Professional Documents

Culture Documents

DS - EnCal - 3000 - EN - 2012.04.30

DS - EnCal - 3000 - EN - 2012.04.30

Uploaded by

said_rahmansyah4750Copyright:

Available Formats

You might also like

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Cat 312D2 L Excavadeira PDFDocument468 pagesCat 312D2 L Excavadeira PDFIsmael Grünhäuser100% (2)

- Basic Maintenance KPI MetricsDocument20 pagesBasic Maintenance KPI MetricsKrishna Jasha100% (5)

- 31-TMSS-06 (Rev 00)Document8 pages31-TMSS-06 (Rev 00)GardellNo ratings yet

- Sequence Control - LC64Document34 pagesSequence Control - LC64said_rahmansyah4750No ratings yet

- Sequence Control - LC64Document34 pagesSequence Control - LC64said_rahmansyah4750No ratings yet

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- Elster-Instromet Encal3000 GCDocument0 pagesElster-Instromet Encal3000 GCsaid_rahmansyah4750No ratings yet

- Elster Encal3000 DatasheetDocument4 pagesElster Encal3000 DatasheetpradeepNo ratings yet

- Landis Libra 310 OverviewDocument2 pagesLandis Libra 310 OverviewLuis CoelhoNo ratings yet

- Ethernet Intelligent Pressure Scanner: Netscanner™ SystemDocument8 pagesEthernet Intelligent Pressure Scanner: Netscanner™ SystemljboorNo ratings yet

- IMR 7500 - Continuous Emission Monitoring System (CEM) PDFDocument4 pagesIMR 7500 - Continuous Emission Monitoring System (CEM) PDFdejavu77No ratings yet

- Golar Viking Case Study NSFMWDocument7 pagesGolar Viking Case Study NSFMWMatteo ConciNo ratings yet

- AnalyserDocument14 pagesAnalyserNaseer HydenNo ratings yet

- Use of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformDocument22 pagesUse of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformAlcimar MonteiroNo ratings yet

- Online Dga PDFDocument8 pagesOnline Dga PDFromaoj671No ratings yet

- Gas Chromatograph ABB PGC5000series PDFDocument12 pagesGas Chromatograph ABB PGC5000series PDFpraveenpedagandhamNo ratings yet

- Gas Calibration Method v2Document9 pagesGas Calibration Method v2Mazhar MahadzirNo ratings yet

- ABB Chromatograph Gas NaturalDocument5 pagesABB Chromatograph Gas NaturalVRIMSANo ratings yet

- Micro GC 3000 BrochureDocument8 pagesMicro GC 3000 BrochureMohd Masri A. Razak100% (1)

- Sitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVDocument6 pagesSitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVpkbijuNo ratings yet

- A Low-Cost Microcontroller-Based Weather Monitoring System-LibreDocument8 pagesA Low-Cost Microcontroller-Based Weather Monitoring System-LibreRohit PatilNo ratings yet

- Ngc8206 Data SheetDocument8 pagesNgc8206 Data SheetAriz Joelee ArthaNo ratings yet

- NGC 8206 Data SheetDocument5 pagesNGC 8206 Data SheetMuhammad Darussalam HerdaniNo ratings yet

- Teledyne 3000taDocument2 pagesTeledyne 3000taRyanNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Process Gas ChromatographRaphyDocument8 pagesProcess Gas ChromatographRaphyoviemeNo ratings yet

- Gas ChromatographyDocument24 pagesGas Chromatographysujiv_sujiv1278No ratings yet

- PLG C 3 Natural Gas ChromatographDocument4 pagesPLG C 3 Natural Gas ChromatographYuli_PribadiNo ratings yet

- IeeeDocument6 pagesIeeeramyadeviNo ratings yet

- Digital Flow Meter For GasDocument1 pageDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Agilent 7890A Network GC Data SheetDocument6 pagesAgilent 7890A Network GC Data Sheettaokan81No ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912Document7 pagesItem Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912A94leo14hsetmaNo ratings yet

- Design and Implementation of Automatic Air Flow Rate Control SystemDocument6 pagesDesign and Implementation of Automatic Air Flow Rate Control Systemresy fauziahNo ratings yet

- Safe LPG For Home: Project Guide: Group MembersDocument30 pagesSafe LPG For Home: Project Guide: Group MembersSiji VargheseNo ratings yet

- Agilent 7890A Gas ChromatographDocument16 pagesAgilent 7890A Gas ChromatographDuodo NguyenNo ratings yet

- Gigasft IrDocument8 pagesGigasft IrCesar BerruecoNo ratings yet

- Micro GC Varian 4900 - BrochureDocument12 pagesMicro GC Varian 4900 - BrochureEng Kombe Chemical100% (1)

- Meteo Dataloggers & Sensors: Automatic Measuring StationsDocument12 pagesMeteo Dataloggers & Sensors: Automatic Measuring StationsMilton Damián Cornejo ReyesNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- PIC18LF4620 Based Customizable Wireless Sensor Node To Detect Hazardous Gas Pipeline LeakageDocument4 pagesPIC18LF4620 Based Customizable Wireless Sensor Node To Detect Hazardous Gas Pipeline LeakageNitheshksuvarnaNo ratings yet

- Greenline 8000 Basic Price and InfoDocument6 pagesGreenline 8000 Basic Price and InfoRobson SantosNo ratings yet

- Discussion On Modern Trend in MeasuremenDocument23 pagesDiscussion On Modern Trend in MeasuremenTitipong PulbunrojNo ratings yet

- 2000 CIGRE Paper 12-204Document8 pages2000 CIGRE Paper 12-204Anonymous 9VcxlFErfNo ratings yet

- 002 - Gas ChromatographDocument52 pages002 - Gas Chromatographtubagus syariefNo ratings yet

- Advance Process ControlDocument11 pagesAdvance Process Control김형진No ratings yet

- Oxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDocument5 pagesOxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDidit AndiatmokoNo ratings yet

- Mini TransDocument2 pagesMini TransAhmedRaafatNo ratings yet

- Digital Flow Meter For GasDocument1 pageDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Sensor de ConcentracionDocument20 pagesSensor de ConcentracionMihail Meza ApolinarioNo ratings yet

- OverviewDocument20 pagesOverviewHashemAliHashem100% (1)

- Real Time Water Wash System of Gas Turbine in Power PlantDocument4 pagesReal Time Water Wash System of Gas Turbine in Power PlantfaisalnadimNo ratings yet

- Iisco Training Report 2019Document20 pagesIisco Training Report 2019Aakarsh PrasadNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Control of Boiler Operation Using PLC - SCADADocument9 pagesControl of Boiler Operation Using PLC - SCADARoshan RaiNo ratings yet

- Digital Flow Meter For GasDocument1 pageDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Effect of Ignition Timing On Fuel Consumption and EmissionsDocument11 pagesEffect of Ignition Timing On Fuel Consumption and Emissionsjlee_296737No ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- BioEngineering - CompDocument2 pagesBioEngineering - Compsaid_rahmansyah4750No ratings yet

- Instrument OpticDocument19 pagesInstrument Opticsaid_rahmansyah4750No ratings yet

- OIMBTCPDocument71 pagesOIMBTCPsaid_rahmansyah4750No ratings yet

- Elster Instromet Q.sonicDocument2 pagesElster Instromet Q.sonicsaid_rahmansyah4750No ratings yet

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- FD960 Density MeterDocument2 pagesFD960 Density Metersaid_rahmansyah4750No ratings yet

- Elster-Instromet Encal3000 GCDocument0 pagesElster-Instromet Encal3000 GCsaid_rahmansyah4750No ratings yet

- ID900 Density MeterDocument2 pagesID900 Density Metersaid_rahmansyah4750No ratings yet

- SG900 Specific GravityDocument2 pagesSG900 Specific Gravitysaid_rahmansyah4750No ratings yet

- 570 Data SheetDocument2 pages570 Data Sheetsaid_rahmansyah4750No ratings yet

- Ca'e 'Ate' L ! I I: Ilv I LL - UgeDocument5 pagesCa'e 'Ate' L ! I I: Ilv I LL - Ugesaid_rahmansyah4750No ratings yet

- General Configuration For Liquid Flow CalculationDocument3 pagesGeneral Configuration For Liquid Flow Calculationsaid_rahmansyah4750No ratings yet

- CH 11 OrganizationDocument1 pageCH 11 OrganizationSaid Rahmansyah100% (1)

- Muhammadhafizi 2022765415 Art&CraftDocument10 pagesMuhammadhafizi 2022765415 Art&Craftwan saiyidah nafisahNo ratings yet

- Mechanical Engineering DesignDocument22 pagesMechanical Engineering DesignFarid AsyrafNo ratings yet

- Two-Dimensional Inverse DynamicsDocument22 pagesTwo-Dimensional Inverse DynamicsEric Urbina SantibañezNo ratings yet

- Mineral Wool Pipe InsulationDocument4 pagesMineral Wool Pipe InsulationMiguel Martinez GuerreroNo ratings yet

- Anand Manuel's ResumeDocument2 pagesAnand Manuel's ResumeanandmanuelNo ratings yet

- Ship ConstructionDocument157 pagesShip ConstructionBehendu PereraNo ratings yet

- Rapid Data Migration To SAP S/4HANADocument40 pagesRapid Data Migration To SAP S/4HANAtempuserNo ratings yet

- Civil Engineers Letter of Reference For MastersDocument2 pagesCivil Engineers Letter of Reference For MastersSyed ShaheenNo ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet

- Safety Relay LC ControllerDocument5 pagesSafety Relay LC ControlleraguilavmNo ratings yet

- KAR Products - Penetrating OilDocument5 pagesKAR Products - Penetrating Oiljaredf@jfelectric.com100% (2)

- 009 (1) .BC415 Communication Interfaces in ABAPDocument228 pages009 (1) .BC415 Communication Interfaces in ABAPChandramouli BalachandranNo ratings yet

- 2.2.12. Boiling PointDocument1 page2.2.12. Boiling PointgeneticodrugsNo ratings yet

- Mechanics of Materials Equation SheetDocument3 pagesMechanics of Materials Equation SheetAramis Kelkelyan100% (1)

- Unit IV - 2 PDFDocument28 pagesUnit IV - 2 PDFruhi gambhirNo ratings yet

- XenoyDocument2 pagesXenoyJuanjo HornoNo ratings yet

- Deformation Mechanism Maps - Oct27Document41 pagesDeformation Mechanism Maps - Oct27Fame Boy SamNo ratings yet

- SBC Code 305 MasonaryDocument129 pagesSBC Code 305 MasonaryMohammed Ghareib NasrNo ratings yet

- Detector TechnologyDocument42 pagesDetector TechnologyCosmin DuceaNo ratings yet

- Phet ConductivityDocument2 pagesPhet ConductivityjuanNo ratings yet

- DIY Car Painting TipsDocument9 pagesDIY Car Painting TipsJohn BrownNo ratings yet

- I Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendDocument11 pagesI Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendSahariar Bin ShafiqueNo ratings yet

- 568f Pec Ts GuideDocument72 pages568f Pec Ts GuideLuciano F LopesNo ratings yet

- Manual Book Mov Auma PDFDocument44 pagesManual Book Mov Auma PDFDidi Gunawan100% (1)

- D2 Use CasesDocument27 pagesD2 Use Casesለዛ ፍቅርNo ratings yet

- Helweg1991-Selecting Optimum Discharge Rate For Water WellDocument6 pagesHelweg1991-Selecting Optimum Discharge Rate For Water WellAgit Surya DwitamaNo ratings yet

DS - EnCal - 3000 - EN - 2012.04.30

DS - EnCal - 3000 - EN - 2012.04.30

Uploaded by

said_rahmansyah4750Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS - EnCal - 3000 - EN - 2012.04.30

DS - EnCal - 3000 - EN - 2012.04.30

Uploaded by

said_rahmansyah4750Copyright:

Available Formats

EnCal3000

Energy measurement analyser

Applications

- Fiscal Energy measurement - Quantitative measurement of natural gas components - Gas quality control measurement

Main features

C6+ within 3 minutes* C9+ within 5 minutes* Repeatability < 0.01 % Double block and bleed Stream select for 5 streams TCP/IP communication Data storage in accordance with API 21.1 standard IP 66 outdoor housing Calculations in accordance with ISO 6976, GPA 2172 or GOST 22667

Brief information

The EnCal3000 is a gas chromatograph specially designed for natural gas energy measurements. This state-of-the-art analyser uses chromatography components based on the latest micro electro-mechanical systems (MEMS) and capillary column technique. This results in highly repeatable and accurate analysis results. The compact, explosion proof design includes the analytical hardware, stream selection and all required electronics for standalone operation. The capillary column technology used in the EnCal 3000 has a superior performance compared to the conventional used packed column technique. Optimum peak separation in combination with a very sensitive and linear TCD detector results in a system with a high accuracy over a large range of gases. Since the carrier gas pressure is electronically controlled ambient temperature changes have no inuence on peak retention times. The design of the EnCal3000 is such that the unit can be placed outdoors close to the sample point without the need of an expensive temperature controlled environment. Communication with the EnCal 3000 can be established using the TCP/IP connection and two Modbus ports. The conguration of the EnCal3000 is carried out with the help of the software package RGC 3000. This software package can be used to congure the (freely programmable) Modbus listing, the analyser method, alarm settings, and all other available parameters in the analyser. RGC3000 is the only user interface to the EnCal3000, which means a separate control unit is not required to operate the instrument or to change any conguration parameters. The TCP/IP connection offers a lot of communication possibilities, like networking capabilities. By using Modbus via TCP/IP multiple instruments such as ow computers can be connected to the EnCal3000. Besides the RGC3000 software package, the unit can be supplied with a powerful diagnostic software tool, which can be used to analyse the internally stored data. 35 days of data is stored in the EnCals solid state memory in accordance with the API 21.1 standard. With the help of the History logger software, this data can be retrieved, presented and transferred to HTML based reports. The modular design of the EnCal3000 enables the servicing of the analyser by non-specialist personnel and keeps instrument down-time very short. The use of the MEMS based components results in far lower consumption of utilities like the Helium carrier gas. All of this contributes to lower operational costs compared to traditional gas chromatographs.

* Detailed analysis up to n-C8 (C6+) respectively n-C9 (C9+) including all isomers and other hydrocarbons, no backush

Instromet

EnCal3000: Energy measurement analyser

Conguration software

The main functions of the RGC 3000 conguration software are: - Conguration of the analyser method and application - Setting of alarms + limits - Printing of chromatograms, conguration and analysis results - Performing manually activated calibrations A special feature of the RGC software is the recalculation option that enables the user to change an integration parameter and check the effect of this change without performing a new analysis. The EnCal 3000 simply recalculates the analysis results based on the raw data of a previously performed analysis. This is a time-saving option, whenever the operator needs to optimize the analysis. The RGC3000 software can also be used to update the embedded software of the gas chromatograph, should any new software releases become available. This can be done locally or remotely, provided the EnCal3000 is connected to a network, which can be accessed remotely. Because all analyser parameters are available electronically, the remote control capabilities are much more valuable than with traditional gas chromatographs. The column head pressure and temperatures of the analytical components, for example, can be changed or checked remotely. The Modbus conguration of the EnCal 3000 is freely programmable. It can be customized to the application and to the equipment communicating with the analyser. Both the serial Modbus and the Modbus via TCP/IP can be tested using the WINDCS software tool.

Modbus over TCP/IP EnCal3000

Ethernet 10 base-T

Switch RGC3000 protocol

Elster-Instromet supervisory system Flow computer

RGC3000 local

API data storage

In todays natural gas market it is becoming increasingly important to have reliable energy measurement data concerning the gas transported through the pipeline. To secure the analysis data of the EnCal3000 the analyser is equipped with an internal data storage of 35 days. This means that all analysis and calibrations performed during this period can be retrieved, even if all communication between the instrument and external devices such as ow computers has failed for a certain period of time. This data is stored in accordance with the API 21.1 standard and can be retrieved with a software tool called History logger. Using this software tool the internally stored data can be retrieved, viewed, stored on a PC and printed out in congurable reports.

Data communication

Communication with the EnCal 3000 can be established using the TCP/IP connection and two congurable (RS 232/485) Modbus ports. If a PC is connected running the RGC 3000 software package, this always uses the TCP/IP connection. This PC with the RGC3000 software is the only user interface with the gas chromatograph. This means a separate control unit is not required to operate the instrument or to change any of the instruments conguration parameters. The TCP/IP connection offers a lot of communication possibilities, like networking capabilities. By using Modbus via TCP/IP, multiple instruments such as ow computers can be connected to the EnCal3000.

Product data sheet

Sampling

An important part of the entire measurement system is the sample retraction and sample transport. The gas that is retracted from the pipe-line must be a representative sample, condensation must be prevented and the pressure must, in most cases, be reduced from very high pressures down to 2 4 barg. Depending on company or country regulations several systems can be used. The most economic system is a (retractable) sample probe with integrated pressure reduction. The main advantage of these sample probes is that the pressure reduction is done inside the pipeline and the heat capacity of the gas in the pipe-line prevents the gas from condensation. The sample probe contains an integrated membrane, which separates any free liquids that might be present in the pipeline from the gas before it can enter the tubing leading to the EnCal 3000 analyser. To prevent the gas from condensation during the transport to the EnCal 3000 it is recommended to provide heat tracing of the transport lines. Whether heat tracing is required and what capacities are needed depends largely on the dewpoint of the gas and the ambient temperatures.

VENTS

DATA power EnCal3000

Calibration gas

Helium

Helium

Pipeline

Pipeline

Calibration and carrier gas

The EnCal 3000 uses Helium as a carrier gas. To make sure that an uninterrupted supply of Helium is guaranteed, the use of a Helium switch-over system is recommended. This is a pressure regulator to which two gas cylinders can be connected. The pressure of both bottles is reduced to the required value with a small pressure difference between the two reduced pressures. The bottle with the higher pressure is depleted rst and once the pressure of this bottle is lower than the pressure of the second bottle, the supply is taken over by the second bottle enabling the user to replace the rst bottle. To protect the analyser against failure of the pressure regulator, the use of a safety relief valve at the outlet of the pressure regulator is recommended.

The calibration gas is a very important factor and determines the overall accuracy of the complete measurement system! After all, the EnCal3000 can never be more accurate than the calibration gas it is calibrated with. The accuracy of the certicate is, of course, important but on top of this, there are several other issues to be considered, e.g. the optimum composition, the ambient temperatures of the gas cylinder and the possible condensation of the higher hydrocarbons in the calibration gas. Elster-Instromet can advise you on each of these subjects and we supply all required accessories, such as pressure regulators, bottle heaters and even complete cabinets or bottle stands for outdoor installations.

analyser is acceptable a fast loop system is required. The EnCal3000 has a built in fast loop system. This means that if the analyser is running several streams in a sequence the next stream to be analysed will be ushed automatically with a ush rate of approx. 20-30 NL/hr. This is sufcient to ush at least 100 meters of 1/8 sample line. By installing two ow meters behind the EnCal3000, the user can see both the normal gas sample ow and the sample bypass ow. Since the fast loop bypasses the moisture lter in the EnCal3000, it does not negatively inuence life time of the lter. The internal fast loop system of the EnCal 3000 saves substantial costs compared with individual fast loops per sample stream.

Multi stream sampling

In an ideal situation, the EnCal 3000 is placed as close to the sample point as possible. However, in most situations, especially where two or more gases of different meter runs are to be sampled, there will be a certain distance to the sampling points. To make sure that the lag time between the various sample points and the

EnCal3000: Energy measurement analyser

Technical data

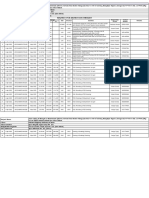

Analytical hardware Analysis output Gas composition range 2 parallel isothermal GC modules with narrow-bore capillary column technology in combination with MEMS based analytical components Full composition of natural gas up to C6+ or C9+ (option)* Heating value, density, Wobbe index neo-C5 : 0 0.25 % N2 : 0 22 % C5 : 0 0.25 % CH4 : 55 100 % CO2 : 0 20 % C6 : 0 0.20 % C2H : 0 14 % C7 : 0 0.10 % C3 : 0 10 % C8 : 0 0.05 % C4 : 0 10 % C9+ : 0 0.05 % Concentrations outside these ranges and other components on request Repeatability (according to ISO 6976 par. 9.1.1): < 0.01 % for all calculated properties 5 ppm Detection limit for C5: Analysis time: 3 min. for C6+ analysis, 5 min. for C9+ analysis Temperature: -20 C to +55 C Base 37 cm x height 37 cm ( 14 x height 14) < 30 kg ATEX II2G E Ex d IIB T4, KEMA 05ATEX2191 IP 66, Vibration and shock test in acc. with IEC 60068-2-31 and 64 EMC according to EN 61000-6-2 and EN 61000-6-4 PTB Metrological Certicate Reference No. PTB-3.31-4016861 24 VDC, 18 W nominal (50 W start-up peak) for non-heated version 24 VDC, 120 W nominal (170 W start-up peak) for heated version (ambient < 0 C) Ethernet UTP 10 Base-T for ModBus TCP/IP and PC link (max. distance 100 meter) Two RS 232/485 ports for ModBus RTU or ASCII (3 wire connection for both RS232 and 485) Complete stand-alone operation, including all calculations and generation of report formats, without need for operator intervention. Calculations in acc. with ISO 6976, GPA 2172, GOST 22667 or ASTM D3588 Windows 2000 or Windows XP professional edition (Service Pack 1 or higher) 1000 MHz processor, 512 MB RAM, CD-rom player, free Ethernet port. History Log: local storage of last 35 days of all analytical data (analysis, events, alarms, averages, last chromatogram, calibration data) in accordance with API Report 21.1 All data can be made available in XML format Input pressure range 2 4 barg, sample gas must be free from particles and liquid, temperature < 55 C Double block and bleed stream selection for up to 5 streams and 1 calibration gas. Integrated fast loop system with bypass ow of 20 30 Nl/hr. (software selectable) Quality N5.0, supply pressure 5.5 0.5 barg, consumption 8 ml/min Pressure regulator should contain a safety relief set at 6.5 barg Supply pressure 2 4 barg. Consumption 600 ml/day (at atm. pressure) Composition depending on application

Performance

Ambient conditions Dimensions Weight Approvals

Power supply Interfaces Analyser

PC requirements Data logging

Sample gas inlets

Helium Calibration gas

* Detailed analysis up to n-C8 (C6+) respectively n-C9 (C9+) including all isomers and other hydrocarbons, no backush

Your contacts

Germany Elster GmbH Steinern Str. 19 - 21 55252 Mainz-Kastel T +49 6134 605 0 F +49 6134 605 223 www.elster-instromet.com info@elster-instromet.com Belgium Elster NV/SA Rijkmakerlaan 9 2910 Essen T +32 3 670 0700 F +32 3 667 6940 www.elster-instromet.com info@elster-instromet.com 73030150 Singapore Elster-Instromet Sdn. Bhd. (Singapore Branch) 29 Tai Seng Avenue #06-05A Natural Cool Lifestyle Hub Singapore 534119 T +65 6247 7728 F +65 6848 9003 sales@elster-instromet.com.sg Copyright 2012 Elster GmbH All rights reserved. Subject to change without prior notice

Vital Connections

EnCal3000 EN03

A30.04.2012

You might also like

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Cat 312D2 L Excavadeira PDFDocument468 pagesCat 312D2 L Excavadeira PDFIsmael Grünhäuser100% (2)

- Basic Maintenance KPI MetricsDocument20 pagesBasic Maintenance KPI MetricsKrishna Jasha100% (5)

- 31-TMSS-06 (Rev 00)Document8 pages31-TMSS-06 (Rev 00)GardellNo ratings yet

- Sequence Control - LC64Document34 pagesSequence Control - LC64said_rahmansyah4750No ratings yet

- Sequence Control - LC64Document34 pagesSequence Control - LC64said_rahmansyah4750No ratings yet

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- Elster-Instromet Encal3000 GCDocument0 pagesElster-Instromet Encal3000 GCsaid_rahmansyah4750No ratings yet

- Elster Encal3000 DatasheetDocument4 pagesElster Encal3000 DatasheetpradeepNo ratings yet

- Landis Libra 310 OverviewDocument2 pagesLandis Libra 310 OverviewLuis CoelhoNo ratings yet

- Ethernet Intelligent Pressure Scanner: Netscanner™ SystemDocument8 pagesEthernet Intelligent Pressure Scanner: Netscanner™ SystemljboorNo ratings yet

- IMR 7500 - Continuous Emission Monitoring System (CEM) PDFDocument4 pagesIMR 7500 - Continuous Emission Monitoring System (CEM) PDFdejavu77No ratings yet

- Golar Viking Case Study NSFMWDocument7 pagesGolar Viking Case Study NSFMWMatteo ConciNo ratings yet

- AnalyserDocument14 pagesAnalyserNaseer HydenNo ratings yet

- Use of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformDocument22 pagesUse of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformAlcimar MonteiroNo ratings yet

- Online Dga PDFDocument8 pagesOnline Dga PDFromaoj671No ratings yet

- Gas Chromatograph ABB PGC5000series PDFDocument12 pagesGas Chromatograph ABB PGC5000series PDFpraveenpedagandhamNo ratings yet

- Gas Calibration Method v2Document9 pagesGas Calibration Method v2Mazhar MahadzirNo ratings yet

- ABB Chromatograph Gas NaturalDocument5 pagesABB Chromatograph Gas NaturalVRIMSANo ratings yet

- Micro GC 3000 BrochureDocument8 pagesMicro GC 3000 BrochureMohd Masri A. Razak100% (1)

- Sitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVDocument6 pagesSitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVpkbijuNo ratings yet

- A Low-Cost Microcontroller-Based Weather Monitoring System-LibreDocument8 pagesA Low-Cost Microcontroller-Based Weather Monitoring System-LibreRohit PatilNo ratings yet

- Ngc8206 Data SheetDocument8 pagesNgc8206 Data SheetAriz Joelee ArthaNo ratings yet

- NGC 8206 Data SheetDocument5 pagesNGC 8206 Data SheetMuhammad Darussalam HerdaniNo ratings yet

- Teledyne 3000taDocument2 pagesTeledyne 3000taRyanNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Process Gas ChromatographRaphyDocument8 pagesProcess Gas ChromatographRaphyoviemeNo ratings yet

- Gas ChromatographyDocument24 pagesGas Chromatographysujiv_sujiv1278No ratings yet

- PLG C 3 Natural Gas ChromatographDocument4 pagesPLG C 3 Natural Gas ChromatographYuli_PribadiNo ratings yet

- IeeeDocument6 pagesIeeeramyadeviNo ratings yet

- Digital Flow Meter For GasDocument1 pageDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Agilent 7890A Network GC Data SheetDocument6 pagesAgilent 7890A Network GC Data Sheettaokan81No ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912Document7 pagesItem Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912A94leo14hsetmaNo ratings yet

- Design and Implementation of Automatic Air Flow Rate Control SystemDocument6 pagesDesign and Implementation of Automatic Air Flow Rate Control Systemresy fauziahNo ratings yet

- Safe LPG For Home: Project Guide: Group MembersDocument30 pagesSafe LPG For Home: Project Guide: Group MembersSiji VargheseNo ratings yet

- Agilent 7890A Gas ChromatographDocument16 pagesAgilent 7890A Gas ChromatographDuodo NguyenNo ratings yet

- Gigasft IrDocument8 pagesGigasft IrCesar BerruecoNo ratings yet

- Micro GC Varian 4900 - BrochureDocument12 pagesMicro GC Varian 4900 - BrochureEng Kombe Chemical100% (1)

- Meteo Dataloggers & Sensors: Automatic Measuring StationsDocument12 pagesMeteo Dataloggers & Sensors: Automatic Measuring StationsMilton Damián Cornejo ReyesNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- PIC18LF4620 Based Customizable Wireless Sensor Node To Detect Hazardous Gas Pipeline LeakageDocument4 pagesPIC18LF4620 Based Customizable Wireless Sensor Node To Detect Hazardous Gas Pipeline LeakageNitheshksuvarnaNo ratings yet

- Greenline 8000 Basic Price and InfoDocument6 pagesGreenline 8000 Basic Price and InfoRobson SantosNo ratings yet

- Discussion On Modern Trend in MeasuremenDocument23 pagesDiscussion On Modern Trend in MeasuremenTitipong PulbunrojNo ratings yet

- 2000 CIGRE Paper 12-204Document8 pages2000 CIGRE Paper 12-204Anonymous 9VcxlFErfNo ratings yet

- 002 - Gas ChromatographDocument52 pages002 - Gas Chromatographtubagus syariefNo ratings yet

- Advance Process ControlDocument11 pagesAdvance Process Control김형진No ratings yet

- Oxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDocument5 pagesOxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDidit AndiatmokoNo ratings yet

- Mini TransDocument2 pagesMini TransAhmedRaafatNo ratings yet

- Digital Flow Meter For GasDocument1 pageDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Sensor de ConcentracionDocument20 pagesSensor de ConcentracionMihail Meza ApolinarioNo ratings yet

- OverviewDocument20 pagesOverviewHashemAliHashem100% (1)

- Real Time Water Wash System of Gas Turbine in Power PlantDocument4 pagesReal Time Water Wash System of Gas Turbine in Power PlantfaisalnadimNo ratings yet

- Iisco Training Report 2019Document20 pagesIisco Training Report 2019Aakarsh PrasadNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Digital Flow Meter For GasDocument2 pagesDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Control of Boiler Operation Using PLC - SCADADocument9 pagesControl of Boiler Operation Using PLC - SCADARoshan RaiNo ratings yet

- Digital Flow Meter For GasDocument1 pageDigital Flow Meter For GasMASSFLOWMEASUREMENTSNo ratings yet

- Effect of Ignition Timing On Fuel Consumption and EmissionsDocument11 pagesEffect of Ignition Timing On Fuel Consumption and Emissionsjlee_296737No ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- BioEngineering - CompDocument2 pagesBioEngineering - Compsaid_rahmansyah4750No ratings yet

- Instrument OpticDocument19 pagesInstrument Opticsaid_rahmansyah4750No ratings yet

- OIMBTCPDocument71 pagesOIMBTCPsaid_rahmansyah4750No ratings yet

- Elster Instromet Q.sonicDocument2 pagesElster Instromet Q.sonicsaid_rahmansyah4750No ratings yet

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- FD960 Density MeterDocument2 pagesFD960 Density Metersaid_rahmansyah4750No ratings yet

- Elster-Instromet Encal3000 GCDocument0 pagesElster-Instromet Encal3000 GCsaid_rahmansyah4750No ratings yet

- ID900 Density MeterDocument2 pagesID900 Density Metersaid_rahmansyah4750No ratings yet

- SG900 Specific GravityDocument2 pagesSG900 Specific Gravitysaid_rahmansyah4750No ratings yet

- 570 Data SheetDocument2 pages570 Data Sheetsaid_rahmansyah4750No ratings yet

- Ca'e 'Ate' L ! I I: Ilv I LL - UgeDocument5 pagesCa'e 'Ate' L ! I I: Ilv I LL - Ugesaid_rahmansyah4750No ratings yet

- General Configuration For Liquid Flow CalculationDocument3 pagesGeneral Configuration For Liquid Flow Calculationsaid_rahmansyah4750No ratings yet

- CH 11 OrganizationDocument1 pageCH 11 OrganizationSaid Rahmansyah100% (1)

- Muhammadhafizi 2022765415 Art&CraftDocument10 pagesMuhammadhafizi 2022765415 Art&Craftwan saiyidah nafisahNo ratings yet

- Mechanical Engineering DesignDocument22 pagesMechanical Engineering DesignFarid AsyrafNo ratings yet

- Two-Dimensional Inverse DynamicsDocument22 pagesTwo-Dimensional Inverse DynamicsEric Urbina SantibañezNo ratings yet

- Mineral Wool Pipe InsulationDocument4 pagesMineral Wool Pipe InsulationMiguel Martinez GuerreroNo ratings yet

- Anand Manuel's ResumeDocument2 pagesAnand Manuel's ResumeanandmanuelNo ratings yet

- Ship ConstructionDocument157 pagesShip ConstructionBehendu PereraNo ratings yet

- Rapid Data Migration To SAP S/4HANADocument40 pagesRapid Data Migration To SAP S/4HANAtempuserNo ratings yet

- Civil Engineers Letter of Reference For MastersDocument2 pagesCivil Engineers Letter of Reference For MastersSyed ShaheenNo ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet

- Safety Relay LC ControllerDocument5 pagesSafety Relay LC ControlleraguilavmNo ratings yet

- KAR Products - Penetrating OilDocument5 pagesKAR Products - Penetrating Oiljaredf@jfelectric.com100% (2)

- 009 (1) .BC415 Communication Interfaces in ABAPDocument228 pages009 (1) .BC415 Communication Interfaces in ABAPChandramouli BalachandranNo ratings yet

- 2.2.12. Boiling PointDocument1 page2.2.12. Boiling PointgeneticodrugsNo ratings yet

- Mechanics of Materials Equation SheetDocument3 pagesMechanics of Materials Equation SheetAramis Kelkelyan100% (1)

- Unit IV - 2 PDFDocument28 pagesUnit IV - 2 PDFruhi gambhirNo ratings yet

- XenoyDocument2 pagesXenoyJuanjo HornoNo ratings yet

- Deformation Mechanism Maps - Oct27Document41 pagesDeformation Mechanism Maps - Oct27Fame Boy SamNo ratings yet

- SBC Code 305 MasonaryDocument129 pagesSBC Code 305 MasonaryMohammed Ghareib NasrNo ratings yet

- Detector TechnologyDocument42 pagesDetector TechnologyCosmin DuceaNo ratings yet

- Phet ConductivityDocument2 pagesPhet ConductivityjuanNo ratings yet

- DIY Car Painting TipsDocument9 pagesDIY Car Painting TipsJohn BrownNo ratings yet

- I Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendDocument11 pagesI Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendSahariar Bin ShafiqueNo ratings yet

- 568f Pec Ts GuideDocument72 pages568f Pec Ts GuideLuciano F LopesNo ratings yet

- Manual Book Mov Auma PDFDocument44 pagesManual Book Mov Auma PDFDidi Gunawan100% (1)

- D2 Use CasesDocument27 pagesD2 Use Casesለዛ ፍቅርNo ratings yet

- Helweg1991-Selecting Optimum Discharge Rate For Water WellDocument6 pagesHelweg1991-Selecting Optimum Discharge Rate For Water WellAgit Surya DwitamaNo ratings yet