Professional Documents

Culture Documents

Ceara Roses Australia Hydrop

Ceara Roses Australia Hydrop

Uploaded by

mauriciomathiasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ceara Roses Australia Hydrop

Ceara Roses Australia Hydrop

Uploaded by

mauriciomathiasCopyright:

Available Formats

Cear Roses

Rose Production in Brazil

New varieties are screened for disease resistance in a trial area.

Over the past decade, Brazil has developed an important rose production industry in the cooler north-eastern highlands. MAURICIO MATHIAS reports the regions rapid development is only limited by transportation obstacles to market destinations.

Practical Hydroponics & Greenhouses . July/August . 2008. 27

Heleno Assis, one of the production managers at Reijers Produco de Rosas.

Up to 100,000 stems are cut daily.

n the overall international flower market Brazil is still a minor player, one whose main potential still lies in its internal consumer market of nearly 190 million people. However, slowly but surely, exports of the floriculture industry have been on the rise since 2002, and every year after that has seen a new national export record for the sector, having reached US$37 million last year. This amount is dwarfed though when compared to other countries in South America such as Ecuador and Colombia, both cut-flower export powerhouses. Colombia, for example, is the worlds biggest rose exporter and the second largest flower exporter, only behind the Netherlands. Even though Colombias industry is only 40 years old, in 2007 they exceeded US$1 billion in flower exports. Their secret? Sector organisation, nearly ideal climate altitude near the equator, and a short distance to their main consumer market, the USA, are among the key ingredients. All of that has been known for a while in Brazil, which is a top world producer of several ag products such as soy, coffee, tobacco, orange juice - and beef, having recently overtaken Australia at that. However, it is general knowledge that Brazil doesnt have high-altitude areas such as Colombias main flower producing zone, the Bogota Savannah at 2,500 metres. So, even for the average Brazilian, it came as a surprise when the north-eastern state of Cear started a promotion program to attract investors and growers to develop a new rose export production area. As it turned out, a previous study requested by that state government had showed that a region called the Ibiapaba plateau, 350km away from Fortaleza, the state capital, had enough of a night cooling effect to allow for good flower cultivation. Due to its 900 metre altitude it has a cooler average temperature than the rest of Cear. Located almost at the equator (at 4 S, compared to Darwin at 7 S), the state has 2,800 hours of sunshine per year. This regions good local climate is known by its local people, a few vegetable growers among them, and only one major fruit company, but it is almost entirely unheard of by the rest of the country. Cears coast is a known vacation destination within Brazil due to its palm tree-dotted, white-sand beaches, which are also a major attraction for European tourists looking for a warm destination

Cearosa was the first company to build a plastic rose house in the Cear region.

A geneal view of the Ceara countryside not unlike parts of Australia.

28 . Practical Hydroponics & Greenhouses . July/August . 2008

during northern hemisphere winters, helped by the fact that it is only an 8-hour flight away from Lisbon, Portugal. However, while the states coastal economy had boomed with tourism-driven businesses, its hinterland hasnt improved as much. Brazils total land mass is slightly larger than that of Australia, but the contrast between the climate of its different regions is probably even sharper. The country may be best known worldwide for the Amazon forest, but its semi-arid north-eastern landscape has more similarities with Australias interior. Some areas may not have any rainfall for years so, not surprisingly, it is Brazils least economically developed region, and naturally many of its people migrate to urban centres in search of jobs. In the year 2000 with all these facts at hand, the Cear state government set out to work with the Colombian example in mind. Flowers are a crop with much added-value, which would be good for the overall economy. It also requires considerable labor per ha, creating local jobs and stopping migration. At the time the Brazilian currency, the Real (R$), was devaluating towards the US dollar, so exports were being supported by the federal government. The airline companies that flew tourists in could take extra cargo on their way back to Europe or so went the thought at the time. In any case, it would be a shorter trip to export roses to Europe from Cear than from Brazils traditional flower-producing regions at more southern locations. To top it off, cost of production tended to be lower than in the more developed and industrialised south. There was only one catch of course; they would have to let the rest of the world know about it.

paperwork could be checked, and the flowers could be inspected by the authorities at an appropriate temperature. The room is exclusively dedicated to flowers, but for transit only, not storage. The very first company to build a 1ha plastic house and harvest the first Cear rose was Cearosa, which interestingly enough was also a newcomer to the business. Owned by Paulo Selbach, an executive from another industry who believed in this opportunity, it was started in the year 2000. Cearosas main difference from the other companies that followed has been the constant focus on the national market rather than exports. Since day one, Cearosas production manager has been the Colombian Julio Cantillo, hired by Selbach while Julio was still consulting to the state agency as part of a program to bring in foreign expertise. And through these years Cantillo has accomplished a doubling of the initial yield in some of the varieties by adapting to the local conditions. One of them has gone from 60 to 120 stem/m2 per year. Firstly, the sandy soils would drain the fertigation too quickly so lots more organic matter was incorporated in later plantings, which also helped some varieties to produce a much-appreciated longer stem. The arching pruning was also adopted in 2003, and replanted sections have a tighter spacing reduced from 50 to 35 cm between rows to make use of the higher light intensity. These new sections now start producing at 10 weeks after planting, instead of the previous 12 weeks.

Hydroponic roses

The second company to set up shop was Reijers Produo de Rosas, part of the biggest rose growing group in Brazil. With headquarters in the state of So Paulo, and branches in a neighboring state also

Flora-Brasilis

And that they did. Cear set up a partnership with federal agency Apex, in charge of supporting export initiatives, called the Flora-Brasilis program. With their funding they participated in some of the main horticulture trade shows in the USA and Europe in order to attract investors and to assess exporting possibilities. The Horti-fair in the Netherlands was one of the shows where Cear had their own stand for a couple of years. On top of access to the original government geophysical study showing where the best soils and underground water in Ibiapaba plateau were, what they offered to incoming business was assistance to buyers to find land, and help negotiating it if necessary. There was also a guarantee to service utilities up to the farm gate. However, there would be no preferential financing outside the regular loans from development banks. Naturally the Flora-Brasilis program participated in the national trade show circuit as well, and there it ended up creating the most attraction where it was least expected. Established rose-growing companies from the populous, more industrialised southern states didnt see a new rose area in Cear as possible competition, but as an option for expansion at a lower-cost location, closer to their export destination and at a climate where production wouldnt slow down during winter. All the better for Cear since the international firms they had initially aimed at didnt materialise. There were several visits by potential investors, some negotiation and a couple of them even bought land there, but no rose-growing started.

A north-eastern rose

Before a whole new sector was started in earnest, a few possible obstacles had to be removed. One of them was infrastructure. A cold room was built at the state capital airport so all the export

Practical Hydroponics & Greenhouses . July/August . 2008. 29

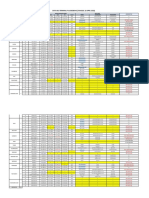

in the south, their Cear branch has become the largest greenhouse area in Ibiapaba, totaling 20ha of roses all grown hydroponically. Coconut coir has been their substrate of choice from the start. Initially using drip-irrigated 12L pots with two to three plants per pot, and 20L pots with up to four plants, these plastic containers are filled with coir and topped off with dried, chopped palm leaves. These help keep in the moisture, which would otherwise evaporate from the substrate top. Plus, they are an inexpensive, easy-to-find material, a by-product from the extraction of wax from carnauba palm leaves, a major local industry. More recently, cultivation has evolved to continuous troughs of metal wiring, covered with a white plastic liner, also filled with coir. The drain is collected at the far end of the rows in half of all greenhouses, and recirculated back into the irrigation solution. Some of the areas with pots have been fitted with liners underneath for drain collection as well. Presently, the company works with eight commercial varieties and since they export and sell in the national market, they have to keep up with the latest international trends for new colours. Half of the area is presently planted with classic red roses, and the other half divided by other colours requested by their European customers. On an average day, between 80,000 to 100,000 stems are cut, transported to their cooled pack room, sorted and trucked to their own distribution centre in Fortaleza, or exported. In order to maintain head size homogeneity, the same area may be harvested up to three times a day. Each house has its own supervisor and a fixed team that works the same areas. Once cut and trimmed, stems are placed in plastic boxes filled with water. In turn, these are transferred to a cart once the worker is done with a row, and the cart is transported by a suspended monorail system to the pack house. A total of 250 workers are employed at this site, but more expansion is underway with at least 2ha more planned for this year.

Pest and diseases

The main disease challenges are downy and powdery mildew, depending on the time of the year. But in general among most local companies, huge improvements have been made lately with biological pest and disease control. By choosing more resistant varieties and applying beneficial fungi, chemical spraying has

Each house has its own supervisor and a fixed team that works the same areas.

A recent innovation is continuous troughs covered with a white plastic liner and filled with coir.

Once cut and trimmed, stems are placed in plastic boxes.

30 . Practical Hydroponics & Greenhouses . July/August . 2008

been drastically reduced. To keep pest mites under check during the dry season, beneficial mites are regularly introduced. Other companies in the area include Reijers Agrifloricultura, which cultivates 8ha in a nearby location, with 2ha more under construction. At this firm though, all roses are soil-cultivated, and almost organically at that. The beds are 80% compost made of manioc meal, gypsum, lime, bone meal, micronutrients and bokashi, a type of organic fertiliser - a combination that has worked to prevent a common soil nematode from getting to the plants. Originally an exporting project as well, since 2006 they have been entirely dedicated to the national market due to a problem that has been a major stumbling block for further sector development - the lack of air freight room in international flights.

Bottleneck

Even though most firms have grown considerably since they started up, they could have grown more, or faster if they had guaranteed transportation to their market destinations. Charter flights with tourists arent big or regular enough during the year for the necessary steady flow to supply their customers year-round. On the other hand, the planted area at the moment hasnt shown itself attractive enough yet for airline companies to commit regular cargo flights, so at the moment it has become a chicken and egg issue. This may have hurt the regions development somewhat, but hasnt stopped Cear from becoming Brazils main rose exporting state in a short 7-year period. The state went from a net importer of flowers from the rest of Brazil in 1999 to US$5 million in exports last year, and growing. Considering covered- and field-production, Cear totalled 288ha of diverse flowers at the end of 2006. No small feat for a part of the country where no major flower enterprise had been attempted before. Based on this success story the Flora-Brasilis program with Apex support has been renewed and now represents 39 companies from eight states in Brazil.

Half of the area is presently planted with classic red roses.

About the author

Mauricio Mathias is a horticultural consultant for greenhouse vegetables in Brazil. He is also a regular contributor on greenhouse crops and related topics to international horticultural publications. Email: mauriciomathias@hotmail.com b

The main disease challenges are downy and powdery mildew.

Ibiapaba plateau has a cooler average temperature than the rest of Cear.

Dried, chopped palm leaves help keep in the moisture.

Practical Hydroponics & Greenhouses . July/August . 2008. 31

You might also like

- Managerial Statistics-Notes On All ChapterDocument73 pagesManagerial Statistics-Notes On All ChapterNati PUFFxKID100% (1)

- EVERGREEN CASE - Transport & Insurance in Foreign TradeDocument16 pagesEVERGREEN CASE - Transport & Insurance in Foreign TradePhương Trâm HuỳnhNo ratings yet

- Case Pacari Premium Organic ChocolateDocument14 pagesCase Pacari Premium Organic ChocolateLina Bustillo100% (3)

- AquacycleUserGuide PDFDocument82 pagesAquacycleUserGuide PDFMariana_AlbertoNo ratings yet

- Ecuador RosesDocument4 pagesEcuador RosesJainish KorantNo ratings yet

- Guide Book Videotron PDFDocument34 pagesGuide Book Videotron PDFMade Utari DewiNo ratings yet

- Growing An Industry - GEDocument3 pagesGrowing An Industry - GEmauriciomathiasNo ratings yet

- Plant Production and Supply in Southern Brazil: Country FileDocument3 pagesPlant Production and Supply in Southern Brazil: Country FilemauriciomathiasNo ratings yet

- Secrets of The Ribeira ValleyDocument3 pagesSecrets of The Ribeira ValleymauriciomathiasNo ratings yet

- Avocado Hass FinalDocument12 pagesAvocado Hass FinalJuan Pablo PintoNo ratings yet

- Budding Ceará 9.3Document3 pagesBudding Ceará 9.3mauriciomathiasNo ratings yet

- Agriturism As An Added-Value Option For Growers: Grower ReportDocument2 pagesAgriturism As An Added-Value Option For Growers: Grower ReportmauriciomathiasNo ratings yet

- Ecuadors Flower Industry Case StudyDocument4 pagesEcuadors Flower Industry Case StudyIshtiaq Ahmed MugdhaNo ratings yet

- Colombia's Flower Power: Country FileDocument3 pagesColombia's Flower Power: Country FilemauriciomathiasNo ratings yet

- Hiranaka AtibaiaDocument2 pagesHiranaka AtibaiamauriciomathiasNo ratings yet

- Modern Commerce Options Enhance Export Scope: MarketingDocument3 pagesModern Commerce Options Enhance Export Scope: MarketingmauriciomathiasNo ratings yet

- The Flower TradeDocument2 pagesThe Flower TradeHoàng AnNo ratings yet

- Roses With Altitude: Why Ecuador's Flower Industry Stands OutDocument2 pagesRoses With Altitude: Why Ecuador's Flower Industry Stands OutMd. Zahid Hossan 1911877630No ratings yet

- Practice Case StudyDocument4 pagesPractice Case StudyMd. Atikur Rahman 1831472030No ratings yet

- English - Cherries in ChileDocument2 pagesEnglish - Cherries in ChileDanielNo ratings yet

- Flower Industry in ColombiaDocument7 pagesFlower Industry in ColombiaFarissa Ch. LázaroNo ratings yet

- When Better Doesn't Pay - The Case of Ecuadorian RosesDocument9 pagesWhen Better Doesn't Pay - The Case of Ecuadorian Rosesandrea santosNo ratings yet

- When Better Doesn't Pay - The Case of Ecuadorian RosesDocument9 pagesWhen Better Doesn't Pay - The Case of Ecuadorian RosesReichell PilarNo ratings yet

- Flower Shop (Body)Document92 pagesFlower Shop (Body)MarkLesterEstrellaMabagosNo ratings yet

- Sage Publications, Inc., American Academy of Political and Social Science The Annals of The American Academy of Political and Social ScienceDocument3 pagesSage Publications, Inc., American Academy of Political and Social Science The Annals of The American Academy of Political and Social ScienceFederico YouNo ratings yet

- GE ArakiDocument5 pagesGE ArakimauriciomathiasNo ratings yet

- Neighbourly Advice COPF Expands Services: EditorialDocument2 pagesNeighbourly Advice COPF Expands Services: EditorialmauriciomathiasNo ratings yet

- Dutch Flower ClusterDocument4 pagesDutch Flower ClusterSameer VijNo ratings yet

- Inb372 Section10 Group ADocument3 pagesInb372 Section10 Group Asamim hasanNo ratings yet

- 'Ij Oifd P J Rik.t, Ti.: TO What Extent Can Afbican Sustain Theib This .RrnoDocument1 page'Ij Oifd P J Rik.t, Ti.: TO What Extent Can Afbican Sustain Theib This .RrnoSyifaa' NajibNo ratings yet

- Case 3 - Ecuadorean Rose IndustryDocument6 pagesCase 3 - Ecuadorean Rose IndustryMauricio BedonNo ratings yet

- The Amazon Basin (Brazil)Document17 pagesThe Amazon Basin (Brazil)chrisZENGOOD tvNo ratings yet

- PRESENTATIONDocument2 pagesPRESENTATIONSaadia YaghiNo ratings yet

- Name: Briyith Dayana Garcia Codigo: 5053211 Avocado OriginDocument6 pagesName: Briyith Dayana Garcia Codigo: 5053211 Avocado OriginBRIYITHNo ratings yet

- Florverde Celebrates Ten Years of Change: Country FileDocument4 pagesFlorverde Celebrates Ten Years of Change: Country FilemauriciomathiasNo ratings yet

- Research Paper Topics On BrazilDocument6 pagesResearch Paper Topics On Brazilafeaynwqz100% (1)

- Part3bPart4c With ReferencesDocument7 pagesPart3bPart4c With ReferencesMoira C. VilogNo ratings yet

- The Amazon Basin (Brazil)Document17 pagesThe Amazon Basin (Brazil)chrisZENGOOD tvNo ratings yet

- RoyalFloraHolland StrategicSupplyChainofCutFlowersBusinessDocument16 pagesRoyalFloraHolland StrategicSupplyChainofCutFlowersBusinessaravind ragavan eNo ratings yet

- Review of Plant Studies: Tadele Yeshiwas Tizazu Melkamu Alemayehu WorkieDocument10 pagesReview of Plant Studies: Tadele Yeshiwas Tizazu Melkamu Alemayehu Workiewoldetinsae fentieNo ratings yet

- Module II Pre-Work Cases Case Study - 3: Summer Time: "Water Please"Document9 pagesModule II Pre-Work Cases Case Study - 3: Summer Time: "Water Please"neelmtiwariNo ratings yet

- Chapter One: Introduction: Floristry Plant BreedingDocument54 pagesChapter One: Introduction: Floristry Plant Breedingraja ganeshNo ratings yet

- THE YAM COMPANY - Gabriela LozanoDocument6 pagesTHE YAM COMPANY - Gabriela LozanoGabriela LozanoNo ratings yet

- Comprehension Excercise G11Document3 pagesComprehension Excercise G11Mumba Martin ChikomboNo ratings yet

- Assignment (506) : TopicDocument4 pagesAssignment (506) : TopicMasood SadaqatNo ratings yet

- The Cocoanut With reference to its products and cultivation in the PhilippinesFrom EverandThe Cocoanut With reference to its products and cultivation in the PhilippinesNo ratings yet

- 2 Caso LDFI - Royal Flora Holland-Strategic Supply Chain of Cut Flowers BusinessDocument16 pages2 Caso LDFI - Royal Flora Holland-Strategic Supply Chain of Cut Flowers BusinessCrisbel GOMEZ POMANo ratings yet

- Nursery ReportDocument5 pagesNursery Reportarifeen_091No ratings yet

- Part 4C Competitive Advantage of The CompanyDocument4 pagesPart 4C Competitive Advantage of The CompanyMoira C. VilogNo ratings yet

- 52093-Texto Do Artigo-222232-223836-10-20200302Document6 pages52093-Texto Do Artigo-222232-223836-10-20200302Kevin TanureNo ratings yet

- IAC FTech - 2005 Review 9.2Document3 pagesIAC FTech - 2005 Review 9.2mauriciomathiasNo ratings yet

- International Business Management: Market Audit and Competitive Market Analysis Members of The GroupDocument29 pagesInternational Business Management: Market Audit and Competitive Market Analysis Members of The GroupDonald AnguloNo ratings yet

- Flower Nursery Business PlanDocument47 pagesFlower Nursery Business PlanScribdTranslationsNo ratings yet

- Geography Resoucres - 2013 Trial Paper Question SolutionDocument1 pageGeography Resoucres - 2013 Trial Paper Question SolutionLOLNo ratings yet

- Flower Business Flourish Floriculture: A Study On Bangladesh.Document5 pagesFlower Business Flourish Floriculture: A Study On Bangladesh.inventionjournals100% (1)

- Review of The Related Literature: Definition and Nature of Some Home ChemicalsDocument11 pagesReview of The Related Literature: Definition and Nature of Some Home ChemicalsErlyn Grace RedobladoNo ratings yet

- Productivity Levels Among CountriesDocument8 pagesProductivity Levels Among CountriesMelanie Walleska Herrera MoreiraNo ratings yet

- Wyler SucculentsDocument2 pagesWyler Succulentsapi-356761277No ratings yet

- Reading Passage 1Document14 pagesReading Passage 1vinothasoniNo ratings yet

- The Ecuadorean Rose IndustryDocument2 pagesThe Ecuadorean Rose IndustryManchla100% (2)

- 3.4.1 Summary: Examples of Cottage IndustryDocument6 pages3.4.1 Summary: Examples of Cottage IndustryYuri IllianaNo ratings yet

- The Craft Industry Dec 2008Document29 pagesThe Craft Industry Dec 2008kimmisharmaNo ratings yet

- Investing in AgricultureDocument3 pagesInvesting in AgricultureTeodora RemetanNo ratings yet

- The Making of Dutch Flower CultureDocument55 pagesThe Making of Dutch Flower CultureB DarbariNo ratings yet

- FVT Q-Type 6.5Document1 pageFVT Q-Type 6.5mauriciomathiasNo ratings yet

- Eggplant Production in California: Production Areas and SeasonsDocument3 pagesEggplant Production in California: Production Areas and SeasonsmauriciomathiasNo ratings yet

- IAC FTech - 2005 Review 9.2Document3 pagesIAC FTech - 2005 Review 9.2mauriciomathiasNo ratings yet

- SP Market Note 9.8Document1 pageSP Market Note 9.8mauriciomathiasNo ratings yet

- Neighbourly Advice COPF Expands Services: EditorialDocument2 pagesNeighbourly Advice COPF Expands Services: EditorialmauriciomathiasNo ratings yet

- The Thirty-Nine Steps NTDocument184 pagesThe Thirty-Nine Steps NTmauriciomathiasNo ratings yet

- Lazzeri 9.4 PDFDocument1 pageLazzeri 9.4 PDFmauriciomathiasNo ratings yet

- The Thirty-Nine Steps NT PDFDocument184 pagesThe Thirty-Nine Steps NT PDFmauriciomathiasNo ratings yet

- Budding Ceará 9.3Document3 pagesBudding Ceará 9.3mauriciomathiasNo ratings yet

- Modern Commerce Options Enhance Export Scope: MarketingDocument3 pagesModern Commerce Options Enhance Export Scope: MarketingmauriciomathiasNo ratings yet

- Secrets of The Ribeira ValleyDocument3 pagesSecrets of The Ribeira ValleymauriciomathiasNo ratings yet

- Juncao in BrazilDocument2 pagesJuncao in BrazilmauriciomathiasNo ratings yet

- Flower Under Quality Control LazzeriDocument1 pageFlower Under Quality Control LazzerimauriciomathiasNo ratings yet

- Russian Food Embargo Benefit To Brazil UncertainDocument6 pagesRussian Food Embargo Benefit To Brazil UncertainmauriciomathiasNo ratings yet

- Plant Production and Supply in Southern Brazil: Country FileDocument3 pagesPlant Production and Supply in Southern Brazil: Country FilemauriciomathiasNo ratings yet

- Invasive Plant Research Laboratory Anti-Piracy Activity ContinuesDocument2 pagesInvasive Plant Research Laboratory Anti-Piracy Activity ContinuesmauriciomathiasNo ratings yet

- Hiranaka AtibaiaDocument2 pagesHiranaka AtibaiamauriciomathiasNo ratings yet

- Phil Collins PresentationDocument12 pagesPhil Collins Presentationapi-315724509No ratings yet

- Hhtfa8e ch01 SMDocument83 pagesHhtfa8e ch01 SMkbrooks323No ratings yet

- Workplace Software and Skills - WEB IlfJtcPDocument1,101 pagesWorkplace Software and Skills - WEB IlfJtcPlkeremoieltonNo ratings yet

- TT4875Document1 pageTT4875Benjazz31No ratings yet

- Nar Ont 1 GbpsDocument49 pagesNar Ont 1 GbpsCatalin StoicescuNo ratings yet

- Interview Assessment FormDocument3 pagesInterview Assessment FormCristina BocanialaNo ratings yet

- 5 Lb. Book of GRE Practice Problems (2nd Edition - Latest)Document191 pages5 Lb. Book of GRE Practice Problems (2nd Edition - Latest)MRAAKNo ratings yet

- Profile Summary: Sindhu RaoDocument3 pagesProfile Summary: Sindhu RaoVijay SamuelNo ratings yet

- DLD CEL 120 Lab Manual PDFDocument65 pagesDLD CEL 120 Lab Manual PDFBurhanNo ratings yet

- (Ebook PDF) Practical Guide To U.S. Taxation of International Transactions 12th Edition DownloadDocument33 pages(Ebook PDF) Practical Guide To U.S. Taxation of International Transactions 12th Edition Downloadkassummxgdx100% (88)

- Terminal Pulogebang PDFDocument2 pagesTerminal Pulogebang PDFEka SanusiNo ratings yet

- Text Book Solution Lesson - 6 (Local Self Govt. in Urban Areas)Document6 pagesText Book Solution Lesson - 6 (Local Self Govt. in Urban Areas)Sahasra KiranNo ratings yet

- Strategies For Lesson PlanningDocument14 pagesStrategies For Lesson PlanningVince NavarezNo ratings yet

- Lecture 4-5-240 - Fraud - Compatibility ModeDocument35 pagesLecture 4-5-240 - Fraud - Compatibility ModeSourav MahadiNo ratings yet

- Factoring & Forfeiting: Learning ObjectivesDocument7 pagesFactoring & Forfeiting: Learning ObjectivesLohith SanjeevNo ratings yet

- Introduction To Industrial Networks: Unit 3Document31 pagesIntroduction To Industrial Networks: Unit 3Mantenimiento MendezNo ratings yet

- Lulu PDF Creation GuideDocument3 pagesLulu PDF Creation GuideThomas DenmarkNo ratings yet

- Review Article The Roles and Responsibilities of Management Accountants in The Era of GlobalizationDocument2 pagesReview Article The Roles and Responsibilities of Management Accountants in The Era of GlobalizationJose Fanny100% (1)

- David Aguilar ResumeDocument1 pageDavid Aguilar ResumeDavidAguilarNo ratings yet

- Slurry Pumps Ar1 PDFDocument40 pagesSlurry Pumps Ar1 PDFsanjayagrawal70-1No ratings yet

- AR11Document241 pagesAR11Mohib Ullah YousafzaiNo ratings yet

- Pile RockDocument31 pagesPile RockpandianNo ratings yet

- 0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Document2 pages0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Miguel RojasNo ratings yet

- Scema Monitor PDFDocument91 pagesScema Monitor PDFAlex100% (1)

- Keshab Chandra Panda Vs StateDocument5 pagesKeshab Chandra Panda Vs StateShivangiNo ratings yet

- Service Manual: Controller Sigma Control 2Document33 pagesService Manual: Controller Sigma Control 2Mukhlis YasinNo ratings yet