Professional Documents

Culture Documents

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Uploaded by

Thirukumaran ElangovanCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Plumbarius Which Was Taken From The Latin Word PlumbumDocument7 pagesPlumbarius Which Was Taken From The Latin Word PlumbumJocel SangalangNo ratings yet

- PurifierDocument14 pagesPurifierMohammad Jahid Alam100% (1)

- 750 T Crane Load Chart PDFDocument1 page750 T Crane Load Chart PDFThirukumaran ElangovanNo ratings yet

- Steam Turbine & Generator Lifting PlanDocument4 pagesSteam Turbine & Generator Lifting PlanThirukumaran ElangovanNo ratings yet

- Method Statement With Risk AssesmentDocument1 pageMethod Statement With Risk AssesmentThirukumaran ElangovanNo ratings yet

- Method Statement With Risk AssesmentDocument22 pagesMethod Statement With Risk AssesmentThirukumaran ElangovanNo ratings yet

- Characterization of Industrial Waste WatersDocument11 pagesCharacterization of Industrial Waste WatersDr. Akepati Sivarami ReddyNo ratings yet

- Process Control AssDocument24 pagesProcess Control AssGkou DojkuNo ratings yet

- Utilities Pugeda Quiz 2Document1 pageUtilities Pugeda Quiz 2corazon philNo ratings yet

- 03 PDFDocument84 pages03 PDFMorn AmornsakNo ratings yet

- Biodata BioconDocument9 pagesBiodata BioconNoor ZarifNo ratings yet

- Guidelines For Canadian Drinking Water Quality Summary TableDocument22 pagesGuidelines For Canadian Drinking Water Quality Summary TablechristianNo ratings yet

- Filter Cloth CatalogueDocument8 pagesFilter Cloth CatalogueChandra Sekar RNo ratings yet

- Franz Damayo FSDocument29 pagesFranz Damayo FSFranz Julius Adriane DamayoNo ratings yet

- Chemical Program Administration ManualDocument8 pagesChemical Program Administration ManualsudyNo ratings yet

- Ecoblue Solenoid PumpDocument6 pagesEcoblue Solenoid PumpXTREME_10No ratings yet

- Tio2 BDDocument88 pagesTio2 BDSuleman TariqNo ratings yet

- Advanced Wastewater TreatmentDocument42 pagesAdvanced Wastewater TreatmentAbhay PatilNo ratings yet

- Coal Based Granular Activated Carbon: ParametersDocument1 pageCoal Based Granular Activated Carbon: ParametersENDALKACHEW KERIENo ratings yet

- 2012 Chemetrics CTLGDocument91 pages2012 Chemetrics CTLGFamc CmafNo ratings yet

- The Problem and Its Setting Background of The StudyDocument12 pagesThe Problem and Its Setting Background of The StudyAnnaNo ratings yet

- WS - Module - 2 - Treatment of WaterDocument21 pagesWS - Module - 2 - Treatment of Waternasla100% (1)

- CrystalBrochure PDFDocument8 pagesCrystalBrochure PDFTarekNo ratings yet

- Ionic Systems Catalogue 2013 UKDocument23 pagesIonic Systems Catalogue 2013 UKAnonymous NS65s3ckXNo ratings yet

- Watertreatment Plant-3rd EditionDocument24 pagesWatertreatment Plant-3rd EditionHOMAYOUN KHADIVINo ratings yet

- Hawassa MoHA Millennium Pepsi-Cola Factory SDocument98 pagesHawassa MoHA Millennium Pepsi-Cola Factory SBereket Getnet100% (4)

- PHD Skibinski 20180219 Clean PdfaDocument187 pagesPHD Skibinski 20180219 Clean PdfaHersh F. HawramyNo ratings yet

- Lecture 2 Water SystemDocument31 pagesLecture 2 Water SystemGelo MarananNo ratings yet

- Product Name Generic Product NameDocument4 pagesProduct Name Generic Product Namet_i_f_anoNo ratings yet

- Water Treatment Plant Consumables and MsdsDocument8 pagesWater Treatment Plant Consumables and Msdscharmine.thomasNo ratings yet

- Water Supply EngineeringDocument837 pagesWater Supply EngineeringSubira Munishi100% (4)

- Monarch Water Product GuideDocument16 pagesMonarch Water Product Guidenermeen ahmedNo ratings yet

- Cambridge O Level: Chemistry 5070/12Document16 pagesCambridge O Level: Chemistry 5070/12Islamabad ALMA SchoolNo ratings yet

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Uploaded by

Thirukumaran ElangovanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Uploaded by

Thirukumaran ElangovanCopyright:

Available Formats

12/24/13

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Home

Profile

Quality

Products

Segment

Certificates

FAQ

Clients

Gallary

Export Network

Contact

Downloads

Carrier

Power Plant Industries

Waste Water Treatment - Sewage Treatment Plant - Grey Water Treatment - Decentralised STP - Containerized STP - Skid Mounted STP - STP for labor camp - Compact STP - Sustainable STP - STP for weekend home - Tertiary Treatment with Ozonation Water Treatment Solutions

chemtronicsindia.com/power_plant_industries.htm

Water is the lifeblood of a power plant. Needed in vast quantities to produce steam and for cooling purposes, U.S. thermoelectric power producers use more than 70 trillion gallons of water per year. To effectively use water within a plant, it must be treated to meet each individual site's needs, which vary with the influent source water quality; type of boiler, discharge requirements and whether or not "used" water is recycled within the plant. Technologies used in Power plants are: 1. Cooling Tower Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid. Common applications include cooling the

1/4

12/24/13

- Drinking Water Treatment - Swimming Pool/Ponds - Process Water Treatment - Type II RO Water - Laundry Water Treatment - Cooling Tower Treatment - Municipal Drinking Water - Sea Water Desalination - River/Lake/Dam Ground Air Treatment Solutions - Operation Room Fumigation - Odor removal / Control - Indoor Air Treatment - Indoor Air Quality (IAQ) - HVAC / AHU Ozonation - Air Disinfection - VOC Reduction - Sick Building Syndrome - Production Industry - Packing Industry

process heat and cool the working fluid. Common applications include cooling the circulating water used in oil refineries, chemical plants, power stations and building cooling. .They are often associated with nuclear power plants in popular culture.

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

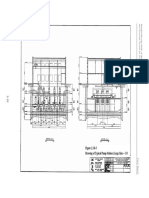

2. D. M. Plant DM Plant is an Ion exchange technology used to remove salts (cations and anions) from water. Soluble chemical compounds, when dissolved in water, become ionized; that is their molecules dissociate into positively and negatively charged components called ions. Consider common table salt, sodium chloride. In its solid form, this compound consists of one sodium atom (Na) and one chlorine atom (Cl) tightly coupled together (NaCl). When dissolved in water, however, the compound splits into two ions Na+ and Cl- A Typical two-bed DM Plant consists of two FRP vessels connected in series along with its internal fittings. The first unit consists of high capacity strongly acidic cation exchange resin, which converts positive ions of salt and replaces them with hydrogen ions to form respective acids, which are absorbed in next vessel by strongly basic anion exchange resin. The water obtained by this process shows conductivity less than 30 S/cm and Total Dissolved Solids less than 10 ppm.Further high purity water can be achieved by Mixed Bed Deionizers, which are designed to produce high purity treated water. They can be used as polishing units after two beds DM Plant to obtain high purity water. 3. STP Following are the two methods to treat waste water in sewage treatment plant. A Conventional Method Conventional sewage treatment may involve three stages, called primary, secondary and tertiary treatment. Primary treatment consists of temporarily holding the sewage in a quiescent basin where heavy solids can settle to the bottom while oil, grease and lighter solids float to the surface. The settled and floating materials are removed and the remaining liquid may be discharged or subjected to secondary treatment. Secondary treatment removes dissolved and suspended biological matter. Secondary treatment is typically performed by indigenous, water-borne microorganisms in a managed habitat. Secondary treatment may require a separation process to remove the micro-organisms from the treated water prior to discharge or tertiary treatment.

Green Building LEED Indoor Air Quality Solutions Sustainable Building Sick Building Syndrome (SBS)

Contact Us Project Office Address : 28, Satyam Industrial Estate, Subhash Road, Jogeshwari (East) Mumbai 400 060 INDIA

chemtronicsindia.com/power_plant_industries.htm

2/4

12/24/13

treatment.

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

Tertiary treatment is sometimes defined as anything more than primary and secondary treatment. Treated water is sometimes disinfected chemically or physically (for example, by lagoons and microfiltration) prior to discharge into a stream, river, bay, lagoon or wetland, or it can be used for the irrigation of a golf course, green way or park. If it is sufficiently clean, it can also be used for groundwater recharge or agricultural purposes. B Ozonation Method The incoming raw sewage pass through a bar screen chamber to remove coarse suspended solids, fibers, plastics etc. and is collected into a septic tank / holding tank. The tank will have 24 48 hours holding capacity, with suitable compartments to separate the heavy sludge solids present in the incoming sewage. A sewage transfer pump will transfer the raw effluent into a manual self cleaning filter, and then pressure sand filter & then onward to an ozonator. Ozone will be injected into the raw sewage and mixed in to a contact chamber / holding tank. The ozone will oxidize the organics present in the sewage, thereby reducing the BOD / COD levels of the sewage to acceptable limits. The ozonated effluent will be filtered through a pressure sand filter to remove trace suspended solids / turbidity, etc. The outlet water can be reused suitably for toilet flushing, gardening, etc. 4. River water treatment Water purification is a process of removing undesirable chemicals, materials, and biological contaminants from raw water. The goal is to produce water fit for a specific purpose. Water purification may also be designed for a variety of other purposes, including meeting the requirements of medical, pharmacology, chemical and industrial applications. In general the methods used include Physical processes such as. Pre-Ozonation flocculation filtration / Aeration chlorination pH Correction

chemtronicsindia.com/power_plant_industries.htm

Designed & Hosted by : MID Promoted by : GID

3/4

12/24/13

Designed & Hosted by : MID Promoted by : GID

Power Plant Industries, DM Plant, Cooling Tower, River Water Treatment, Mumbai, India

chemtronicsindia.com/power_plant_industries.htm

4/4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Plumbarius Which Was Taken From The Latin Word PlumbumDocument7 pagesPlumbarius Which Was Taken From The Latin Word PlumbumJocel SangalangNo ratings yet

- PurifierDocument14 pagesPurifierMohammad Jahid Alam100% (1)

- 750 T Crane Load Chart PDFDocument1 page750 T Crane Load Chart PDFThirukumaran ElangovanNo ratings yet

- Steam Turbine & Generator Lifting PlanDocument4 pagesSteam Turbine & Generator Lifting PlanThirukumaran ElangovanNo ratings yet

- Method Statement With Risk AssesmentDocument1 pageMethod Statement With Risk AssesmentThirukumaran ElangovanNo ratings yet

- Method Statement With Risk AssesmentDocument22 pagesMethod Statement With Risk AssesmentThirukumaran ElangovanNo ratings yet

- Characterization of Industrial Waste WatersDocument11 pagesCharacterization of Industrial Waste WatersDr. Akepati Sivarami ReddyNo ratings yet

- Process Control AssDocument24 pagesProcess Control AssGkou DojkuNo ratings yet

- Utilities Pugeda Quiz 2Document1 pageUtilities Pugeda Quiz 2corazon philNo ratings yet

- 03 PDFDocument84 pages03 PDFMorn AmornsakNo ratings yet

- Biodata BioconDocument9 pagesBiodata BioconNoor ZarifNo ratings yet

- Guidelines For Canadian Drinking Water Quality Summary TableDocument22 pagesGuidelines For Canadian Drinking Water Quality Summary TablechristianNo ratings yet

- Filter Cloth CatalogueDocument8 pagesFilter Cloth CatalogueChandra Sekar RNo ratings yet

- Franz Damayo FSDocument29 pagesFranz Damayo FSFranz Julius Adriane DamayoNo ratings yet

- Chemical Program Administration ManualDocument8 pagesChemical Program Administration ManualsudyNo ratings yet

- Ecoblue Solenoid PumpDocument6 pagesEcoblue Solenoid PumpXTREME_10No ratings yet

- Tio2 BDDocument88 pagesTio2 BDSuleman TariqNo ratings yet

- Advanced Wastewater TreatmentDocument42 pagesAdvanced Wastewater TreatmentAbhay PatilNo ratings yet

- Coal Based Granular Activated Carbon: ParametersDocument1 pageCoal Based Granular Activated Carbon: ParametersENDALKACHEW KERIENo ratings yet

- 2012 Chemetrics CTLGDocument91 pages2012 Chemetrics CTLGFamc CmafNo ratings yet

- The Problem and Its Setting Background of The StudyDocument12 pagesThe Problem and Its Setting Background of The StudyAnnaNo ratings yet

- WS - Module - 2 - Treatment of WaterDocument21 pagesWS - Module - 2 - Treatment of Waternasla100% (1)

- CrystalBrochure PDFDocument8 pagesCrystalBrochure PDFTarekNo ratings yet

- Ionic Systems Catalogue 2013 UKDocument23 pagesIonic Systems Catalogue 2013 UKAnonymous NS65s3ckXNo ratings yet

- Watertreatment Plant-3rd EditionDocument24 pagesWatertreatment Plant-3rd EditionHOMAYOUN KHADIVINo ratings yet

- Hawassa MoHA Millennium Pepsi-Cola Factory SDocument98 pagesHawassa MoHA Millennium Pepsi-Cola Factory SBereket Getnet100% (4)

- PHD Skibinski 20180219 Clean PdfaDocument187 pagesPHD Skibinski 20180219 Clean PdfaHersh F. HawramyNo ratings yet

- Lecture 2 Water SystemDocument31 pagesLecture 2 Water SystemGelo MarananNo ratings yet

- Product Name Generic Product NameDocument4 pagesProduct Name Generic Product Namet_i_f_anoNo ratings yet

- Water Treatment Plant Consumables and MsdsDocument8 pagesWater Treatment Plant Consumables and Msdscharmine.thomasNo ratings yet

- Water Supply EngineeringDocument837 pagesWater Supply EngineeringSubira Munishi100% (4)

- Monarch Water Product GuideDocument16 pagesMonarch Water Product Guidenermeen ahmedNo ratings yet

- Cambridge O Level: Chemistry 5070/12Document16 pagesCambridge O Level: Chemistry 5070/12Islamabad ALMA SchoolNo ratings yet