Professional Documents

Culture Documents

Technictehal Data TN0 - SS

Technictehal Data TN0 - SS

Uploaded by

Mihai ApostoliuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technictehal Data TN0 - SS

Technictehal Data TN0 - SS

Uploaded by

Mihai ApostoliuCopyright:

Available Formats

1 of 4

TN0

316L

DOSING PUMP

nexa SERIES-Hydraulic Double Diaphragm

! "#$% "&'&(&

Technical data can be changed without notice.

TD_TN0_SS_rev.4.2

nexa series includes plunger and hydraulic diaphragm dosing pumps designed in compliance with API 675

Standards; the conformity to the API Standards implies a heavy duty design, high safety and severe controls of the

performances during the tests. The broad variety of heads execution offers a wide selection of dosing pumps to

cover practically any application needs. In addition the full compliance with the ATEX European Directive gives the

possibility to install these pumps in classified areas too.

Mechanism

Available in different sizes, they are mechanical return type, giving the maximum reliability in all working conditions.

General Specifications:

Low noise integral gearbox, worm type, oil bath lubricated

Reduced energy consumption based on low friction rolling bearings design

High flexibility multiple mechanism solution to permit different piston speeds (SPM) on the same group

Micrometric stroke lenght adjustment both manually and/or automatically actuated.

Automatic stroke length variation by electrical servomotor, pneumatic actuator or frequency converter

Linearity and repeatability in compliance with API 675 Standards.

Easy on field installation of electrical servomotor on manual stroke adjustment mechanism.

Diaphragm Pumphead

High capacity flexibility! On site easy volume changing by changing the piston cartridge

Easy to change spares parts (all one cartridge solution).

Maximum compatibility PTFE diaphragm

Visual or remote diaphragm failure detection

Technical characteristics

Flow rates: from 0,270 to 19,0 lph @ 50Hz

Max Pressure: 12 MPa (120 bar)

Ambient temperature: -10 C + 40 C

Max altitude: 1000 m (A.S.L.)

Fluid operating temperature: -10 C + 70 C

Viscosity up to 1000 mPas (1000 cP) (Higher on

request)

Stroke adjustment during operation from 0 to 100%

Accuracy 1 % on the turndown ratio 10:1

Built-in overpressure valve

Double diaphragm and diagnostic of the rupture

Diaphragm duration up to 20.000 hours, depending of

the application

Multiheads (up to six) solutions

API 675 compliance

CE marking

ATEX II 2 G c IIB T4 compliance

Protection: IP 55

Epoxy painting at 125 micron

2 of 4

TN0

316L

DOSING PUMP

nexa SERIES-Hydraulic Double Diaphragm

! "#$% "&'&(&

Technical data can be changed without notice.

TD_TN0_SS_rev.4.2

PUMP KEY CODE

1

1

Number of pump head

Simplex pump

2Codice

Type of pump head (double diaphragm or packed-plunger)

T

Plunger diameter

2

3/4

from 6 to 20 mm

5/6

Mechanism model

N0

Stroke length 10 mm

7/8

Pump head material

0620

9

B

C

Double balls

Triple balls

Va lve type

10

General options

7

Standard execution

11 Flow rate adjustment

M

E

P

Manual with adjustment knob (Standard execution)

Electric actuator

Pneumatic actuator

12 Gear rati o

F

L

1:15

1:20

1:25

13

Electric motors poles

2

4

6

2 poles (not available ATEX version)

4 poles

6 poles

14

Installed power

0,18 kW

B

15

Pump head options

V

0

16

Standard execution

Mechanism options

1 T 06 N0 2F B 7 M L 6 B V 0

5

Compliance with regulation "ATEX 94/4/CE 2 G c B T4 (for zone 1) !! !!

Double diaphragm with built-in overpressure valve, air-bleed valve and mechanically actuated oil replenishing

R

Visual diaphragm failure detection (Standard execution)

Remote diaphragm failure detection

VALVE SEAT VALVE SEAL HEAD BALL DAPHRAGM

2F

316SS PTFE 316SS 316SS 316SS

3 of 4

TN0

316L

DOSING PUMP

nexa SERIES-Hydraulic Double Diaphragm

! "#$% "&'&(&

Technical data can be changed without notice.

TD_TN0_SS_rev.4.2

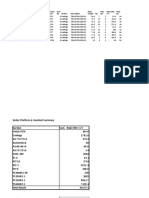

HYDRAULIC CHARACTERISTICS

Performances:

l/h gph

bar p.s.i.

lph gph

Strokes

/min lph gph

Strokes

/min bar p.s.i.

1 T 0 6 N 0 2 F C 7 M L 6 B V 0 0,270 0,071 37 0,324 0,086 44 120 1740 1/4" F -0,40

1 T 0 6 N 0 2 F C 7 M I 6 B V 0 0,352 0,093 47 0,422 0,111 56 120 1740 1/4" F -0,40

1 T 0 6 N 0 2 F C 7 M L 4 B V 0 0,425 0,112 56 0,510 0,135 67 120 1740 1/4" F -0,40

1 T 0 6 N 0 2 F C 7 M I 4 B V 0 0,540 0,143 70 0,648 0,171 84 120 1740 1/4" F -0,40

1 T 0 6 N 0 2 F C 7 M F 4 B V 0 0,729 0,193 93 0,875 0,231 112 120 1740 1/4" F -0,40

1 T 0 6 N 0 2 F C 7 M L 2 B V 0 0,884 0,234 112 1,061 0,280 134 120 1740 1/4" F -0,40

1 T 0 8 N 0 2 F C 7 M I 6 B V 0 0,86 0,23 47 1,03 0,27 56 120 1740 1/4" F -0,45

1 T 0 8 N 0 2 F C 7 M L 4 B V 0 1,03 0,27 56 1,24 0,33 67 120 1740 1/4" F -0,45

1 T 0 8 N 0 2 F C 7 M I 4 B V 0 1,30 0,34 70 1,56 0,41 84 120 1740 1/4" F -0,45

1 T 0 8 N 0 2 F C 7 M F 4 B V 0 1,74 0,46 93 2,09 0,55 112 120 1740 1/4" F -0,45

1 T 0 8 N 0 2 F C 7 M L 2 B V 0 2,10 0,55 112 2,52 0,67 134 120 1740 1/4" F -0,45

1 T 1 0 N 0 2 F C 7 M I 6 B V 0 1,48 0,39 47 1,78 0,47 56 120 1740 1/4" F -0,50

1 T 1 0 N 0 2 F C 7 M L 4 B V 0 1,79 0,47 56 2,15 0,57 67 120 1740 1/4" F -0,50

1 T 1 0 N 0 2 F C 7 M I 4 B V 0 2,26 0,60 70 2,71 0,72 84 120 1740 1/4" F -0,50

1 T 1 0 N 0 2 F C 7 M F 4 B V 0 3,04 0,80 93 3,65 0,96 112 120 1740 1/4" F -0,50

1 T 1 0 N 0 2 F C 7 M L 2 B V 0 3,68 0,97 112 4,42 1,17 134 120 1740 1/4" F -0,50

1 T 1 2 N 0 2 F C 7 M I 6 B V 0 2,27 0,60 47 2,72 0,72 56 120 1740 1/4" F -0,40

1 T 1 2 N 0 2 F C 7 M L 4 B V 0 2,71 0,72 56 3,25 0,86 67 120 1740 1/4" F -0,40

1 T 1 2 N 0 2 F C 7 M I 4 B V 0 3,40 0,90 70 4,08 1,08 84 120 1740 1/4" F -0,40

1 T 1 2 N 0 2 F C 7 M F 4 B V 0 4,54 1,20 93 5,45 1,44 112 120 1740 1/4" F -0,40

1 T 1 2 N 0 2 F C 7 M L 2 B V 0 5,48 1,45 112 6,58 1,74 134 120 1740 1/4" F -0,40

1 T 1 5 N 0 2 F B 7 M I 6 B V 0 3,97 1,05 47 4,76 1,26 56 107 1552 1/4" F -0,45

1 T 1 5 N 0 2 F B 7 M L 4 B V 0 4,68 1,24 56 5,62 1,48 67 107 1552 1/4" F -0,45

1 T 1 5 N 0 2 F B 7 M I 4 B V 0 5,78 1,53 70 6,94 1,83 84 107 1552 1/4" F -0,45

1 T 1 5 N 0 2 F B 7 M F 4 B V 0 7,59 2,01 93 9,11 2,41 112 107 1552 1/4" F -0,45

1 T 1 5 N 0 2 F B 7 M L 2 B V 0 9,09 2,40 112 10,91 2,88 134 107 1552 1/4" F -0,45

1 T 2 0 N 0 2 F B 7 M I 6 B V 0 7,8 2,10 47 9,4 2,5 56 57 827 1/4" F -0,60

1 T 2 0 N 0 2 F B 7 M L 4 B V 0 9,3 2,50 56 11,2 3,0 67 57 827 1/4" F -0,60

1 T 2 0 N 0 2 F B 7 M I 4 B V 0 11,7 3,10 70 14,0 3,7 84 57 827 1/4" F -0,60

1 T 2 0 N 0 2 F B 7 M F 4 B V 0 15,7 4,10 93 18,8 5,0 112 57 827 1/4" F -0,60

1 T 2 0 N 0 2 F B 7 M L 2 B V 0 19,0 5,00 112 22,8 6,0 134 57 827 1/4" F -0,60

Flow rate at

max pressure

Max

speed

Flow rate at

max pressure

Max

speed 0,18

B

Pump Model

NPSHr

[barg]

0,270/19,0

Suc/Dis

Connec

60Hz 50 Hz

BSPP

Max pressure

Electric

motor kW

Liquid end

material

316L

1740/827

0,086/6,0

120/57

Test with water @ 20C.

4 of 4

TN0

316L

DOSING PUMP

nexa SERIES-Hydraulic Double Diaphragm

! "#$% "&'&(&

Technical data can be changed without notice.

TD_TN0_SS_rev.4.2

Allowable loads referred to pump nozzles

Fx 0.10 kN Mx 0.04 kNm

Fy 0.12 kN My 0.04 kNm

Fz 0.10 kN Mz 0.04 kNm

DIMENSIONS [mm] EXTIMATED WEIGHT

kg (without motor)

PUMP MODEL A B C D

1T06N02FC.. BSPP 1/4"F 144 144 282 30

1T08N02FC.. BSPP 1/4"F 144 144 282 30

1T10N02FC.. BSPP 1/4"F 144 144 282 30

1T12N02FC.. BSPP 1/4"F 149 149 279 30,5

1T15N02FB.. BSPP 1/4"F 126 126 279 30,5

1T20N02FB.. BSPP 1/4"F 149 149 279 30,5

Electric

motor size

2 Poles

kw

4 Poles

kw

6 Poles

kw

TEFC

1xM16x1.5

EExde

1xM25x1.5

E kg E kg

63 0.18 0.18 0.18 193 4 224 16

FIXING HOLES VIEW FROM Z

You might also like

- Axial Generator Calculator - English VersionDocument55 pagesAxial Generator Calculator - English VersionMihai ApostoliuNo ratings yet

- DH3-31MA-T-SCT-0001 Commissioning Procedure of Complete-Set Startup of Steam Turbine REV.0Document24 pagesDH3-31MA-T-SCT-0001 Commissioning Procedure of Complete-Set Startup of Steam Turbine REV.0Lan Rung100% (1)

- Catálogo de Peças Cx220 - 240c s2 - Ano 2016Document611 pagesCatálogo de Peças Cx220 - 240c s2 - Ano 2016pedro100% (3)

- Abdalwahab 02Document1 pageAbdalwahab 02abdalmonaem1986No ratings yet

- 880CF - 84519655PC - en-USDocument1,470 pages880CF - 84519655PC - en-USalexvitordasilvapugas17No ratings yet

- Uni-Sfer: Full Bore Ball Valve, F/F Threaded, With Steel HandleDocument1 pageUni-Sfer: Full Bore Ball Valve, F/F Threaded, With Steel Handlekishore vpNo ratings yet

- Boiler StructureDocument100 pagesBoiler StructureumashankarsinghNo ratings yet

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- Uni-Sfer: Full Bore Ball Valve, F/F Threaded, With Aluminum HandleDocument1 pageUni-Sfer: Full Bore Ball Valve, F/F Threaded, With Aluminum HandleAnonymous 80HAPYsoNo ratings yet

- Valvula de Balanceo Automatico Tipo KDocument6 pagesValvula de Balanceo Automatico Tipo Kcarmen hernandezNo ratings yet

- SAGInoMIYA 4-Way Reversing ValvesDocument8 pagesSAGInoMIYA 4-Way Reversing ValvescarieerNo ratings yet

- Tech Tips: Fitting Torque ChartDocument7 pagesTech Tips: Fitting Torque ChartAnthony David Martínez VallejoNo ratings yet

- AIR COOLED FLUID COOLER SERIES VFC Submittal R1Document2 pagesAIR COOLED FLUID COOLER SERIES VFC Submittal R1switchfoot_3dNo ratings yet

- Danfoss Sagonomiya Válvulas 4vías STF VHVDocument8 pagesDanfoss Sagonomiya Válvulas 4vías STF VHVGerencia Comercial North Eco EnergyNo ratings yet

- STPS3045CW PDFDocument9 pagesSTPS3045CW PDFalbertoavila77No ratings yet

- PNL WH 03Document9 pagesPNL WH 03Reasat AzimNo ratings yet

- Metrado de Acero: Longitud TotalDocument62 pagesMetrado de Acero: Longitud TotalKarol ZeveNo ratings yet

- TC Coolant Pump Userguide - 2020 - V2Document10 pagesTC Coolant Pump Userguide - 2020 - V2Luc DuchesneNo ratings yet

- Spare Parts Master N (8105.181)Document20 pagesSpare Parts Master N (8105.181)Julian M. AndrettiNo ratings yet

- VZBA-4F-L-ASY-PSI-US - 3-Way Ball Valve Assembly VZBA-4F-L and VZBA-4F-TDocument2 pagesVZBA-4F-L-ASY-PSI-US - 3-Way Ball Valve Assembly VZBA-4F-L and VZBA-4F-TGigin PlusNo ratings yet

- Technical Data 214403246Document214 pagesTechnical Data 214403246Jhoersino TurpoNo ratings yet

- VS3V HandtagDocument1 pageVS3V Handtagbeta101No ratings yet

- A 3-W F P SSB V: Pneumatic ActuatorsDocument2 pagesA 3-W F P SSB V: Pneumatic Actuatorsjuanmvp89No ratings yet

- 15-ScanJet SC 15TW Instruction ManualDocument43 pages15-ScanJet SC 15TW Instruction Manualogurmehmetali07No ratings yet

- 2500 Brass Ball Valve ISO 5211Document1 page2500 Brass Ball Valve ISO 5211Andrew Newham (AK Valves Limited)No ratings yet

- Danfoss STF 0715GDocument8 pagesDanfoss STF 0715GFede BerniNo ratings yet

- ValvulaReversora 20140825150343Document8 pagesValvulaReversora 20140825150343SantosNo ratings yet

- PL 708aDocument25 pagesPL 708aam8445244No ratings yet

- API - Iadc Recommended Drill String Make-Up TorqueDocument2 pagesAPI - Iadc Recommended Drill String Make-Up TorqueQuality controller100% (6)

- Flyer Evolution Mikro enDocument2 pagesFlyer Evolution Mikro enEduardo hernandezNo ratings yet

- Hook-Up OffbaseDocument18 pagesHook-Up OffbaseTarun YadavNo ratings yet

- Ermeto FITTINGS Part 4Document36 pagesErmeto FITTINGS Part 4carmaNo ratings yet

- Electrical Part ListDocument6 pagesElectrical Part ListdachajiNo ratings yet

- 1.EPV NORTH SEA Exploded PartviewDocument45 pages1.EPV NORTH SEA Exploded PartviewPSC RFQNo ratings yet

- PDFDocument2 pagesPDFMichell Quinteros GilerNo ratings yet

- Pressure Ratings General Reference 112613Document2 pagesPressure Ratings General Reference 112613Tezalea RobletoNo ratings yet

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- Use With 787TC, 797TC Hoses. Flange: Catalog 4400 USDocument1 pageUse With 787TC, 797TC Hoses. Flange: Catalog 4400 USAlex barkerNo ratings yet

- Rexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDocument24 pagesRexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDarioNo ratings yet

- Pres RateDocument2 pagesPres RatescemanjuNo ratings yet

- Super-Sfer: Full Bore Brass Ball Valve, F/F Threaded, With Aluminium HandleDocument1 pageSuper-Sfer: Full Bore Brass Ball Valve, F/F Threaded, With Aluminium HandleAnonymous 80HAPYsoNo ratings yet

- 75 Series, Hydraulic Quick Coupling (Carbon Steel) Iso-7241-A, Pin TypeDocument3 pages75 Series, Hydraulic Quick Coupling (Carbon Steel) Iso-7241-A, Pin TypeSHANENo ratings yet

- ZDFRPM21254C: Product Information PacketDocument14 pagesZDFRPM21254C: Product Information PacketJhon Steven EscobarNo ratings yet

- Centrifugal PumpDocument32 pagesCentrifugal PumpAshok SrivatsanNo ratings yet

- Fv-Cat-322-0316 Htaf PDFDocument2 pagesFv-Cat-322-0316 Htaf PDFTaylor RamirezNo ratings yet

- Technical Product Sheet: Polypropylene PipesDocument9 pagesTechnical Product Sheet: Polypropylene PipesasasbNo ratings yet

- GIW Technical Series: Pipe Flange BoltsDocument4 pagesGIW Technical Series: Pipe Flange BoltsTravis SkinnerNo ratings yet

- Catalog 4400 US: Transportation - Air Brake HoseDocument1 pageCatalog 4400 US: Transportation - Air Brake Hoseanoop9079No ratings yet

- Ack Series Check Valve Catalog en Us 1570042Document1 pageAck Series Check Valve Catalog en Us 1570042Mouayed ZeadanNo ratings yet

- FMK4 Male Stud ConnectorDocument1 pageFMK4 Male Stud ConnectorrijalharunNo ratings yet

- 1020 PDFDocument180 pages1020 PDFСергій XрестикNo ratings yet

- PVAR Catalog PDFDocument16 pagesPVAR Catalog PDFrenebbNo ratings yet

- V Op V C Op C Rte Folio Instrumento Liq D Cantidad Reaj. PlazoDocument2 pagesV Op V C Op C Rte Folio Instrumento Liq D Cantidad Reaj. PlazoJosé Andres Jorquera BaltraNo ratings yet

- Unidad Básica 47000755 Diagrama EléctricoDocument64 pagesUnidad Básica 47000755 Diagrama EléctricoAndres TrujilloNo ratings yet

- BallValues PDFDocument12 pagesBallValues PDFDevdatt WaghuleNo ratings yet

- March Pump Manual 7 Plastic 0155 0046 1000 Rev32Document2 pagesMarch Pump Manual 7 Plastic 0155 0046 1000 Rev32Asima Jaya TamaNo ratings yet

- 4WP Datasheet EN 1Document4 pages4WP Datasheet EN 1Marles Eneque SolanoNo ratings yet

- Rotorseal Tech Specs PDFDocument19 pagesRotorseal Tech Specs PDFMykola TitovNo ratings yet

- 2) LV Switchgear 6Document2 pages2) LV Switchgear 6ChowKC03No ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Corresponding Author: Aamo@ntnu - NoDocument6 pagesCorresponding Author: Aamo@ntnu - NoMihai ApostoliuNo ratings yet

- ELearning LDS Complete US 2Document49 pagesELearning LDS Complete US 2Mihai ApostoliuNo ratings yet

- Blade Offset and Pitch Effects in A High Solidity VAWTDocument10 pagesBlade Offset and Pitch Effects in A High Solidity VAWTMihai ApostoliuNo ratings yet

- WholewholeDocument397 pagesWholewholeMihai ApostoliuNo ratings yet

- Recent Trends in Automobile SeminarDocument18 pagesRecent Trends in Automobile SeminarKkbhuvan KkNo ratings yet

- LNG Operare ManualDocument306 pagesLNG Operare ManualLaurentiu Dumitrache80% (5)

- Heavy Oil Conversion OptionsDocument21 pagesHeavy Oil Conversion OptionsSangeeta GargNo ratings yet

- Design and Economic Analysis of A Photovoltaic System: A Case StudyDocument9 pagesDesign and Economic Analysis of A Photovoltaic System: A Case StudyIfeanyi Henry NjokuNo ratings yet

- Technical Report 2 Coal-Fired Steam Power Plant DesignDocument2 pagesTechnical Report 2 Coal-Fired Steam Power Plant DesignYehosuah RanoaNo ratings yet

- Ps2113 Distributed Generation and Microgrid 2013 14Document2 pagesPs2113 Distributed Generation and Microgrid 2013 14Eric Hernandez0% (1)

- Muhammad Ali: Career ObjectiveDocument2 pagesMuhammad Ali: Career ObjectiveMuhammad aliNo ratings yet

- CFB Boiler - Site Inspection Guidelines and ProtocolDocument100 pagesCFB Boiler - Site Inspection Guidelines and ProtocolXcdxtvNo ratings yet

- 5kw Off Gird Solar System QuotationDocument2 pages5kw Off Gird Solar System Quotationabul abbas100% (3)

- MN FieldDocument54 pagesMN Fieldarunrajmech09No ratings yet

- Francis Turbines: - Examples - Losses in Francis Turbines - NPSH - Main DimensionsDocument39 pagesFrancis Turbines: - Examples - Losses in Francis Turbines - NPSH - Main DimensionsAshwini Kumar RaiNo ratings yet

- Pompa WWTDocument1 pagePompa WWTtomoNo ratings yet

- Chem Assignment Unit IDocument1 pageChem Assignment Unit IMuhammad BilalNo ratings yet

- VRF LG - Multi VDocument7 pagesVRF LG - Multi VMinh PhatNo ratings yet

- E38 Fuel Mixture PreparationDocument1 pageE38 Fuel Mixture Preparationsuatma DjieNo ratings yet

- PMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetDocument2 pagesPMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetfarhaNo ratings yet

- Solar Mobile ChargerDocument16 pagesSolar Mobile ChargerDivyanshu nagar0% (1)

- Boilers - Basic Principles and TypesDocument16 pagesBoilers - Basic Principles and Typeswilber100% (1)

- View Certificate: NOTICE: This Is NOT An Official CertificateDocument3 pagesView Certificate: NOTICE: This Is NOT An Official Certificate30 . Nguyễn Bảo NguyễnNo ratings yet

- Modelling and Simulation of Steam Jet Ejectors PDFDocument8 pagesModelling and Simulation of Steam Jet Ejectors PDFLucas RossiniNo ratings yet

- Sacred Sun and Lead Carbon Battery Comparisons 2019Document3 pagesSacred Sun and Lead Carbon Battery Comparisons 2019Tony AsseiroNo ratings yet

- TurboDocument8 pagesTurboKorichiKarimNo ratings yet

- FootValve PBV ProductflyerDocument2 pagesFootValve PBV ProductflyerMarco PompaNo ratings yet

- Cronus - Deck A: 2X2 MetersDocument4 pagesCronus - Deck A: 2X2 MetersXosé Lois PérezNo ratings yet

- Paramawe Solar Engineering Assesment Report - FinalDocument18 pagesParamawe Solar Engineering Assesment Report - FinalALPHONCENo ratings yet

- BCM One Marks & Two Marks Question With AnswerDocument10 pagesBCM One Marks & Two Marks Question With AnswerSathis KumarNo ratings yet

- SPE AFRC 2588537 MSSolarEnergyDocument9 pagesSPE AFRC 2588537 MSSolarEnergygulya CharievaNo ratings yet

- Li-Ion Battery & Charger Time Reference, Compatibility ChartDocument1 pageLi-Ion Battery & Charger Time Reference, Compatibility Charthamidin_syarifNo ratings yet

- BHGE TrainingDocument6 pagesBHGE TrainingchdiNo ratings yet