Professional Documents

Culture Documents

Timberkits: Lion Instructions

Timberkits: Lion Instructions

Uploaded by

Calama Arica São PauloCopyright:

Available Formats

You might also like

- Graceful Kelly BagDocument9 pagesGraceful Kelly BagPatricia Pereira100% (1)

- KGe Profiler ManualDocument5 pagesKGe Profiler ManualReinaldo PulidoNo ratings yet

- Automata Cat and Mouse PDFDocument9 pagesAutomata Cat and Mouse PDFBruno ThiagoNo ratings yet

- Worm Harvester 212011Document0 pagesWorm Harvester 212011mattpac3No ratings yet

- Fabric Building Assembly GuideDocument15 pagesFabric Building Assembly GuideWaqas Haider100% (1)

- Informacion Zippers PDFDocument2 pagesInformacion Zippers PDFFederico Cintrón Fiallo100% (2)

- Amigurumi 34jyoti A Painted Indian ElephantDocument8 pagesAmigurumi 34jyoti A Painted Indian ElephantMónica Campos Pérez100% (3)

- CRAFT VILLAGE, VELLAR THIRUVANANTHAPURAM, KERALA. Project Report by Sudheesh Kumar S S (Designer)Document104 pagesCRAFT VILLAGE, VELLAR THIRUVANANTHAPURAM, KERALA. Project Report by Sudheesh Kumar S S (Designer)anashwara80% (5)

- Miniature Marble Machine For WEB 259013455Document2 pagesMiniature Marble Machine For WEB 259013455Squinkle78% (9)

- Reedmaking NotesDocument3 pagesReedmaking Notesapi-201119152No ratings yet

- Dirt Maker 14 ManualDocument16 pagesDirt Maker 14 Manualcompudog0% (1)

- Eco Power Instruction Manual WebDocument10 pagesEco Power Instruction Manual WebJuliano CordeiroNo ratings yet

- FreebirdDocument5 pagesFreebirdLucas Nahuel AsiainNo ratings yet

- K Ge Reeds Profiling Machine ManualDocument6 pagesK Ge Reeds Profiling Machine ManualNeuromante3223No ratings yet

- RodSmith Build-It! KitsDocument1 pageRodSmith Build-It! KitsCamil BwoyNo ratings yet

- Better BoxesDocument6 pagesBetter Boxes71valiant100% (1)

- Assembly Guide Form I ToDocument10 pagesAssembly Guide Form I ToChivalrous SpringNo ratings yet

- Patrol Box PlansDocument10 pagesPatrol Box PlansAlessandro UrendaNo ratings yet

- Comfy Crown PatternDocument16 pagesComfy Crown PatternSilvia TeixeiraNo ratings yet

- (Artigo) Ajuste de Projeção Do Espelho Do ViolinoDocument15 pages(Artigo) Ajuste de Projeção Do Espelho Do ViolinoRodolfo MinhotoNo ratings yet

- Step 1: Procedural Steps ImagesDocument4 pagesStep 1: Procedural Steps Imagesapi-336491889No ratings yet

- Build A Cremation CaskDocument7 pagesBuild A Cremation CaskJeffrey Michael Atencio100% (1)

- Apple With SwingDocument12 pagesApple With SwingMilen Solakov100% (2)

- Workshops - Composite, Riveting, Fabric & MaintenanceDocument6 pagesWorkshops - Composite, Riveting, Fabric & Maintenanceairbuk doeing100% (1)

- Circoflex Building InstructionsDocument4 pagesCircoflex Building InstructionsGiacomo Marco ToigoNo ratings yet

- Glasses InstructionsDocument4 pagesGlasses InstructionsFranco 06100% (1)

- Mascara Plague DRDocument21 pagesMascara Plague DRdiego trujilloNo ratings yet

- 1903 Wright Flyer Model InstructionsDocument12 pages1903 Wright Flyer Model InstructionsAntónio OliveiraNo ratings yet

- Nesting Tables: REQUIREMENTS FOR THIS PROJECT-I Made The Tables As They Are ShownDocument11 pagesNesting Tables: REQUIREMENTS FOR THIS PROJECT-I Made The Tables As They Are Shown- yAy3e -No ratings yet

- Gripper SDocument9 pagesGripper Ssantiago_vNo ratings yet

- Ornithopter 2 PDFDocument1 pageOrnithopter 2 PDFMarco Antônio Gomes ApolinarioNo ratings yet

- FrogDocument10 pagesFrogbnh2No ratings yet

- Arabesque BagDocument13 pagesArabesque Baghematite7No ratings yet

- Bensen b8 PDFDocument8 pagesBensen b8 PDFmaxNo ratings yet

- Combination Lock Instructions v1dDocument20 pagesCombination Lock Instructions v1demreNo ratings yet

- Woodworking Guide - Basic JoineryDocument6 pagesWoodworking Guide - Basic JoineryMrPaulCorcoran100% (1)

- How To String A Lacrosse Stick: Completion Time: Approximately 1 HourDocument13 pagesHow To String A Lacrosse Stick: Completion Time: Approximately 1 Hourdwb5307No ratings yet

- PDF Mini Clip Pie InstructionsDocument6 pagesPDF Mini Clip Pie InstructionsMarija CvetkovićNo ratings yet

- How To Make A Space ShuttleDocument4 pagesHow To Make A Space Shuttlelori millerNo ratings yet

- Grrrobot!Document16 pagesGrrrobot!soloinformacionNo ratings yet

- Combination LockDocument6 pagesCombination LockFahrudin NoorNo ratings yet

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- How To Fit An Upgrade ChipDocument1 pageHow To Fit An Upgrade ChipAllegra AmiciNo ratings yet

- Acoustic Guitar PlansDocument7 pagesAcoustic Guitar PlansFrançesko Astroza80% (5)

- Shuttle Solid Rocket Booster's and External TankDocument6 pagesShuttle Solid Rocket Booster's and External TankJefferson MatheusNo ratings yet

- Bed and Storage BoxesDocument9 pagesBed and Storage Boxespoimandres100% (1)

- Provisional Press Laser InstructionsDocument8 pagesProvisional Press Laser Instructionsrobert smithNo ratings yet

- Shorelandr ManualDocument8 pagesShorelandr ManualWaaboooo wañangoNo ratings yet

- Cove Cutting Jigs For The BT3000 by Jim FryeDocument8 pagesCove Cutting Jigs For The BT3000 by Jim FryeozilogNo ratings yet

- Lilac Mini MessengerDocument16 pagesLilac Mini MessengerДрагана Станковић100% (1)

- Pattern Kennedy BagDocument25 pagesPattern Kennedy BagCristina Stanica100% (4)

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Cut Your OwnDocument2 pagesCut Your Ownalbanil96No ratings yet

- How To Assemble A Bee Hive Box or Super - A Beginner Beekeeper's GuideDocument17 pagesHow To Assemble A Bee Hive Box or Super - A Beginner Beekeeper's Guidekorki77No ratings yet

- Hexie Garden Quilt: 9 Whimsical Hexagon Blocks to Appliqué & PieceFrom EverandHexie Garden Quilt: 9 Whimsical Hexagon Blocks to Appliqué & PieceNo ratings yet

- Loom Magic Charms!: 25 Cool Designs That Will Rock Your RainbowFrom EverandLoom Magic Charms!: 25 Cool Designs That Will Rock Your RainbowNo ratings yet

- FFXII - TZA - Bazaar ChecklistDocument51 pagesFFXII - TZA - Bazaar ChecklistDika JayaNo ratings yet

- Exploring Dimensional Quilt Art BLAD WebDocument8 pagesExploring Dimensional Quilt Art BLAD WebInterweave100% (2)

- Arms A and Armor: Galleries OFDocument17 pagesArms A and Armor: Galleries OFJohann Piñón SalgadoNo ratings yet

- Social Studies AssignmentDocument8 pagesSocial Studies AssignmentHemraj LekhramNo ratings yet

- Encyclopedia of OrbDocument22 pagesEncyclopedia of OrbgssqNo ratings yet

- Jib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFDocument3 pagesJib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFAnonymous N2Se0bYNo ratings yet

- ResinDocument2 pagesResingirasolete100% (1)

- The Chalcolithic CultureDocument6 pagesThe Chalcolithic CultureKing SivanathNo ratings yet

- 12 - Sheet Metal FormingDocument138 pages12 - Sheet Metal FormingShihe Song100% (1)

- Tag Heuer Carrera Calibre 36 - Google Shopping 2Document1 pageTag Heuer Carrera Calibre 36 - Google Shopping 2zayyaanNo ratings yet

- 50 Different Types of Clocks With Pictures in 2019 Styles at LifeDocument29 pages50 Different Types of Clocks With Pictures in 2019 Styles at Liferaghunath670743No ratings yet

- APL Compensation PlanDocument15 pagesAPL Compensation PlanRuchika RuchikaNo ratings yet

- SP99Document77 pagesSP99saopaulo100% (1)

- Lecture 2.introduction To Ore Microscopy 1Document16 pagesLecture 2.introduction To Ore Microscopy 1Dwi LekatompessyNo ratings yet

- Progress Check: Incident ReportDocument4 pagesProgress Check: Incident ReportEspañol Wency BalonNo ratings yet

- Indian Archaeology 1955-56 A ReviewDocument160 pagesIndian Archaeology 1955-56 A Reviewmillian0987No ratings yet

- Flower Show Schedule 2015Document12 pagesFlower Show Schedule 2015api-216452145No ratings yet

- Falkrest AbbeyDocument46 pagesFalkrest AbbeyNicoNo ratings yet

- DND PSM 20040827bDocument6 pagesDND PSM 20040827bNathan HeinemanNo ratings yet

- Big Blue EyesDocument5 pagesBig Blue Eyesapi-240311485No ratings yet

- Bunny Ear Napkin RingsDocument4 pagesBunny Ear Napkin RingsMarlis BennettNo ratings yet

- Curse of Strahd Introductory AdventureDocument12 pagesCurse of Strahd Introductory Adventuretheseventeenth100% (6)

- Skinner Auction Catalogue 2448 - Fine JewelryDocument107 pagesSkinner Auction Catalogue 2448 - Fine JewelrySkinnerAuctions100% (7)

- Decorative Finishes: Imogen Waitt © May, 2010Document5 pagesDecorative Finishes: Imogen Waitt © May, 2010api-132751606No ratings yet

- Gem-A CCFDocument4 pagesGem-A CCFAlfonso HarisNo ratings yet

- Final Tanishq Marketing StrategyDocument36 pagesFinal Tanishq Marketing StrategyBalwant OjhaNo ratings yet

- Annual Report 0708Document94 pagesAnnual Report 0708Kumaresan GopalNo ratings yet

- List of Commonly Confused HomonymsDocument17 pagesList of Commonly Confused Homonymsseanwindow5961No ratings yet

Timberkits: Lion Instructions

Timberkits: Lion Instructions

Uploaded by

Calama Arica São PauloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Timberkits: Lion Instructions

Timberkits: Lion Instructions

Uploaded by

Calama Arica São PauloCopyright:

Available Formats

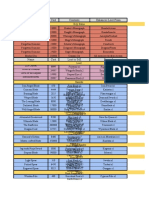

To assemble the handle shaft place a bead of glue in one of the holes of the crank plate.

Push the short length of 6mm diameter dowel into the hole until the end is flush with the other side. Slide a 10mm long collar onto the longest piece of 6mm dowel.With a bead of glue in the other hole of the crank plate, push the shaft into this hole so that the end is flush with the crank plate surface. Put a small amount of glue onto the shaft next to the crank plate and move the collar up to the crank plate turning it as you do so to spread the glue inside.

Check out the HELPFUL HINTS before getting started located on the back of the instructions on the bottom left hand side.

Put a bead of glue in a short collar and push in the remaining 6mm diam shaft so that one surface of the collar is flush with the end of the dowel.

In the same way push the drive shaft through the other hole and glue on another long collar and then 25mm disc.The disc will fit between the two 5mm pegs so that when the handle is turned the triangular follower will move up and down.

Wooden Mechanical Toys and Animated Working Models 7 1/2 long x 3 1/2 wide x 9 high Jenobi, Inc 10400 Westoffice Dr, Suite 111 Houston,TX, 77042 sales@timberkitsus.com www.timberkitsus.com Main: +1 (713) 953-1452 Fax: +1 (832) 209-7252 Glue two 3mm pegs, 27mm long, into the back hind leg unit so that the ends are flush with the back surface. Push the slots in the base strip onto the two back slots of the end plates.

Timberkits

Lion Instructions

With glue in the end holes of the triangular follower push in the two 5mm diam dowels; check that the 25mm disc will fit between them with a little space to spare. Place a bead of glue in the small hole and push in the 3mm x 25mm bamboo until the end is flush with the surface.

Push the shaft through the hole nearest to the centre of one of the base sides as shown. Put a drop of glue on the shaft about halfway along. Slide on a 20mm long collar turning it as you do so. Slide it up to the base side but leave a very small gap so that the shaft can be turned easily. Put glue on the shaft near the end of the long collar and slide on the triangular follower tight up to the collar (the 3mm peg should be pointing towards the handle side of the base) Make sure the shaft is free to turn.

Put the 3mm hole in the long end of the bent pull rod over the 3mm peg in the triangular follower. Place the holes in the other base side over the ends of the two 6mm shafts. Slide the end plates upwards into the slots in the base sides.

Glue two 3mm x 35mm pegs into the holes of the layer 8 mane piece, as shown. Glue a 3mm x 21mm peg onto the layer 7 mane piece into the top hole as shown. Place the two empty holes in the layer 7 piece over the pegs in layer 8. Glue two 3mm x 27mm pegs into the two holes in a front leg unit.

Glue a 3mm x 17mm peg onto the hole nearest to the back slot in a body side piece.

10 Put the top hole at the back end of the body side piece over the top peg on the hind leg unit; the other peg will pass through the slot. Place the top hole of the pull rod over the 4mm x 17mm peg in the body side piece. By turning the handle the body side piece should move up and down. Push one of the pegs in the front leg through the hole in the body side and the other will pass through the slot. Now push the lowest peg in the mane through the top hole of the body.The mane and the leg should both swing freely on their pivots.

Not suitable for children 3 years and under small parts with risk of choking

Please turn over

Place the two holes of layer 6 over the two upper pegs in the mane. Place one end of the long straight link over the peg through the slot at the back end of the body and the other end over the middle peg in the mane unit.When the handle is turned the body will move up and down and the mane will swing backwards and forwards. Position layer 5 over the two pegs in the mane, leaving out the peg through the long straight link. Glue a 3mm x 8mm peg into the lower hole of the tail so the end is flush with the back surface. Position, but do not glue, the upper hole over the upper peg of the hind leg unit.

Position layer 4 over layer 5. Glue a 3mm x 8mm peg into the end hole of the triangular link (12a) Place the two holes of the triangular link over the pegs in the front leg which stick through the lower hole and the slot. Put the short straight link over the peg sticking through the back slot in the body and the other end over the front slot.The notched link goes over the stub peg in the tail unit and the stub peg on the triangular unit with the notch upwards and towards the tail. 12.

With a bead of glue in the hole below the slot at the back end of the remaining body side, push the body unit over the five pegs, two of which will pass through the slots; there should be no glue in any of the other holes. Do not press the body side too close up to the links; turn the handle and check that everything moves The body side may need loosening slightly. Position layer 3 on the two pegs on layer 4.

HELPFUL HINTS: Check all the parts in trays very carefully. Read the instructions and look at all the diagrams. Get a clear idea of how the parts fit together before you start work. Do not glue anything until you are sure you understand how it should be assembled. Remember once something is glued together you cannot go back. Assemble with out glue first, to make sure they fit. To stop the wood squeaking when it is moving use a little silicone wax (the sort you apply on a cloth, not a spray and not beeswax which stays sticky). Wax surfaces which are in contact as they move. Remember if you bey wax in the wrong place, the glue will not stick to that surface. If you colour your model do not get paint on any surface which moves against another.

With a bead of glue in each of the upper holes in the remaining hind leg unit position over the front slots in the base sides and spring onto the two pegs. Make sure that you do not push the leg unit too tight up to the body. Secure the base unit by pushing the long bamboo lengths through the end holes of the base sides and the two base strips; glue if necessary.When the handle is turned the body will move up and down, the jaws will open and close, the front legs will claw the air and the tail will wave.

With beads of glue in both holes of the remaining front leg, position on the two lower front pegs sticking through the body side; do not push too tightly up to the body side. Check when the handle is turned that all parts move correctly. If the leg is too close it will cause too much friction. Position mane layer 2 on the two head pegs and with a bead of glue in each of the holes in mane layer 1. Push onto the ends of the pegs, but do not push too tightly to the body side.Turn the handle and check all parts are moving.

You might also like

- Graceful Kelly BagDocument9 pagesGraceful Kelly BagPatricia Pereira100% (1)

- KGe Profiler ManualDocument5 pagesKGe Profiler ManualReinaldo PulidoNo ratings yet

- Automata Cat and Mouse PDFDocument9 pagesAutomata Cat and Mouse PDFBruno ThiagoNo ratings yet

- Worm Harvester 212011Document0 pagesWorm Harvester 212011mattpac3No ratings yet

- Fabric Building Assembly GuideDocument15 pagesFabric Building Assembly GuideWaqas Haider100% (1)

- Informacion Zippers PDFDocument2 pagesInformacion Zippers PDFFederico Cintrón Fiallo100% (2)

- Amigurumi 34jyoti A Painted Indian ElephantDocument8 pagesAmigurumi 34jyoti A Painted Indian ElephantMónica Campos Pérez100% (3)

- CRAFT VILLAGE, VELLAR THIRUVANANTHAPURAM, KERALA. Project Report by Sudheesh Kumar S S (Designer)Document104 pagesCRAFT VILLAGE, VELLAR THIRUVANANTHAPURAM, KERALA. Project Report by Sudheesh Kumar S S (Designer)anashwara80% (5)

- Miniature Marble Machine For WEB 259013455Document2 pagesMiniature Marble Machine For WEB 259013455Squinkle78% (9)

- Reedmaking NotesDocument3 pagesReedmaking Notesapi-201119152No ratings yet

- Dirt Maker 14 ManualDocument16 pagesDirt Maker 14 Manualcompudog0% (1)

- Eco Power Instruction Manual WebDocument10 pagesEco Power Instruction Manual WebJuliano CordeiroNo ratings yet

- FreebirdDocument5 pagesFreebirdLucas Nahuel AsiainNo ratings yet

- K Ge Reeds Profiling Machine ManualDocument6 pagesK Ge Reeds Profiling Machine ManualNeuromante3223No ratings yet

- RodSmith Build-It! KitsDocument1 pageRodSmith Build-It! KitsCamil BwoyNo ratings yet

- Better BoxesDocument6 pagesBetter Boxes71valiant100% (1)

- Assembly Guide Form I ToDocument10 pagesAssembly Guide Form I ToChivalrous SpringNo ratings yet

- Patrol Box PlansDocument10 pagesPatrol Box PlansAlessandro UrendaNo ratings yet

- Comfy Crown PatternDocument16 pagesComfy Crown PatternSilvia TeixeiraNo ratings yet

- (Artigo) Ajuste de Projeção Do Espelho Do ViolinoDocument15 pages(Artigo) Ajuste de Projeção Do Espelho Do ViolinoRodolfo MinhotoNo ratings yet

- Step 1: Procedural Steps ImagesDocument4 pagesStep 1: Procedural Steps Imagesapi-336491889No ratings yet

- Build A Cremation CaskDocument7 pagesBuild A Cremation CaskJeffrey Michael Atencio100% (1)

- Apple With SwingDocument12 pagesApple With SwingMilen Solakov100% (2)

- Workshops - Composite, Riveting, Fabric & MaintenanceDocument6 pagesWorkshops - Composite, Riveting, Fabric & Maintenanceairbuk doeing100% (1)

- Circoflex Building InstructionsDocument4 pagesCircoflex Building InstructionsGiacomo Marco ToigoNo ratings yet

- Glasses InstructionsDocument4 pagesGlasses InstructionsFranco 06100% (1)

- Mascara Plague DRDocument21 pagesMascara Plague DRdiego trujilloNo ratings yet

- 1903 Wright Flyer Model InstructionsDocument12 pages1903 Wright Flyer Model InstructionsAntónio OliveiraNo ratings yet

- Nesting Tables: REQUIREMENTS FOR THIS PROJECT-I Made The Tables As They Are ShownDocument11 pagesNesting Tables: REQUIREMENTS FOR THIS PROJECT-I Made The Tables As They Are Shown- yAy3e -No ratings yet

- Gripper SDocument9 pagesGripper Ssantiago_vNo ratings yet

- Ornithopter 2 PDFDocument1 pageOrnithopter 2 PDFMarco Antônio Gomes ApolinarioNo ratings yet

- FrogDocument10 pagesFrogbnh2No ratings yet

- Arabesque BagDocument13 pagesArabesque Baghematite7No ratings yet

- Bensen b8 PDFDocument8 pagesBensen b8 PDFmaxNo ratings yet

- Combination Lock Instructions v1dDocument20 pagesCombination Lock Instructions v1demreNo ratings yet

- Woodworking Guide - Basic JoineryDocument6 pagesWoodworking Guide - Basic JoineryMrPaulCorcoran100% (1)

- How To String A Lacrosse Stick: Completion Time: Approximately 1 HourDocument13 pagesHow To String A Lacrosse Stick: Completion Time: Approximately 1 Hourdwb5307No ratings yet

- PDF Mini Clip Pie InstructionsDocument6 pagesPDF Mini Clip Pie InstructionsMarija CvetkovićNo ratings yet

- How To Make A Space ShuttleDocument4 pagesHow To Make A Space Shuttlelori millerNo ratings yet

- Grrrobot!Document16 pagesGrrrobot!soloinformacionNo ratings yet

- Combination LockDocument6 pagesCombination LockFahrudin NoorNo ratings yet

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- How To Fit An Upgrade ChipDocument1 pageHow To Fit An Upgrade ChipAllegra AmiciNo ratings yet

- Acoustic Guitar PlansDocument7 pagesAcoustic Guitar PlansFrançesko Astroza80% (5)

- Shuttle Solid Rocket Booster's and External TankDocument6 pagesShuttle Solid Rocket Booster's and External TankJefferson MatheusNo ratings yet

- Bed and Storage BoxesDocument9 pagesBed and Storage Boxespoimandres100% (1)

- Provisional Press Laser InstructionsDocument8 pagesProvisional Press Laser Instructionsrobert smithNo ratings yet

- Shorelandr ManualDocument8 pagesShorelandr ManualWaaboooo wañangoNo ratings yet

- Cove Cutting Jigs For The BT3000 by Jim FryeDocument8 pagesCove Cutting Jigs For The BT3000 by Jim FryeozilogNo ratings yet

- Lilac Mini MessengerDocument16 pagesLilac Mini MessengerДрагана Станковић100% (1)

- Pattern Kennedy BagDocument25 pagesPattern Kennedy BagCristina Stanica100% (4)

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Cut Your OwnDocument2 pagesCut Your Ownalbanil96No ratings yet

- How To Assemble A Bee Hive Box or Super - A Beginner Beekeeper's GuideDocument17 pagesHow To Assemble A Bee Hive Box or Super - A Beginner Beekeeper's Guidekorki77No ratings yet

- Hexie Garden Quilt: 9 Whimsical Hexagon Blocks to Appliqué & PieceFrom EverandHexie Garden Quilt: 9 Whimsical Hexagon Blocks to Appliqué & PieceNo ratings yet

- Loom Magic Charms!: 25 Cool Designs That Will Rock Your RainbowFrom EverandLoom Magic Charms!: 25 Cool Designs That Will Rock Your RainbowNo ratings yet

- FFXII - TZA - Bazaar ChecklistDocument51 pagesFFXII - TZA - Bazaar ChecklistDika JayaNo ratings yet

- Exploring Dimensional Quilt Art BLAD WebDocument8 pagesExploring Dimensional Quilt Art BLAD WebInterweave100% (2)

- Arms A and Armor: Galleries OFDocument17 pagesArms A and Armor: Galleries OFJohann Piñón SalgadoNo ratings yet

- Social Studies AssignmentDocument8 pagesSocial Studies AssignmentHemraj LekhramNo ratings yet

- Encyclopedia of OrbDocument22 pagesEncyclopedia of OrbgssqNo ratings yet

- Jib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFDocument3 pagesJib Crane Inspection Report 04-1005195 - J1610688 - NQC1154 - PDFAnonymous N2Se0bYNo ratings yet

- ResinDocument2 pagesResingirasolete100% (1)

- The Chalcolithic CultureDocument6 pagesThe Chalcolithic CultureKing SivanathNo ratings yet

- 12 - Sheet Metal FormingDocument138 pages12 - Sheet Metal FormingShihe Song100% (1)

- Tag Heuer Carrera Calibre 36 - Google Shopping 2Document1 pageTag Heuer Carrera Calibre 36 - Google Shopping 2zayyaanNo ratings yet

- 50 Different Types of Clocks With Pictures in 2019 Styles at LifeDocument29 pages50 Different Types of Clocks With Pictures in 2019 Styles at Liferaghunath670743No ratings yet

- APL Compensation PlanDocument15 pagesAPL Compensation PlanRuchika RuchikaNo ratings yet

- SP99Document77 pagesSP99saopaulo100% (1)

- Lecture 2.introduction To Ore Microscopy 1Document16 pagesLecture 2.introduction To Ore Microscopy 1Dwi LekatompessyNo ratings yet

- Progress Check: Incident ReportDocument4 pagesProgress Check: Incident ReportEspañol Wency BalonNo ratings yet

- Indian Archaeology 1955-56 A ReviewDocument160 pagesIndian Archaeology 1955-56 A Reviewmillian0987No ratings yet

- Flower Show Schedule 2015Document12 pagesFlower Show Schedule 2015api-216452145No ratings yet

- Falkrest AbbeyDocument46 pagesFalkrest AbbeyNicoNo ratings yet

- DND PSM 20040827bDocument6 pagesDND PSM 20040827bNathan HeinemanNo ratings yet

- Big Blue EyesDocument5 pagesBig Blue Eyesapi-240311485No ratings yet

- Bunny Ear Napkin RingsDocument4 pagesBunny Ear Napkin RingsMarlis BennettNo ratings yet

- Curse of Strahd Introductory AdventureDocument12 pagesCurse of Strahd Introductory Adventuretheseventeenth100% (6)

- Skinner Auction Catalogue 2448 - Fine JewelryDocument107 pagesSkinner Auction Catalogue 2448 - Fine JewelrySkinnerAuctions100% (7)

- Decorative Finishes: Imogen Waitt © May, 2010Document5 pagesDecorative Finishes: Imogen Waitt © May, 2010api-132751606No ratings yet

- Gem-A CCFDocument4 pagesGem-A CCFAlfonso HarisNo ratings yet

- Final Tanishq Marketing StrategyDocument36 pagesFinal Tanishq Marketing StrategyBalwant OjhaNo ratings yet

- Annual Report 0708Document94 pagesAnnual Report 0708Kumaresan GopalNo ratings yet

- List of Commonly Confused HomonymsDocument17 pagesList of Commonly Confused Homonymsseanwindow5961No ratings yet