Professional Documents

Culture Documents

OFI Testing Equipment

OFI Testing Equipment

Uploaded by

Ahmed AliCopyright:

Available Formats

You might also like

- Maharashtra HSC Chemistry Paper 1-Target PublicationDocument54 pagesMaharashtra HSC Chemistry Paper 1-Target PublicationKhanAbdullah78% (18)

- Mop 22 001 A Operating Manual ClarificationDocument32 pagesMop 22 001 A Operating Manual ClarificationNguyễn Khoa100% (1)

- OEM Pall Prufier Brochure PDFDocument8 pagesOEM Pall Prufier Brochure PDFhaggNo ratings yet

- Extrusion Press Maintenance ManualDocument55 pagesExtrusion Press Maintenance ManualDejan Mitrović100% (6)

- Crude Oil ProcessingDocument8 pagesCrude Oil Processingmarcomaciel3061No ratings yet

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Process Description: Venezuela Jose Mixing Plant Wastewater Treatment Package Equipment (PK-1330330)Document20 pagesProcess Description: Venezuela Jose Mixing Plant Wastewater Treatment Package Equipment (PK-1330330)Erick 27 LibreNo ratings yet

- Dissolved Air Flotation (DAF)Document2 pagesDissolved Air Flotation (DAF)kinley dorjeeNo ratings yet

- Daf Sop 1.0Document16 pagesDaf Sop 1.0KELVIN TECHNOLOGIESNo ratings yet

- Transformer Oil PurificationDocument7 pagesTransformer Oil PurificationAther AliNo ratings yet

- H2 FLOW - DAF - Process - DescriptionDocument8 pagesH2 FLOW - DAF - Process - DescriptionPriyaNo ratings yet

- Dissolved Air Flotation (DAF) SystemDocument8 pagesDissolved Air Flotation (DAF) Systemneeraj sharmaNo ratings yet

- Manual O&M PFL Reúso Membranas UF DivididoDocument29 pagesManual O&M PFL Reúso Membranas UF DivididoJavier OvalleNo ratings yet

- Iom DafDocument17 pagesIom DafrubeningarNo ratings yet

- Ibp1868 12Document8 pagesIbp1868 12Marcelo Varejão CasarinNo ratings yet

- Difloat - BrochureDocument8 pagesDifloat - Brochurejpsingh75100% (1)

- Dissolved Air Floatation (Daf) Unit: ApplicationDocument2 pagesDissolved Air Floatation (Daf) Unit: ApplicationAVIJIT MITRANo ratings yet

- Savant Labs Highlight ASTM D3427 Air Release TestingDocument2 pagesSavant Labs Highlight ASTM D3427 Air Release TestingPhoebe Jean MalapayNo ratings yet

- Data Sheet Sw30hrle-400Document2 pagesData Sheet Sw30hrle-400Alexis Antonio Jara VidalNo ratings yet

- DAF Theory 1Document3 pagesDAF Theory 1rvkumar61No ratings yet

- Ecosafe Ro Membrane CatalogDocument11 pagesEcosafe Ro Membrane CatalogecosafeNo ratings yet

- 2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFDocument28 pages2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFVelibor Karanović100% (1)

- Series 4000 Cyclosep Centrifugal SeparatorDocument7 pagesSeries 4000 Cyclosep Centrifugal SeparatorValiNo ratings yet

- 1c Process Operation SystemDocument20 pages1c Process Operation SystemrubensNo ratings yet

- Dissolved Air FlotationDocument2 pagesDissolved Air FlotationmcsfuvNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- Polyethylene and Polypropylene Manufacturing: Technical Guidance Package For Chemical SourcesDocument26 pagesPolyethylene and Polypropylene Manufacturing: Technical Guidance Package For Chemical SourcesbaneNo ratings yet

- Dissolved Air Flotation TheoryDocument2 pagesDissolved Air Flotation TheoryLasandu WanniarachchiNo ratings yet

- Dalal Wiped Film EvaporatorDocument8 pagesDalal Wiped Film EvaporatorVenkat Giri100% (1)

- Types of Hydraulic FluidsDocument5 pagesTypes of Hydraulic FluidsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjNo ratings yet

- Condensate StabilizerDocument16 pagesCondensate Stabilizern73686861100% (1)

- Flocculants - Polymers For Coagulation of Solids and Sludge - TRAMFLOC, InCDocument7 pagesFlocculants - Polymers For Coagulation of Solids and Sludge - TRAMFLOC, InCRaghavendra Pratap SinghNo ratings yet

- WTS DAF CatalogueDocument5 pagesWTS DAF CatalogueLye YpNo ratings yet

- AIR PRODUCTS Agrochemical Adjuvants GuideDocument8 pagesAIR PRODUCTS Agrochemical Adjuvants GuideRomán M Martín del CNo ratings yet

- Vws Oil GasDocument8 pagesVws Oil GasFabricio TrosarelloNo ratings yet

- AST Short Path DistillationDocument9 pagesAST Short Path DistillationAshokkumar ThakkarNo ratings yet

- GDS113 Filtros Pall PDFDocument4 pagesGDS113 Filtros Pall PDFJohn Avila DelgadilloNo ratings yet

- Optimized One-Step Pretreatment Enhancing The Benefits of Air Flotation and Media FiltrationDocument18 pagesOptimized One-Step Pretreatment Enhancing The Benefits of Air Flotation and Media FiltrationMunir AbdullahNo ratings yet

- Rethinking Dissolved Air Flotation (Daf) Design For Industrial PretreatmentDocument14 pagesRethinking Dissolved Air Flotation (Daf) Design For Industrial PretreatmentDewesh SinghNo ratings yet

- EPA608 TrainingDocument338 pagesEPA608 Traininglecue21No ratings yet

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Document9 pagesThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNo ratings yet

- Keller VDN VenturiDocument8 pagesKeller VDN Venturijpdavila205No ratings yet

- P06e Destillationstechnik 09Document16 pagesP06e Destillationstechnik 09Nurul AniraNo ratings yet

- Flow Assurance HomeworkDocument9 pagesFlow Assurance HomeworkLívia Costa MelloNo ratings yet

- Internship Report BYCODocument24 pagesInternship Report BYCOGhazanferAli100% (1)

- EPE Donaldson Purify and Pressure FiltersDocument132 pagesEPE Donaldson Purify and Pressure FiltersJamin SmtpngNo ratings yet

- How To Flush Gearboxes and Bearing Housings: Noria CorporationDocument6 pagesHow To Flush Gearboxes and Bearing Housings: Noria CorporationiagoramonNo ratings yet

- Reverse Osmosis Model R4X40 Installation InstructionsDocument16 pagesReverse Osmosis Model R4X40 Installation InstructionsWattsNo ratings yet

- Degasification of Polymer in The Vacuum EvaporatorDocument4 pagesDegasification of Polymer in The Vacuum EvaporatorUlricNo ratings yet

- Name Raj Goswami: Course Name Class Year Subject Code Subject Name InstituteDocument25 pagesName Raj Goswami: Course Name Class Year Subject Code Subject Name InstituteRaj GoswamiNo ratings yet

- The Ohsol PresentationDocument53 pagesThe Ohsol PresentationArsalan QadirNo ratings yet

- ETS - DAF White PaperDocument14 pagesETS - DAF White PapermjasdNo ratings yet

- Operation and Maintenance Manual: Effluent Treatment PlantDocument49 pagesOperation and Maintenance Manual: Effluent Treatment PlantOmkar Bharankar100% (1)

- Filtro de AireDocument2 pagesFiltro de AireAndres Uzzi GuzmanNo ratings yet

- The Power of Testing: Pilot Testing Services For A Wide Range of Unit OperationsDocument4 pagesThe Power of Testing: Pilot Testing Services For A Wide Range of Unit OperationsbracioNo ratings yet

- 10 - Filmtech MembraneDocument2 pages10 - Filmtech MembraneAnonymous XbmoAFtINo ratings yet

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Miscellaneous Treatment Processes PDFDocument6 pagesMiscellaneous Treatment Processes PDFAhmed AliNo ratings yet

- Heat ProblemsDocument17 pagesHeat ProblemsAhmed AliNo ratings yet

- Applications of Egg Shell and Egg Shell Membrane As AdsorbentsDocument13 pagesApplications of Egg Shell and Egg Shell Membrane As AdsorbentsAhmed AliNo ratings yet

- Problems: CHEM1020Document45 pagesProblems: CHEM1020Ahmed AliNo ratings yet

- 04-Control of Volatile Organic Compounds (VOCs)Document187 pages04-Control of Volatile Organic Compounds (VOCs)Ahmed AliNo ratings yet

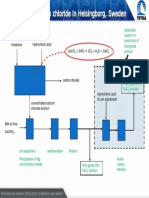

- Dedicated System For Production of Food Grade Product: Limestone Caco + 2Hcl Co + H O + Cacl Hydrochloric AcidDocument1 pageDedicated System For Production of Food Grade Product: Limestone Caco + 2Hcl Co + H O + Cacl Hydrochloric AcidAhmed AliNo ratings yet

- Evap DesignDocument16 pagesEvap DesignAhmed Ali100% (3)

- 1992 Lazaridis Daf Metal IonsDocument16 pages1992 Lazaridis Daf Metal IonsAhmed AliNo ratings yet

- Extraction of Chlorophyll From Alfalfa PlantDocument13 pagesExtraction of Chlorophyll From Alfalfa PlantAhmed AliNo ratings yet

- Soxhlet Ex.Document2 pagesSoxhlet Ex.Ahmed AliNo ratings yet

- 5-Explosion WeldingDocument13 pages5-Explosion WeldingRamu AmaraNo ratings yet

- ANSWERS-Ionic Bonding WorksheetDocument2 pagesANSWERS-Ionic Bonding WorksheetKyler FungNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- E-Coat Inputs: A) Part InformationDocument5 pagesE-Coat Inputs: A) Part InformationAnjan MalusareNo ratings yet

- CH311 - Experiment 6 - Sterol Extraction From Sea WaterDocument2 pagesCH311 - Experiment 6 - Sterol Extraction From Sea WaterNarelle IaumaNo ratings yet

- Iqwq Ce1091 VPWLD D7 4556 - 0Document7 pagesIqwq Ce1091 VPWLD D7 4556 - 0jacksonbello34No ratings yet

- Carefiber Product CatalogueDocument65 pagesCarefiber Product Catalogueramiro gutierrez cedeñoNo ratings yet

- Iraqi Building Code Requirements For Reinforced Concrete (1987) - 3Document71 pagesIraqi Building Code Requirements For Reinforced Concrete (1987) - 3mamandawe50% (2)

- Ductility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedDocument11 pagesDuctility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedNorhafizah Bt SallehNo ratings yet

- Grinnell Series 8000Document8 pagesGrinnell Series 8000Sergio Gana GonzalezNo ratings yet

- Quotation-Tirupati GardenDocument12 pagesQuotation-Tirupati GardenAnonymous fLgaidVBhzNo ratings yet

- Abrasiguard AA Straight Polyurethane Lined Pipe DatasheetDocument3 pagesAbrasiguard AA Straight Polyurethane Lined Pipe DatasheetBeaver Process EquipmentNo ratings yet

- Precast EnvelopeDocument70 pagesPrecast Envelopesdutta2591No ratings yet

- Brass - WikipediaDocument18 pagesBrass - WikipediaTahafanMaggedonNo ratings yet

- Scale PresentationDocument59 pagesScale PresentationMohamed SadekNo ratings yet

- 02 - Chapter 1 With ReferencesDocument17 pages02 - Chapter 1 With ReferencesAKHTAR RAJANo ratings yet

- Table For Angles in Compression PDFDocument4 pagesTable For Angles in Compression PDFMikeNo ratings yet

- Joule ThomsonDocument4 pagesJoule Thomsonmartian2003No ratings yet

- Goldium Steel Lamination CRNGO CRGODocument1 pageGoldium Steel Lamination CRNGO CRGOdisse_detiNo ratings yet

- Chemical Leakage From LG Polymers Plant: VisakhapatnamDocument8 pagesChemical Leakage From LG Polymers Plant: VisakhapatnamHafsa KhanNo ratings yet

- Learning Guide in Science 9 Q2 W3Document2 pagesLearning Guide in Science 9 Q2 W3Angela La Guardia LolongNo ratings yet

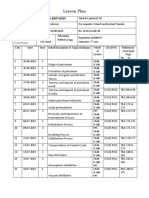

- Lesson Plan: Course Start Date Subject: Code/NameDocument3 pagesLesson Plan: Course Start Date Subject: Code/Nameanon_348923763No ratings yet

- 9701 s04 QP 2 PDFDocument8 pages9701 s04 QP 2 PDFSanthi RamanNo ratings yet

- 1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgDocument13 pages1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgbanhrangNo ratings yet

- 2 Bolted ConnectionsDocument335 pages2 Bolted ConnectionsJagal UdayaNo ratings yet

- Latihan Menjawab Kertas 3 1 A Student Carried Out An Experiment To Determine The Empirical Formula ofDocument5 pagesLatihan Menjawab Kertas 3 1 A Student Carried Out An Experiment To Determine The Empirical Formula ofMasitah Abu BakarNo ratings yet

- Spot Welder MILLER ResistanceDocument16 pagesSpot Welder MILLER ResistanceEdSolo100% (1)

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- Importance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsDocument18 pagesImportance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsJessel Galicia100% (1)

OFI Testing Equipment

OFI Testing Equipment

Uploaded by

Ahmed AliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OFI Testing Equipment

OFI Testing Equipment

Uploaded by

Ahmed AliCopyright:

Available Formats

OFI Testing Equipment, Inc.

Telefonos: 713-880-9885 Email: sales@ofite.com

Productos

Cementacion Terminaciones Ensayos de Testigos Lodos de Perforacion Laboratorios Moviles Perfil de Inyeccion Reactivos Reacondicionado Restauracion Estimulacion Provisiones Aguas Residuales Novedades

Item: 298-00 Descripcion: Diffused Air - Dissolved Air Flotation Test Apparatus (DADAFTA), 115 Volt Flotation is a unit operation used to separate solids or liquid particles from a liquid phase. Separation is brought about by the introduction of fine gas (usually air) bubbles into the liquid phase. The bubbles attach to the particulate matter, and the buoyant force of the combined particle and gas bubbles is great enough to cause the particle to rise to the surface. Air bubbles are added or caused to form by one of the following methods:

Servicios MSDS Instrucciones

Noticias Registracion Formularios

1. Diffused Air Flotation - Aeration produced by passing air through a porous media. 2. Dissolved Air Flotation - Injection of air while the liquid is under pressure, followed by the release of the pressure. In water/wastewater treatment, flotation is mainly used to remove suspended matter and to concentrate biological sludges. The principal advantage of flotation over sedimentation is that very small or light particles that settle slowly can be removed more completely and in a shorter time. Applications of the Diffused Air - Dissolved Air Flotation apparatus in the field of water/wastewater treatment include: 1. Separation of flocculated matter in the clarification of surface water. 2. Separation of flocculated or non-flocculated oil in wastewater from refineries, airports, and steelworks. 3. Separation of metallic hydroxides or pigments in the treatment. 4. Thickening of the activated sludge (or mixed sludge and primary sludge) from organic wastewater treatment plants.

Chemical flotation aids are often used to enhance the Diffused Air - Dissolved Air Flotation (DADAFTA) process. The most effective chemicals used are moderate weight polyamines or very high molecular weight cationic polyacrylamide polymers. Polymers can increase solid recovery in the

floated sludge from 85% to 98% and can also reduce the suspended solids in the subnatant. The OFITE DADAFTA allows the user to simulate a flotation process on a small scale. The DADAFTA can be used to measure the floatability of a particular sludge in designing treatment plants and to evaluate chemical flotation aids. A few of the DADAFTA features include: Clear, unibody pressure cell withstands pressures up to 125 psi (8.6 bar). Oil-less 115-volt piston air compressor for high efficiency and constant performance. Permeable ceramic disk used for the diffuser can be removed, cleaned, and reused. Chemical flotation aid inlet with septum. Stainless steel paddle for additional mixing capabilities. Easy-to-read flow meter and pressure gauge. Quick disconnect fittings.

You might also like

- Maharashtra HSC Chemistry Paper 1-Target PublicationDocument54 pagesMaharashtra HSC Chemistry Paper 1-Target PublicationKhanAbdullah78% (18)

- Mop 22 001 A Operating Manual ClarificationDocument32 pagesMop 22 001 A Operating Manual ClarificationNguyễn Khoa100% (1)

- OEM Pall Prufier Brochure PDFDocument8 pagesOEM Pall Prufier Brochure PDFhaggNo ratings yet

- Extrusion Press Maintenance ManualDocument55 pagesExtrusion Press Maintenance ManualDejan Mitrović100% (6)

- Crude Oil ProcessingDocument8 pagesCrude Oil Processingmarcomaciel3061No ratings yet

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Process Description: Venezuela Jose Mixing Plant Wastewater Treatment Package Equipment (PK-1330330)Document20 pagesProcess Description: Venezuela Jose Mixing Plant Wastewater Treatment Package Equipment (PK-1330330)Erick 27 LibreNo ratings yet

- Dissolved Air Flotation (DAF)Document2 pagesDissolved Air Flotation (DAF)kinley dorjeeNo ratings yet

- Daf Sop 1.0Document16 pagesDaf Sop 1.0KELVIN TECHNOLOGIESNo ratings yet

- Transformer Oil PurificationDocument7 pagesTransformer Oil PurificationAther AliNo ratings yet

- H2 FLOW - DAF - Process - DescriptionDocument8 pagesH2 FLOW - DAF - Process - DescriptionPriyaNo ratings yet

- Dissolved Air Flotation (DAF) SystemDocument8 pagesDissolved Air Flotation (DAF) Systemneeraj sharmaNo ratings yet

- Manual O&M PFL Reúso Membranas UF DivididoDocument29 pagesManual O&M PFL Reúso Membranas UF DivididoJavier OvalleNo ratings yet

- Iom DafDocument17 pagesIom DafrubeningarNo ratings yet

- Ibp1868 12Document8 pagesIbp1868 12Marcelo Varejão CasarinNo ratings yet

- Difloat - BrochureDocument8 pagesDifloat - Brochurejpsingh75100% (1)

- Dissolved Air Floatation (Daf) Unit: ApplicationDocument2 pagesDissolved Air Floatation (Daf) Unit: ApplicationAVIJIT MITRANo ratings yet

- Savant Labs Highlight ASTM D3427 Air Release TestingDocument2 pagesSavant Labs Highlight ASTM D3427 Air Release TestingPhoebe Jean MalapayNo ratings yet

- Data Sheet Sw30hrle-400Document2 pagesData Sheet Sw30hrle-400Alexis Antonio Jara VidalNo ratings yet

- DAF Theory 1Document3 pagesDAF Theory 1rvkumar61No ratings yet

- Ecosafe Ro Membrane CatalogDocument11 pagesEcosafe Ro Membrane CatalogecosafeNo ratings yet

- 2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFDocument28 pages2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFVelibor Karanović100% (1)

- Series 4000 Cyclosep Centrifugal SeparatorDocument7 pagesSeries 4000 Cyclosep Centrifugal SeparatorValiNo ratings yet

- 1c Process Operation SystemDocument20 pages1c Process Operation SystemrubensNo ratings yet

- Dissolved Air FlotationDocument2 pagesDissolved Air FlotationmcsfuvNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- Polyethylene and Polypropylene Manufacturing: Technical Guidance Package For Chemical SourcesDocument26 pagesPolyethylene and Polypropylene Manufacturing: Technical Guidance Package For Chemical SourcesbaneNo ratings yet

- Dissolved Air Flotation TheoryDocument2 pagesDissolved Air Flotation TheoryLasandu WanniarachchiNo ratings yet

- Dalal Wiped Film EvaporatorDocument8 pagesDalal Wiped Film EvaporatorVenkat Giri100% (1)

- Types of Hydraulic FluidsDocument5 pagesTypes of Hydraulic FluidsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjNo ratings yet

- Condensate StabilizerDocument16 pagesCondensate Stabilizern73686861100% (1)

- Flocculants - Polymers For Coagulation of Solids and Sludge - TRAMFLOC, InCDocument7 pagesFlocculants - Polymers For Coagulation of Solids and Sludge - TRAMFLOC, InCRaghavendra Pratap SinghNo ratings yet

- WTS DAF CatalogueDocument5 pagesWTS DAF CatalogueLye YpNo ratings yet

- AIR PRODUCTS Agrochemical Adjuvants GuideDocument8 pagesAIR PRODUCTS Agrochemical Adjuvants GuideRomán M Martín del CNo ratings yet

- Vws Oil GasDocument8 pagesVws Oil GasFabricio TrosarelloNo ratings yet

- AST Short Path DistillationDocument9 pagesAST Short Path DistillationAshokkumar ThakkarNo ratings yet

- GDS113 Filtros Pall PDFDocument4 pagesGDS113 Filtros Pall PDFJohn Avila DelgadilloNo ratings yet

- Optimized One-Step Pretreatment Enhancing The Benefits of Air Flotation and Media FiltrationDocument18 pagesOptimized One-Step Pretreatment Enhancing The Benefits of Air Flotation and Media FiltrationMunir AbdullahNo ratings yet

- Rethinking Dissolved Air Flotation (Daf) Design For Industrial PretreatmentDocument14 pagesRethinking Dissolved Air Flotation (Daf) Design For Industrial PretreatmentDewesh SinghNo ratings yet

- EPA608 TrainingDocument338 pagesEPA608 Traininglecue21No ratings yet

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Document9 pagesThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNo ratings yet

- Keller VDN VenturiDocument8 pagesKeller VDN Venturijpdavila205No ratings yet

- P06e Destillationstechnik 09Document16 pagesP06e Destillationstechnik 09Nurul AniraNo ratings yet

- Flow Assurance HomeworkDocument9 pagesFlow Assurance HomeworkLívia Costa MelloNo ratings yet

- Internship Report BYCODocument24 pagesInternship Report BYCOGhazanferAli100% (1)

- EPE Donaldson Purify and Pressure FiltersDocument132 pagesEPE Donaldson Purify and Pressure FiltersJamin SmtpngNo ratings yet

- How To Flush Gearboxes and Bearing Housings: Noria CorporationDocument6 pagesHow To Flush Gearboxes and Bearing Housings: Noria CorporationiagoramonNo ratings yet

- Reverse Osmosis Model R4X40 Installation InstructionsDocument16 pagesReverse Osmosis Model R4X40 Installation InstructionsWattsNo ratings yet

- Degasification of Polymer in The Vacuum EvaporatorDocument4 pagesDegasification of Polymer in The Vacuum EvaporatorUlricNo ratings yet

- Name Raj Goswami: Course Name Class Year Subject Code Subject Name InstituteDocument25 pagesName Raj Goswami: Course Name Class Year Subject Code Subject Name InstituteRaj GoswamiNo ratings yet

- The Ohsol PresentationDocument53 pagesThe Ohsol PresentationArsalan QadirNo ratings yet

- ETS - DAF White PaperDocument14 pagesETS - DAF White PapermjasdNo ratings yet

- Operation and Maintenance Manual: Effluent Treatment PlantDocument49 pagesOperation and Maintenance Manual: Effluent Treatment PlantOmkar Bharankar100% (1)

- Filtro de AireDocument2 pagesFiltro de AireAndres Uzzi GuzmanNo ratings yet

- The Power of Testing: Pilot Testing Services For A Wide Range of Unit OperationsDocument4 pagesThe Power of Testing: Pilot Testing Services For A Wide Range of Unit OperationsbracioNo ratings yet

- 10 - Filmtech MembraneDocument2 pages10 - Filmtech MembraneAnonymous XbmoAFtINo ratings yet

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Miscellaneous Treatment Processes PDFDocument6 pagesMiscellaneous Treatment Processes PDFAhmed AliNo ratings yet

- Heat ProblemsDocument17 pagesHeat ProblemsAhmed AliNo ratings yet

- Applications of Egg Shell and Egg Shell Membrane As AdsorbentsDocument13 pagesApplications of Egg Shell and Egg Shell Membrane As AdsorbentsAhmed AliNo ratings yet

- Problems: CHEM1020Document45 pagesProblems: CHEM1020Ahmed AliNo ratings yet

- 04-Control of Volatile Organic Compounds (VOCs)Document187 pages04-Control of Volatile Organic Compounds (VOCs)Ahmed AliNo ratings yet

- Dedicated System For Production of Food Grade Product: Limestone Caco + 2Hcl Co + H O + Cacl Hydrochloric AcidDocument1 pageDedicated System For Production of Food Grade Product: Limestone Caco + 2Hcl Co + H O + Cacl Hydrochloric AcidAhmed AliNo ratings yet

- Evap DesignDocument16 pagesEvap DesignAhmed Ali100% (3)

- 1992 Lazaridis Daf Metal IonsDocument16 pages1992 Lazaridis Daf Metal IonsAhmed AliNo ratings yet

- Extraction of Chlorophyll From Alfalfa PlantDocument13 pagesExtraction of Chlorophyll From Alfalfa PlantAhmed AliNo ratings yet

- Soxhlet Ex.Document2 pagesSoxhlet Ex.Ahmed AliNo ratings yet

- 5-Explosion WeldingDocument13 pages5-Explosion WeldingRamu AmaraNo ratings yet

- ANSWERS-Ionic Bonding WorksheetDocument2 pagesANSWERS-Ionic Bonding WorksheetKyler FungNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- E-Coat Inputs: A) Part InformationDocument5 pagesE-Coat Inputs: A) Part InformationAnjan MalusareNo ratings yet

- CH311 - Experiment 6 - Sterol Extraction From Sea WaterDocument2 pagesCH311 - Experiment 6 - Sterol Extraction From Sea WaterNarelle IaumaNo ratings yet

- Iqwq Ce1091 VPWLD D7 4556 - 0Document7 pagesIqwq Ce1091 VPWLD D7 4556 - 0jacksonbello34No ratings yet

- Carefiber Product CatalogueDocument65 pagesCarefiber Product Catalogueramiro gutierrez cedeñoNo ratings yet

- Iraqi Building Code Requirements For Reinforced Concrete (1987) - 3Document71 pagesIraqi Building Code Requirements For Reinforced Concrete (1987) - 3mamandawe50% (2)

- Ductility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedDocument11 pagesDuctility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedNorhafizah Bt SallehNo ratings yet

- Grinnell Series 8000Document8 pagesGrinnell Series 8000Sergio Gana GonzalezNo ratings yet

- Quotation-Tirupati GardenDocument12 pagesQuotation-Tirupati GardenAnonymous fLgaidVBhzNo ratings yet

- Abrasiguard AA Straight Polyurethane Lined Pipe DatasheetDocument3 pagesAbrasiguard AA Straight Polyurethane Lined Pipe DatasheetBeaver Process EquipmentNo ratings yet

- Precast EnvelopeDocument70 pagesPrecast Envelopesdutta2591No ratings yet

- Brass - WikipediaDocument18 pagesBrass - WikipediaTahafanMaggedonNo ratings yet

- Scale PresentationDocument59 pagesScale PresentationMohamed SadekNo ratings yet

- 02 - Chapter 1 With ReferencesDocument17 pages02 - Chapter 1 With ReferencesAKHTAR RAJANo ratings yet

- Table For Angles in Compression PDFDocument4 pagesTable For Angles in Compression PDFMikeNo ratings yet

- Joule ThomsonDocument4 pagesJoule Thomsonmartian2003No ratings yet

- Goldium Steel Lamination CRNGO CRGODocument1 pageGoldium Steel Lamination CRNGO CRGOdisse_detiNo ratings yet

- Chemical Leakage From LG Polymers Plant: VisakhapatnamDocument8 pagesChemical Leakage From LG Polymers Plant: VisakhapatnamHafsa KhanNo ratings yet

- Learning Guide in Science 9 Q2 W3Document2 pagesLearning Guide in Science 9 Q2 W3Angela La Guardia LolongNo ratings yet

- Lesson Plan: Course Start Date Subject: Code/NameDocument3 pagesLesson Plan: Course Start Date Subject: Code/Nameanon_348923763No ratings yet

- 9701 s04 QP 2 PDFDocument8 pages9701 s04 QP 2 PDFSanthi RamanNo ratings yet

- 1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgDocument13 pages1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgbanhrangNo ratings yet

- 2 Bolted ConnectionsDocument335 pages2 Bolted ConnectionsJagal UdayaNo ratings yet

- Latihan Menjawab Kertas 3 1 A Student Carried Out An Experiment To Determine The Empirical Formula ofDocument5 pagesLatihan Menjawab Kertas 3 1 A Student Carried Out An Experiment To Determine The Empirical Formula ofMasitah Abu BakarNo ratings yet

- Spot Welder MILLER ResistanceDocument16 pagesSpot Welder MILLER ResistanceEdSolo100% (1)

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- Importance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsDocument18 pagesImportance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsJessel Galicia100% (1)