Professional Documents

Culture Documents

332C

332C

Uploaded by

Lo Siento de VerdadCopyright:

Available Formats

You might also like

- Obsolescence Management in The Supply Chain With The IEC 62402-2019 Standard - Sergio GarciaDocument17 pagesObsolescence Management in The Supply Chain With The IEC 62402-2019 Standard - Sergio GarciaEduardo Jorge pintoNo ratings yet

- Denwacho CivilDocument15 pagesDenwacho CivilAli WaqasNo ratings yet

- Solution Manual Mechanical Engineering Principles John Bird 1Document24 pagesSolution Manual Mechanical Engineering Principles John Bird 1ridwansadely100% (1)

- Form Calibration EquipmentDocument5 pagesForm Calibration EquipmentLelie Eka Nurningtias IINo ratings yet

- Owner'S Manual: M4 A1 Carbine - M4 CQB - M4 CQCDocument28 pagesOwner'S Manual: M4 A1 Carbine - M4 CQB - M4 CQCbahriun syahriNo ratings yet

- Ansi 107 VS 207 (2009)Document13 pagesAnsi 107 VS 207 (2009)RobVajko100% (1)

- NE01 103RevACDocument25 pagesNE01 103RevACMarlene Yuriserll Ruiz MuñozNo ratings yet

- Norma EN 746-2Document13 pagesNorma EN 746-2RobertoSerraoNo ratings yet

- KodaksDocument723 pagesKodaksorestes100% (1)

- FB2255 Series Instrument PC2255: Service ManualDocument125 pagesFB2255 Series Instrument PC2255: Service ManualAldo Angel ValdiviaNo ratings yet

- Niosh 6009 PDFDocument5 pagesNiosh 6009 PDFCaleb ConnerNo ratings yet

- Plastometer MP200Document138 pagesPlastometer MP200Ricardo0% (1)

- Vibration Meter 2513Document6 pagesVibration Meter 2513info5280No ratings yet

- Fast Guide To Oee PDFDocument27 pagesFast Guide To Oee PDFAtakan TunaliNo ratings yet

- TCVN 5040-1990 (ISO 6790-1986) Equipment For Fire Protection and Fire Fighting - Graphical Symbols For Fire Protection Plans - Specifications PDFDocument14 pagesTCVN 5040-1990 (ISO 6790-1986) Equipment For Fire Protection and Fire Fighting - Graphical Symbols For Fire Protection Plans - Specifications PDFDoThanhTungNo ratings yet

- Implementation of Lean Warehousing To Reduce The Level of Returns in A Distribution CompanyDocument5 pagesImplementation of Lean Warehousing To Reduce The Level of Returns in A Distribution CompanyIbrahim SkakriNo ratings yet

- 1762 of 4 Data FormatDocument2 pages1762 of 4 Data FormatSANKPLYNo ratings yet

- Wirtz Cork and Product BrochureDocument9 pagesWirtz Cork and Product BrochureKy VuNo ratings yet

- Technology Audit: David P JasperDocument3 pagesTechnology Audit: David P Jasperjeferson zapataNo ratings yet

- Ctpat Prog Benefits GuideDocument4 pagesCtpat Prog Benefits Guidenilantha_bNo ratings yet

- Ohsas 18001 2007 - HseDocument6 pagesOhsas 18001 2007 - HseirfanahmarNo ratings yet

- Itc Te210eDocument2 pagesItc Te210ezliang100% (2)

- A3 Dos 2014 OctubreDocument17 pagesA3 Dos 2014 OctubreJavier AvilaNo ratings yet

- Nom 004 STPS 1999Document1 pageNom 004 STPS 1999Eduardo DiazNo ratings yet

- 3M 6800 Full Face MaskDocument6 pages3M 6800 Full Face MaskAlvarioNo ratings yet

- FMDS0788Document45 pagesFMDS0788hhNo ratings yet

- TD1002 Heat Transfer Datasheet PDFDocument2 pagesTD1002 Heat Transfer Datasheet PDFlecala 205No ratings yet

- PET cb-602Document1 pagePET cb-602hervian100% (1)

- Flyer Mach2 en 02Document2 pagesFlyer Mach2 en 02Abdelhamid Chergui0% (1)

- Case 5 WinnebagoDocument7 pagesCase 5 WinnebagoUsmanNo ratings yet

- Structure Fires Caused by Hot Work: Marty AhrensDocument14 pagesStructure Fires Caused by Hot Work: Marty AhrensBurgosg ValeryNo ratings yet

- ISO 22002-5 Requisitos Previos de Seguridad Alimentaria en El Transporte y AlmacenamientoDocument34 pagesISO 22002-5 Requisitos Previos de Seguridad Alimentaria en El Transporte y AlmacenamientoCarlos lopezNo ratings yet

- Ibm 4610-2CR and 2NR Service ManualDocument132 pagesIbm 4610-2CR and 2NR Service ManualAngel L.Hernandez OcasioNo ratings yet

- Gigabyte GA-H61M-S1 r3.0 BoardviewDocument2 pagesGigabyte GA-H61M-S1 r3.0 BoardviewANH TUANNo ratings yet

- Eclipse Airheat Burners: Ah-Ma SeriesDocument22 pagesEclipse Airheat Burners: Ah-Ma Seriescarlosloucao100% (1)

- Tuff Gut Brochure 11x17Document2 pagesTuff Gut Brochure 11x17Leonardo Alvarez0% (1)

- PWC Sci 112008Document48 pagesPWC Sci 112008lovologisticsNo ratings yet

- Learning To EvolveDocument44 pagesLearning To EvolveJohn VatistasNo ratings yet

- 3 - BRWall BR40 Video Wall Controller Datasheet - v3.7Document32 pages3 - BRWall BR40 Video Wall Controller Datasheet - v3.7Vero AcunaNo ratings yet

- AADvance Manual de SeguridadDocument134 pagesAADvance Manual de SeguridadIsaac MendibleNo ratings yet

- Iso 11734 1995Document9 pagesIso 11734 1995Sohila ashorNo ratings yet

- Cambium Spectrum AnalyzerDocument7 pagesCambium Spectrum AnalyzerRaafat Younis100% (1)

- Terminal Stud Size ChartDocument1 pageTerminal Stud Size ChartLi RusNo ratings yet

- DeltaDocument20 pagesDeltaClaudio TurlherNo ratings yet

- Chili Pepper Consumption and Gastric Cancer in Mexico: A Case-Control StudyDocument11 pagesChili Pepper Consumption and Gastric Cancer in Mexico: A Case-Control StudyChristian Trejo AlanyaNo ratings yet

- FMDS07111FDocument8 pagesFMDS07111Fyerrisiddappa KNo ratings yet

- Manual Detector de GasesDocument221 pagesManual Detector de GasesjimenezjacoboNo ratings yet

- Msds Mt-Floc-8655 (1) (Ingles)Document3 pagesMsds Mt-Floc-8655 (1) (Ingles)LuzMarinaYucraNo ratings yet

- ASTM D454 04 - Standard Test Method For Rubber Deterioration by Heat and Air PressureDocument4 pagesASTM D454 04 - Standard Test Method For Rubber Deterioration by Heat and Air PressureAndre SpirimNo ratings yet

- Screw Compressor Air Cooled Chiller CatalogDocument64 pagesScrew Compressor Air Cooled Chiller CatalogManuel Guardia AraujoNo ratings yet

- Mde/Mdg17Cs: Turbovent TechnologyDocument2 pagesMde/Mdg17Cs: Turbovent TechnologyMási de LaféNo ratings yet

- Glycol Dehydration Systems BrochureDocument2 pagesGlycol Dehydration Systems BrochureJenny BuchananNo ratings yet

- Superior Performance Through Innovative Technology - VEGA IndustriesDocument72 pagesSuperior Performance Through Innovative Technology - VEGA IndustriesNael50% (2)

- Broch 6700 New 1Document2 pagesBroch 6700 New 1rumboherbalNo ratings yet

- Double Flap Gate ValvesDocument16 pagesDouble Flap Gate ValvesMatias MancillaNo ratings yet

- DM45 - Series: Atlas Copco Blasthole DrillsDocument4 pagesDM45 - Series: Atlas Copco Blasthole DrillsYo'lbin Salvatierra BaltazarNo ratings yet

- ManualDocument8 pagesManualSherif AdelNo ratings yet

- Perforadora Sobre OrugaDocument28 pagesPerforadora Sobre OrugaHenrry RVNo ratings yet

- MD6240 2 PDFDocument28 pagesMD6240 2 PDFWill WeinsoffNo ratings yet

- Tunnel Boring Machine PDFDocument2 pagesTunnel Boring Machine PDFfritzNo ratings yet

- SullaireDocument12 pagesSullaireAnonymous 61zHIpNo ratings yet

- Pipe and Fittings Data ChartsDocument20 pagesPipe and Fittings Data ChartskavNo ratings yet

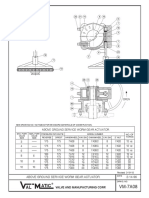

- AL Atic: Above Ground Service Worm Gear Actuator 2-14-96Document1 pageAL Atic: Above Ground Service Worm Gear Actuator 2-14-96Lo Siento de VerdadNo ratings yet

- WEB Latinomineria 74 PDFDocument84 pagesWEB Latinomineria 74 PDFLo Siento de VerdadNo ratings yet

- Europe's Premier Manufacturer of Aftermarket Crusher Spare and Wear PartsDocument6 pagesEurope's Premier Manufacturer of Aftermarket Crusher Spare and Wear PartsLo Siento de VerdadNo ratings yet

- SBS STT Battery Instruction ManualDocument12 pagesSBS STT Battery Instruction ManualLo Siento de VerdadNo ratings yet

- Ts Battery PaperDocument2 pagesTs Battery PaperLo Siento de VerdadNo ratings yet

- The Truth About Batteries-White PaperDocument13 pagesThe Truth About Batteries-White PaperRahul ShelkeNo ratings yet

- Diapositivas Clase 02Document37 pagesDiapositivas Clase 02Lo Siento de VerdadNo ratings yet

- Engineering DynamicsDocument17 pagesEngineering DynamicsLo Siento de VerdadNo ratings yet

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 pagesBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNo ratings yet

- Multiple Choice: Encircle The Letter of The Correct AnswerDocument2 pagesMultiple Choice: Encircle The Letter of The Correct AnswerNieva MinitivaNo ratings yet

- Cyclic IrregulaityDocument41 pagesCyclic IrregulaitypeterNo ratings yet

- Spesifikasi Teknis Pengadaan Peralatan Laboratorium: Direktorat Jenderal Perikanan BudidayaDocument6 pagesSpesifikasi Teknis Pengadaan Peralatan Laboratorium: Direktorat Jenderal Perikanan BudidayaSanabil CitraNo ratings yet

- FreyrSCADA DNP Client Simulator User ManualDocument12 pagesFreyrSCADA DNP Client Simulator User ManualThiago AlvesNo ratings yet

- Influence of Polymer On The Performance of Bentonite As A Drilling FluidDocument6 pagesInfluence of Polymer On The Performance of Bentonite As A Drilling FluidLutfur RahmanNo ratings yet

- Unit IDocument54 pagesUnit ISrivatsan SureshNo ratings yet

- EASEUS Partition Master 6.1.1 Professional Edition HELPDocument27 pagesEASEUS Partition Master 6.1.1 Professional Edition HELPthisiscoffeeNo ratings yet

- Paulaner CloneDocument1 pagePaulaner CloneandreililioanceaNo ratings yet

- Fractional Time Delay Estimation AlgorithmDocument8 pagesFractional Time Delay Estimation AlgorithmandradesosNo ratings yet

- Mav Ip Physics-1Document8 pagesMav Ip Physics-1poojitnatarajanNo ratings yet

- Quality Assurance of Laboratory Results: A Challenge in Health Care ManagementDocument6 pagesQuality Assurance of Laboratory Results: A Challenge in Health Care Managementrizkiyah prabawantiNo ratings yet

- Stable, Bounded and Periodic Solutions in A Non-Linear Second Order Ordinary Differential Equation.Document5 pagesStable, Bounded and Periodic Solutions in A Non-Linear Second Order Ordinary Differential Equation.AJER JOURNALNo ratings yet

- DX DiagDocument30 pagesDX Diagtheresa.rgscapizNo ratings yet

- Database Fundamentals by Theophilus EdetDocument230 pagesDatabase Fundamentals by Theophilus EdetSebastian A. Montanchez SaldarriagaNo ratings yet

- Configuring Tomcat To Work With IISDocument3 pagesConfiguring Tomcat To Work With IISWill Wolff-MyrenNo ratings yet

- Putchars: Chapter 4 Macro Function - Scredit Software User ManualDocument7 pagesPutchars: Chapter 4 Macro Function - Scredit Software User ManualryoNo ratings yet

- 6 16Document2 pages6 16Indira KarimovaNo ratings yet

- Chapter 2Document50 pagesChapter 2mopliqNo ratings yet

- Training FileDocument7 pagesTraining Filenarindersingh7302789No ratings yet

- 五十铃isuzu Hatichi 4hk1 6hk1 ManualDocument351 pages五十铃isuzu Hatichi 4hk1 6hk1 Manual蔡苏100% (2)

- Spec Sheet SD200Document8 pagesSpec Sheet SD200Yohanes ArgamNo ratings yet

- VCF Anhydrous Ammonia (NH3)Document4 pagesVCF Anhydrous Ammonia (NH3)Edgar GuardiaNo ratings yet

- EE 355 A: Computer Programming in C++ (E) : (Lecture-2) TopicDocument10 pagesEE 355 A: Computer Programming in C++ (E) : (Lecture-2) TopicluckyNo ratings yet

- NOTES (2023-2024) Subject: Physics Lab Manual Class: Xii Sec: A Experiment No:3 - Concave MirrorDocument5 pagesNOTES (2023-2024) Subject: Physics Lab Manual Class: Xii Sec: A Experiment No:3 - Concave MirrorKing of KingsNo ratings yet

- SNIPPETS Everything You Wanted To Know About ThemDocument6 pagesSNIPPETS Everything You Wanted To Know About ThemDadang KurniaNo ratings yet

- Vlsi Design UNIT-1: Lecture-2Document4 pagesVlsi Design UNIT-1: Lecture-2Venky VenkateshNo ratings yet

- Mebu S.4 Maths 2024Document5 pagesMebu S.4 Maths 2024akyatwinejoshua100% (3)

- Static Electricity Static ElectricityDocument4 pagesStatic Electricity Static ElectricitycashmoneybagsNo ratings yet

- Student Worksheet #1 - How Airbags WorkDocument2 pagesStudent Worksheet #1 - How Airbags WorkEman FatimaNo ratings yet

332C

332C

Uploaded by

Lo Siento de VerdadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

332C

332C

Uploaded by

Lo Siento de VerdadCopyright:

Available Formats

INDUSTRIAL GRID CASTING MACHINE MODEL 332C

THE WIRTZ MODEL 332C GRID CASTER FOR PRODUCTION OF INDUSTRIAL BATTERY GRIDS USING EITHER LEAD CALCIUM OR LEAD ANTIMONY TO PRODUCE HIGH QUALITY GRIDS.

The 332C Industrial Grid Caster is an easy to operate, easy to maintain machine, producing uniform size and weight grids - in four to twelve cycles per minute. It features a unique grid transfer mechanism with grid centering and a pallet die entry mechanism that eliminates jams and mis-trims. As a result, the 332C can produce up to 60% more grids than competitive casters. All machines have complete internal piping for gas, air, water and mold coolant. Additionally, a rubberized internal scrap conveyor belt returns waste to the melting pot. For increased production and improved quality, the Wirtz 332C caster is the hands down winner for calcium or antimony alloys.

INDUSTRIAL GRID CASTING MACHINE MODEL 332C

General Specifications Variable speed drive. Machine speed of 4-12 cycles per minute depending on grid type, thickness, and grid alloy. Standard mold sizes are 10.25" (260.35mm) x 24" (609.6mm), 30" (762mm) or 32" (812.8mm). Will accept mold sizes of 12" (304.8mm) x 24" (609.6mm) or 32" (812.8mm) , 13" (330.2mm) x 30" (762mm), and 13" (330.2mm) x 32" (812.8mm). Standard grid sizes are from 5.375" (136.53mm) to 8.25" (209.55mm) wide and from 9.25" (234.95mm) to 25.25" (641.25mm) high not including lugs. Maximum lug to lug dimension 27.25" (692.15mm). Special alterations can be made to increase maximum grid width from 8.25" (209.55mm) to 9.25" (234.95mm). All internal piping is complete for gas, air, water and mold coolant. Swing out mold corking bracket for easy accessibility to the mold for corking, washing and changing. Air filter, regulator and lubricator for air system. Heat and ventilation shields and hoods over ladle remove heat and gases for comfort and safety. Standard color of machine is Wirtz Blue with safety yellow guards. Grid take-off at 32 (812.8mm) for ergonomic handling. Motors located under the grid caster to minimize layout profile. Separate air regulator and quick connect hose for mold airflow vent bars. Options Special trim die sizes 5.375" (136.53mm) thru 8.25" (209.55mm) Ammeters to monitor electric heater circuits ( indicate malfunction of heater circuit). Can be supplied for electric ladle, electric mold heaters and electric feedline. Mold wash pans and brush for cleaning molds. Speed indicator.

Sight gauges for all mold coolant lines. Power mold corking bracket (air operated). Modifications to accept up to 9.25" (234.95mm) trimmed grids (gate only). Castmaster 2000 automated temperature control and speed control system for optimum quality and quantity production. Die lubricating system for Model 332C. Manifold piping for ease in machine set-up. Second lead delivery system for use with different lead alloy. Allen Bradley series SLC-500 PLC controller available. Utility Requirements Cooling Water Supply Temperature: Volume: Pressure: Air Volume: Pressure: Fuel Pressure:

Max 75 deg F (24 deg C) 100 GPH (375 Liters/Hr) 80 PSI (5520 m bar) max 20 PSI (1380 m bar) min Optimum 4 CFM (.1 m Cu/Min) 100 PSI (6900 m bar) max 80 PSI (5520 m bar) min

14" WC (350mmWC) max 5" WC (127mmWC) min Natural Gas 1000 BTU/CuFt Volume: 25 CFH (.7 M Cu/Hr) Propane 2500 BTU/CuFt Volume: 10 CFH (.3 M Cu/Hr) Ventilation (Note figure may also be included in the ventilation requirements for the furnace) Volume: 1000 CFM (28.2 M Cu/Hr) Electrical 460v, 60hz, 3-phase standard 200v to 575v, 50hz or 60hz, 3-phase available upon request

BATTERYRECYCLING

S Y S T E M S

1105 Twenty-Fourth Street, P .O.Box 5006, Port Huron, MI USA 48061 1.810.987.7600 Fax: 1.810.987.8135 email: wolsales@wirtzusa.com

You might also like

- Obsolescence Management in The Supply Chain With The IEC 62402-2019 Standard - Sergio GarciaDocument17 pagesObsolescence Management in The Supply Chain With The IEC 62402-2019 Standard - Sergio GarciaEduardo Jorge pintoNo ratings yet

- Denwacho CivilDocument15 pagesDenwacho CivilAli WaqasNo ratings yet

- Solution Manual Mechanical Engineering Principles John Bird 1Document24 pagesSolution Manual Mechanical Engineering Principles John Bird 1ridwansadely100% (1)

- Form Calibration EquipmentDocument5 pagesForm Calibration EquipmentLelie Eka Nurningtias IINo ratings yet

- Owner'S Manual: M4 A1 Carbine - M4 CQB - M4 CQCDocument28 pagesOwner'S Manual: M4 A1 Carbine - M4 CQB - M4 CQCbahriun syahriNo ratings yet

- Ansi 107 VS 207 (2009)Document13 pagesAnsi 107 VS 207 (2009)RobVajko100% (1)

- NE01 103RevACDocument25 pagesNE01 103RevACMarlene Yuriserll Ruiz MuñozNo ratings yet

- Norma EN 746-2Document13 pagesNorma EN 746-2RobertoSerraoNo ratings yet

- KodaksDocument723 pagesKodaksorestes100% (1)

- FB2255 Series Instrument PC2255: Service ManualDocument125 pagesFB2255 Series Instrument PC2255: Service ManualAldo Angel ValdiviaNo ratings yet

- Niosh 6009 PDFDocument5 pagesNiosh 6009 PDFCaleb ConnerNo ratings yet

- Plastometer MP200Document138 pagesPlastometer MP200Ricardo0% (1)

- Vibration Meter 2513Document6 pagesVibration Meter 2513info5280No ratings yet

- Fast Guide To Oee PDFDocument27 pagesFast Guide To Oee PDFAtakan TunaliNo ratings yet

- TCVN 5040-1990 (ISO 6790-1986) Equipment For Fire Protection and Fire Fighting - Graphical Symbols For Fire Protection Plans - Specifications PDFDocument14 pagesTCVN 5040-1990 (ISO 6790-1986) Equipment For Fire Protection and Fire Fighting - Graphical Symbols For Fire Protection Plans - Specifications PDFDoThanhTungNo ratings yet

- Implementation of Lean Warehousing To Reduce The Level of Returns in A Distribution CompanyDocument5 pagesImplementation of Lean Warehousing To Reduce The Level of Returns in A Distribution CompanyIbrahim SkakriNo ratings yet

- 1762 of 4 Data FormatDocument2 pages1762 of 4 Data FormatSANKPLYNo ratings yet

- Wirtz Cork and Product BrochureDocument9 pagesWirtz Cork and Product BrochureKy VuNo ratings yet

- Technology Audit: David P JasperDocument3 pagesTechnology Audit: David P Jasperjeferson zapataNo ratings yet

- Ctpat Prog Benefits GuideDocument4 pagesCtpat Prog Benefits Guidenilantha_bNo ratings yet

- Ohsas 18001 2007 - HseDocument6 pagesOhsas 18001 2007 - HseirfanahmarNo ratings yet

- Itc Te210eDocument2 pagesItc Te210ezliang100% (2)

- A3 Dos 2014 OctubreDocument17 pagesA3 Dos 2014 OctubreJavier AvilaNo ratings yet

- Nom 004 STPS 1999Document1 pageNom 004 STPS 1999Eduardo DiazNo ratings yet

- 3M 6800 Full Face MaskDocument6 pages3M 6800 Full Face MaskAlvarioNo ratings yet

- FMDS0788Document45 pagesFMDS0788hhNo ratings yet

- TD1002 Heat Transfer Datasheet PDFDocument2 pagesTD1002 Heat Transfer Datasheet PDFlecala 205No ratings yet

- PET cb-602Document1 pagePET cb-602hervian100% (1)

- Flyer Mach2 en 02Document2 pagesFlyer Mach2 en 02Abdelhamid Chergui0% (1)

- Case 5 WinnebagoDocument7 pagesCase 5 WinnebagoUsmanNo ratings yet

- Structure Fires Caused by Hot Work: Marty AhrensDocument14 pagesStructure Fires Caused by Hot Work: Marty AhrensBurgosg ValeryNo ratings yet

- ISO 22002-5 Requisitos Previos de Seguridad Alimentaria en El Transporte y AlmacenamientoDocument34 pagesISO 22002-5 Requisitos Previos de Seguridad Alimentaria en El Transporte y AlmacenamientoCarlos lopezNo ratings yet

- Ibm 4610-2CR and 2NR Service ManualDocument132 pagesIbm 4610-2CR and 2NR Service ManualAngel L.Hernandez OcasioNo ratings yet

- Gigabyte GA-H61M-S1 r3.0 BoardviewDocument2 pagesGigabyte GA-H61M-S1 r3.0 BoardviewANH TUANNo ratings yet

- Eclipse Airheat Burners: Ah-Ma SeriesDocument22 pagesEclipse Airheat Burners: Ah-Ma Seriescarlosloucao100% (1)

- Tuff Gut Brochure 11x17Document2 pagesTuff Gut Brochure 11x17Leonardo Alvarez0% (1)

- PWC Sci 112008Document48 pagesPWC Sci 112008lovologisticsNo ratings yet

- Learning To EvolveDocument44 pagesLearning To EvolveJohn VatistasNo ratings yet

- 3 - BRWall BR40 Video Wall Controller Datasheet - v3.7Document32 pages3 - BRWall BR40 Video Wall Controller Datasheet - v3.7Vero AcunaNo ratings yet

- AADvance Manual de SeguridadDocument134 pagesAADvance Manual de SeguridadIsaac MendibleNo ratings yet

- Iso 11734 1995Document9 pagesIso 11734 1995Sohila ashorNo ratings yet

- Cambium Spectrum AnalyzerDocument7 pagesCambium Spectrum AnalyzerRaafat Younis100% (1)

- Terminal Stud Size ChartDocument1 pageTerminal Stud Size ChartLi RusNo ratings yet

- DeltaDocument20 pagesDeltaClaudio TurlherNo ratings yet

- Chili Pepper Consumption and Gastric Cancer in Mexico: A Case-Control StudyDocument11 pagesChili Pepper Consumption and Gastric Cancer in Mexico: A Case-Control StudyChristian Trejo AlanyaNo ratings yet

- FMDS07111FDocument8 pagesFMDS07111Fyerrisiddappa KNo ratings yet

- Manual Detector de GasesDocument221 pagesManual Detector de GasesjimenezjacoboNo ratings yet

- Msds Mt-Floc-8655 (1) (Ingles)Document3 pagesMsds Mt-Floc-8655 (1) (Ingles)LuzMarinaYucraNo ratings yet

- ASTM D454 04 - Standard Test Method For Rubber Deterioration by Heat and Air PressureDocument4 pagesASTM D454 04 - Standard Test Method For Rubber Deterioration by Heat and Air PressureAndre SpirimNo ratings yet

- Screw Compressor Air Cooled Chiller CatalogDocument64 pagesScrew Compressor Air Cooled Chiller CatalogManuel Guardia AraujoNo ratings yet

- Mde/Mdg17Cs: Turbovent TechnologyDocument2 pagesMde/Mdg17Cs: Turbovent TechnologyMási de LaféNo ratings yet

- Glycol Dehydration Systems BrochureDocument2 pagesGlycol Dehydration Systems BrochureJenny BuchananNo ratings yet

- Superior Performance Through Innovative Technology - VEGA IndustriesDocument72 pagesSuperior Performance Through Innovative Technology - VEGA IndustriesNael50% (2)

- Broch 6700 New 1Document2 pagesBroch 6700 New 1rumboherbalNo ratings yet

- Double Flap Gate ValvesDocument16 pagesDouble Flap Gate ValvesMatias MancillaNo ratings yet

- DM45 - Series: Atlas Copco Blasthole DrillsDocument4 pagesDM45 - Series: Atlas Copco Blasthole DrillsYo'lbin Salvatierra BaltazarNo ratings yet

- ManualDocument8 pagesManualSherif AdelNo ratings yet

- Perforadora Sobre OrugaDocument28 pagesPerforadora Sobre OrugaHenrry RVNo ratings yet

- MD6240 2 PDFDocument28 pagesMD6240 2 PDFWill WeinsoffNo ratings yet

- Tunnel Boring Machine PDFDocument2 pagesTunnel Boring Machine PDFfritzNo ratings yet

- SullaireDocument12 pagesSullaireAnonymous 61zHIpNo ratings yet

- Pipe and Fittings Data ChartsDocument20 pagesPipe and Fittings Data ChartskavNo ratings yet

- AL Atic: Above Ground Service Worm Gear Actuator 2-14-96Document1 pageAL Atic: Above Ground Service Worm Gear Actuator 2-14-96Lo Siento de VerdadNo ratings yet

- WEB Latinomineria 74 PDFDocument84 pagesWEB Latinomineria 74 PDFLo Siento de VerdadNo ratings yet

- Europe's Premier Manufacturer of Aftermarket Crusher Spare and Wear PartsDocument6 pagesEurope's Premier Manufacturer of Aftermarket Crusher Spare and Wear PartsLo Siento de VerdadNo ratings yet

- SBS STT Battery Instruction ManualDocument12 pagesSBS STT Battery Instruction ManualLo Siento de VerdadNo ratings yet

- Ts Battery PaperDocument2 pagesTs Battery PaperLo Siento de VerdadNo ratings yet

- The Truth About Batteries-White PaperDocument13 pagesThe Truth About Batteries-White PaperRahul ShelkeNo ratings yet

- Diapositivas Clase 02Document37 pagesDiapositivas Clase 02Lo Siento de VerdadNo ratings yet

- Engineering DynamicsDocument17 pagesEngineering DynamicsLo Siento de VerdadNo ratings yet

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 pagesBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNo ratings yet

- Multiple Choice: Encircle The Letter of The Correct AnswerDocument2 pagesMultiple Choice: Encircle The Letter of The Correct AnswerNieva MinitivaNo ratings yet

- Cyclic IrregulaityDocument41 pagesCyclic IrregulaitypeterNo ratings yet

- Spesifikasi Teknis Pengadaan Peralatan Laboratorium: Direktorat Jenderal Perikanan BudidayaDocument6 pagesSpesifikasi Teknis Pengadaan Peralatan Laboratorium: Direktorat Jenderal Perikanan BudidayaSanabil CitraNo ratings yet

- FreyrSCADA DNP Client Simulator User ManualDocument12 pagesFreyrSCADA DNP Client Simulator User ManualThiago AlvesNo ratings yet

- Influence of Polymer On The Performance of Bentonite As A Drilling FluidDocument6 pagesInfluence of Polymer On The Performance of Bentonite As A Drilling FluidLutfur RahmanNo ratings yet

- Unit IDocument54 pagesUnit ISrivatsan SureshNo ratings yet

- EASEUS Partition Master 6.1.1 Professional Edition HELPDocument27 pagesEASEUS Partition Master 6.1.1 Professional Edition HELPthisiscoffeeNo ratings yet

- Paulaner CloneDocument1 pagePaulaner CloneandreililioanceaNo ratings yet

- Fractional Time Delay Estimation AlgorithmDocument8 pagesFractional Time Delay Estimation AlgorithmandradesosNo ratings yet

- Mav Ip Physics-1Document8 pagesMav Ip Physics-1poojitnatarajanNo ratings yet

- Quality Assurance of Laboratory Results: A Challenge in Health Care ManagementDocument6 pagesQuality Assurance of Laboratory Results: A Challenge in Health Care Managementrizkiyah prabawantiNo ratings yet

- Stable, Bounded and Periodic Solutions in A Non-Linear Second Order Ordinary Differential Equation.Document5 pagesStable, Bounded and Periodic Solutions in A Non-Linear Second Order Ordinary Differential Equation.AJER JOURNALNo ratings yet

- DX DiagDocument30 pagesDX Diagtheresa.rgscapizNo ratings yet

- Database Fundamentals by Theophilus EdetDocument230 pagesDatabase Fundamentals by Theophilus EdetSebastian A. Montanchez SaldarriagaNo ratings yet

- Configuring Tomcat To Work With IISDocument3 pagesConfiguring Tomcat To Work With IISWill Wolff-MyrenNo ratings yet

- Putchars: Chapter 4 Macro Function - Scredit Software User ManualDocument7 pagesPutchars: Chapter 4 Macro Function - Scredit Software User ManualryoNo ratings yet

- 6 16Document2 pages6 16Indira KarimovaNo ratings yet

- Chapter 2Document50 pagesChapter 2mopliqNo ratings yet

- Training FileDocument7 pagesTraining Filenarindersingh7302789No ratings yet

- 五十铃isuzu Hatichi 4hk1 6hk1 ManualDocument351 pages五十铃isuzu Hatichi 4hk1 6hk1 Manual蔡苏100% (2)

- Spec Sheet SD200Document8 pagesSpec Sheet SD200Yohanes ArgamNo ratings yet

- VCF Anhydrous Ammonia (NH3)Document4 pagesVCF Anhydrous Ammonia (NH3)Edgar GuardiaNo ratings yet

- EE 355 A: Computer Programming in C++ (E) : (Lecture-2) TopicDocument10 pagesEE 355 A: Computer Programming in C++ (E) : (Lecture-2) TopicluckyNo ratings yet

- NOTES (2023-2024) Subject: Physics Lab Manual Class: Xii Sec: A Experiment No:3 - Concave MirrorDocument5 pagesNOTES (2023-2024) Subject: Physics Lab Manual Class: Xii Sec: A Experiment No:3 - Concave MirrorKing of KingsNo ratings yet

- SNIPPETS Everything You Wanted To Know About ThemDocument6 pagesSNIPPETS Everything You Wanted To Know About ThemDadang KurniaNo ratings yet

- Vlsi Design UNIT-1: Lecture-2Document4 pagesVlsi Design UNIT-1: Lecture-2Venky VenkateshNo ratings yet

- Mebu S.4 Maths 2024Document5 pagesMebu S.4 Maths 2024akyatwinejoshua100% (3)

- Static Electricity Static ElectricityDocument4 pagesStatic Electricity Static ElectricitycashmoneybagsNo ratings yet

- Student Worksheet #1 - How Airbags WorkDocument2 pagesStudent Worksheet #1 - How Airbags WorkEman FatimaNo ratings yet