbitraNo ratings yet

- Setting Sheet For Rex 521Document6 pagesSetting Sheet For Rex 521mad_sam282729No ratings yet

- Effect of High and Low VoltageDocument2 pagesEffect of High and Low VoltageBhupinder SinghNo ratings yet

- Installation and Commissioning Procedure FOR Exide Plante Type Standby Batteries Complete With First Charge Instructions and Maintenance PracticeDocument24 pagesInstallation and Commissioning Procedure FOR Exide Plante Type Standby Batteries Complete With First Charge Instructions and Maintenance PracticeSaran KumarNo ratings yet

- Maximum Demand ControllerDocument4 pagesMaximum Demand ControllerDIWAKAR NNo ratings yet

- Operation, Erection & Maintenance For Power TrafoDocument50 pagesOperation, Erection & Maintenance For Power TrafoJagdeep KumarNo ratings yet

- MPR300Document4 pagesMPR300KUNALJAY100% (1)

- Cheyyar Co-Op Sugar Mills LTD.: (15Mw Co-Gen Power Plant)Document11 pagesCheyyar Co-Op Sugar Mills LTD.: (15Mw Co-Gen Power Plant)Vijay PitchaiahNo ratings yet

- MM30 743Document4 pagesMM30 743sigmasurat100% (1)

- Relay TerminalsDocument3 pagesRelay Terminalssundars_sriNo ratings yet

- Lecture Notes - 19Document32 pagesLecture Notes - 19Bhaskar1411No ratings yet

- HWX SparesDocument6 pagesHWX SparesMohan SaravanaNo ratings yet

- Panel and APFC SpecDocument34 pagesPanel and APFC SpecreddyloginNo ratings yet

- Transformer ProtectionDocument22 pagesTransformer ProtectionRuben MaychelNo ratings yet

- Why LT Motors Are Delta Connected and HT Motors Are Star Connected - 4Document2 pagesWhy LT Motors Are Delta Connected and HT Motors Are Star Connected - 4Shah JayNo ratings yet

- 25ref RelayDocument8 pages25ref Relaysikander843562No ratings yet

- Schneider Protection RelayDocument8 pagesSchneider Protection Relayeugene oneillNo ratings yet

- Distance Protection Relay of LineDocument11 pagesDistance Protection Relay of LineYahya DarNo ratings yet

- ABB Test Report For Bcu Relay: P A N e LD e T A Il SDocument3 pagesABB Test Report For Bcu Relay: P A N e LD e T A Il SJayamkondanNo ratings yet

- SPR, RCS-9627CN, NoDocument5 pagesSPR, RCS-9627CN, NoAmaresh NayakNo ratings yet

- Genesis Mit 114 RelaysDocument32 pagesGenesis Mit 114 RelaysVijay Suryavanshi100% (3)

- Easun MIT114Document32 pagesEasun MIT114chandraprakashhh0% (1)

- MJT 315 - or Rev 1-1 PDFDocument32 pagesMJT 315 - or Rev 1-1 PDFashish_muley100% (1)

- Easun Reyrolle Limited: Application and Commissioning Manual Mit161 RelayDocument24 pagesEasun Reyrolle Limited: Application and Commissioning Manual Mit161 RelaySumonto MajiNo ratings yet

- Notes On Tripping RelaysDocument7 pagesNotes On Tripping RelaysSenthil KumarNo ratings yet

- Polyphase SystemsDocument11 pagesPolyphase SystemsRafat ThongNo ratings yet

- C57 109-1985Document10 pagesC57 109-1985mjimenezg100% (1)

- S 2807914Document4 pagesS 2807914Rafat ThongNo ratings yet

- Advc2 3002rev1 0Document6 pagesAdvc2 3002rev1 0Rafat ThongNo ratings yet

- ABB Hard To Find Information On Distribution Systems Part IIDocument27 pagesABB Hard To Find Information On Distribution Systems Part IIRafat ThongNo ratings yet

- TechRef Overhead Line Models PDFDocument29 pagesTechRef Overhead Line Models PDFRafat ThongNo ratings yet

- TechRef Load PDFDocument26 pagesTechRef Load PDFRafat ThongNo ratings yet

- TechRef Imeas PDFDocument9 pagesTechRef Imeas PDFRafat ThongNo ratings yet

- TechRef CableConstants PDFDocument21 pagesTechRef CableConstants PDFRafat ThongNo ratings yet

- Conversion TablesDocument2 pagesConversion TablesKumarNo ratings yet

- Certification No. 1118: DLMS User AssociationDocument1 pageCertification No. 1118: DLMS User AssociationRafat ThongNo ratings yet

- Trinetics Switches Ultravac Ii200Document4 pagesTrinetics Switches Ultravac Ii200Rafat ThongNo ratings yet

- DLL Mother TongueDocument41 pagesDLL Mother TongueMarxPascualBlancoNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet

- Ozone Therapy Is Safest Known TherapyDocument35 pagesOzone Therapy Is Safest Known Therapyherdin2008100% (1)

- 12 Abm Bangelyns Group1Document64 pages12 Abm Bangelyns Group1G-VALDEZ, SHELAHNo ratings yet

- FracShield Composite Frac PlugDocument3 pagesFracShield Composite Frac PlugJOGENDRA SINGHNo ratings yet

- OpenFOAM编程指南Document100 pagesOpenFOAM编程指南Feishi XuNo ratings yet

- UNHCR Hygiene Promotion GuidelinesDocument112 pagesUNHCR Hygiene Promotion GuidelinesBrandie ShackelfordNo ratings yet

- Qsi540-600Document74 pagesQsi540-600Lorenzo RossiNo ratings yet

- MT2OL-Ia6 2 1Document136 pagesMT2OL-Ia6 2 1QUILIOPE, JUSTINE JAY S.No ratings yet

- About BITS CmdletsDocument3 pagesAbout BITS CmdletsvashsauNo ratings yet

- How To Improve Battery Life of Your Galaxy Note 10 and Note 10Document18 pagesHow To Improve Battery Life of Your Galaxy Note 10 and Note 10rainpcruzNo ratings yet

- EC Physical Sciences Grade 11 November 2022 P1 and MemoDocument25 pagesEC Physical Sciences Grade 11 November 2022 P1 and MemokhulntandoNo ratings yet

- Statement of PurposeDocument3 pagesStatement of PurposeehsanNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- Alere G1 Glucose Meter ManualDocument55 pagesAlere G1 Glucose Meter ManualSundar Rajan33% (6)

- Manual C28 Plus enDocument28 pagesManual C28 Plus enSveto SlNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- REVISING EXERCISES 1baDocument3 pagesREVISING EXERCISES 1baAlvaro LorcaNo ratings yet

- WRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkDocument2 pagesWRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkFatmah El WardagyNo ratings yet

- Mic 2 Mkii Installation Instructions and Reference Handbook 4189320057 UkDocument70 pagesMic 2 Mkii Installation Instructions and Reference Handbook 4189320057 Ukkamel kamelNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Worksheet Research-Title FINALDocument3 pagesWorksheet Research-Title FINALJierroe EvangelistaNo ratings yet

- Free CV Template 31Document1 pageFree CV Template 31Aaron WilsonNo ratings yet

- The Design of An Annular Combustion Chamber: October 2017Document11 pagesThe Design of An Annular Combustion Chamber: October 2017ko koNo ratings yet

- MTCNA Lab Guide INTRA 1st Edition - Id.en PDFDocument87 pagesMTCNA Lab Guide INTRA 1st Edition - Id.en PDFreyandyNo ratings yet

- Support/downloads or Scan Above QR Code For Detailed Policy WordingDocument10 pagesSupport/downloads or Scan Above QR Code For Detailed Policy Wordingraj VenkateshNo ratings yet

- Suntrust VeronaDocument12 pagesSuntrust Veronalyanca majanNo ratings yet