Professional Documents

Culture Documents

Calculation 1

Calculation 1

Uploaded by

SuchitKOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation 1

Calculation 1

Uploaded by

SuchitKCopyright:

Available Formats

2)

Frictional forces between pipe and support

Out of 6 nos. of cooling tower thrust due to frictional force between roller support & pipe for a length of 3.505m of pipe work of each cooling tower:

2.1

!hrust due to frictional force between roller support & pipe "fr # $. % &here $ ' (oefficient of friction )0.* % + !otal weight of pipe in kgs for a length of 3.505m )&eight of pipe per meter 33,.12- .gs. "fr # $. % # 0.* / )33,.12- / 3.505 / -.,1 "fr # *.65 k0

Out of 311 nos. of cooling tower thrust due to frictional force between roller support & pipe for a length of 6.-0m of pipe work of each cooling tower:

2.2

!hrust due to frictional force between roller support & pipe "fr # $. % &here $ ' (oefficient of friction )0.* % + !otal weight of pipe in kgs for a length of 6.-0m )&eight of pipe per meter 33,.12- .gs. "fr # $. % # 0.* / )33,.12- / 6.-0 / -.,1 "fr # -.15 k0

3) Flow effects in the pipe (500 dia. Condenser water return pipe)

3.1 (entrifugal forces acting on -02 elbow due to flow of water and change of direction of flow. "c # 3ensit4 of fluid flowing through pipe / )5elocit4 of fluid / 6rea of pipe / 7 8 -.,1) accn due to gra5it4 &here9 7 is in radian & radian -0 #) : 82 # 1000 / )2.;; 2 / ): 8* / )0.*,,-5 2/ ): 82 8 -.,1 # 1000 / -.,1 / 6.61 / 1.5;8-.,1 # 230.; 0 "c # 0.230; k0

2

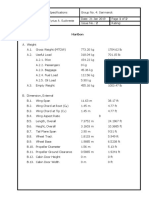

4) Dead weight of all pipe, co ponent and insulation inclusi!e of water

*.1 &eight of pipe )500 dia. 8 meter # 3ensit4 of pipe material )(arbon <teel / = : 8* )0.50,2 + 0.*,,-52 > &here9 ?ipe inside diameter )@3 # 0.*,,-5m ?ipe outside diameter )O3 # 0.50,m # ;,50 / =): 8* / )0.50,2 + 0.*,,-52 > # 116.5 .gs. 8 meter

*.2

&eight of fluid )water flowing through pipe 8 meter # 3ensit4 of fluid / =): 8* )1.0*;-* 2> # 1000 / =): 8* / )0.*,,-52 > # 1,; .gs 8 meter &eight of @nsulation material & accessories + *.05 kgs. !herefore9 !otal weight of pipe )including 10A <afet4 factor # &eight of pipe 8 m 1 &eight of fluid flowing through pipe 8 m 1 &eight of insulation material and accessories # 116.5 1 1,; 1 *.05 1 )0.10 / !otal weight # 30;.55 1 )0.10/ 30;.55 # 33,.2 kgs8 meter

*.3 &eight of pipe )dia 500 for ,.5 m length from commissioning station to inlet Of cooling tower # 33,.2 / ,.5 # 2,;5 .gs

*.*

!otal weight of pipe for a length of ,.5m )"rom Butter fl4 5al5e )BC to inlet of cooling tower including )wt. BC & orifice plate )O? 1 &t. of motoriDed control 5al5e 1 &t. of -0 deg. Elbow # )33,.2 / ,.5 1 51* 133* 1 1;,.6 #3-01 .gs. *.5 &eight of pipe for a length of 0.;12m )"rom main header 1500dia to commissioning station # &eight of pipe8meter / 0.;12 # 33,.2 / 0.;12 # 2*1 .gs. *.5 &eight of each roller support # 50 kgs

*.6 &eight of 3*0/230/12mm thick plate )1 nos. # )0.3*0/0.230/0.012 / 3ensit4 of mild steel # )0.3*0/0.230/0.012 / ;,50.g8m3. # ;.36 .gs. *.; &eight of ,00/250/12mm thick plate )1 nos. # )0.,00/0.250/0.012 / 3ensit4 of mild steel # )0.,00/0.250/0.012 / ;,50.g8m3. # 1,.,* .gs. *., &eight of 150/150/12mm thick plate )2nos # )0.150/0.150/0.012 /2/3ensit4 of mild steel # )0.150/0.150/0.012 / 2 / ;,50.g8m3. # *.2* .gs. "ut of # nos. of cooling tower forces acting downward for a length of 3.505 hori$ontal pipe wor% of each cooling tower& of

!otal forces acting downwards )for 3.505 m of horiDontal pipe work # !otal weight on steel structure / -.,1 # =!otal weight of ?ipe 1&t. of Elbow 1 %oller support1 &t. of 1nos. of )3*0/230/12 plate 1 &t. of 1nos. of ),00/250/12 mm plate 1 &t. of * nos.F16 nut & bolt 1 &t. of 2nos. of )150/150/12 mmplate 1 &t. of * nos.F12 nut & bolt> / -.,1

# =)3.505 / 33,.2 11;,.6 150 1 ;.3;1111,.,*1*.2*1 0.250> / -.,1> # 1*.1, k0 "ut of 3'( nos. of cooling tower forces acting downward for a length of #.)0 hori$ontal pipe wor% of each cooling tower& of

!otal forces acting downwards )for 6.-0 m of horiDontal pipe work # !otal weight on steel structure / -.,1 # =!otal weight of ?ipe 1&t. of Elbow 1 %oller support1 &t. of 1nos. of )3*0/230/12 plate 1 &t. of 1nos. of ),00/250/12 mm plate 1 &t. of * nos.F16 nut & bolt 1 &t. of 2nos. of )150/150/12 mmplate 1 &t. of * nos.F12 nut & bolt> / -.,1 # =)6.-0 / 33,.2 11;,.6 1)50 1 ;.3;1111,.,*1*.2*1 0.250 G2> / -.,1 # 26.2* k0

!otal weight of )dia. 500 (&% 5ertical pipe on support 1 for length of 3.2 meter )from elbow to bo/ section welded to dia 500 (&% pipe # &eight of pipe for a length of 3.2 meter 1 weight of elbow # =)33,.2 / 3.2 1 1;,.6> / -.,1 *(2.3+ ,!otal weight of )dia. 500 (&% 5ertical pipe on support 2 for length of 2.2 meter )from 1st bo/ section welded to dia 500 (&% pipe to 2nd bo/ section welded to pipe # &eight of pipe for a length of 2.2 meter 1 weight of motoriDed 5al5e # =)33,.2 / 2.2 1 33*> / -.,1 *(0.5+ ,-.

!otal weight of )dia. 500 (&% 5ertical pipe on support 3 for length of 2.; meter )from 2nd bo/ section welded to dia 500 (&% pipe to 3rd bo/ section welded to pipe # &eight of pipe for a length of 2.; meter 1 &eight of orifice plate # =)33,.2 / 2.; 1 1,0> / -.,1

*(0.+2 ,-.

C"-C./01"-&

2otal thrust acting on hori$ontal pipe & "orces due to pipework e/pansion9 " # 6;6.5- k0.

?ressure effects )(entrifugal forces 9 "c # 0.230; k0. "rictional forces9 "r # 563.,3 k0

2otal thrust acting on !ertical pipe & "orces due to pipework e/pansion9 " # 563.,3 k0.

?ressure effects )(entrifugal forces 9 "c # 0.230; k0. "rictional forces9 "r # '563.,3 k0

%esol5ing the forces in H'direction & 4'direction at -00 Elbow due to change of fluid direction 3ressure effect in 45direction "c # 0.230; / cos *50 # 0.230; / 0.;0; # 0.163 k0 3ressure effect in 65direction "c # 0.230; / sin *50 # 0.230; / 0.;0; # 0.163 k0

(2otal thrust force in 75direction)$ * "orces due to pipework e/pansion 1 pressure effect in I'direction # 563.,3 1 0.163 # 56*.00 k0 (2otal thrust force in 65direction)8 * "orces due to pipework e/pansion 1 pressure effect in I'direction # 563.,3 1 0.163 # 56*.00 k0 !herefore9 %esultant force acting at -00 Elbow: <in # !hrust force in I'direction8 %esultant force &here9 6ngle is 450 %esultant force # 56*8 <in 450 # 56*80.;0;

# ;-;.;3 k0

You might also like

- Design of Penstock Pipe For A HydroelectDocument21 pagesDesign of Penstock Pipe For A Hydroelectjanardhana100% (1)

- Fcom A318/319/320Document3,666 pagesFcom A318/319/320Mark Busse100% (13)

- Solved ProblemSetEquipDesign2Document11 pagesSolved ProblemSetEquipDesign2Rachel Hechanova100% (1)

- Tightening TorqueDocument6 pagesTightening TorqueShirish100% (1)

- Obervermuntwerk II Penstock DesignDocument10 pagesObervermuntwerk II Penstock DesignPeter MeusburgerNo ratings yet

- Thrust Stand Design Principles PDFDocument11 pagesThrust Stand Design Principles PDFUMANG JAINNo ratings yet

- Boeing 737 Supplement 6-EICASDocument7 pagesBoeing 737 Supplement 6-EICASJavier100% (5)

- Estimation of The Ship Resistance & Engine SelectionDocument16 pagesEstimation of The Ship Resistance & Engine SelectionNikolas DekkoNo ratings yet

- Steam Systems Piping: Chapter C3Document51 pagesSteam Systems Piping: Chapter C3Marcelo MorenoNo ratings yet

- Exercise No. 3: Drain Hole Drilling, Rev. 1, 25.10.04Document3 pagesExercise No. 3: Drain Hole Drilling, Rev. 1, 25.10.04SrWilson Z AriasNo ratings yet

- IBR 353-359 FlangesDocument5 pagesIBR 353-359 FlangesRajivharolikarNo ratings yet

- 9A01401 Strength of Materials - IIDocument4 pages9A01401 Strength of Materials - IIsivabharathamurthyNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978No ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- MS 01 107Document12 pagesMS 01 107Floyd AnthonyNo ratings yet

- Design 1 Assignment 2Document3 pagesDesign 1 Assignment 2PwoliNo ratings yet

- Especificaciones Max Pump Series S High SpeedDocument29 pagesEspecificaciones Max Pump Series S High SpeedJuan Pablo Martínez CortesNo ratings yet

- Re Exam Paper Nov08, Smt211tDocument5 pagesRe Exam Paper Nov08, Smt211tPortia ShilengeNo ratings yet

- Question Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle JointsDocument25 pagesQuestion Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle Jointsamol pogakeNo ratings yet

- 323113-PF Chain Link FencingDocument3 pages323113-PF Chain Link Fencingabdullah sahibNo ratings yet

- DLT 5054-1996Document245 pagesDLT 5054-1996ecsuperalNo ratings yet

- Drilling Engineering: PETE 203Document48 pagesDrilling Engineering: PETE 203sereptNo ratings yet

- Casing Design 2005Document48 pagesCasing Design 2005serept0% (1)

- Swagelok Tubing DataDocument8 pagesSwagelok Tubing DataSyahirul Alim100% (1)

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- Rig DesginDocument25 pagesRig Desginriobm100% (1)

- Rig DesginDocument25 pagesRig DesginImam Pranadipa100% (1)

- L Inverted Siphon 3rd CDocument6 pagesL Inverted Siphon 3rd CPreston VargheseNo ratings yet

- Bill of Quantity and Project Estimate: Earth Work in ExcavationDocument5 pagesBill of Quantity and Project Estimate: Earth Work in Excavationasingh400No ratings yet

- Tension Properties For Materials Used in ShipbuildingDocument10 pagesTension Properties For Materials Used in ShipbuildingKarla JuárezNo ratings yet

- Steel Tips - Composite Beam Design With Metal Deck PDFDocument9 pagesSteel Tips - Composite Beam Design With Metal Deck PDFmateus456No ratings yet

- Full TextDocument6 pagesFull TextMuhammad AffandiNo ratings yet

- Piping Tie-Rod Design Made SimpleDocument3 pagesPiping Tie-Rod Design Made SimpleSeungmin PaekNo ratings yet

- CHE 480 Practice Questions-10Document15 pagesCHE 480 Practice Questions-10harisjawedNo ratings yet

- Erosion Behaviour and Mechanisms For Steam Turbine Rotor BladesDocument6 pagesErosion Behaviour and Mechanisms For Steam Turbine Rotor BladesGholamreza MahmoodiNo ratings yet

- Stress Relief Boreback BoxDocument3 pagesStress Relief Boreback BoxDaisuke Numata100% (1)

- Rud RapurDocument9 pagesRud RapurdipenkhandhediyaNo ratings yet

- MS 01 179Document12 pagesMS 01 179Billy ZununNo ratings yet

- Drilling Engineering: PETE 203Document48 pagesDrilling Engineering: PETE 203AbdullahNo ratings yet

- Drilling Engineering: PETE 203Document48 pagesDrilling Engineering: PETE 203nicessg@gmail.comNo ratings yet

- Bhel WF SpoolDocument4 pagesBhel WF SpoolDonna GrayNo ratings yet

- Stress Analysis of Steam Generator Shell Nozzle Junction For Sodium Cooled Fast Breeder ReactorDocument9 pagesStress Analysis of Steam Generator Shell Nozzle Junction For Sodium Cooled Fast Breeder ReactorVinh Do Thanh100% (1)

- SSAB Water Mains enDocument12 pagesSSAB Water Mains enservice techniqueNo ratings yet

- Pipe Sizing and Pressure Drop CalculationDocument7 pagesPipe Sizing and Pressure Drop Calculationvino2win100% (1)

- Casing DesignDocument48 pagesCasing Designdrillinganaco60% (5)

- Vijay BhaskarDocument2 pagesVijay BhaskarVijaybhaskar ReddyNo ratings yet

- PACKAGE 67 (III) /2014-15: Odisha Power Transmission Corporation LimitedDocument6 pagesPACKAGE 67 (III) /2014-15: Odisha Power Transmission Corporation LimitedVelu SamyNo ratings yet

- GratingDocument8 pagesGratingGhanshyam PandeyNo ratings yet

- HTTP WWW - Grainger.com Images Catalog 402 4351.PDF Concat True&BaseURL HTTP WWW - GraingerDocument1 pageHTTP WWW - Grainger.com Images Catalog 402 4351.PDF Concat True&BaseURL HTTP WWW - GraingerSebastian PVNo ratings yet

- VesselsDocument3 pagesVesselsMuhammad NopriyansyahNo ratings yet

- Assignment No 1 MD-1..Document3 pagesAssignment No 1 MD-1..Yadnyesh TaNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- Tools List For Kiln & Cooler ErectionDocument2 pagesTools List For Kiln & Cooler ErectionarsharmNo ratings yet

- Integral Orifice Flow Elements, 1 and 1 Inch Pipe Sizes: Measurement Made EasyDocument8 pagesIntegral Orifice Flow Elements, 1 and 1 Inch Pipe Sizes: Measurement Made EasyalanNo ratings yet

- ChimneyDocument10 pagesChimneyAsitha LunuwaththaNo ratings yet

- Module 5 ChimneysDocument5 pagesModule 5 Chimneysn.s.patkarNo ratings yet

- Composite Beam Design Metal DeckDocument9 pagesComposite Beam Design Metal Decksilveer12No ratings yet

- Act 11 INGE4010-4015 S12Document2 pagesAct 11 INGE4010-4015 S12Jesus Emanuel RosarioNo ratings yet

- Schedule of Grilles and Diffusers: Project: S.M.R.C DohaDocument4 pagesSchedule of Grilles and Diffusers: Project: S.M.R.C DohaSuchitKNo ratings yet

- FIDICDocument10 pagesFIDICSuchitKNo ratings yet

- 2-Nd Floor Bell-B Pressure Area Served by SL - No: Space Number Space Name Air Terminal Device Referance Supply AirDocument20 pages2-Nd Floor Bell-B Pressure Area Served by SL - No: Space Number Space Name Air Terminal Device Referance Supply AirSuchitKNo ratings yet

- Heater BatteryDocument1 pageHeater BatterySuchitKNo ratings yet

- Prova Copa 2017Document8 pagesProva Copa 2017Carlos Eduardo BeckerNo ratings yet

- For Batch B1.1 Prepared By:-: Vijay PainulyDocument25 pagesFor Batch B1.1 Prepared By:-: Vijay PainulyPrajwalNo ratings yet

- ASTRID Rocket Flight TestDocument7 pagesASTRID Rocket Flight TestKhoa VũNo ratings yet

- 1947 AAF T-2 Report - Lorin Ramjets For Fighters - E Sänger and I BredtDocument71 pages1947 AAF T-2 Report - Lorin Ramjets For Fighters - E Sänger and I BredtJose G ANo ratings yet

- Design of An Unmanned Hovercraft: International Journal of Computer Engineering in Research TrendsDocument5 pagesDesign of An Unmanned Hovercraft: International Journal of Computer Engineering in Research TrendsH JNo ratings yet

- Catalogue Nacelle Tooling A320neoDocument31 pagesCatalogue Nacelle Tooling A320neoPablo RestrepoNo ratings yet

- Performance of Gas Turbine EngineDocument35 pagesPerformance of Gas Turbine EngineKusmaliah Oksa100% (1)

- EGB323 Week 8 Lecture ENG 2019Document59 pagesEGB323 Week 8 Lecture ENG 2019polfzxkwwavcrlnllzNo ratings yet

- What Is Aerodynamics - NASADocument5 pagesWhat Is Aerodynamics - NASAAhmad Badius ZamanNo ratings yet

- Propeller TheoryDocument9 pagesPropeller TheoryFlorenceNo ratings yet

- Propulsion of Offshore Support VesselsDocument8 pagesPropulsion of Offshore Support VesselsPatrick Araujo RamalhoNo ratings yet

- Report 1 ESTIMATION OF THE SHIP RESISTANCEDocument16 pagesReport 1 ESTIMATION OF THE SHIP RESISTANCEpsda kseNo ratings yet

- 1286376Document52 pages1286376servetNo ratings yet

- Lecture 1006 - Engine Performance ParametersDocument20 pagesLecture 1006 - Engine Performance ParametersBhushan BissaNo ratings yet

- Multiphysics Simulation For Marine Applications: CD-adapcoDocument100 pagesMultiphysics Simulation For Marine Applications: CD-adapcoesmaeil013100% (2)

- Atmospheric Ascent Guidance For Rocket-Powered Launch VehiclesDocument11 pagesAtmospheric Ascent Guidance For Rocket-Powered Launch VehiclesBonzi BuddyNo ratings yet

- Resistance and Power CalculationDocument23 pagesResistance and Power CalculationgksahaNo ratings yet

- Transverse Thrust On The PropellerDocument12 pagesTransverse Thrust On The PropellerNuman Kooliyat IsmethNo ratings yet

- Thrust Block CalcsDocument3 pagesThrust Block CalcsThiruvasagam Subramanian0% (1)

- Lecture-17 PPT For CubesatDocument27 pagesLecture-17 PPT For CubesatDaniele BarberaNo ratings yet

- Aerodynamics of Vertical Landing Rocket Vehicle With Engine Thrust in Landing PhaseDocument9 pagesAerodynamics of Vertical Landing Rocket Vehicle With Engine Thrust in Landing PhaseJesus Eduardo Duran DelfinNo ratings yet

- C06. FläktWoods - Jet Thrust System - The Solution To Car Park VentilationDocument12 pagesC06. FläktWoods - Jet Thrust System - The Solution To Car Park VentilationCzarSASNo ratings yet

- CT Question Bank Ref PDFDocument64 pagesCT Question Bank Ref PDFGanesh GuptaNo ratings yet

- Dokumen - Tips - Mekanika Teknik 56245c7b3055d PDFDocument4 pagesDokumen - Tips - Mekanika Teknik 56245c7b3055d PDFAn AnNo ratings yet

- 1 Perbandingan Metode Prediksi18303297 MainDocument16 pages1 Perbandingan Metode Prediksi18303297 MainR abdNo ratings yet

- Reports Summary PDFDocument60 pagesReports Summary PDFGrant Irving Gorre TomaubNo ratings yet