Professional Documents

Culture Documents

Guide To Changing Axles On Your Millenia by Matt64341: Red - Upper Leading Link

Guide To Changing Axles On Your Millenia by Matt64341: Red - Upper Leading Link

Uploaded by

LousMX5Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide To Changing Axles On Your Millenia by Matt64341: Red - Upper Leading Link

Guide To Changing Axles On Your Millenia by Matt64341: Red - Upper Leading Link

Uploaded by

LousMX5Copyright:

Available Formats

Guide to Changing Axles on your Millenia By Matt64341 I finally changed my driver's side axle the other night and

it went very smoothly. There are a lot of details and steps that could be done differently or even skipped completely, but this is what worked for me. Also there are some spots where you can run into problems that you should be prepared for, but that was not the case for mine. In total it took me 3 hours including set up and 'some' clean up, and I work slowly. This was a drivers side axle on a ! ", but the same instructions should apply to both sides for any year and either engine with little or no differences. I tend to go into a lot of detail, so there may be some obvious#unnecessary details that you already know or could have easily figured out. Also, if you have any $uestions about anything, %ust ask me and I will clarify.

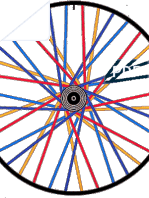

Red Upper Leading Link Blue Upper Lateral Link ello! "ie Rod #nd $%uter& Green Lo!er Ball 'oint

&efore I started, I hit the axle nut every few days with '& blaster over a couple of weeks. It might have done nothing, but my axle nut came off and the splines pulled right out of the hub with no problem, and I wonder if that had something to do with it. (y axle appeared to be original, so it was probably in the hub for the last )! years, and a lot of people have had fro*en axles on all different years. +ou can spray as much and as often as you want in there because nothing in there is going to be harmed by the spray, so I would recommend doing it. ,ow you need to get the axle nut off. If you have good air tools, you might be all set - and probably don't need this guide either. +ou will need to unbend the pinched in part of the locknut to start and use a person or ob%ect to press the brakes down hard to keep the wheel from turning. (y stock axle nut was 3!mm .or )/3#012, but the new one was 33mm .or )/4#)32 so make sure you have the correct sockets for removal and re/installation. I started off with a half inch breaker bar and sheered the end right off, so I would recommend you go straight for 3#51 drive for this. I got a 3#51 sliding T breaker bar and 3#51 impact sockets. The sockets are massive, the sidewalls are almost a $uarter inch thick. Impact grade might be overkill, but I did not worry at all about not being able to handle the tor$ue. I added about a 5 foot extension and it got the nut off.

"ame "ocket "i*e6 3#51 drive impact vs. )#71 drive standard grade ,ext you can see whether or not you will run into trouble. 8se a piece of wood in between and hit the end of the axle with a hammer. If it falls in, you are in luck. If not, you can hit it with '& blaster, and try again. If you still are not having luck, put the locknut back on until the end is flush with the end of the axle and hammer on that. &ut don't use too much force or you could damage the axle or other parts. Also if you have access to a puller, or can make something up to work, you can try that too. At this point, if it is really fro*en, you have to decide what you are going to do next. +ou can put the nut back on and take it somewhere, put the nut back on and remove to spray every few days and see if you can get it unfro*en, or you can remove the whole knuckle, hub, and axle as a whole and bring it to a shop that is willing to try to get it out. If you can get the axle out, then you can keep going. 9emove the wheel. ,ext, loosen but don't remove the 3 )4mm bolts that hold the lower ball %oint on. +ou will want a good )4mm socket for that, and you might want to use a short pipe on the breaker bar to get them free. Then remove the bolt that holds the tie rod end in and the two bolts that hold the upper leading link to the body. +ou will need to separate the tie rod end at the ball %oint from the knuckle, which might be hard to do. +ou should use a removal tool for this so you don't crush in the threads by hammering. This should be a cheap tool or it can be rented at auto*one. Also pull the upper leading link out of the two bolt studs and swing it around to the other side. ,ow finish removing the three bolts on the lower ball %oint. The knuckle is now only held on by the upper lateral link. It isn't necessary, but you can remove this too by taking off the nut and removing popping out the ball %oint. The whole knuckle would be free at that point which might make things easier. (y bolt was rusted pretty badly, and I didn't want to risk breaking anything so I left it on. I moved the knuckle around

enough to get the axle out of the hub completely. I put a bolt back in the lower ball %oint .in the wrong hole2 %ust so all the weight wouldn't be on the lateral link and to hold the knuckle out of my way. All that is left to do is to remove the axle from the transmission. I dropped part of the splash shield out of the way, which is a few ):mm bolts. I used a prybar to put between the axle and transmission and popped it out. I had to try several different tools before I found one that fit well and was able to get it out. ;nce I got the right one, it did not take much force. It should not be sei*ed in there. It has a retaining ring that holds it in place, so it will not %ust slide out without some help. ,ow the axle is free. It might be a pain to get it out completely, but it is a matter of finding the right way to turn it. All the hard work has been done. +ou now %ust need to take your new axle and grease the splines well so they don't sei*e up for next time. Install the axle in the reverse order of removal. Also, grease any ball %oints you separated so they will be easier to remove in the future. Tighten the new locknut to )45/73! foot pounds. I used a )!: ft. lb. Tor$ue wrench .)#71 drive2, and went from )::/)!: in intervals and felt how much I was turning it each time then when I hit )!:, I finished tightening by feel to get it up to tor$ue. "upposedly, an over/tor$ued locknut can lead to axle failure. I don't know if I believe that, but it will at least be easier to remove in the future than if it was put on with too much force. <astly, tor$ue everything you removed to the correct value. (e)essary "or*ue +alues, Axle <ocknut <ower &all =oint &olts Tie 9od >nd &all =oint 8pper <ateral <ink &all =oint 8pper <eading <ink ,uts )45/73! ft. lbs !0/03 ft. lbs 5)/! ft. lbs 5)/! ft. lbs 70/30 ft. lbs

You might also like

- Tranny Removal GuideDocument23 pagesTranny Removal Guidedurallymax100% (6)

- Mercedes Benz Kompressor Pulley Installation GuideDocument14 pagesMercedes Benz Kompressor Pulley Installation Guidekilofome05No ratings yet

- Sig Mosquito Dis-Assemble and Re-AssembleDocument28 pagesSig Mosquito Dis-Assemble and Re-Assemblercol8314100% (1)

- GSG-5 DisassemblyDocument16 pagesGSG-5 DisassemblyJim DagerNo ratings yet

- Tagum Cooperative New Membership FormDocument7 pagesTagum Cooperative New Membership FormJeremiah CortezNo ratings yet

- 420a Edz SwapDocument12 pages420a Edz SwapAll StaffNo ratings yet

- Schimbare Semering UleiDocument19 pagesSchimbare Semering Uleiradu2000vNo ratings yet

- Bridge Port Milling Machine ManualDocument70 pagesBridge Port Milling Machine Manualfposta100% (1)

- BMW E61 Tailgate Wiring Repair PDFDocument35 pagesBMW E61 Tailgate Wiring Repair PDFImre MartonNo ratings yet

- DIY For Rebuilding An S2000 Transmission by Ronnuke of S2ki - Com (7.30.13)Document38 pagesDIY For Rebuilding An S2000 Transmission by Ronnuke of S2ki - Com (7.30.13)Bruce BruceNo ratings yet

- How To Remove Supercharger From Sea Doo RXP RXT RXPX RXTXDocument15 pagesHow To Remove Supercharger From Sea Doo RXP RXT RXPX RXTXMatthew ConleyNo ratings yet

- Tesla Model S Rear Door Handle ReplacementDocument12 pagesTesla Model S Rear Door Handle ReplacementAnonymous TjcIWjNo ratings yet

- ISO10816-6 Reciprocating Machine Above 100 KW 1995 - AMD 1 2015Document6 pagesISO10816-6 Reciprocating Machine Above 100 KW 1995 - AMD 1 2015PAOLO GIANNELLINo ratings yet

- EQ5 Szíjhajtás EngDocument37 pagesEQ5 Szíjhajtás EngcsavargaNo ratings yet

- Maytag MAV8600AWWDocument7 pagesMaytag MAV8600AWWwork_to_playNo ratings yet

- Seal InstructionsDocument15 pagesSeal InstructionsTeran G EugenioNo ratings yet

- QB78 TuneDocument11 pagesQB78 TuneSadBoiH0urs 1100% (1)

- QB79 Tune and ModificationsDocument11 pagesQB79 Tune and ModificationsMirosław Jurczyszyn100% (1)

- V-Maxx Fitting GuideDocument9 pagesV-Maxx Fitting GuideLahiru PereraNo ratings yet

- How To Repair Your Broken OdometerDocument18 pagesHow To Repair Your Broken OdometerDavid AnghelNo ratings yet

- Porsche 944 Hatch Re-Sealing ProcedureDocument29 pagesPorsche 944 Hatch Re-Sealing Procedureorbix42No ratings yet

- How To Fix A Droopy Sun VisorDocument8 pagesHow To Fix A Droopy Sun VisorsurfsandNo ratings yet

- ClutchDocument14 pagesClutchM.MouseNo ratings yet

- ClutchDocument14 pagesClutchM.MouseNo ratings yet

- Servicing A Webasto Thermo Top C Diesel BoilerDocument10 pagesServicing A Webasto Thermo Top C Diesel BoilersailorporNo ratings yet

- TF 727 RebuildDocument10 pagesTF 727 Rebuild4porte3No ratings yet

- TB RepairDocument67 pagesTB Repairmladen vukusicNo ratings yet

- Mercedes-Benz Mechanical Odometer RepairDocument12 pagesMercedes-Benz Mechanical Odometer RepairdabronzaNo ratings yet

- Alfa 156 Front Suspension V 2Document5 pagesAlfa 156 Front Suspension V 2Danny Sabato100% (1)

- Fitting A Mantec Swing-Away Wheel CarrierDocument8 pagesFitting A Mantec Swing-Away Wheel CarrierClive TurnerNo ratings yet

- Porsche 944 DashremovalinstallationDocument25 pagesPorsche 944 DashremovalinstallationDaryl G. JurbalaNo ratings yet

- Bertrand Lens Focus RepairDocument37 pagesBertrand Lens Focus RepairAlicia GordonNo ratings yet

- How To Reclock A MustangDocument32 pagesHow To Reclock A MustangBob johnNo ratings yet

- Replacing Shift Linkage Bushing: SymptomsDocument5 pagesReplacing Shift Linkage Bushing: SymptomsbelchiorNo ratings yet

- AssemblyDocument5 pagesAssemblyAdrian MacayaNo ratings yet

- Wheel Bearing Repacking or ReplacementDocument8 pagesWheel Bearing Repacking or Replacementthe_monkeys_teacupNo ratings yet

- Homemade Scroll Saw Part - 2Document31 pagesHomemade Scroll Saw Part - 2progNo ratings yet

- How To Set Up Your CarbsDocument37 pagesHow To Set Up Your CarbsMonserrat Stevens PescadorNo ratings yet

- Old SchoolRs Carb Cleaning GuideDocument29 pagesOld SchoolRs Carb Cleaning GuideStaggerMacFly JmacNo ratings yet

- How To Disassemble A South Bend Lathe For MovingDocument3 pagesHow To Disassemble A South Bend Lathe For MovingAnonymous f6goFflg3TNo ratings yet

- PG 1 Bearing Replacement GuideDocument69 pagesPG 1 Bearing Replacement GuideDamián Martínez SánchezNo ratings yet

- 1996-Suzuki-Dr350se - EmbragueDocument8 pages1996-Suzuki-Dr350se - EmbragueRami SalasNo ratings yet

- Clutch Cable Adjustment OneDocument19 pagesClutch Cable Adjustment OneEduardo Yagüe GomezNo ratings yet

- Dismantling The R3M GearboxDocument24 pagesDismantling The R3M Gearboxteo teoNo ratings yet

- Bicycle Wheel TruingDocument7 pagesBicycle Wheel TruingJesse MynerNo ratings yet

- M & S Series Trigger ResetDocument8 pagesM & S Series Trigger ResetCole Walker100% (1)

- Valve Adjustment For 16 Valve Suzuki GS MotorsDocument9 pagesValve Adjustment For 16 Valve Suzuki GS Motorsmiki-likiNo ratings yet

- Start of Injection Regulation - SOLVED! DYI!Document14 pagesStart of Injection Regulation - SOLVED! DYI!Cosmin DxiNo ratings yet

- Rebuilding A Spoked Wheel For The Royal Enfield BulletDocument18 pagesRebuilding A Spoked Wheel For The Royal Enfield BulletSrikanth Sridharan100% (1)

- Wheel Building 101Document3 pagesWheel Building 101Lopez GardoNo ratings yet

- Rear Shock Rebuild On A GL1200 GoldwingDocument28 pagesRear Shock Rebuild On A GL1200 GoldwingValdir GomieroNo ratings yet

- Orion 15 ServiceDocument3 pagesOrion 15 ServiceIan MahoneyNo ratings yet

- Modificacion CNC X CarveDocument5 pagesModificacion CNC X CarveelmanoNo ratings yet

- Edited by Gewilli Snowball'S Orignial Page With Zoomed ImagesDocument13 pagesEdited by Gewilli Snowball'S Orignial Page With Zoomed ImagesLuca Anca MadalinaNo ratings yet

- Intake Manifold Cleaning 101 - VW TdiDocument16 pagesIntake Manifold Cleaning 101 - VW TdiMike WaltersNo ratings yet

- Jupiter 8 Manual de ServicioDocument8 pagesJupiter 8 Manual de ServicioJosé Antonio Ocón LópezNo ratings yet

- Conversion A Discos Traseros en TercelDocument11 pagesConversion A Discos Traseros en TercelWillLokiNo ratings yet

- Recaro Repair GuideDocument12 pagesRecaro Repair GuideEnrique LlanosNo ratings yet

- 24K Service PictorialDocument50 pages24K Service Pictorialplaton20022No ratings yet

- 63-82 Steering Box RebuildDocument10 pages63-82 Steering Box Rebuildvince cNo ratings yet

- Shrike Build Option - Multi-PartDocument25 pagesShrike Build Option - Multi-PartRonald ZezeanuNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- Pilot SpeakUP1 Learners EngDocument80 pagesPilot SpeakUP1 Learners EngPham Le Viet VuNo ratings yet

- Synfocity : Chawhma Inkhawm Chawhma InkhawmDocument4 pagesSynfocity : Chawhma Inkhawm Chawhma InkhawmMizoram Presbyterian Church SynodNo ratings yet

- Haldex QuickDocument84 pagesHaldex QuickAndherson DasilvaNo ratings yet

- Cruz Vs Secretary of DENRDocument1 pageCruz Vs Secretary of DENRKate Bernadette MadayagNo ratings yet

- 5a's Method - The God Stealer 1Document13 pages5a's Method - The God Stealer 1Ervia Kryxzyn Baguio100% (2)

- MBA501 Managing OrganizationsDocument4 pagesMBA501 Managing OrganizationsRifnas AhamedNo ratings yet

- 2019-20 AplDocument39 pages2019-20 AplNaveen ChilukuriNo ratings yet

- 5 Assignment-V-Construction-of-Words-and-PhrasesDocument2 pages5 Assignment-V-Construction-of-Words-and-Phrasesmaria tanNo ratings yet

- Design of Software Technology Learning Platform For Grade 12 STEM Students of FAITH Fidelis Senior High SchoolDocument21 pagesDesign of Software Technology Learning Platform For Grade 12 STEM Students of FAITH Fidelis Senior High SchoolEnrico JoseNo ratings yet

- How To Write A2 English CourseworkDocument8 pagesHow To Write A2 English Courseworkmtywrhajd100% (2)

- Hubbard O'Brien: MicroeconomicsDocument46 pagesHubbard O'Brien: MicroeconomicsNoxNo ratings yet

- Distosia BahuDocument185 pagesDistosia BahuAdith Fileanugraha100% (1)

- 08 New Testament Survey Teachers ManualDocument70 pages08 New Testament Survey Teachers Manualjericbotilo17No ratings yet

- Project Plan BirdfeederDocument2 pagesProject Plan BirdfeederJessie-Marie Mata MorcosoNo ratings yet

- Holiday (Isra Wal Miraj A Night Journey of Prophet Muhammad S.A.W)Document8 pagesHoliday (Isra Wal Miraj A Night Journey of Prophet Muhammad S.A.W)Rey GenosaNo ratings yet

- 6-Step Behavior Modification Planning Worksheet: Set Specific Behavioral GoalsDocument3 pages6-Step Behavior Modification Planning Worksheet: Set Specific Behavioral GoalsLiane ShamidoNo ratings yet

- Socso Confirms Covid-19 Is An Occupational Disease Eligible For Workers' CompensationDocument2 pagesSocso Confirms Covid-19 Is An Occupational Disease Eligible For Workers' CompensationAnah IsNo ratings yet

- Science Technology and Society MODULE 3Document7 pagesScience Technology and Society MODULE 3jesson cabelloNo ratings yet

- Lamb Historical ReenactmentDocument13 pagesLamb Historical ReenactmentlikmdogNo ratings yet

- 25415-Low Cost RF Synthesizer Uses Generic ICs PDFDocument6 pages25415-Low Cost RF Synthesizer Uses Generic ICs PDFCrispin Meneleo ValenzuelaNo ratings yet

- 2020 8th PEC BahawalpurDocument301 pages2020 8th PEC BahawalpurFast ComputersNo ratings yet

- The Introduction To Computer ScienceDocument48 pagesThe Introduction To Computer ScienceJohnNo ratings yet

- Exporting AVI and JPEG Evidence in The Smart ClientDocument2 pagesExporting AVI and JPEG Evidence in The Smart ClientciracusaNo ratings yet

- Ejecrcicios Ingles, R e S U e L T o 31-03Document11 pagesEjecrcicios Ingles, R e S U e L T o 31-03Andres TapiasNo ratings yet

- 7 - Regional Ecumenical Christian Councils in IndiaDocument11 pages7 - Regional Ecumenical Christian Councils in IndiaAjo Alex100% (1)

- PDC551800EN014.1 - Manual Globe - Database Documentation CRM 403 (En)Document248 pagesPDC551800EN014.1 - Manual Globe - Database Documentation CRM 403 (En)migc2004No ratings yet

- Greaves Cotton: Upgraded To Buy With A PT of Rs160Document3 pagesGreaves Cotton: Upgraded To Buy With A PT of Rs160ajd.nanthakumarNo ratings yet

- Recognition of Construction Contract Revenue Based On PSAK 34 at PT Tunggal Jaya RayaDocument8 pagesRecognition of Construction Contract Revenue Based On PSAK 34 at PT Tunggal Jaya RayamegakadirNo ratings yet