Professional Documents

Culture Documents

WHR 1

WHR 1

Uploaded by

Ashok KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WHR 1

WHR 1

Uploaded by

Ashok KumarCopyright:

Available Formats

Waste Heat Recovery

KeyTo Higher Energy Efciency

Optimization of technical and efciency parameters for waste heat recovery system

15th/16th November 2013 Mumbai 18th/19th November 2013 Delhi 20th/21st November 2013 Kolkata 22nd/23rd November 2013 Chennai

Objective : Main objective of this two day training program on Waste Heat Recovery = Key to Higher Energy Efciency is to appraise the participants on Identication of the existing energy system Break-up of the energy resources being used Heat-Power cycle ratio of the system Identify sources of waste heat / power available Potential to recover the waste heat. Identifying WHR options and evaluating cost-benet analysis of the options Selecting the best technology and Quantication of the option in terms of energy savings and protability This program is based on the industrial experience and expertise of the faculty in Petroleum Rening, Petrochemical , Fertilizer and Power Generation Industries. Benets of attending this program. Tangible benets of attending this program are Participants shall be able to identify energy conservation areas quantitatively and implement waste energy recovery projects . Identify the behavior of energy intensive equipments even when a number of process variables exert their inuence on the equipment's performance and efciency. Shall be able to sustain unit throughput quantity and quality at minimum cost of production Meet all the production / generation targets at minimum cost of energy and maximize prot margin. This program helps the participants in understanding the total system clearly and helps to determine the energy links by a number of practical examples and case studies ,which may be very useful for the participants to apply similar methodology for their system with certain modications. The compact disk provided with the manual covers WHR concepts in PDF format with hyper linked templates to carry out some elementary calculations. With the knowledge gained from this program, it is believed that the participants will be greatly beneted in optimizing heat-power cycle ratio to achieve maximum energy efciency. The overall purpose of this program is to appraise the participants on the role of Waste Heat Recovery on Energy efciency of the total system, subsystem and equipment for taking corrective actions at the right time and right cost. This is based on the concept, 'One ounce of prevention is better than hundred pounds of cure.' www.marcepinc.com

Waste Heat Recovery

KeyTo Higher Energy Efciency

Optimization of technical and efciency parameters for waste heat recovery system

15th/16th November 2013 Mumbai 18th/19th November 2013 Delhi 20th/21st November 2013 Kolkata 22nd/23rd November 2013 Chennai

Course Facilitator:

Dr. G. G. Rajan

Dr. Rajan has a 31 years of extensive experience and experties in Refining, Petrochemical & Fertilizer industries. A Chemical Engineer by profession with qualifications in Mathematics, Statistics, Management, Operations Research and Computer Applications. He has developed a number of process models and has published and presented about 150 papers in national and Inter National Seminars related to energy, environment, utility management, process decisioneering etc. He has written a book titled Optimizing Energy Efficiencies in the Industry, Published by Tata McGraw Hill and McGraw Hill USA. He has also written a book titled Practical Energy Efficiency optimization published by PennWell,US in 2006. Prior to this, he was the Chief Manager in the dept. of Energy of KRL. He was deputed to Centre for High Technology, by the Ministry of Petroleum in India as an Additional Director in 1988, for a span of six years to accomplish special assignments. He has won a number of awards for his concepts on Productivity Management. He also has been the Chairman of an Energy Audit Team in 1990s, set up by the Ministry of Petroleum and Natural Gas for energy auditing of three major refineries (CPCL, Kochi Refineries Ltd, HPCL Vizag Refinery). Besides this he had conducted energy auditing of petrochemical plants like Asian Peroxide Ltd, HOCL, KRL-Aromatics Plant, BPC Aromatics Plant, Fine papers Dubai etc. By virtue of his contribution to Technology, he has been selected as a member of International Who is Who Society, in Gibralter. His area of specialization is Energy and Environment Auditing, Performance Evaluation, Bench Marking, Productivity Analysis and Profit Maximization, Operation, Maintenance and Troubleshooting of equipments including failure analysis and prediction.

www.marcepinc.com

Waste Heat Recovery

KeyTo Higher Energy Efciency

Optimization of technical and efciency parameters for waste heat recovery system

15th/16th November 2013 Mumbai 18th/19th November 2013 Delhi 20th/21st November 2013 Kolkata 22nd/23rd November 2013 Chennai

Two days training agenda:

Day-One

INDUSTRIAL ENERGY STSTEM Energy consumption pattern of major processes Energy wise break up of Total Energy Input Energy mix impact productivity / protability of energy intensive industries Energy cost elements Energy cost reduction by Efciency improvement (Technology / energy efcient process / equipment, improvised techniques) Energy recycling (waste heat) Energy recovery (waste heat) INTRODUCTION TO WASTE HEAT RECOVERY About waste heat Energy input / output analysis Total system audit to identify waste heat areas and prioritization. Quantifying waste heat for Energy efciency improvement schemes Setting waste heat / energy recovery priority Pareto's model Waste heat recovery impact on production cost, protability, environment and safety. Constraints in waste energy recovery DEVELOPING WASTE HEAT RECOVERY SCHEMES. WHR classication - temperature-wise High temperature range where heat is available at a temperature above 650 oC.( e.g. blast furnace / incinerator waste gas ) Medium temperature range is between 250 to 650 oC Low temperature range i.e. below 250 oC. WHR examples related to Rening Petrochemical Fertilizer and Power Generation Industries. GENERAL WASTE HEAT RECOVERY METHODS Pre heating combustion air Boilers Furnaces using recuperation Ovens Gas turbines using regenerators etc Parameters to be considered for waste heat recovery Economics of waste heat recovery Case studies Micro level Macro level

Day-Two

ENERGY MIX / PROCESS MIX OPTIONS / IMPACT Cost- benet analysis of WHR schemes Overcoming operational constraints Retrots for WHR Waste heat recovery methods (case studies) heaters ( Air pre heaters ) boilers ( Economizer / Air pre heater ) turbine exhausts compressors DG exhaust gas Regenerator off gas CASE STUDIES / EXERCISE ON EACH CHAPTER. COMBINED HEAT-POWER CYCLE OPTIMIZATION MODERN HEAT RECOVERY METHODS MINI PROGRAM CD Demo. WORKED OUT EXAMPLES Discussion and summing up

Note : In this program, participants are encouraged to bring their own problems for discussion and analysis.

www.marcepinc.com

Registration Page:

Waste Heat Recovery

KeyTo Higher Energy Efciency

Optimization of technical and efciency parameters for waste heat recovery system

15th/16th November 2013 Mumbai 18th/19th November 2013 Delhi 20th/21st November 2013 Kolkata 22nd/23rd November 2013 Chennai

Please register the following delegate/s for (For Additional delegates please photocopy this form)

PARTICIPATION DETAILS

Name: Designation: Email: Location:

Organisation Details & Authorization: I / We Hereby Confirm To The Above And Authorize Our Participants To The Programme. Please Send The Invoice To:

Company Name: Nominating Authority: Designation: Company Postal Address: Tel No.: Cell No.: * This Booking is Invalid Without Signature Email:

Signature

Investment fees

01 Delegate - INR: 27,500/- (Base Price)

Service Tax @ 12.36% Program coordinator: Mr. Raj Khanna on: Cell: or email: 09167469140 rajkhanna@marcepinc.com

Payment Terms:

Payment Is Required Within 5 Working Days From the Date Of Invoice. Account Transfer/Cheque/DD Should Be In Favour Of Marcep

Inc. Payable At Par In Mumbai.

NON- RESIDENTIAL PROGRAME

Participation Fees Include: Workshop kit Documentation, Refreshment, Luncheon, Certificate Of Participation

Terms & Conditions: Fees are inclusive of programme materials and refreshments. Payment Terms: Following completion and return of the registration form, full payment is required within 5 days from receipt of invoice. PLEASE NOTE: Payment must be received prior to the event date. A receipt will be issued on payment. Due to limited seats space, we advice early registration to avoid disappointment. A cancellation fee will be charged under the terms outlined below. Cancellation/Subsitituion: Provided the total fee has been paid, substitutions at no extra charge will be allowed to attend the seminar. Substitutions prior to event and on date of the event will be allowed subject to an administration fee of equal to10% of the total fee that is to be transferred . Otherwise all bookings carry a 50% cancellation liability immediately after a signed sales contract has been received by Marcep Inc. (as defined above). . Cancellations must be received in writing by an email or by fax three (3) weeks before the conference is to be held in order to obtain a credit voucher representing 50% of the total fee to be utilized against the cost of any future Marcep Inc. conference. Thereafter, the full conference fee is payable and is non refundable. The service charge is completely nonrefundable and non-creditable. Payment terms are five days and payment must be made prior to the start of the conference. By signing this contract, the client agrees that in case of dispute or cancellation of this contract that Marcep Inc. will not be able to mitigate its losses for any less than 50% of the total contract value. In the event the cancellation is made one day before the event or on the day of the event then there will be no refund. If, for any reason, Marcep Inc. decides to cancel or postpone this Payment Policy: conference, Marcep Inc. is not responsible for any covering airfare, hotel, or other travel costs incurred by clients. The conference fee will not be refunded, but can be credited to a future conference. Event programme content is subject to change without notice. Copyright etc: All intellectual property rights in all materials produced or distributed by Marcep Inc. in connection with this event is expressly reserved and any unauthorized duplication, publication or distribution is prohibited.

Marcep Inc.

Suite 12,Sagar Tower,Off S.V. Road,Opp 24 Carat Cinema Jogeshwari (W). Mumbai-400102. India

For Registration: Tel - 022-40510100 Fax - 022-40510102 info@marcepinc.com

R

You might also like

- Sage X3 - User Guide - SE - Reports - Common Data-US000Document108 pagesSage X3 - User Guide - SE - Reports - Common Data-US000caplusinc100% (1)

- JLPT n5 Study Material - Nihongo IchibanDocument13 pagesJLPT n5 Study Material - Nihongo IchibankirankumarmrNo ratings yet

- En ConDocument313 pagesEn ConItilekha DashNo ratings yet

- UOP Energy Management Solutions PaperDocument5 pagesUOP Energy Management Solutions PaperDeni Yudha PermanaNo ratings yet

- Ch.2 QADocument9 pagesCh.2 QArogers4759100% (1)

- Tell Me About Your SelfDocument4 pagesTell Me About Your SelfAmely sarah kamalNo ratings yet

- Brochure - Energy Management and Audit 2023Document2 pagesBrochure - Energy Management and Audit 2023sujithn89No ratings yet

- Energy Conservation in Thermal SystemsDocument34 pagesEnergy Conservation in Thermal SystemsAditya Kumar50% (2)

- Energy Efficiency in Sugar Plant Steam and Power Generation PDFDocument6 pagesEnergy Efficiency in Sugar Plant Steam and Power Generation PDFSrikanth SriNo ratings yet

- 1.3 Energy Management & AuditDocument39 pages1.3 Energy Management & AuditVirendra ZopeNo ratings yet

- Template - Energy Audit, Preliminary and Detailed Energy Audit, Methodology, Instruments Used, Conducting An Energy Audit On 07-08-2021353919Document4 pagesTemplate - Energy Audit, Preliminary and Detailed Energy Audit, Methodology, Instruments Used, Conducting An Energy Audit On 07-08-2021353919apexpredator832No ratings yet

- Energy Efficiency Workshop Brochure 2013 and Workshop Registration Form - ForM ADocument4 pagesEnergy Efficiency Workshop Brochure 2013 and Workshop Registration Form - ForM AJoshua MakenaNo ratings yet

- Energy Trainers International: The Gulf HotelDocument7 pagesEnergy Trainers International: The Gulf HotelAkgNo ratings yet

- DSM Techniques, ApplicationDocument29 pagesDSM Techniques, ApplicationRaja RamNo ratings yet

- Sem - Announcement - Enhance CCPP Perf - Jakarta - Mar 2022Document7 pagesSem - Announcement - Enhance CCPP Perf - Jakarta - Mar 2022Hứa Thông TriệuNo ratings yet

- 1 (1) 3energymgt&auditDocument39 pages1 (1) 3energymgt&auditK.S.MAYILVAGHANANNo ratings yet

- Maximising Refinery Margin With Minimal CapexDocument12 pagesMaximising Refinery Margin With Minimal CapexWon JangNo ratings yet

- Energy Auditing: Do Not Estimate When You Can Calculate! Do Not Calculate When You Can Measure!!Document70 pagesEnergy Auditing: Do Not Estimate When You Can Calculate! Do Not Calculate When You Can Measure!!humbleaviNo ratings yet

- ECM Paper 6Document18 pagesECM Paper 6AggaNo ratings yet

- Energy AuditDocument2 pagesEnergy AuditsushankNo ratings yet

- Home Energy Management System ThesisDocument4 pagesHome Energy Management System ThesisLisa Riley100% (2)

- CHP HandbookDocument85 pagesCHP HandbookKosala GunawardanaNo ratings yet

- EMangConts PrivateDocument11 pagesEMangConts PrivateGajanan PatangeNo ratings yet

- Compressed Air System Design, Operating and MaintenanceDocument29 pagesCompressed Air System Design, Operating and Maintenanceibrahim1961No ratings yet

- CIVIL Energy AuditDocument20 pagesCIVIL Energy AuditJokerNo ratings yet

- Energy ManagementDocument51 pagesEnergy Managementdeadlegend14No ratings yet

- Ieee Format of Energy Audit of Our CollegeDocument3 pagesIeee Format of Energy Audit of Our CollegeSunil ShettyNo ratings yet

- Energy Management Combined PDFDocument473 pagesEnergy Management Combined PDFf20201839No ratings yet

- BEE 2015, Bureau of Energy Efficiency Entrance Exam, BEE Syllabus, BEE Dates and Notification, EligibilityDocument7 pagesBEE 2015, Bureau of Energy Efficiency Entrance Exam, BEE Syllabus, BEE Dates and Notification, Eligibilityheman_tNo ratings yet

- Performance of Generating Plant CommitteeDocument3 pagesPerformance of Generating Plant Committeehappale2002No ratings yet

- MS-CERT-Energy Audit Scheme-TEA PDFDocument11 pagesMS-CERT-Energy Audit Scheme-TEA PDFqms1234No ratings yet

- Research ArticleDocument11 pagesResearch ArticleMukhtiar AliNo ratings yet

- COGENERATION: Technology and Economics: Electricity Out Fuel in Heat or Cooling OutDocument4 pagesCOGENERATION: Technology and Economics: Electricity Out Fuel in Heat or Cooling OutShrikant KajaleNo ratings yet

- Epeng 308 Energy Management & AuditingDocument8 pagesEpeng 308 Energy Management & AuditinggwemeowenNo ratings yet

- Combined Cycle Power PerformanceDocument4 pagesCombined Cycle Power PerformanceSyedNadeemAhmedNo ratings yet

- PHD Thesis On Energy AuditDocument5 pagesPHD Thesis On Energy Auditexuhszief100% (2)

- AuditDocument31 pagesAuditGanga Rao Ganga100% (1)

- Hands On Training For "Energy Conservation in Compressed Air System"Document3 pagesHands On Training For "Energy Conservation in Compressed Air System"AkshayKadbeNo ratings yet

- Green Team: Business Energy Audit ManualDocument39 pagesGreen Team: Business Energy Audit ManualTrigen EnergiNo ratings yet

- Energy and Carbon Strategy For Accountants: Reporting IssuesDocument8 pagesEnergy and Carbon Strategy For Accountants: Reporting IssuesMacquarieCPANo ratings yet

- Design and Fabrication of Electricity Production System From Industrial Heat or Waste Material ReportDocument20 pagesDesign and Fabrication of Electricity Production System From Industrial Heat or Waste Material ReportErole Technologies Pvt ltd Homemade EngineerNo ratings yet

- Manual of EctDocument43 pagesManual of EctRamesh ParmarNo ratings yet

- Energy AuditDocument33 pagesEnergy Auditmirage2oasis3No ratings yet

- Energy AuditDocument20 pagesEnergy AuditGOLDEN digger100% (1)

- Bba005 EnergyDocument173 pagesBba005 Energyhumayan kabirNo ratings yet

- Energy ManagementDocument10 pagesEnergy ManagementPratik RanjanNo ratings yet

- Solution Dynamics Boiler Efficiency ImprovementDocument2 pagesSolution Dynamics Boiler Efficiency ImprovementtvsshindeNo ratings yet

- Eem Module2 2Document23 pagesEem Module2 2Binod Da PerfectsoulNo ratings yet

- Implementation PhaseDocument4 pagesImplementation PhaseFmuharIrolNo ratings yet

- 1.3 Energy Management & AuditNDocument34 pages1.3 Energy Management & AuditNvmramakrishnanNo ratings yet

- Sabp A 012Document92 pagesSabp A 012sethu1091No ratings yet

- Textbook Solutions Manual For Guide To Energy Management 8Th Edition International Version Klaus Dieter E Pawlik Ebook All Chapter PDFDocument54 pagesTextbook Solutions Manual For Guide To Energy Management 8Th Edition International Version Klaus Dieter E Pawlik Ebook All Chapter PDFalba.desrochers305100% (4)

- Emirates Energy Award: Name of Organization/Individual Being Nominated For This AwardDocument4 pagesEmirates Energy Award: Name of Organization/Individual Being Nominated For This AwardIbrahim FaroukNo ratings yet

- Evaluate Your Cooling TowerDocument5 pagesEvaluate Your Cooling TowerUpendranath BhupalNo ratings yet

- Energy Audit: Gnanamani College of Technology Namakkal, Tamil NaduDocument10 pagesEnergy Audit: Gnanamani College of Technology Namakkal, Tamil Nadugayatri ganeshNo ratings yet

- FOUR STEPS of Energy Management For EIP Website 071025 PDFDocument10 pagesFOUR STEPS of Energy Management For EIP Website 071025 PDFJulio RicardoNo ratings yet

- Let's Go Green Fellows: Assignment On An Environmental IssueDocument13 pagesLet's Go Green Fellows: Assignment On An Environmental IssueNadeeshan WadugeNo ratings yet

- Ram Seminar ReportDocument23 pagesRam Seminar ReportYerrolla RamalingamNo ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Multi-Objective Optimization in Chemical Engineering: Developments and ApplicationsFrom EverandMulti-Objective Optimization in Chemical Engineering: Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Mathematics OF Investment: Cavite State UniversityDocument14 pagesMathematics OF Investment: Cavite State UniversityAlyssa Bianca AguilarNo ratings yet

- Elsie W. Rudisill and Coal, Feed and Lumber Company, Inc. v. Southern Railway Company, 548 F.2d 488, 4th Cir. (1977)Document2 pagesElsie W. Rudisill and Coal, Feed and Lumber Company, Inc. v. Southern Railway Company, 548 F.2d 488, 4th Cir. (1977)Scribd Government DocsNo ratings yet

- Note Antibacterial Activity of Medicinal Plants From The PhilippinesDocument4 pagesNote Antibacterial Activity of Medicinal Plants From The PhilippinesRey TantiadoNo ratings yet

- Adaptive Design of Machine Tool GearboxesDocument9 pagesAdaptive Design of Machine Tool Gearboxesأحمد دعبسNo ratings yet

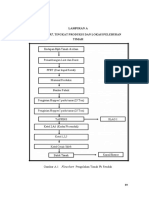

- Flowchart, Tingkat Produksi Dan Lokasi Peleburan: Lampiran ADocument11 pagesFlowchart, Tingkat Produksi Dan Lokasi Peleburan: Lampiran Aanton wibowoNo ratings yet

- Pisaycom NotesDocument7 pagesPisaycom NotesAmelia Ria CanlasNo ratings yet

- Quasi Turbine 140505201837 Phpapp01Document16 pagesQuasi Turbine 140505201837 Phpapp01pravesh singh100% (1)

- Ktisis Floor Coatings BrochureDocument8 pagesKtisis Floor Coatings Brochureakis5375No ratings yet

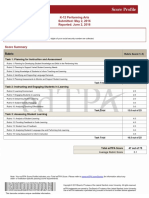

- EdtpaDocument7 pagesEdtpaapi-310967404No ratings yet

- 095-Everett vs. Asia Banking Corp 49 Phil 512Document8 pages095-Everett vs. Asia Banking Corp 49 Phil 512Jopan SJNo ratings yet

- TilingDocument1 pageTilingazerNo ratings yet

- SEDGs GuidelinesDocument16 pagesSEDGs GuidelinesvijayhmakwanaNo ratings yet

- Volume Correction Factors - Diesel Fuel: Issued: July 2018Document5 pagesVolume Correction Factors - Diesel Fuel: Issued: July 2018lasithNo ratings yet

- CARI-Checklist For Assessing Readiness For Implementation-BARWICKDocument5 pagesCARI-Checklist For Assessing Readiness For Implementation-BARWICKabbass.alseadyNo ratings yet

- Franchising Reading Materials 2019Document40 pagesFranchising Reading Materials 2019Nardsdel Rivera50% (2)

- S/4HANA Configuration Case Phase I - Handbook: Product Motivation PrerequisitesDocument75 pagesS/4HANA Configuration Case Phase I - Handbook: Product Motivation PrerequisitesDianPramana100% (2)

- Modified M.SC SyllabusDocument27 pagesModified M.SC SyllabusAbhishekBanerjeeNo ratings yet

- Costs and Benefits of MarketingDocument46 pagesCosts and Benefits of MarketingSyeda Maryium Fatima100% (1)

- Model Delone and Mclean Dalam Aplikasi Absensi Super Hana Di PT Telkom PalembangDocument6 pagesModel Delone and Mclean Dalam Aplikasi Absensi Super Hana Di PT Telkom PalembangZahwa PutriNo ratings yet

- Walters Ms With Images, 4-09-1Document66 pagesWalters Ms With Images, 4-09-1Robert BranchNo ratings yet

- PRV Catlogue-Samson (09!06!09)Document6 pagesPRV Catlogue-Samson (09!06!09)pkrishna984No ratings yet

- Ict1 July2014 ColorDocument289 pagesIct1 July2014 ColorLawrence ManaliliNo ratings yet

- PhenomenologyDocument27 pagesPhenomenologyMerasol Matias Pedrosa100% (1)

- OilCharacterization Adeyab PDFDocument18 pagesOilCharacterization Adeyab PDFJhosymarSantosGutierrezNo ratings yet

- ReflectionDocument1 pageReflectionThess Tecla Zerauc Azodnem100% (1)

- Hooke Jeeves Method - 15Document11 pagesHooke Jeeves Method - 15Kelly SantosNo ratings yet

- PTC Creo Schematics DatasheetDocument5 pagesPTC Creo Schematics DatasheetJose Angel RodriguezNo ratings yet