Professional Documents

Culture Documents

United States Patent 1191: (54) Heat and Kinetic Absorption Lining

United States Patent 1191: (54) Heat and Kinetic Absorption Lining

Uploaded by

david19775891Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent 1191: (54) Heat and Kinetic Absorption Lining

United States Patent 1191: (54) Heat and Kinetic Absorption Lining

Uploaded by

david19775891Copyright:

Available Formats

United States Patent 1191

Acs '

1111

[451

3.596.441 8/1971 Lundahl....

3,814,458

June 4, 1974

................ . 55/3110 x

[54] HEAT AND KINETIC ABSORPTION LINING FOR AIR BAG

3.632.415

3.638,755

' 1/1972

2/1972

Franklin....

Sack . . . . . . . . . . . . ..

ll7/138.8 N x

280/150 AB x

[75] Inventor: Steven N. Acs, Sarina, Ontario, Canada [73]- Assignee: Allied Chemical Corporation, New

York, NY.

3.660.138

5/1972

Gorrell ................... .. 117/1381; N x

FOREIGN PATENTS OR APPLICATIONS

1.946.607 5/1971 Germany .................... .. 200/150 AB

[22] Filed: Sept. 10, 1971 [21'] Appl. No.: 179,397

[52] US. Cl.

[51]

Primary Examiner-David Schonberg

Assistant ExaminerJohn P. Silverstrim

Atmrney,Agent, or Firm-.lonathan Plaut

280/150 AB, 55/380, 1 17/138.8N, ISO/2.1

' 117/1388 N

[5 7 ]

ABSTRACT

Int. Cl. .......................................... .. B60! 21/08

[58] Field of Search..... 280/150 AB; 150/1; 55/380;

[56]

2,646,370

3.184.742

This invention relates to combined heat and kinetic energy absorption in a passenger restraint system as a result of the use of a barrier contained within the pas

senger restraint bag. More specifically, this invention

relates to the introduction of non-elastic, but indepen dent, heat and kinetic energy absorbing bag or other barrier material within the air bag which is utilized to

restrain forward motion of a passenger within a motor

References Cited

UNITED STATES PATENTS

7/1953

4/1965

Nelson ............................ .. 244/31 X

Cutler .......... ..

vehicle.

3.473.824 3.552.770

10/1969 l/197l

Carey Berryman et ................... .. 280/150 AB

2 Claims, 2 Drawing Figures

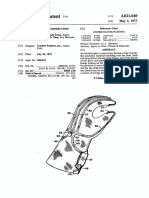

PATENTEDJUN 419M

3.814.458

STEVEN AC3 INVENTOR.

BY:

\\ '\ IL \\ ~ \ MW

ATTORNEY.

3,814,458

2

fore full inflation; and

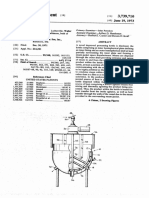

FIG. 2 is a second embodiment of the invention at

full inflation. >

HEAT AND KINETIC ABSORPTION LINING FOR AIR BAG

BACKGROUND OF THE INVENTION This invention relates to heat and kinetic energy ab

sorption in a passenger restraint system as a result of

According to the invention, an in?ating medium is

5 obtained from a source I, as is well known in the art.

For example, the in?ating medium is gas obtained from

either a gas generator system or a combined com

the use of an independent expansible barrier contained within and of just less than the same volume when in ?ated as the passenger restraint bag. More speci?cally,

this invention relates to the introduction of a heat and

kinetic energy absorbing expansible, but inelastic, bag

made of ?ber glass material, in one embodiment, within the air bag which is utilized to restrain forward motion

of a passenger within a motor vehicle.

pressed gas and gas generating source. The in?ating medium is directed toward heat and kinetic energy ab sorbing bag in the form of an expandable, but not elas tic, low porosity or substantially non-porous bag 2, said inner bag 2 being contained within an outer passenger restraint bag 4. All of the in?ating material is directed into the inner bag 2. The temperature of the in?ating

medium in one embodiment, a steering wheel embodi

ment, in an outer bag without the inner bag is in the ' range of 250 to 350F., but with the inclusion of a ?ber ,

One of the problems in the in?ation of passenger re straining air bags by a generated gas, or a combination of generated gas and stored gas, especially in the driv

ers steering wheel unit where a relatively small bag is involved, is the heat caused by the generation of the gas and its rapid movement into the passenger restraint bag. The level of heat produced may result in tempera

glass inner bag, in one embodiment, which may be

woven, is reduced to about 150F., the bags in that em bodiment having a volume when ?lled of about 2 cu. ft.

Other heat absorbing materials, such as nylon fabric

coated with aluminumized neoprene, may also be uti

energy concurrently. These and other objects and advantages will become

more apparent in the context of the following more de

tures in the bag from 250 to 350F. lized for the inner bag, but ?ber glass is preferable and It is, therefore, an object of this invention to provide especially advantageous since it provides good heat ab for the absorption of the heat energy of the gas expand~ 25 sorbing qualities while having the strength to absorb ki ing an air bag restraint system and to dissipate kinetic netic energy of gas ?lling the bag.

The inner bag will expand on ?lling, absorbing the energy of the inflating material entering thereinto, and

30

tailed description of the invention.

move in a direction so as to conform to the space of the

outer bag as it expands toward it. The volume of the

DETAILED DESCRIPTION OF THE INVENTION Generally, according to the invention, heat energy

absorbing means is provided within a passenger re straint bag, typically to be found within an automobile. 35

inner bag is just less than the volume of the outer bag when fully expanded, as shown in FIG. 2. The'outer bag 4 may be formed of suitable material, such as nylon.

We claim: 1. In?atable restraint system comprising a source of

The heat energy absorbing means is in the form of'a ?ber glass inner expansible, but not stretchable, and low porosity bag, in one embodiment, which is just less

than substantially the same volume as the passenger re

in?ating gas, an outer bag of predetermined volume

when fully in?ated,tan independent and expandable,

40

straint outer bag. This heat energy absorbing inner bag

will function to absorb kinetic energy as it expands to

take the shape of the concurrently-expanding outer

bag.

In addition, the heat and kinetic energy absorption of the inner bag provides a redundancy advantage in that if said expansion medium should fail, the inner bag

45

but inelastic, heat and kinetic energy absorbing inner bag of smaller volume than the outer bag when fully in ?ated independent of and located in said outer bag, means for introducing all of the in?ating gas directed toward the outer bag into said inner bag to expand said inner bag, said inner bag conforming to the shape of said outer bag when said gas is introduced thereinto

and of just less than the same volume as the outer bag when both are fully expanded by said gas, said inner would still function to provide passenger restraint. bag being formed of nylon fabric coated with alumi The US. Pat. No. to Carey et al., 3,473,824 discloses nized neoprene. a system with inner barrier and outer bag arrangement for absorption of kinetic energy of the in?ating me 50 2. In?atable restraint system comprising a source of in?ating gas, an outer bag of predetermined volume dium. However, in Carey et al., the inner barrier merely when fully in?ated, an expandable, but inelastic, ki unfolds and then bursts or otherwise emits the in?ating netic energy absorbing inner bag of smaller volume medium into the outer bag. In US. Pat. No. 3,522,770

to Berryman is shown as coated or attached to the in

than the outer bag when fully in?ated independent of

ing all of the in?ating gas directed toward the outer bag into said inner bag to expand said inner bag, said inner bag conforming to the shape of said outer bag when said gas is introduced thereinto and of just less than the same volume as the outer bag when expanded by said

gas.

* * * * *

side of the restraining bag, a costly process which does 55 and located in said outer bag, heat absorbing ?ber glass material included in said inner bag, means for introduc not provide for the concurrent kinetic energy absorp

tion and redundancy advantages previously mentioned.

Describing in further detail in relation to the draw

ings:

FIG. 1 shows the embodiment of the invention in which an energy absorbing expandable inner bag lo

cated within the passenger restraint outer bag just be- '

65

You might also like

- Module 05 - Macros 1 Rev 03Document14 pagesModule 05 - Macros 1 Rev 03ercanpekNo ratings yet

- 10 Years of Romanian Mathematical Competitions - Radu Gologan PDFDocument7 pages10 Years of Romanian Mathematical Competitions - Radu Gologan PDFDumi NeluNo ratings yet

- The Votator Process For Chilling and Aerating Oils and FatsDocument3 pagesThe Votator Process For Chilling and Aerating Oils and FatsGrecia SuffoNo ratings yet

- Business Analyst Interview QuestionsDocument11 pagesBusiness Analyst Interview QuestionsALI RIZWAN100% (2)

- May 9, 1972 J. G. Webster Etal 3,662,057: Original Filled May 22, 1968 2 Sheets-SheetDocument8 pagesMay 9, 1972 J. G. Webster Etal 3,662,057: Original Filled May 22, 1968 2 Sheets-SheetGuilherme Dos Santos MoreiraNo ratings yet

- PatentDocument4 pagesPatentbcshendeNo ratings yet

- Us 5237927Document4 pagesUs 5237927wewewewNo ratings yet

- Us 4715285Document2 pagesUs 4715285dgfsduuwioNo ratings yet

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Document4 pagesUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanNo ratings yet

- Olin BWP Primer Patent - US3062146Document5 pagesOlin BWP Primer Patent - US3062146orpheus1972No ratings yet

- United States Patent (191: Gross Et AlDocument5 pagesUnited States Patent (191: Gross Et AlRajesh KoothrapaliNo ratings yet

- Brit. J. Anaesth. (1964), 36, 53: C. Bishop, D. S. Robertson, and S. R. WilliamsDocument5 pagesBrit. J. Anaesth. (1964), 36, 53: C. Bishop, D. S. Robertson, and S. R. WilliamsJosé Manuel SilvaNo ratings yet

- Design of Hot Air Balloon System: Defence Institute of Advanced Technology, PuneDocument28 pagesDesign of Hot Air Balloon System: Defence Institute of Advanced Technology, Puneprakush01975225403No ratings yet

- MNMNDocument4 pagesMNMNfernando Ancaya AncayaNo ratings yet

- United States Patent (19) : Assistant Examiner-Arthur O. HendersonDocument7 pagesUnited States Patent (19) : Assistant Examiner-Arthur O. HendersonDylan WielfredNo ratings yet

- United States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Document13 pagesUnited States Patent 119) ' (111 4,213,924: Shirley, Jr. (45) Jul. 22, 1980Javier Alejandro Rodriguez MelgozaNo ratings yet

- United States Patent (19) : Burger (45) Apr. 24, 1979Document17 pagesUnited States Patent (19) : Burger (45) Apr. 24, 1979Mustafa ŞENNo ratings yet

- (1947, June 21) US2547086 Heating DrumDocument3 pages(1947, June 21) US2547086 Heating DrumaegosmithNo ratings yet

- Chemistry Coursework Self Heating CansDocument7 pagesChemistry Coursework Self Heating Canskqgcnxejd100% (2)

- Ambalaje 3Document5 pagesAmbalaje 3Cristina AlexandraNo ratings yet

- Oct-4, 1966 James E. Webb: 'L QiiiiiiiihiiiiihiiiiihiiihiiiiiiiiihiiiiiiiihhhhiihhiiihiDocument10 pagesOct-4, 1966 James E. Webb: 'L Qiiiiiiiihiiiiihiiiiihiiihiiiiiiiiihiiiiiiiihhhhiihhiiihidavid19775891No ratings yet

- Unites States m1 3,791,297: Ate-T" 1191'Document4 pagesUnites States m1 3,791,297: Ate-T" 1191'rte678No ratings yet

- Title: Archimedes Blimp: Experiment DesignDocument5 pagesTitle: Archimedes Blimp: Experiment DesignTanthree QyubhyNo ratings yet

- Heating, Ventilation, and Air Conditioning-20230116013328Document48 pagesHeating, Ventilation, and Air Conditioning-20230116013328EDUARDO ALCANTARA JRNo ratings yet

- U/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2Document4 pagesU/ /////////I It //////////// ///.////: (12) United States Patent (10) Patent No.: US 6,607,011 B2ererNo ratings yet

- EO Penetration in PolyethyleneDocument8 pagesEO Penetration in PolyethyleneSurendar KesavanNo ratings yet

- Us 3464121 PNEUMATIC DRYDocument4 pagesUs 3464121 PNEUMATIC DRYCesar EnochNo ratings yet

- Sept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1Document6 pagesSept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1kikkuri13No ratings yet

- United States Patent (191: (56) References CitedDocument6 pagesUnited States Patent (191: (56) References Citedandrew22No ratings yet

- Paper 17 DesignDocument7 pagesPaper 17 DesignJohannes Angga PanjaitanNo ratings yet

- Illlllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLDocument18 pagesIlllllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLSteric ZeytraNo ratings yet

- Struthers Scientific & International Corporation v. Rappl & Hoenig Co., Inc., 453 F.2d 250, 2d Cir. (1972)Document8 pagesStruthers Scientific & International Corporation v. Rappl & Hoenig Co., Inc., 453 F.2d 250, 2d Cir. (1972)Scribd Government DocsNo ratings yet

- Frank W. Egan & Company and William H. Willert v. Modern Plastic MacHinery Corp, 387 F.2d 319, 3rd Cir. (1968)Document8 pagesFrank W. Egan & Company and William H. Willert v. Modern Plastic MacHinery Corp, 387 F.2d 319, 3rd Cir. (1968)Scribd Government DocsNo ratings yet

- Applications For Ideal Gas LawsDocument6 pagesApplications For Ideal Gas Lawsdreamxtreme16No ratings yet

- 02 Xxxyyy US53 Fadf 536004235Document6 pages02 Xxxyyy US53 Fadf 536004235Octavio HernandezNo ratings yet

- Selection of Thermal Insulation Thickness of Cold Store EnclosuresDocument10 pagesSelection of Thermal Insulation Thickness of Cold Store EnclosuresArnel AlmacinNo ratings yet

- Episode 603 1 Warming Up A Gas by Speeding Up Its Particles - 0 - 0Document2 pagesEpisode 603 1 Warming Up A Gas by Speeding Up Its Particles - 0 - 0MarcoWetzelNo ratings yet

- How A Hot Air Balloon Works and Its Major PartsDocument1 pageHow A Hot Air Balloon Works and Its Major PartsDarknessNo ratings yet

- US3960807Document5 pagesUS3960807Sayyed Abdul QayyumNo ratings yet

- AutoclaveDocument8 pagesAutoclaveMohd Azzeeruff HafizNo ratings yet

- Continental Can Company, Inc. v. Crown Cork & Seal Company, Inc., 415 F.2d 601, 3rd Cir. (1969)Document8 pagesContinental Can Company, Inc. v. Crown Cork & Seal Company, Inc., 415 F.2d 601, 3rd Cir. (1969)Scribd Government DocsNo ratings yet

- Steam JacketsDocument1 pageSteam Jacketsomar.moradi3707No ratings yet

- MSL GUÍA TÉCNICA 4 PUNTO DE HIELO GENERADOR DE HUMEDAD V2, Dic 2017Document4 pagesMSL GUÍA TÉCNICA 4 PUNTO DE HIELO GENERADOR DE HUMEDAD V2, Dic 2017Yeidy Milena Nova AlmanzaNo ratings yet

- Design of Carton Air Blast Freezing SystemsDocument5 pagesDesign of Carton Air Blast Freezing Systemsvickers100% (1)

- Experimental Testing of The Wick-Concept InsulationDocument8 pagesExperimental Testing of The Wick-Concept InsulationSharat ChandraNo ratings yet

- Ijmet 10 01 065Document7 pagesIjmet 10 01 065IAEME PUBLICATIONNo ratings yet

- Study and Theoretical Calculation On New Type of Adsorption ChillerDocument9 pagesStudy and Theoretical Calculation On New Type of Adsorption ChillerUmut Sinan ÇetinbaşNo ratings yet

- Kknothe,+09 SchmidtDocument16 pagesKknothe,+09 SchmidtSriyonoNo ratings yet

- Jacketed VesselsDocument2 pagesJacketed VesselsImamRNNo ratings yet

- Energies: Performance Evaluation of A Desiccant Dehumidifier With A Heat Recovery UnitDocument12 pagesEnergies: Performance Evaluation of A Desiccant Dehumidifier With A Heat Recovery UnitspiritveluNo ratings yet

- 1 s2.0 S1290072923004015 MainDocument17 pages1 s2.0 S1290072923004015 MainAndika RivaldiNo ratings yet

- Sépt 9, 1969 R. P. Gosm ND 3466,196: Filed Nov. 12, 1965Document7 pagesSépt 9, 1969 R. P. Gosm ND 3466,196: Filed Nov. 12, 1965david19775891No ratings yet

- Types of Jackets For Reaction VesselDocument4 pagesTypes of Jackets For Reaction VesselPRATHU SINGHNo ratings yet

- Experiment 3 - Loss On IgnitionDocument5 pagesExperiment 3 - Loss On IgnitionSeth Aboagye JnrNo ratings yet

- US4464989Document5 pagesUS4464989Nqobane MakhobaNo ratings yet

- United States Patent (191: Schaper Et A1Document3 pagesUnited States Patent (191: Schaper Et A1Juan Pablo EspinosaNo ratings yet

- WHP Reference-Guide FINALDocument24 pagesWHP Reference-Guide FINALDewanjee AshrafNo ratings yet

- Gasifier For Damp Fuel-monorator-EngDocument10 pagesGasifier For Damp Fuel-monorator-EngMarky MaypoNo ratings yet

- Aspects of Lead Acid Battery Technology 5 Dry Charging of Formed Negative PlatesDocument12 pagesAspects of Lead Acid Battery Technology 5 Dry Charging of Formed Negative PlatestjkiddNo ratings yet

- Seaflex - Analysis of Fabric Structures - PimmAJ - ThesisDocument303 pagesSeaflex - Analysis of Fabric Structures - PimmAJ - Thesisjeedan100% (1)

- July 19, 1960: ObjectDocument3 pagesJuly 19, 1960: ObjectVansala GanesanNo ratings yet

- 3-1 Energiøkonomiske TørreprocesserDocument15 pages3-1 Energiøkonomiske TørreprocesservhendrayawanNo ratings yet

- Gamer! Lee Miller: Dec. 26, 1944. - H - Null-Er Des. 139,861 'Document2 pagesGamer! Lee Miller: Dec. 26, 1944. - H - Null-Er Des. 139,861 'david19775891No ratings yet

- United States Patent: Shah-HosseiniDocument28 pagesUnited States Patent: Shah-Hosseinidavid19775891No ratings yet

- Che-Torah Tape/10W) Po-Feng 33333333? 3% 13/5882 5152??Document16 pagesChe-Torah Tape/10W) Po-Feng 33333333? 3% 13/5882 5152??david19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0311283 A1Document28 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0311283 A1david19775891No ratings yet

- United States Patent: Muras Et Al. (10) Patent N0.: (45) Date of PatentDocument11 pagesUnited States Patent: Muras Et Al. (10) Patent N0.: (45) Date of Patentdavid19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0013586 A1Document13 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0013586 A1david19775891No ratings yet

- Us 20130218893Document16 pagesUs 20130218893david19775891No ratings yet

- United States Patent: (12) (10) Patent N0.: US 8,250,105 B2 Bollinger Et Al. (45) Date of Patent: Aug. 21, 2012Document41 pagesUnited States Patent: (12) (10) Patent N0.: US 8,250,105 B2 Bollinger Et Al. (45) Date of Patent: Aug. 21, 2012david19775891No ratings yet

- Us 20120245970Document67 pagesUs 20120245970david19775891No ratings yet

- 305 / Create Statistical Data: Test/Refine ModelDocument32 pages305 / Create Statistical Data: Test/Refine Modeldavid19775891No ratings yet

- United States Patent: Prahlad Et A1. (10) Patent N0.: (45) Date of PatentDocument34 pagesUnited States Patent: Prahlad Et A1. (10) Patent N0.: (45) Date of Patentdavid19775891No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,315,981 B2Document34 pagesUlllted States Patent (10) Patent N0.: US 8,315,981 B2david19775891No ratings yet

- Us 20130182895Document39 pagesUs 20130182895david19775891No ratings yet

- European Patent Application: Method and Computer Program For Statistical and Data-Mining Processing of Large Data SetsDocument16 pagesEuropean Patent Application: Method and Computer Program For Statistical and Data-Mining Processing of Large Data Setsdavid19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0318015 A1Document26 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0318015 A1david19775891No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,332,087 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,332,087 B2david19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0311047 A1Document12 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0311047 A1david19775891No ratings yet

- United States Patent: Machalek (10) Patent N0.: (45) Date of PatentDocument21 pagesUnited States Patent: Machalek (10) Patent N0.: (45) Date of Patentdavid19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0259890 A1Document11 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0259890 A1david19775891No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,466,810 B2Document12 pagesUlllted States Patent (10) Patent N0.: US 8,466,810 B2david19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0073547 A1Document16 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0073547 A1david19775891No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,380,740 B2Document23 pagesUlllted States Patent (10) Patent N0.: US 8,380,740 B2david19775891No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0290317 A1Document30 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0290317 A1david19775891No ratings yet

- United States Patent (10) Patent N0.: US 8,249,892 B2Document14 pagesUnited States Patent (10) Patent N0.: US 8,249,892 B2david19775891No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,275,604 B2Document21 pagesUlllted States Patent (10) Patent N0.: US 8,275,604 B2david19775891No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,370,386 B1Document17 pagesUlllted States Patent (10) Patent N0.: US 8,370,386 B1david19775891No ratings yet

- MF Gel Card Centrifuge & Gel Card Incubator Cat.2020Document2 pagesMF Gel Card Centrifuge & Gel Card Incubator Cat.2020محمد الشيميNo ratings yet

- Vinayak Narwade Test 6Document32 pagesVinayak Narwade Test 6V kNo ratings yet

- PPDocument12 pagesPPsanto_r05No ratings yet

- Chapter2 Starting A New ProjectDocument22 pagesChapter2 Starting A New Projecteman71No ratings yet

- Cambridge IGCSE: Computer Science 0478/23Document16 pagesCambridge IGCSE: Computer Science 0478/23Sean KeithNo ratings yet

- Java Lab QB - CIE-2024Document4 pagesJava Lab QB - CIE-2024rounak282002No ratings yet

- RB Conveyor Belt - Pipe 20181001Document9 pagesRB Conveyor Belt - Pipe 20181001PaulRamosNo ratings yet

- ATI FirePro V7800 DatasheetDocument2 pagesATI FirePro V7800 Datasheetjbarboza2236No ratings yet

- Sanket Pandya TDDSDocument29 pagesSanket Pandya TDDSsktniperNo ratings yet

- J14289 Digital Thread Whitepaper SingleDocument16 pagesJ14289 Digital Thread Whitepaper SingleLeonardo RamosNo ratings yet

- Intro To LV in 3 Hours For Control and SimDocument81 pagesIntro To LV in 3 Hours For Control and SimNI-US100% (5)

- Java Quiz PDFDocument106 pagesJava Quiz PDFNadaBelaRadaNo ratings yet

- Structural Design Calculation of CCT at BhimavaramDocument61 pagesStructural Design Calculation of CCT at Bhimavaramepe civilNo ratings yet

- FlywheelDocument10 pagesFlywheelKasam SantoshrishiNo ratings yet

- Breaker Failure ProtectionDocument2 pagesBreaker Failure ProtectionNasser Abdel RaoufNo ratings yet

- Sukatan Pelajaran Matematik KBSRDocument13 pagesSukatan Pelajaran Matematik KBSRAhimin KerisimNo ratings yet

- Answers: (Anticipation Guide and Lesson 4-1)Document18 pagesAnswers: (Anticipation Guide and Lesson 4-1)Mazahir Mohammad BakirNo ratings yet

- Exhumation and Design of Anchorages in Chalk Barley Mothersille Weerasinghe Ice Publication 2003Document22 pagesExhumation and Design of Anchorages in Chalk Barley Mothersille Weerasinghe Ice Publication 2003Kenny CasillaNo ratings yet

- Oliveboard SSC ShortcutsDocument24 pagesOliveboard SSC ShortcutsSlowSolid NotLiquidNo ratings yet

- Mooring of Ships - Forces (Document168 pagesMooring of Ships - Forces (shakirhamid6687100% (5)

- Msunit 2 GraspsDocument6 pagesMsunit 2 Graspsapi-338845804No ratings yet

- Shanghai TowerDocument11 pagesShanghai TowerErik Nevala-LEe50% (2)

- HHDocument48 pagesHHbipin012No ratings yet

- Notes On SetsDocument8 pagesNotes On SetsJpricarioNo ratings yet

- Para Sa CompreDocument9 pagesPara Sa CompreJunard AsentistaNo ratings yet

- Incorporating Artificial Intelligence in ShoppingDocument6 pagesIncorporating Artificial Intelligence in ShoppingGaby HayekNo ratings yet

- TO1-Group-5 Soil Mechanics Lab Experiment No. 4Document7 pagesTO1-Group-5 Soil Mechanics Lab Experiment No. 4Xam AcostaNo ratings yet