Professional Documents

Culture Documents

Program Manager Plastics Engineering in Chicago IL Resume Dennis Tortorella

Program Manager Plastics Engineering in Chicago IL Resume Dennis Tortorella

Uploaded by

DennisTortorellaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Program Manager Plastics Engineering in Chicago IL Resume Dennis Tortorella

Program Manager Plastics Engineering in Chicago IL Resume Dennis Tortorella

Uploaded by

DennisTortorellaCopyright:

Available Formats

DENNIS J.

TORTORELLA

Mount Prospect, Illinois 60056 DTortorell@aol.com 847-635-7106 Home 847-997-3719 Cell AREAS OF EXPERTISE Program Management Plastic Product Design Conceptual Packaging Design Project Team Building Manufacturing Cost Reduction Injection Molding Productivity Improvement Design of Experiments Six Sigma Plant Layout & Improvement Process Control Project Management Customer Relations Corrective Actions Process Engineering

PROFESSIONAL EXPERIENCE IMI CORNELIUS Glendale Heights, IL 4/2005 to 9/2013 Manufacturer of Beverage Dispensing Equipment Design Manager, Materials Development Currently works for both NPD Group on new injection molded plastic componentry and assemblies, and Continuous Engineering Dept. to address field issues on existing equipment related to plastics applications. Was part of the team that in 2010 was responsible for $2.4M cost reduction programs for plastics material changes, part consolidation and new and updated tooling programs. Specifies engineering grade FDA or NSF51/61 materials for food contact areas, and was instrumental in correcting plastic design issues allowing Global Certification by McDonalds of a next generation beverage-dispensing valve. Responsibilities also include implementing changes based on involvement in corporate 8D programs. Establishing the root cause, help problem solve, and create validation and testing parameters for various projects. Established a Corporate Tool Design Standards book for standardization and cost savings. Also responsible as the corporate liaison for all equipment updates on all Coca-Cola authorized products and components. CREATIVE PACKAGING Div., of Precise Technology / Courtesy Corp. Buffalo Grove, IL Manufacturer of Engineered Plastic Packaging Components 4/2001 to 12/2004 Program Engineering Manager Reporting to VP of Engineering, responsible for managing packaging components and assembly projects from concept through to production and release to manufacturing. Projects for food and beverage industry leaders H.J. Heinz, Gatorade, Kraft and Pillsbury were the main customer focus, with projects with these companies having annual sales of $3 to 7 million, and project budgets of $1 to 2.5 million. Also oversaw product designs for ease of manufacturing, preparation of quotations of products, tooling designs as related to product, tooling schedules, and assembly equipment to major customers. Also defined and worked with customers to establish overall project goals, define and specify product requirements, write product specifications, prepare estimates and recommendations for plant modification for new projects. I also generated tool sampling requirements; tool validation protocols, and develop with customers their performance goals and criteria. MASTER MOLDED PRODUCTS CORP. Elgin, IL 1/1998 to 12/2000 Custom injection molder for Packaging, Industrial and Automotive markets. Program Manager, Packaging Combined responsibilities for ISO-9001/QS-9000 Business Group for all aspects of developing new high volume tooling for over-caps, closures, and for consumer and industrial products. My responsibilities include initial product design specifications, performance criteria, product concepts design, product and tooling quotations, project time lines right through to production start, qualification, and final customer approval. Automotive programs utilized PPAP procedures in conformance with ISO requirements as outlined by supplier.

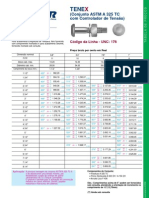

TENEX CORPORATION Elk Grove Village, IL 2/1995 to 1/1998 Injection Molder of Plastic Storage, Office and Computer Products. Manager, Research and Development Reporting to the Director of Operations, responsibilities included new product design and development, tool design and qualification of new injection tools and dies into production lines, and extrusion roll production machinery for chairmat production. Responsibilities include training of plant personnel when new product lines became released into production. Other responsibilities include specifying new equipment for injection molding plant expansion, including temperature controllers, overhead crane systems, resin delivery systems, temperature zone controllers, and all other equipment required for high volume production of plastic components for the home office and storage markets.

FELLOWES MANUFACTURING Itasca, IL 5/1993 to 2/1995 Injection Molder of Computer and Office Products Sr. Product Engineer Responsible for managing outside product design developments, establishing product costs, developing tooling sources, overseeing construction of new tools, and product refinements upon start up of production runs. Developed plans for cost reducing manufacturing assembly methods, wrote Master Process Sheets and quality standards documents for components and sub-assemblies. CREATIVE PACKAGING, Div. of Courtesy Corp. Buffalo Grove, IL 4/1991 to 5/1993 Manufacturer of Plastics Caps and Closures Project Engineer/ Project Manager Responsible for developing new products from conception through to manufacturing including concept design, mold and tooling design, sampling and tooling qualification and approval. SEAQUIST CLOSURES, Div. of Pittway Corp. Crystal Lake, IL 10/1983 to 1/1991 Injection Molder of Caps and Closures Senior Tool Engineer Responsibilities included reviewing and critiquing of new tooling designs, making recommendations on improved designs, overseeing construction and assuring that new tooling is built to specification and delivered on time. Other responsibilities included setting up and sampling new tooling, trouble shooting and debugging, and approving tooling for start-up production runs. EDUCATION Milwaukee School of Engineering Architectural Engineering Construction Technology; ABCET Elgin Community College Plastics Technology Courses ADDITIONAL -Six Sigma Green Belt 2007 -Proficient in Excel, AS400, MS Project, Word, Power Point. -Certified by SPI in Injection Molding Operations 2004 -Awarded three (3) United States Design Patents for consumer and computer product designs. 6,871,764 A1; 5,443,160; and 5,799,783. -Two United States and Foreign Patents pending for designs of packaging components. -Scientific Injection Molding and Statistical Q.C. Rodney J. Groleau and Assoc. -Philip Crosby School of Quality Improvement Certificate of completion.

You might also like

- Process Engineer in Houston TX Resume Douglas Chiau Funn MaDocument3 pagesProcess Engineer in Houston TX Resume Douglas Chiau Funn MaDouglasChiauFunnMaNo ratings yet

- M/S. Laxmi Automobile Works: Project ReportDocument14 pagesM/S. Laxmi Automobile Works: Project Report8897477809No ratings yet

- Director Engineering Manager in Atlanta GA Resume Gary SobusDocument4 pagesDirector Engineering Manager in Atlanta GA Resume Gary SobusGarySobusNo ratings yet

- Vice President Engineering in San Antonio TX Resume David LingreyDocument4 pagesVice President Engineering in San Antonio TX Resume David LingreyDavidLingreyNo ratings yet

- Name Mobile Phone Email Address Linkedin: EngineeringDocument2 pagesName Mobile Phone Email Address Linkedin: EngineeringdannyNo ratings yet

- Design Engineer (A&c)Document2 pagesDesign Engineer (A&c)JayMehta2No ratings yet

- Quality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanDocument4 pagesQuality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanJoannesHuseanNo ratings yet

- Director Engineering in Detroit MI Resume Shashank KarnikDocument3 pagesDirector Engineering in Detroit MI Resume Shashank Karnikshashankkarnik100% (1)

- VP Engineering Program Management in Detroit MI Resume George MouaikelDocument2 pagesVP Engineering Program Management in Detroit MI Resume George MouaikelGeorge MouaikelNo ratings yet

- TQM Chapter 7Document32 pagesTQM Chapter 7Patricia Anne Arintoc MoreloNo ratings yet

- Director Program Management in Auburn Hills MI Resume Greggory OrlandiDocument4 pagesDirector Program Management in Auburn Hills MI Resume Greggory OrlandiGreggoryOrlandiNo ratings yet

- Chapter 4 OpmanwithTQMDocument29 pagesChapter 4 OpmanwithTQMDaniel HuetNo ratings yet

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocument2 pagesManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczNo ratings yet

- Anil CV 20170101Document4 pagesAnil CV 20170101ANILNo ratings yet

- ATS - Primitivo Garcia Jr. - 2023Document3 pagesATS - Primitivo Garcia Jr. - 2023albertofragafernandezNo ratings yet

- Module 3 - PPT - Operation Management TQMDocument57 pagesModule 3 - PPT - Operation Management TQMMacsNo ratings yet

- MODULE 3 - Product and DesignDocument15 pagesMODULE 3 - Product and DesignRhodora SantosNo ratings yet

- P.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludeDocument2 pagesP.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludesdvikkiNo ratings yet

- SugoshVenkataraman PDFDocument7 pagesSugoshVenkataraman PDFtera.secret santaNo ratings yet

- Planning and DesigningDocument20 pagesPlanning and Designingvinit PatidarNo ratings yet

- Manufacturing Process Engineer in Albuquerque NM Resume David SteeleDocument4 pagesManufacturing Process Engineer in Albuquerque NM Resume David SteeleDavidSteeleNo ratings yet

- Michael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Document3 pagesMichael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Jeremy WilliamsNo ratings yet

- Jarema Czarnecki Resume BriefDocument2 pagesJarema Czarnecki Resume Briefapi-246855342No ratings yet

- Resume - Joel Goins - 2011Document2 pagesResume - Joel Goins - 2011Joel GoinsNo ratings yet

- Product Design and DevelopmentDocument27 pagesProduct Design and DevelopmentGur- FeatNo ratings yet

- Product and Service DesignDocument46 pagesProduct and Service DesignRebecca LisingNo ratings yet

- Amit Mudgal - Polymer Technologist With Work Ex of More Than 7 Years in Research & Business DevelopmentDocument4 pagesAmit Mudgal - Polymer Technologist With Work Ex of More Than 7 Years in Research & Business Developmentamit_mudgal2007No ratings yet

- Product Design 01Document6 pagesProduct Design 01Mounesh7No ratings yet

- Research Scientist - Engineer Job - Ingenia Polymers - Brantford, ON - Indeed - CaDocument2 pagesResearch Scientist - Engineer Job - Ingenia Polymers - Brantford, ON - Indeed - Caming_zhu10No ratings yet

- Principal Defense Mechanical Engineer in Huntsville AL Resume Jeffery WhitfordDocument2 pagesPrincipal Defense Mechanical Engineer in Huntsville AL Resume Jeffery WhitfordJeffreyWhitfordNo ratings yet

- Module 2Document4 pagesModule 2maricrisNo ratings yet

- Project Engineering Manager in Dayton OH Resume Rick PelfreyDocument2 pagesProject Engineering Manager in Dayton OH Resume Rick PelfreyRickPelfreyNo ratings yet

- Steven L. Henderson, CPM: Mechanical Design & Manufacturing EngineerDocument2 pagesSteven L. Henderson, CPM: Mechanical Design & Manufacturing EngineerShort Term Equity IdeasNo ratings yet

- Plant Manager or Production Manager or Production SupervisorDocument3 pagesPlant Manager or Production Manager or Production Supervisorapi-77414806No ratings yet

- CV Kevin Moriarty 20170828Document7 pagesCV Kevin Moriarty 20170828api-372585023No ratings yet

- Sales CEO President VP Director in West Palm Beach FL Resume Gary ReidDocument3 pagesSales CEO President VP Director in West Palm Beach FL Resume Gary ReidGaryReid2No ratings yet

- Edwin Montoya CVDocument6 pagesEdwin Montoya CVPaps MontoyaNo ratings yet

- CH - 2 - Product and Service DesignDocument62 pagesCH - 2 - Product and Service DesignYogesh GirgirwarNo ratings yet

- Mechanical Design EngineerDocument4 pagesMechanical Design Engineerapi-79066865No ratings yet

- Joshua Pilkin Resume 022124Document2 pagesJoshua Pilkin Resume 022124Joshua PilkinNo ratings yet

- Sample ResumesDocument3 pagesSample ResumesinboxsweetsNo ratings yet

- OPERATIONS MANAGEMENT NOTES & REVIEWER (Midterm 1st Sem)Document11 pagesOPERATIONS MANAGEMENT NOTES & REVIEWER (Midterm 1st Sem)Princess Delos SantosNo ratings yet

- 2018 EdgardoJosueCharlesAguillon Resume CV 1Document4 pages2018 EdgardoJosueCharlesAguillon Resume CV 1Rui TaiyouNo ratings yet

- Chapter 2 Designing-Product-Services-And-PrcessesDocument31 pagesChapter 2 Designing-Product-Services-And-PrcessesRomeo De Guzman Jr.No ratings yet

- Pom Chapter 4 PubDocument7 pagesPom Chapter 4 PubAhon BatangueñoNo ratings yet

- DFMDocument7 pagesDFMaraz_1985No ratings yet

- Engineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerDocument2 pagesEngineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerRichardMestlerNo ratings yet

- BME01.HM3C.Chapter 7. Roa, GiovanniDocument13 pagesBME01.HM3C.Chapter 7. Roa, Giovannigiovanni roaNo ratings yet

- 09 01 16 DCD EngineeringResumeDocument3 pages09 01 16 DCD EngineeringResumeChris D'MelloNo ratings yet

- Design TechnologyDocument19 pagesDesign TechnologyAnanya UppalNo ratings yet

- Product Development R&D CPG Director in NYC Resume Mark AlexanderDocument2 pagesProduct Development R&D CPG Director in NYC Resume Mark AlexanderMarkAlexander2No ratings yet

- Ample Esume: BjectiveDocument1 pageAmple Esume: BjectiveJoy JohnNo ratings yet

- Concurrent Engineering SeminarDocument24 pagesConcurrent Engineering SeminarArjun Prasad100% (1)

- Product DesignDocument18 pagesProduct DesignPangitkaNo ratings yet

- 1 s2.0 S0925527314003521 Main PDFDocument11 pages1 s2.0 S0925527314003521 Main PDFfukicohNo ratings yet

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonDocument2 pagesVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1No ratings yet

- OM Lecture 3 Product and Service DesignDocument26 pagesOM Lecture 3 Product and Service DesignDawit HusseinNo ratings yet

- Tablica VarenjaDocument7 pagesTablica VarenjaZivadin LukicNo ratings yet

- 16793theory of CostDocument54 pages16793theory of CostHardik SharmaNo ratings yet

- C01 First Test (Classification and Behaviour of Cost)Document5 pagesC01 First Test (Classification and Behaviour of Cost)Zaira Anees100% (1)

- Fix Construcao CivilDocument32 pagesFix Construcao CivilCrismkNo ratings yet

- Preprufe® 300R Plus & 160R PlusDocument6 pagesPreprufe® 300R Plus & 160R PlusCan AkanselNo ratings yet

- Quality ControlDocument3 pagesQuality ControlAnkit33% (3)

- Nitoflor FC110 PDFDocument2 pagesNitoflor FC110 PDFriverwilliams0% (1)

- Manufacture of Portland CementDocument3 pagesManufacture of Portland Cementlaura kayNo ratings yet

- SBTLDocument46 pagesSBTLMilan PitrodaNo ratings yet

- Instrumentation 02-2011 PDFDocument40 pagesInstrumentation 02-2011 PDFGina Moron MoronNo ratings yet

- Springwire Xinhua 2006Document10 pagesSpringwire Xinhua 2006teban09No ratings yet

- 23) 3d Printing in Organic Synthesis PDFDocument14 pages23) 3d Printing in Organic Synthesis PDFlolitica123456No ratings yet

- Neumáticos Michelin 44-80r57Document4 pagesNeumáticos Michelin 44-80r57carlucido247970No ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- ASME B31.4 Riser CalcDocument14 pagesASME B31.4 Riser CalcCastorNoroñoNo ratings yet

- Rubber Processing TechnologyDocument41 pagesRubber Processing TechnologySyama TripathyNo ratings yet

- Lean Consultants DirectoryDocument193 pagesLean Consultants DirectoryVinodhNo ratings yet

- Drafting Sanitary and Plumbing Layout and DetailsDocument17 pagesDrafting Sanitary and Plumbing Layout and DetailsRod Aquino100% (1)

- GB T 1591 2008 PDFDocument15 pagesGB T 1591 2008 PDFVíctor A. MirAlcNo ratings yet

- What Is The Right Supply Chain For Your ProductDocument19 pagesWhat Is The Right Supply Chain For Your ProductpersonifiedgeniusNo ratings yet

- Current Status of Municipal Solid Waste Generation in Malaysia (2009)Document25 pagesCurrent Status of Municipal Solid Waste Generation in Malaysia (2009)ratna_aqilahNo ratings yet

- MasterRheobuild® 716Document3 pagesMasterRheobuild® 716Jagan Mohana Rao ChinnalaNo ratings yet

- Okala Ecodesign Strategy Guide 2012Document61 pagesOkala Ecodesign Strategy Guide 2012Miguel Andres Garcia LlanosNo ratings yet

- 09 66 13 Portland Cement Terrazzo FlooringDocument9 pages09 66 13 Portland Cement Terrazzo FlooringHans Hans SadzNo ratings yet

- Lifting Chain: Product CatalogueDocument24 pagesLifting Chain: Product CatalogueBob ForeverNo ratings yet

- LEED Implementation Plan Full Draft Nov 23Document61 pagesLEED Implementation Plan Full Draft Nov 23Chris Gonzales100% (1)

- Ultra Thin WhitetoppingDocument36 pagesUltra Thin WhitetoppingAnil Kumsr T B100% (1)

- Detailed Drawing Exercises: Solidworks EducationDocument51 pagesDetailed Drawing Exercises: Solidworks EducationLeonardo AlexNo ratings yet

- Sample Grout Data Sheets-BETEC 110-140-180Document2 pagesSample Grout Data Sheets-BETEC 110-140-180fjafarvandNo ratings yet