Professional Documents

Culture Documents

Ansys History.

Ansys History.

Uploaded by

Eirick Wayne Zuñigga De-ItzelCopyright:

Available Formats

You might also like

- LCS310UR Diagrama2 PDFDocument13 pagesLCS310UR Diagrama2 PDFKnspeis0% (1)

- (1918) Louden Hay Unloading Tools (Catalogue)Document52 pages(1918) Louden Hay Unloading Tools (Catalogue)Herbert Hillary Booker 2nd100% (1)

- Specifications: VMC 4020 Table DimensionsDocument1 pageSpecifications: VMC 4020 Table DimensionsJhojan MuñozNo ratings yet

- Nadca 402 4aDocument44 pagesNadca 402 4awholenumberNo ratings yet

- Ind0101 - GDocument4 pagesInd0101 - Grajit kumarNo ratings yet

- Aluminios y Sus Equivalentes2Document1 pageAluminios y Sus Equivalentes2Augusto PeinadoNo ratings yet

- Tornillo BancoDocument1 pageTornillo Bancoalonsorebolledo3No ratings yet

- ME 322-Manufacturing Processes IDocument2 pagesME 322-Manufacturing Processes Ifirsttenor100% (1)

- SOLIDCast - Workbook Version 8.1.1Document388 pagesSOLIDCast - Workbook Version 8.1.1nurulapriliashNo ratings yet

- An Experimental Study To Corelate Water Jet Impingement Erosion Resistance and Properties of MetallicDocument12 pagesAn Experimental Study To Corelate Water Jet Impingement Erosion Resistance and Properties of MetallicsaatehNo ratings yet

- Ni ResistDocument2 pagesNi ResistAslan AlpNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- Caixas Rolamentos UsaDocument52 pagesCaixas Rolamentos Usakrlos_SW2009No ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- Halder Katalog N5 enDocument815 pagesHalder Katalog N5 enmilasko86No ratings yet

- Steelwise: Are You Properly Specifying Materials?Document9 pagesSteelwise: Are You Properly Specifying Materials?Muhammad AhsunNo ratings yet

- Formule Di MetallurgiaDocument24 pagesFormule Di MetallurgiaLuigi RizziNo ratings yet

- DIN 11851 Welding Liner 316Document1 pageDIN 11851 Welding Liner 316Omar Jesus Coca100% (1)

- Decimals and Fractions: A List of Metric and Imperial UnitsDocument2 pagesDecimals and Fractions: A List of Metric and Imperial UnitsRo Ad0% (2)

- Water Hammer Production and Design Measures in Piping SystemsDocument16 pagesWater Hammer Production and Design Measures in Piping SystemsSivashankar DhanarajNo ratings yet

- Analyze and Optimize Design of A Blender BladeDocument57 pagesAnalyze and Optimize Design of A Blender Bladenikhilesh PrashanthNo ratings yet

- Astm A209 PDFDocument3 pagesAstm A209 PDFgaminNo ratings yet

- Annealed Pickled SS Tubing (MS 02 315 ER0)Document2 pagesAnnealed Pickled SS Tubing (MS 02 315 ER0)herysyam1980No ratings yet

- Maquina para Hacer Clips (Modelo)Document2 pagesMaquina para Hacer Clips (Modelo)Samuel Silva0% (1)

- Hiline ManualDocument206 pagesHiline ManualkarthikNo ratings yet

- Optimal Configuration Design For Plate Heat Ex ChangersDocument16 pagesOptimal Configuration Design For Plate Heat Ex ChangersIvancu IonelNo ratings yet

- Determining Air Change in A Single Zone by Means of A Tracer Gas DilutionDocument18 pagesDetermining Air Change in A Single Zone by Means of A Tracer Gas DilutionGarima GuptaNo ratings yet

- Size MI N (In) Size MA X (In) Abrev Short Word Details Component SDocument16 pagesSize MI N (In) Size MA X (In) Abrev Short Word Details Component SAnthony InostrozaNo ratings yet

- Manual Solve ElecDocument28 pagesManual Solve ElecHenry HcNo ratings yet

- Seguridad en Los Procesos de Soldadura y CorteDocument33 pagesSeguridad en Los Procesos de Soldadura y CorteGino Chavez ValenciaNo ratings yet

- Engineering & Design: Geometric Dimensioning: SectionDocument34 pagesEngineering & Design: Geometric Dimensioning: SectionVinaya Almane DattathreyaNo ratings yet

- Everything You Need To Know About Flatteners and Levelers For Coil Processing - Part IVDocument7 pagesEverything You Need To Know About Flatteners and Levelers For Coil Processing - Part IVertuokumusNo ratings yet

- PS9172S SpotweldDocument13 pagesPS9172S SpotweldmanuelNo ratings yet

- Cadcam (Milling)Document29 pagesCadcam (Milling)Md Rasid SamsuriNo ratings yet

- Quick Start Guide For X1&X1-Carbon-v1Document16 pagesQuick Start Guide For X1&X1-Carbon-v1darkoteamNo ratings yet

- Estrella de Genova CadDocument2 pagesEstrella de Genova CadIng Miguel Angel Rmz HdezNo ratings yet

- Smart Maze Robot ReportDocument40 pagesSmart Maze Robot ReporttarunudayakumarNo ratings yet

- Bolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 pagesBolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- Deep Drawing Analysis by Using Explicit Dynamics in Ansys WorkbenchDocument8 pagesDeep Drawing Analysis by Using Explicit Dynamics in Ansys Workbenchsunhell1611No ratings yet

- Horizon Software: Materials Testing, Analysis and Reporting SoftwareDocument12 pagesHorizon Software: Materials Testing, Analysis and Reporting SoftwareBilly HorshamNo ratings yet

- Hex Jam Nut, SAE J995 Grade 5, Plain Finish: DocumentosDocument2 pagesHex Jam Nut, SAE J995 Grade 5, Plain Finish: DocumentosDiego ChavezNo ratings yet

- Soft Annealing Heat Treatment PDFDocument6 pagesSoft Annealing Heat Treatment PDFsivajirao70No ratings yet

- Estimating The Largest Grain Observed in A Metallographic SectionDocument6 pagesEstimating The Largest Grain Observed in A Metallographic SectionMirtunjayKumarNo ratings yet

- Flame Spraying Gun Uni Spray JetDocument5 pagesFlame Spraying Gun Uni Spray JetCristobal MontalbaNo ratings yet

- 6.1 Catalogo Taladro Fresador PDM - 45-Manual en InglesDocument17 pages6.1 Catalogo Taladro Fresador PDM - 45-Manual en InglesHenry DavichoNo ratings yet

- Datasheet Sandvik 14c28n enDocument3 pagesDatasheet Sandvik 14c28n ensondeadorNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- Ansys TutorialsDocument24 pagesAnsys TutorialsMahdiNo ratings yet

- Ansys14 Classic TutorialDocument21 pagesAnsys14 Classic TutorialMAXNo ratings yet

- Tutorial Completo AnsysDocument416 pagesTutorial Completo AnsysWanderson Horta100% (2)

- Bilder in Bachelor ThesisDocument6 pagesBilder in Bachelor ThesisTye Rausch100% (2)

- ADS Tutorial: A Beginners Tutorial: Modes of OperationDocument13 pagesADS Tutorial: A Beginners Tutorial: Modes of OperationYounes Ait El MaatiNo ratings yet

- Introduction of AnsysDocument3 pagesIntroduction of Ansys20MCE 01 Mehwish KhanNo ratings yet

- Ansys - MEMS Lab IntroductionDocument9 pagesAnsys - MEMS Lab IntroductionJag JagNo ratings yet

- Ansys ManualDocument108 pagesAnsys Manual016 ARUNACHALAM S R MNo ratings yet

- Experiment: 01: Introduction To AnsysDocument21 pagesExperiment: 01: Introduction To AnsysApna VeerNo ratings yet

- ANSYS Utilities: Introduction To Finite Element Analysis Starting Up ANSYS ANSYS Environment ANSYS InterfaceDocument25 pagesANSYS Utilities: Introduction To Finite Element Analysis Starting Up ANSYS ANSYS Environment ANSYS InterfaceajmalNo ratings yet

- Eth Informatik Bachelor ThesisDocument6 pagesEth Informatik Bachelor ThesisCollegePaperHelpFargo100% (2)

- Sample Introduction For Thesis About ComputerDocument4 pagesSample Introduction For Thesis About ComputerBestWriteMyPaperWebsiteHighPoint100% (1)

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Composites ASTMDocument5 pagesComposites ASTMEirick Wayne Zuñigga De-ItzelNo ratings yet

- 1 s2.0 S0038092X11004294 MainDocument10 pages1 s2.0 S0038092X11004294 MainEirick Wayne Zuñigga De-ItzelNo ratings yet

- Progress in Aerospace Sciences: S.L. Chernyshev, A.M. Gaifullin, Yu.N. SviridenkoDocument17 pagesProgress in Aerospace Sciences: S.L. Chernyshev, A.M. Gaifullin, Yu.N. SviridenkoEirick Wayne Zuñigga De-ItzelNo ratings yet

- Progress in Aerospace Sciences: Mehdi Ghoreyshi, Adam Jirásek, Russell M. CummingsDocument51 pagesProgress in Aerospace Sciences: Mehdi Ghoreyshi, Adam Jirásek, Russell M. CummingsEirick Wayne Zuñigga De-ItzelNo ratings yet

- A Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Document9 pagesA Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Guia Overhaul 212Document13 pagesGuia Overhaul 212Eirick Wayne Zuñigga De-ItzelNo ratings yet

- ReamerDocument8 pagesReamerEirick Wayne Zuñigga De-Itzel100% (2)

- Universidad Politécnica Metropolitana de Hidalgo.: Área de Ingeniería. Ingeniería en AeronáuticaDocument2 pagesUniversidad Politécnica Metropolitana de Hidalgo.: Área de Ingeniería. Ingeniería en AeronáuticaEirick Wayne Zuñigga De-ItzelNo ratings yet

- 3300 Partsbook JuneDocument47 pages3300 Partsbook JuneEirick Wayne Zuñigga De-ItzelNo ratings yet

- The Manoeuvring EnvelopeDocument28 pagesThe Manoeuvring EnvelopeEirick Wayne Zuñigga De-ItzelNo ratings yet

- DWDWDocument1 pageDWDWEirick Wayne Zuñigga De-ItzelNo ratings yet

- Traditionally, The MPD Documents Recommended The Use of Block Checks (Letter Checks A, BDocument3 pagesTraditionally, The MPD Documents Recommended The Use of Block Checks (Letter Checks A, BEirick Wayne Zuñigga De-ItzelNo ratings yet

- Type The Document TitleDocument2 pagesType The Document TitleEirick Wayne Zuñigga De-ItzelNo ratings yet

- Tarea 2Document2 pagesTarea 2Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Carbon and Graphite FibersDocument8 pagesCarbon and Graphite FibersEirick Wayne Zuñigga De-ItzelNo ratings yet

- القائمة الالزامية لمنتجات التشييد والبناءDocument13 pagesالقائمة الالزامية لمنتجات التشييد والبناءm.thurwiNo ratings yet

- Device DriverDocument2 pagesDevice DriverglobalpiyushNo ratings yet

- Borland C++ Version 4.0 Users Guide Oct93 PDFDocument462 pagesBorland C++ Version 4.0 Users Guide Oct93 PDFgustavoutpzaNo ratings yet

- Automobile EngineeringDocument66 pagesAutomobile EngineeringŜṟéẻ Ṛąṁ Chowdary100% (1)

- ServiceNow Geneva Release Notes 8-30-2016Document5 pagesServiceNow Geneva Release Notes 8-30-2016Abhishek MishraNo ratings yet

- Aiptek CamcorderDocument36 pagesAiptek CamcorderIsaac Musiwa BandaNo ratings yet

- WebADM ManualDocument76 pagesWebADM Manualgeorges17100% (1)

- Me186 Me TC SurgingDocument2 pagesMe186 Me TC SurgingRani NoumanNo ratings yet

- Day / Night Sensor: DNS25 InstructionDocument1 pageDay / Night Sensor: DNS25 InstructionClea Marie Capacillo BatoonNo ratings yet

- 10 - Imperfection in Solids Point Defects in MetalsDocument12 pages10 - Imperfection in Solids Point Defects in MetalshussainNo ratings yet

- FQ MeterDocument2 pagesFQ MeterJJNo ratings yet

- AL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsDocument15 pagesAL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsSigma-AldrichNo ratings yet

- Koln VRS Tickets Prices Railway NetworkDocument2 pagesKoln VRS Tickets Prices Railway NetworkAndrei BarbuNo ratings yet

- A Review Paper On Technical Data of Present HVDC Links in IndiaDocument7 pagesA Review Paper On Technical Data of Present HVDC Links in IndiaEditor IJRITCCNo ratings yet

- Lenovo Server Storage Price List 2019 SingaporeDocument57 pagesLenovo Server Storage Price List 2019 SingaporeAnchor Business & IT SolutionsNo ratings yet

- Palamuru Lift SchemeDocument2 pagesPalamuru Lift Schemevaranasirk1No ratings yet

- Solutions Chapter6 PDFDocument21 pagesSolutions Chapter6 PDFAnonymous LNtXoE9fgu0% (1)

- DIB - Week 12 - FilterDocument46 pagesDIB - Week 12 - FilterIbrahimNo ratings yet

- The New Firewall Forward Camshaft: PointDocument1 pageThe New Firewall Forward Camshaft: PointAndri OdeNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Tara Apartments HousingDocument22 pagesTara Apartments Housing10Aboli MahajanNo ratings yet

- 6.project Implementation Approach - DR .HasliDocument44 pages6.project Implementation Approach - DR .HasliNoordin Abdul MajidNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- CYME Solar Impact Study ModulesDocument8 pagesCYME Solar Impact Study ModulesclicknagpalNo ratings yet

- Modeling and Control of Two Axis Gimbal System With Dynamic UnbalanceDocument3 pagesModeling and Control of Two Axis Gimbal System With Dynamic UnbalanceFaisal Khan JadoonNo ratings yet

- CBLM For Eim TMDocument57 pagesCBLM For Eim TMrommel montilla100% (2)

- General Information Guide: Release 7.0Document73 pagesGeneral Information Guide: Release 7.0Redoouane RedaNo ratings yet

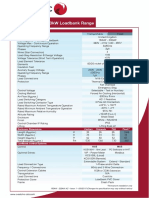

- Datasheet: 150 - 200kW Loadbank Range: DescriptionDocument2 pagesDatasheet: 150 - 200kW Loadbank Range: DescriptionTan Phuong LuongNo ratings yet

- App Builder Host PiDocument414 pagesApp Builder Host PiSadot Enrique Castillo GalanNo ratings yet

- Install GuideDocument2 pagesInstall GuideffdfNo ratings yet

Ansys History.

Ansys History.

Uploaded by

Eirick Wayne Zuñigga De-ItzelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansys History.

Ansys History.

Uploaded by

Eirick Wayne Zuñigga De-ItzelCopyright:

Available Formats

Erick Alberto Trejo Ziga IA Ansys

Universidad Politcnica Metropolitana de Hidalgo Aeronautical engineering Erick Alberto Trejo Ziga Finite element method ANSYS Ing. Celedonio Posadas Carlos 7A 1/Octubre/2013

Erick Alberto Trejo Ziga IA Ansys

Introduction:

Founded in 1970, ANSYS employs more than 2,100 professionals, and many of them are engineers expert in fields such as finite element analysis, computational fluid dynamics, electronics and electromagnetics, and design optimization. Our staff includes more masters and Ph.D.-level engineers than any other simulation provider. ANSYS is passionate about pushing the limits of world-class technology, all so our customers can turn their design concepts into successful, innovative products. The company has been recognized as one of the world's most innovative and fastest -growing companies by prestigious organizations including Business Week and FORTUNE magazines. Over the years, our steady growth and financial strength reflect our commitment to innovation and R&D. We reinvest 15 percent of our revenues each year into research to continually refine our software. We are listed on the NASDAQ stock exchange. ANSYS develops markets and supports engineering simulation software used to foresee how product designs will behave and how manufacturing processes will operate in real-world environments. We continually advance simulation solutions by, first, developing or acquiring the very best technology; then integrating it into a unified and customizable simulation platform that allows engineers to efficiently perform complex simulations involving the interaction of multiple physics; and, finally, providing system services to manage simulation processes and data all so engineers and product developers can spend more time designing and improving products and less time using software and searching for data. Engineering simulation is our sole focus. For more than 40 years, we have consistently advanced this technology to meet evolving customer needs.

Erick Alberto Trejo Ziga IA Ansys

Products:

History :

The usage of the Finite Element Method as a tool to solve engineering problems commercially in industrial applications is quite new. It was used in the late 1950s and early 60s, but not in the same way as it is today. The calculations were at that time carried out by hand and the method was force based, not displacement based as we use it today. In the mid 60s, very specialized computer programs were used to perform the analysis. The 1970s was the time when commercial programs started to emerge. At first, FEM was limited to expensive mainframe computers owned by the aeronautics, automotive, defense and nuclear industries. However, in the late 70s more companies started to use the FEM, and since then, the usage have grown very rapidly. Today commercial programs are very powerful and large, complex problems can be solved by one person on a PC. Many of them have the possibility to handle different kinds of physical phenomena such as e.g. thermo mechanics, electro mechanics and structural mechanics. One often talks about multiphysics, were different kinds of physical phenomena are coupled in the same analysis. There are many available commercial programs, ABAQUS, FLUENT, Comsol Multiphysics, and ANSYS are just a few examples. A full license of a finite element analysis program costs usually in the order of several ten thousands Euro. ANSYS is a widely used commercial general-purpose finite element analysis program.

Erick Alberto Trejo Ziga IA Ansys

Basic program structure :

Treatment of engineering problems basically contains three main parts: create a model, solve the problem, analyse the results. ANSYS, like many other FE-programs, is also divided into three main parts (processors) which are called preprocessor,solution processor, postprocessor. Other software may contain only the preprocessing part or only the postprocessing part. During the analysis you will communicate with ANSYS via a Graphical User Interface (GUI).

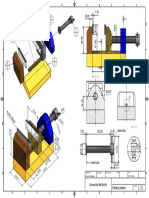

Figure 1: The ANSYS Graphical User Interface (GUI). 1. Utility menu: Here you can access and adjust properties about your session, such as file controls, listing and graphic controls. 2. Toolbar: Push buttons to commonly used commands. 3. Main menu: Here you can find the processors used when analysing your problem. 4. Graphics window: In the graphics window your model is displayed: geometry, elements, visualisation of results and so forth. 5. Input window: You can type commands in the input window.

Erick Alberto Trejo Ziga IA Ansys Preprocessor : Within the preprocessor the model is set up. It includes a number of steps and usually in the following order: Build geometry. Depending on whether the problem geometry is one, two or three dimensional, the geometry consists of creating lines, areas or volumes. These geometries can then, if necessary, be used to create other geometries by the use of boolean operations. The key idea when building the geometry like this is to simplify the generation of the element mesh. Hence, this step is optional but most often used. Nodes and elements can however be created from coordinates only. Define materials. A material is defined by its material constants. Every element has to be assigned a particular material. Generate element mesh. The problem is discretized with nodal points. The nodes are connected to form finite elements, which together form the material volume. Depending on the problem and the assumptions that are made, the element type has to be determined. Common element types are truss, beam, plate, shell and solid elements. Each element type may contain several subtypes, e.g. 2D 4-noded solid, 3D 20-noded solid elements. Therefore, care has to be taken when the element type is chosen. The element mesh can in ANSYS be created in several ways. The most common way is that it is automatically created, however more or less controlled. For example you can specify a certain number of elements in a specific area, or you can force the mesh generator to maintain a specific element size within an area. Certain element shapes or sizes are not recommended and if these limits are violated, a warning will be generated in ANSYS. It is up to the user to create a mesh which is able to generate results with a sufficient degree of accuracy. Solution processor: Here you solve the problem by gathering all specified information about the problem: Apply loads: Boundary conditions are usually applied on nodes or elements. The prescribed quantity can for example be force, traction, displacement, moment, rotation. The loads may in ANSYS also be edited from the preprocessor. Obtain solution: The solution to the problem can be obtained if the whole problem is defined. Postprocessor : Within this part of the analysis you can for example: Visualise the results: For example plot the deformed shape of the geometry or stresses. List the results: If you prefer tabular listings or file printouts, it is possible.

Erick Alberto Trejo Ziga IA Ansys

Similar Products:

1. 2. 3. 4. 5. 6. 7. 8. 9. Abaquis Cosmos Xpress Cosmos Works Comsol Nastran Patran Caelinux Freefem Openfem

Patran:

Patran is a program of computer-aided engineering (CAE), which provides a graphical interface to pre-and post-processing of finite element models and results. The MacNeal-Schwendler Corporation (MSC) is the company that sells it. Since both products are distributed by the same company, is often used as pre-and post-processor of Nastran. Simplified working sequence comprises: 1. Define a geometry. 2.Finite element meshing this geometry. 3. Assign properties to the finite elements. 4. Define the boundary conditions for each load case. 5.Define external loads applied for each load case. 6.Define the type of analysis. 7.Export an input file for a software finite element analysis and run. 8.Patran Import analysis results. 9. Analyze the results using the graphical interface.

Nastran:

is a structural analysis program which applies the finite element method (FEM). It was initially developed by the NASA1 to late 60s with funding from the U.S. government industia for aerospace. The MacNeal-Schwendler Corporation (MSC) was one of the main developers NASTRAN code, which originally was an open source public domain. Currently is The MacNealSchwendler Corporation (MSC), the company that distributes commercial versions of NASTRAN.1 Nastran is written in Fortran and its code consists of more than a million lines. Nastran is widely used in the aerospace industry.

Erick Alberto Trejo Ziga IA Ansys

COMSOL Multiphysics:

is a software package for analysis and resolution by finite elements for various physical and engineering applications, especially coupled phenomena, or multiphysics. COMSOL Multiphysics also offers an extensive and well-managed interface to MATLAB and its toolboxes that provide a wide variety of programming options, preprocessing and postprocessing. It also provides a similar interface to COMSOL Script. The packages are cross-platform (Windows, Mac, Linux, Unix.) In addition to the conventional user interfaces based on physical, COMSOL Multiphysics also allows for entering coupled systems of partial differential equations (PDE). The EDP can be entered directly or using the so-called weak form (see the finite element method for a description of weak formulation). COMSOL was started based on codes developed by a number of graduate students - Germund Dahlquist] for a graduate course in the Royal Institute of Technology (KTH) 1 in Stockholm, Sweden.

Erick Alberto Trejo Ziga IA Ansys

BIBLIOGRAPHY:

http://www.ansys.com http://web.archive.org/web/20090525143359/http://www.feaoptimization.com/ans_macro/ANS-history.txt

Introduction to a finite element analisys program: ANSYS

You might also like

- LCS310UR Diagrama2 PDFDocument13 pagesLCS310UR Diagrama2 PDFKnspeis0% (1)

- (1918) Louden Hay Unloading Tools (Catalogue)Document52 pages(1918) Louden Hay Unloading Tools (Catalogue)Herbert Hillary Booker 2nd100% (1)

- Specifications: VMC 4020 Table DimensionsDocument1 pageSpecifications: VMC 4020 Table DimensionsJhojan MuñozNo ratings yet

- Nadca 402 4aDocument44 pagesNadca 402 4awholenumberNo ratings yet

- Ind0101 - GDocument4 pagesInd0101 - Grajit kumarNo ratings yet

- Aluminios y Sus Equivalentes2Document1 pageAluminios y Sus Equivalentes2Augusto PeinadoNo ratings yet

- Tornillo BancoDocument1 pageTornillo Bancoalonsorebolledo3No ratings yet

- ME 322-Manufacturing Processes IDocument2 pagesME 322-Manufacturing Processes Ifirsttenor100% (1)

- SOLIDCast - Workbook Version 8.1.1Document388 pagesSOLIDCast - Workbook Version 8.1.1nurulapriliashNo ratings yet

- An Experimental Study To Corelate Water Jet Impingement Erosion Resistance and Properties of MetallicDocument12 pagesAn Experimental Study To Corelate Water Jet Impingement Erosion Resistance and Properties of MetallicsaatehNo ratings yet

- Ni ResistDocument2 pagesNi ResistAslan AlpNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- Caixas Rolamentos UsaDocument52 pagesCaixas Rolamentos Usakrlos_SW2009No ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- Halder Katalog N5 enDocument815 pagesHalder Katalog N5 enmilasko86No ratings yet

- Steelwise: Are You Properly Specifying Materials?Document9 pagesSteelwise: Are You Properly Specifying Materials?Muhammad AhsunNo ratings yet

- Formule Di MetallurgiaDocument24 pagesFormule Di MetallurgiaLuigi RizziNo ratings yet

- DIN 11851 Welding Liner 316Document1 pageDIN 11851 Welding Liner 316Omar Jesus Coca100% (1)

- Decimals and Fractions: A List of Metric and Imperial UnitsDocument2 pagesDecimals and Fractions: A List of Metric and Imperial UnitsRo Ad0% (2)

- Water Hammer Production and Design Measures in Piping SystemsDocument16 pagesWater Hammer Production and Design Measures in Piping SystemsSivashankar DhanarajNo ratings yet

- Analyze and Optimize Design of A Blender BladeDocument57 pagesAnalyze and Optimize Design of A Blender Bladenikhilesh PrashanthNo ratings yet

- Astm A209 PDFDocument3 pagesAstm A209 PDFgaminNo ratings yet

- Annealed Pickled SS Tubing (MS 02 315 ER0)Document2 pagesAnnealed Pickled SS Tubing (MS 02 315 ER0)herysyam1980No ratings yet

- Maquina para Hacer Clips (Modelo)Document2 pagesMaquina para Hacer Clips (Modelo)Samuel Silva0% (1)

- Hiline ManualDocument206 pagesHiline ManualkarthikNo ratings yet

- Optimal Configuration Design For Plate Heat Ex ChangersDocument16 pagesOptimal Configuration Design For Plate Heat Ex ChangersIvancu IonelNo ratings yet

- Determining Air Change in A Single Zone by Means of A Tracer Gas DilutionDocument18 pagesDetermining Air Change in A Single Zone by Means of A Tracer Gas DilutionGarima GuptaNo ratings yet

- Size MI N (In) Size MA X (In) Abrev Short Word Details Component SDocument16 pagesSize MI N (In) Size MA X (In) Abrev Short Word Details Component SAnthony InostrozaNo ratings yet

- Manual Solve ElecDocument28 pagesManual Solve ElecHenry HcNo ratings yet

- Seguridad en Los Procesos de Soldadura y CorteDocument33 pagesSeguridad en Los Procesos de Soldadura y CorteGino Chavez ValenciaNo ratings yet

- Engineering & Design: Geometric Dimensioning: SectionDocument34 pagesEngineering & Design: Geometric Dimensioning: SectionVinaya Almane DattathreyaNo ratings yet

- Everything You Need To Know About Flatteners and Levelers For Coil Processing - Part IVDocument7 pagesEverything You Need To Know About Flatteners and Levelers For Coil Processing - Part IVertuokumusNo ratings yet

- PS9172S SpotweldDocument13 pagesPS9172S SpotweldmanuelNo ratings yet

- Cadcam (Milling)Document29 pagesCadcam (Milling)Md Rasid SamsuriNo ratings yet

- Quick Start Guide For X1&X1-Carbon-v1Document16 pagesQuick Start Guide For X1&X1-Carbon-v1darkoteamNo ratings yet

- Estrella de Genova CadDocument2 pagesEstrella de Genova CadIng Miguel Angel Rmz HdezNo ratings yet

- Smart Maze Robot ReportDocument40 pagesSmart Maze Robot ReporttarunudayakumarNo ratings yet

- Bolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 pagesBolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- Deep Drawing Analysis by Using Explicit Dynamics in Ansys WorkbenchDocument8 pagesDeep Drawing Analysis by Using Explicit Dynamics in Ansys Workbenchsunhell1611No ratings yet

- Horizon Software: Materials Testing, Analysis and Reporting SoftwareDocument12 pagesHorizon Software: Materials Testing, Analysis and Reporting SoftwareBilly HorshamNo ratings yet

- Hex Jam Nut, SAE J995 Grade 5, Plain Finish: DocumentosDocument2 pagesHex Jam Nut, SAE J995 Grade 5, Plain Finish: DocumentosDiego ChavezNo ratings yet

- Soft Annealing Heat Treatment PDFDocument6 pagesSoft Annealing Heat Treatment PDFsivajirao70No ratings yet

- Estimating The Largest Grain Observed in A Metallographic SectionDocument6 pagesEstimating The Largest Grain Observed in A Metallographic SectionMirtunjayKumarNo ratings yet

- Flame Spraying Gun Uni Spray JetDocument5 pagesFlame Spraying Gun Uni Spray JetCristobal MontalbaNo ratings yet

- 6.1 Catalogo Taladro Fresador PDM - 45-Manual en InglesDocument17 pages6.1 Catalogo Taladro Fresador PDM - 45-Manual en InglesHenry DavichoNo ratings yet

- Datasheet Sandvik 14c28n enDocument3 pagesDatasheet Sandvik 14c28n ensondeadorNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- Ansys TutorialsDocument24 pagesAnsys TutorialsMahdiNo ratings yet

- Ansys14 Classic TutorialDocument21 pagesAnsys14 Classic TutorialMAXNo ratings yet

- Tutorial Completo AnsysDocument416 pagesTutorial Completo AnsysWanderson Horta100% (2)

- Bilder in Bachelor ThesisDocument6 pagesBilder in Bachelor ThesisTye Rausch100% (2)

- ADS Tutorial: A Beginners Tutorial: Modes of OperationDocument13 pagesADS Tutorial: A Beginners Tutorial: Modes of OperationYounes Ait El MaatiNo ratings yet

- Introduction of AnsysDocument3 pagesIntroduction of Ansys20MCE 01 Mehwish KhanNo ratings yet

- Ansys - MEMS Lab IntroductionDocument9 pagesAnsys - MEMS Lab IntroductionJag JagNo ratings yet

- Ansys ManualDocument108 pagesAnsys Manual016 ARUNACHALAM S R MNo ratings yet

- Experiment: 01: Introduction To AnsysDocument21 pagesExperiment: 01: Introduction To AnsysApna VeerNo ratings yet

- ANSYS Utilities: Introduction To Finite Element Analysis Starting Up ANSYS ANSYS Environment ANSYS InterfaceDocument25 pagesANSYS Utilities: Introduction To Finite Element Analysis Starting Up ANSYS ANSYS Environment ANSYS InterfaceajmalNo ratings yet

- Eth Informatik Bachelor ThesisDocument6 pagesEth Informatik Bachelor ThesisCollegePaperHelpFargo100% (2)

- Sample Introduction For Thesis About ComputerDocument4 pagesSample Introduction For Thesis About ComputerBestWriteMyPaperWebsiteHighPoint100% (1)

- Constituent Content (ASTM D3171) : Composite Materials LaboratoryDocument1 pageConstituent Content (ASTM D3171) : Composite Materials LaboratoryEirick Wayne Zuñigga De-ItzelNo ratings yet

- Composites ASTMDocument5 pagesComposites ASTMEirick Wayne Zuñigga De-ItzelNo ratings yet

- 1 s2.0 S0038092X11004294 MainDocument10 pages1 s2.0 S0038092X11004294 MainEirick Wayne Zuñigga De-ItzelNo ratings yet

- Progress in Aerospace Sciences: S.L. Chernyshev, A.M. Gaifullin, Yu.N. SviridenkoDocument17 pagesProgress in Aerospace Sciences: S.L. Chernyshev, A.M. Gaifullin, Yu.N. SviridenkoEirick Wayne Zuñigga De-ItzelNo ratings yet

- Progress in Aerospace Sciences: Mehdi Ghoreyshi, Adam Jirásek, Russell M. CummingsDocument51 pagesProgress in Aerospace Sciences: Mehdi Ghoreyshi, Adam Jirásek, Russell M. CummingsEirick Wayne Zuñigga De-ItzelNo ratings yet

- A Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Document9 pagesA Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Guia Overhaul 212Document13 pagesGuia Overhaul 212Eirick Wayne Zuñigga De-ItzelNo ratings yet

- ReamerDocument8 pagesReamerEirick Wayne Zuñigga De-Itzel100% (2)

- Universidad Politécnica Metropolitana de Hidalgo.: Área de Ingeniería. Ingeniería en AeronáuticaDocument2 pagesUniversidad Politécnica Metropolitana de Hidalgo.: Área de Ingeniería. Ingeniería en AeronáuticaEirick Wayne Zuñigga De-ItzelNo ratings yet

- 3300 Partsbook JuneDocument47 pages3300 Partsbook JuneEirick Wayne Zuñigga De-ItzelNo ratings yet

- The Manoeuvring EnvelopeDocument28 pagesThe Manoeuvring EnvelopeEirick Wayne Zuñigga De-ItzelNo ratings yet

- DWDWDocument1 pageDWDWEirick Wayne Zuñigga De-ItzelNo ratings yet

- Traditionally, The MPD Documents Recommended The Use of Block Checks (Letter Checks A, BDocument3 pagesTraditionally, The MPD Documents Recommended The Use of Block Checks (Letter Checks A, BEirick Wayne Zuñigga De-ItzelNo ratings yet

- Type The Document TitleDocument2 pagesType The Document TitleEirick Wayne Zuñigga De-ItzelNo ratings yet

- Tarea 2Document2 pagesTarea 2Eirick Wayne Zuñigga De-ItzelNo ratings yet

- Carbon and Graphite FibersDocument8 pagesCarbon and Graphite FibersEirick Wayne Zuñigga De-ItzelNo ratings yet

- القائمة الالزامية لمنتجات التشييد والبناءDocument13 pagesالقائمة الالزامية لمنتجات التشييد والبناءm.thurwiNo ratings yet

- Device DriverDocument2 pagesDevice DriverglobalpiyushNo ratings yet

- Borland C++ Version 4.0 Users Guide Oct93 PDFDocument462 pagesBorland C++ Version 4.0 Users Guide Oct93 PDFgustavoutpzaNo ratings yet

- Automobile EngineeringDocument66 pagesAutomobile EngineeringŜṟéẻ Ṛąṁ Chowdary100% (1)

- ServiceNow Geneva Release Notes 8-30-2016Document5 pagesServiceNow Geneva Release Notes 8-30-2016Abhishek MishraNo ratings yet

- Aiptek CamcorderDocument36 pagesAiptek CamcorderIsaac Musiwa BandaNo ratings yet

- WebADM ManualDocument76 pagesWebADM Manualgeorges17100% (1)

- Me186 Me TC SurgingDocument2 pagesMe186 Me TC SurgingRani NoumanNo ratings yet

- Day / Night Sensor: DNS25 InstructionDocument1 pageDay / Night Sensor: DNS25 InstructionClea Marie Capacillo BatoonNo ratings yet

- 10 - Imperfection in Solids Point Defects in MetalsDocument12 pages10 - Imperfection in Solids Point Defects in MetalshussainNo ratings yet

- FQ MeterDocument2 pagesFQ MeterJJNo ratings yet

- AL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsDocument15 pagesAL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsSigma-AldrichNo ratings yet

- Koln VRS Tickets Prices Railway NetworkDocument2 pagesKoln VRS Tickets Prices Railway NetworkAndrei BarbuNo ratings yet

- A Review Paper On Technical Data of Present HVDC Links in IndiaDocument7 pagesA Review Paper On Technical Data of Present HVDC Links in IndiaEditor IJRITCCNo ratings yet

- Lenovo Server Storage Price List 2019 SingaporeDocument57 pagesLenovo Server Storage Price List 2019 SingaporeAnchor Business & IT SolutionsNo ratings yet

- Palamuru Lift SchemeDocument2 pagesPalamuru Lift Schemevaranasirk1No ratings yet

- Solutions Chapter6 PDFDocument21 pagesSolutions Chapter6 PDFAnonymous LNtXoE9fgu0% (1)

- DIB - Week 12 - FilterDocument46 pagesDIB - Week 12 - FilterIbrahimNo ratings yet

- The New Firewall Forward Camshaft: PointDocument1 pageThe New Firewall Forward Camshaft: PointAndri OdeNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Tara Apartments HousingDocument22 pagesTara Apartments Housing10Aboli MahajanNo ratings yet

- 6.project Implementation Approach - DR .HasliDocument44 pages6.project Implementation Approach - DR .HasliNoordin Abdul MajidNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- CYME Solar Impact Study ModulesDocument8 pagesCYME Solar Impact Study ModulesclicknagpalNo ratings yet

- Modeling and Control of Two Axis Gimbal System With Dynamic UnbalanceDocument3 pagesModeling and Control of Two Axis Gimbal System With Dynamic UnbalanceFaisal Khan JadoonNo ratings yet

- CBLM For Eim TMDocument57 pagesCBLM For Eim TMrommel montilla100% (2)

- General Information Guide: Release 7.0Document73 pagesGeneral Information Guide: Release 7.0Redoouane RedaNo ratings yet

- Datasheet: 150 - 200kW Loadbank Range: DescriptionDocument2 pagesDatasheet: 150 - 200kW Loadbank Range: DescriptionTan Phuong LuongNo ratings yet

- App Builder Host PiDocument414 pagesApp Builder Host PiSadot Enrique Castillo GalanNo ratings yet

- Install GuideDocument2 pagesInstall GuideffdfNo ratings yet