Professional Documents

Culture Documents

Slam Shut Valve

Slam Shut Valve

Uploaded by

ShyBokxCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slam Shut Valve

Slam Shut Valve

Uploaded by

ShyBokxCopyright:

Available Formats

Process Management

TM

Type BM5

SLAM-SHUT VALVES

2

BM5 Slam-Shut Valves

BM5 series slam-shut valve is an automatic shut-off appliance suitable for installation as safety device in regulating

stations and gas distribution piping.

The slam-shut valve has the task to quickly shut off the gas flow when the pressure in control point(s) reaches a fixed

set value.

The valve is sleeve-type and as a consequence does not need any external by-pass to facilitate the opening of the valve

itself.

The valve re-opening can be made only through a manual operation.

The main features are as follows:

Axial flow

Flanged connections

Protected seal pad

Possible to fit in all positions

Pressure control in one or more points of the installation

Starting up following overpressure and/or underpressure

Push-button manual emergency release

Manual reset through rotation of the reset shaft only

Slam-shut valves

3

BM5 Slam-Shut Valves

Shutter Spring

Pad holder Eccentric shaft

BM5 series slam-shut valve is essentially made of an axial flow valve and a pilot allowing to keep the valve open. The

valve body features a shutter valve sliding axially and as a consequence no by-pass is needed for its opening even in the

presence of pressurized gas.

The valve opening can be made only manually by turning the eccentric shaft anticlockwise. The seal pad is not hit by

the gas flow since it is protected by the pad holder and as a consequence is not affected by any possible dirt present in

the gas. When the controlled pressure is within set values of the pilot, this remains set and prevents the rotation of the

eccentric shaft. When this pressure varies beyond setting limits, the pilot releases the eccentric shaft and the valve is

brought to its closing position following the spring thrust.

The pilot is provided with a manual release push-button to

quickly close the slam-shut valve in case of emergency or during

maintenance/checking operations.

Should the valve be used with pilot-operated pressure regulators,

the supply to pilots should be taken downstream of the slam-shut

valve. For this purpose, BM5 valves feature a threaded hole to

be used for supply to pilots; the hole is normally kept closed by a

dowel. The supply to pilots can be made through a standard joint

or through the suitable stud supplied on request.

To the pilots

Operation

4

BM5 Slam-Shut Valves

Construction Features

Technical Features

Materials

Flanged connections

DN 25 - 40 - 50 - 65 - 80 - 100 - 150

Temperature

Standard version

Working -10 C +60 C

Low temperature version

Working -20 C +60 C

Applications

The flange coupling surfaces are normally supplied with a step and finished with a semicircular profile

phonographic groove.

Upon request, the flange coupling surfaces can be supplied with a smooth finish.

The slam-shut valves in the BM5 series are used in natural gas reduction, distribution and transfer

stations.

They can also be used with air, propane, butane, LPG, city gas, nitrogen, carbon dioxide and

hydrogen.

Body Steel

Shutter Steel

O-ring NBR nitrile rubber or FKM

Pad NBR nitrile rubber or FKM

Pad holder Steel

Pressure bar PN 16 PN 25 ANSI 150 ANSI 300 ANSI 600

Allowable pressure PS 16 25 20 50 100

Inlet pressure range b

pu

0 16 0 25 0 20 0 50 0 100

Overpressure set range W

do

0.03 16 0.03 25 0.03 20 0.03 50 0.03 80

Underpressure set range W

du

0.01 16 0.01 25 0.01 20 0.01 50 0.01 80

Accuracy class AG up to 1%

Response time t

a

1 s

Features

5

BM5 Slam-Shut Valves

Coefficient DN 25 DN 40 DN 50 DN 65 DN 80 DN 100 DN 150

C

g

525 1420 2250 3600 5400 8700 18600

C1 29 28 26 28 30 26 28

Calculate the required C

g

with the following:

The following formulas refer to normal operating conditions in a sub-critical state with:

In case of velocities higher than indicated limits, increase the valve diameter.

N.B. The formula appearing above is valid only when the flow rate refers to natural gas.

For other gases, divide the flow rate by the correction factor F.

V = Velocity (m/s)

345.92 = Numerical constant

Q = Flow rate under standard conditions (Stm

3

/h)

DN = Valve nominal diameter (mm)

P

u

= Inlet pressure in relative value (bar)

DN Size

C

g

=

Q

0.525 P1 sine

P1 - P2

P1

3417

C1

P1

2

P2 >

N.B. the sine argument is expressed in sexagesimal degree.

N.B. the sine argument is expressed in sexagesimal degree.

Choose the slam-shut valve with the C

g

higher than the calculated value. After having determined the

slam-shut valve diameter, it is suggested to check that the velocity on the seal seat is not higher than

80 m/sec. by using the following formula:

V

= 345.92

Q

DN

2

1 - 0.002 P

u

1 + P

u

For other gases with different densities, the flow

rate calculated with the above formulas must be

multiplied by the correction factor:

0.6

d

F=

Flow Rate Q

Power Loss p

Q = 0.525 C

g

P1

Q = 0.525 C

g

P1 sine

P1-P2

P1

3417

C1

Calculation procedures

Symbols Q = Natural gas flow rate in Stm

3

/h

P1 = Absolute inlet pressure in bar

P2 = Absolute outlet pressure in bar

Flow Coefficients

C

g

= Flow rate coefficient

C1 = Body shape factor

d = Relative density of the gas

Q

C

g

1,05

2

P1- P1

2

- 4

p =

2

Gas

Relative Density

d

Factor

F

Air 1 0.78

City gas 0.44 1.17

Butane 2.01 0.55

Propane 1.53 0.63

Nitrogen 0.97 0.79

Carbon dioxide 1.52 0.63

Hydrogen 0.07 2.93

6

BM5 Slam-Shut Valves

OS/80X

Servomotor body OS/80X-BP, OS/80X-BPA-D Aluminum

OS/80X-MPA-D, OS/80X-APA-D Steel

Diaphragm Fabric-finished NBR

O-ring NBR rubber

OS/84X, OS/88X

Servomotor body Brass

Lip seal Teflon (PTFE)

O-ring NBR rubber

Pilot

The following pilots are used with the BM5 slam-shut valves:

OS/80X Series: Spring loaded pneumatic device

OS/80X-PN Series: Pneumatic device controlled by PRX series pilots

OS/80X The OS/80X series pilot is supplied in different models according to set ranges required.

The BM5 DN 150 is equipped with a reinforced version OS/80X-R.

PRX/181/182, PRX-AP/181/182

Body Steel

Diaphragm Fabric-finished NBR

O-ring NBR rubber

Technical Features

Materials

Technical Features

Materials

The OS/80X-PN series pilot is supplied in two models:

OS/80X-PN: Pressure range 0.5 to 40 bar.

Appliance made of an OS/80X-APA-D set at about 0.4 bar and a

variable number of PRX/182 pilots for overpressure and PRX/181

for underpressure, as many as necessary to control different points

of the installation.

OS/84X-PN: Pressure range 30 to 80 bar.

Appliance made of an OS/84X set at about 20 bar and a variable number of PRX-AP/182 pilots for

overpressure and PRX-AP/181 for underpressure, as many as necessary to control different points of

the installation.

OS/80X-PN

OS/80X-BP

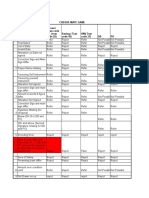

Model

Body Resistance

(bar)

Overpressure Set Range

W

do

(bar)

Underpressure Set Range

W

du

(bar)

Min. Max. Min. Max.

OS/80X-BP 5

0.03 2 0.01 0.60

OS/80X-BPA-D 20

OS/80X-MPA-D

100

0.50 5 0.25 4

OS/80X-APA-D 2 10 0.30 7

OS/84X 5 41 4 16

OS/88X 18 80 8 70

Model

Body Resistance

(bar)

Overpressure Set Range

W

do

(bar)

Underpressure Set Range

W

du

(bar)

Min. Max. Min. Max.

OS/80X-PN 100 0.5 40 0.5 40

OS/84X-PN 100 30 80 30 80

7

BM5 Slam-Shut Valves

BM5 series slam-shut valves can be installed on the piping with both horizontal axis and vertical axis

and with any gas flow orientation.

The pilot can be turned by 90 steps to allow the orientation in vertical position with the adjusting

screws turned upwards in order to obtain an optimal operation and an easier setting control.

To reduce the overall dimensions in a particular installation, the OS/80X-S version with clockwise

resetting is available.

This slam-shut valve has been designed to work even in the presence of relatively dirty gas since the

seal pad is not hit directly by the gas flow.

However, being a safety device, it is suggested to install a filter upstream of it.

Installation and assembly

Orientations

Horizontal

Flow

Vertical

Flow

Flow from right to left Flow from left to right

Downward flow Upward flow

8

BM5 Slam-Shut Valves

Proximity Switch

In order to send the shut-off opening/closing signal, a

proximity switch suitable for installation in hazardous

area is used.

The use of this switch foresees the application of an

intrinsic safety separation barrier which should be

installed in safe area.

The distance between the proximity switch and the

barrier should be calculated according to the type of

gas and installation electrical specifications.

The proximity switch should be positioned at about

0.5 mm from the stem (S).

The adjustment is made by means of adjusting nuts.

On request it is possible to supply the pilot in the

version with two proximity switches in order to

indicate extreme positions of valve opening/closing.

Accessories

IT/3V Three-Way Valve for Setting Control

(P

u

max 50 bar)

It allows the OS/80X operation and setting control,

without having to change the regulator setting.

The valve is installed on the OS/80X control line

and it must be connected to a suitable pressure

source that is capable of reaching the settings of

the OS/80X.

The IT/3V three-way valve is of the spring-return

type and it is equipped with a safety lock plate (B)

on the control knob (Q).

When the plate (B) is pivoted, pressure on the

knob (Q) makes it possible to put the sensitive

member into communication with a pressure

source, thus making it possible to perform

operation and setting tests.

Upon completion of the procedures, releasing the knob will reset normal running conditions. The safety lock plate on

the knob prevents accidental maneuvers.

0.5 mm

S

Adjustment nuts

Proximity

E

C

Downstream

To the pressure

source

To the pilot

Q

B

Electrovalve for Remote Controlled Closure

The OS/80X and the OS/80X-PN equipped with

a shut-off device for minimum pressure, can be

equipped with a 3-way valve with explosion-

proof construction to permit remote-controlled

closure.

Electrovalve

Regulator + Shut-off

9

BM5 Slam-Shut Valves

Slam-shut Valve

BM5

PS/79-1

Monitor Regulator

PS/79-1

OS/80X

L

L

Slam-shut Valve

BM5

PS/79

Gicleur

(1 mm)

Monitor

PRX/182

PRX/181

Regulator

PS/79

OS/80X-PN

Examples of Connections

Overpressure and underpressure control downstream of regulators

Atmospheric pressure Downstream pressure

Installation in a low pressure regulating line.

10

BM5 Slam-Shut Valves

D I

A

A

1

3

7

1

3

7

D I

160 max

160 max

C

E

C

E

B

Type DN 25 DN 40 DN 50 DN 65 DN 80 DN 100 DN 150

A 100 125 145 155 165 195 250

B 220 235 245 255 275 295 365

C 200 205 215 225 245 270 380

D 125 155 165 190 230 275 410

E 260 280 300 320 360 410 585

PN 16

I

184 222 254 276 298.5 352.5 451

PN 25 184 - 254 - 298.5 352.5 451

ANSI 150 184 222 254 276 298.5 352.5 451

ANSI 300 197 235 266.5 292 317.5 368.5 473

ANSI 600 210 251 286 311 336.5 394 508

Vertical Assembly Horizontal Assembly

Overall Dimensions (mm)

N.B. The C dimensions are indicative and refer to the models with larger dimensions.

The threaded opening for the connection of the control line is 1/4 NPT female.

11

BM5 Slam-Shut Valves

Type DN 25 DN 40 DN 50 DN 65 DN 80 DN 100 DN 150

PN 16/25 - ANSI 150 15 21 26 38 54 83 170

ANSI 300/600 17 25 30 41 62 105 280

Weights (kg)

Slam-Shut valve BM5/150 ANSI 600 with OS/80X-APA

Process Management

TM 0022EN_BM5_BUL - 05/2009

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

O.M.T.

Offcina Meccanica Tartarini s.r.l.

Via P. Fabbri, 1

I - 40013 Castel Maggiore (Bologna), Italy

Tel. : +39 - 0514190611

Fax: +39 - 0514190715

E-mail: info.tartarini@emerson.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Tartarini is a mark owned by O.M.T. Offcina Meccanica Tartarini

s.r.l., a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifcations of such

products at any time without notice.

O.M.T. Tartarini does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any O.M.T. Tartarini product

remains solely with the purchaser.

For further information visit www.emersonprocess.com/regulators

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

Francel S.A.

Z.A. La Croix Saint Mathieu

28320 Gallardon

France

Tel: +33 (0)2 37 33 47 00

Fax: +33 (0)2 37 31 46 56

O.M.T. Offcina Meccanica Tartarini s.r.l. 2009 ; All Rights Reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- LPG Technical ProposalDocument5 pagesLPG Technical ProposalShyBokx80% (5)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pet Shop Management SystemDocument79 pagesPet Shop Management SystemGibbbsy43% (14)

- Thrust and Anchor Blocks DesignDocument26 pagesThrust and Anchor Blocks DesignShyBokx100% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LPG Installation TipsDocument3 pagesLPG Installation TipsShyBokx100% (2)

- DPR Guidelines N Procedures For The Design Construction Operation N Maintenance of Oil N Gas Pipeline SysDocument39 pagesDPR Guidelines N Procedures For The Design Construction Operation N Maintenance of Oil N Gas Pipeline SysShyBokx75% (4)

- Bean-Up Rules of ThumbDocument3 pagesBean-Up Rules of ThumbShyBokxNo ratings yet

- Southwest Case Study SolutionDocument12 pagesSouthwest Case Study SolutionGaurav SharmaNo ratings yet

- Cause and Effect MatrixDocument1 pageCause and Effect MatrixShyBokxNo ratings yet

- Summary:: Steitoff Dyatt Engineering LimitedDocument4 pagesSummary:: Steitoff Dyatt Engineering LimitedShyBokxNo ratings yet

- Deepstar - Chevron Multiphase Design Guide PT 1Document105 pagesDeepstar - Chevron Multiphase Design Guide PT 1Smile M75% (4)

- Engineering ChecklistDocument4 pagesEngineering ChecklistShyBokxNo ratings yet

- P&ID ChecklistDocument4 pagesP&ID ChecklistShyBokxNo ratings yet

- Cathodic Protection and Corrosion DefintionsDocument13 pagesCathodic Protection and Corrosion DefintionsShyBokx100% (1)

- Specification For Auto LPG Dispensing StationDocument5 pagesSpecification For Auto LPG Dispensing StationShyBokxNo ratings yet

- Cathodic Protection PDFDocument13 pagesCathodic Protection PDFShyBokxNo ratings yet

- Shared Facility: LPG Domestic Storage and Distribution (Basic Units and Safety Schematic)Document1 pageShared Facility: LPG Domestic Storage and Distribution (Basic Units and Safety Schematic)ShyBokxNo ratings yet

- Municipal Gas Supply: Shared FacilityDocument1 pageMunicipal Gas Supply: Shared FacilityShyBokxNo ratings yet

- WTR2965 PDFDocument1 pageWTR2965 PDFPranay Joshi50% (2)

- Description: Serie 351 - 5.08Mm Vertical Cable Entry Plug - WR-TBL WERI PART NO: 691 351 500 0xxDocument2 pagesDescription: Serie 351 - 5.08Mm Vertical Cable Entry Plug - WR-TBL WERI PART NO: 691 351 500 0xxlogNo ratings yet

- Automobile: Each Detailed Project Reports Cover All The Aspects of Business, From Analysing TheDocument8 pagesAutomobile: Each Detailed Project Reports Cover All The Aspects of Business, From Analysing Themgd5697No ratings yet

- Content: Cc603-Project ManagementDocument20 pagesContent: Cc603-Project ManagementFarhan Jah'roniNo ratings yet

- ARCEL LD ToolingPartDesignDocument4 pagesARCEL LD ToolingPartDesignsuzukirider650No ratings yet

- Feedback & Assistance Cement: Media Queries CSR Queries Energy, Environment and SustainabilityDocument23 pagesFeedback & Assistance Cement: Media Queries CSR Queries Energy, Environment and SustainabilityCorrosion FactoryNo ratings yet

- BatteriesDocument1 pageBatteriesJilly ArasuNo ratings yet

- The 5S Methodology As A Tool For Improving Organization of ProductionDocument7 pagesThe 5S Methodology As A Tool For Improving Organization of Productionaanz007No ratings yet

- Lista Precios FORUMDocument1 pageLista Precios FORUMNoelia Mariella Sanchez RodriguezNo ratings yet

- Separator Design Basics.Document58 pagesSeparator Design Basics.Shijumon KpNo ratings yet

- A PRESENTATION On Modular Mini Refinery Project PDFDocument28 pagesA PRESENTATION On Modular Mini Refinery Project PDFrashidulNo ratings yet

- Xstore 150 UserGuideDocument489 pagesXstore 150 UserGuidetejashreekadamNo ratings yet

- Value AnalysisDocument19 pagesValue Analysisekta1308No ratings yet

- BI Products-ComparisonDocument40 pagesBI Products-Comparisonsharpan5No ratings yet

- Bacolod Brewery: Additive and Deductive Works: Material Diameter LengthDocument1 pageBacolod Brewery: Additive and Deductive Works: Material Diameter LengthWilliam Jefferson RañadaNo ratings yet

- College of Computing and Digital Media: SE 350 - Object-Oriented Software DevelopmentDocument10 pagesCollege of Computing and Digital Media: SE 350 - Object-Oriented Software DevelopmentJenny EverettNo ratings yet

- 01.logistics Plan-REDocument14 pages01.logistics Plan-REAzhar Shaikh75% (4)

- Why Cable PercussionDocument2 pagesWhy Cable PercussionShaiyid DoorsonNo ratings yet

- PassDocument9,348 pagesPassAmal rajNo ratings yet

- Lean Case Study Part IDocument6 pagesLean Case Study Part IAnonymous QI9xEjrbplNo ratings yet

- Tor For Performance Based Contract-ReviewedDocument36 pagesTor For Performance Based Contract-ReviewedS C JhaNo ratings yet

- Cheque Mate Game Current (Tran Code 11) (Tran Code 29) Saving (Tran Code 10) HNI (Tran Code 31)Document1 pageCheque Mate Game Current (Tran Code 11) (Tran Code 29) Saving (Tran Code 10) HNI (Tran Code 31)Nandini JaganNo ratings yet

- As 1462.24-2003 Methods of Test For Plastics Pipes and Fittings Determination of Resistance To Crack PropagatDocument4 pagesAs 1462.24-2003 Methods of Test For Plastics Pipes and Fittings Determination of Resistance To Crack PropagatSAI Global - APACNo ratings yet

- SAP HR - Benefits ConfigurationDocument4 pagesSAP HR - Benefits ConfigurationBharathk KldNo ratings yet

- Con CastDocument148 pagesCon CastRabinarayan DashNo ratings yet

- Cessna 100 SerieS MM D637-1-13 PDFDocument784 pagesCessna 100 SerieS MM D637-1-13 PDFYareth SC0% (1)

- Practical Application of EN ISO 13849-1 For Machine Tools - Eberhard BeckDocument38 pagesPractical Application of EN ISO 13849-1 For Machine Tools - Eberhard BeckGilesHarper100% (1)

- Micros Fidelio FinancialsDocument8 pagesMicros Fidelio FinancialssamaanNo ratings yet