Professional Documents

Culture Documents

Overview of 40 Bridge Structural Health Monitoring Projects

Overview of 40 Bridge Structural Health Monitoring Projects

Uploaded by

rwaidaabbasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overview of 40 Bridge Structural Health Monitoring Projects

Overview of 40 Bridge Structural Health Monitoring Projects

Uploaded by

rwaidaabbasCopyright:

Available Formats

Overview of 40 Bridge Structural Health Monitoring Projects

DANIELE INAUDI, SMARTEC SA, Switzerland, Roctest Ltd, Canada

IBC 09-45

KEYWORDS: Structural Health Monitoring, Bridge Monitoring, Fiber Optic Sensors ABSTRACT: In the last 15 years, fiber optic sensing has become a useful and increasingly widely used tool for structural health monitoring of bridges and other civil structures. We have been fortunate to participate to their development and introduction to real field applications. This paper is an overview of 40 bridge monitoring projects carried out over the last 15 years in 13 different countries. In particular we concentrate on the analysis of the different types of bridges that were monitored, their situation (new construction, existing structure, refurbishment) and the main purpose of the installed monitoring system. Finally, as an example of a Structural Health Monitoring project, we will briefly present the Monitoring system of the new I35W St. Anthony Falls Bridge in Minneapolis. INTRODUCTION The life of each structure is far from being monotonous and predictable. Much like our own existence, its evolution depends on many uncertain events, both internal and external. Some uncertainties arise right during construction, creating structural behaviors that are not predictable by design and simulations. Once in use, each structure is subjected to evolving patterns of loads and other actions. Often the intensity and type of solicitation are very different form the ones taken into account during its design and in many cases they are mostly unknown in both nature and magnitude. The sum of these uncertainties created during design, construction and use poses a great challenge to the engineers and institutions in charge of structural safety, maintenance and operation. Defining service levels and prioritizing maintenance budgets relying only on models and superficial observation can lead to dangerous mistakes and inefficient use of resources. Regular inspection can certainly reduce the level of uncertainty, but still presents important limitations being limited to the observation of the structure's surface during short times spaced by long periods of inactivity. Structural Health Monitoring aims to provide more reliable data on the real conditions of a structure observe its evolution and detect the appearance of new degradations. By installing a number of sensors, measuring parameters relevant to the structural conditions and other important environmental parameters, it is possible to obtain a picture of the structure's state and evolution. Monitoring is a new safety and management tool that ideally complements traditional methods like visual inspection and modeling. This paper resumes the reasons and results of monitoring 40 bridges worldwide in the last 12 years. In that time period, our company and partners has instrumented other bridges (as well as hundreds of other structures), but we limited our overview to those bridges were reliable data was available on the purpose of monitoring and the obtained results. Figure 1 shows a collage of pictures of the bridges considered in this survey. BRIDGE TYPES Lets first consider the distribution of monitored bridges, most of them depicted in Figure 1, both geographically and by type. LOCATION - The 40 bridges considered here are located in the following countries: Austria, Belgium, Canada, Croatia, France, Germany, Italy, Japan, Luxembourg, Russia, Sweden, Switzerland, Taiwan and the USA. The distribution by continent is shown in Figure 2.

The main part of the bridge population is in Europe, reflecting the location of SMARTEC in Switzerland. The prominence of Europe mainly comes from the first years of activity and new projects are more evenly distributed among continents. Furthermore, applications in Asia and the Americas tend to be carried out by our partners, so several projects were not included in the survey because of the lack of details.

Asia 5

Americas 6

Europe 29

Figure 2: Bridge population by continent

Figure 1 Photo Gallery of 35 of the 40 bridges considered in this overview, shows the great variety of bridge types that can benefit form monitoring.

Suspention 2 Cable Stayed 2 Steel Girder 8

Arch 5

19

Steel Truss 1

Cantilever 4

8 7

Concrete Box 3 Concrete Girder 15

Figure 3: Bridge population by structural type BRIDGE TYPE Figure 1 illustrates the diversity of brides that were monitored. There is a prominence of concrete girder bridges, which the also the most common types of bridges in the global population. It is however interesting to notice that signature bridges, including suspension and cablestayed bridges represent only a small percentage, while more ordinary bridges constitute the vast majority of the population. This reflects the fact that monitoring can be applied with success to any type of bridge. LIFETIME PHASE - Monitoring can be applied in different phases of a bridge life. The 40 bridges considered here reflect this diversity. Here is the breakout: New Bridges (installation during construction): 18 Existing Bridges (installation on an existing bridge): 13 Bridges under Refurbishment (installation during works): 9 There is therefore an even distribution between new and existing bridges. MONITORING PURPOSE OF MONITORING - The reasons for monitoring a bridge can be different. The most common are to obtain quantitative date about the structural behavior in order to confirm design assumptions, to provide real-time feed-back during construction and to perform a controlled lifetime extension of a bridge with known problems. Some projects are also considered as demonstration projects, driven more by the interest in new technologies than by a specific monitoring purpose.

Confirm Design Construction Aid Demonstration Lifetime Extension

Figure 3: Purpose of monitoring As shown in Figure 3, in the majority of projects, the main purpose of monitoring was to confirm design assumptions. This is especially true for new bridges, but also applies to many existing bridges, where monitoring helps to evaluate the real current condition of the bridge and allows the engineers to take informed decisions about their future and to plan maintenance or repair actions. In the case of bridges classified as lifetime extension the monitoring system is used to increase the safety of the structure and provide early warning of an acceleration of the known degradations that are being monitored. It is interesting to see how this subdivision has evolved in time (see Figure 4).

Lifetime Extension

Construction Aid

Confirm Design

Demonstration

1995-1998

1999-2002

2003-2007

Figure 4: Time evolution of the reasons for monitoring If in the early years (1995-1998) demonstration projects and applications concerning only the construction phase accounted for a majority of the applications, in more recent times the main reasons for monitoring has become the confirmation of design hypotheses and the controlled lifetime extension of existing structures.

It is important to notice that projects aiming to a confirmation of the design assumptions concern all phases of the bridges lifetime. For new bridges, one can confirm the sound design of the structure; in the case of existing bridges, a monitoring program is usually targeted at fine-tuning the model to the real conditions of the structure. In this case, monitoring is used to reduce the uncertainties introduced during the constructions and the successive degradations. CUSTOMER - A monitoring project can be initiated (and financially supported) by different institutions. In the case of the bridges in this study the paying customers were subdivided as follows: Bridge Owner: 23 University (through research founds): 13 Engineering company: 4 This demonstrates that structural health monitoring is still considered a research topic by many owners. It is however encouraging to see that the majority of projects originate from owners and engineers. INSTALLATION - The same distinction applied to the installation of the monitoring system itself: Owner: 1 University 15 Instrumentation Company 24 Only in one case the system has been installed by a team working directly for the structures owner. In all other cases the system was installed by a professional instrumentation company (in some cases SMARTEC itself) or a university.

This includes the cost of the hardware and the installation, but not the cost of data analysis and system maintenance. Many projects fall in the range below 50000$. These are typically short-term projects or projects with a reduced number of sensors. The category 100-500 k$ typically includes those projects that aim to permanent and autonomous monitoring with remote access. Among the ones considered here, only one bridge instrumentation project exceeded 500000$. INSTALLED SENSORS - The number of sensors installed for each project is the following: 1-10: 19 11-25: 8 26-50: 5 51-100: 5 100+ : 3 Small projects (20 sensors or less) dominate again in this case. SENSOR LOCATION - The sensors can be installed on different parts of the bridge. In the considered projects the most instrumented elements were the following (in some cases multiple elements are monitored): Deck: 9 Load-carrying elements (beams, arch, cables): 31 Piers: 4 Foundations: 2 The main concern is therefore, as expected, with the elements that transfer loads. FREUENCY - Finally, a monitoring project can span different lengths in time and occur with varying frequencies: Short-Term (less than 12 months): 17 Long-Term (more than 12 months, but non continuous): 12 Permanent (continuous monitoring): 11 Short-term monitoring dominates (especially in the early years). In those cases, once the original question is answered, the monitoring system is abandoned. This is typically the case of projects that concern the construction phase in particular.

23

10

$ 0-50k

$ 50-100k

$ 100-500k

$ 500k+

Figure 5: Monitoring system budget BUDGET - Figure 5 shows the distribution of cost for the installed monitoring systems.

RESULTS It is obviously difficult to draw general conclusions about the results obtained by such diverse monitoring projects. We will however try to summaries the main findings in the next paragraphs. SURVIVAL RATE: INSTALLATION - In the case of embedding in concrete, the typical survival rate of SMARTEC sensors is between 90% and 100%. There were however projects with significantly lower survival due to mishandling or installation errors. In the case of surface installation, damaged sensors can be replaced or repaired. In the case of embedded sensors, one has to foresee a certain level of redundancy to account for possible losses or foresee replacements by surface installation or reservation tubing. SURVIVAL RATE: LONG-TERM - Once installed, SMARTEC fiber optic sensors typically age very well. We have observed a failure rate of approximately 1-2 % per year. Higher fatalities were observed in very aggressive environments or were the protection of exposed parts was insufficient. In the case of permanent monitoring systems, the weakest link is usually the measurement system and the associated PC controller. Fortunately, these elements are easily serviced. MAIN FINDINGS - Here are some examples of the main findings that could be gained in the cited projects: Observe the apparition of transversal cracks a few days after concreting. Measure the apparition of the cracks and the associated redistribution of the deformations in a quantitative way. Observe deformations during load test and compared to the ones predicted by finite elements programs and security standards Curvature variations of the bridge under thermal loading Measurements in fresh concrete allowed the prediction of cracking long before the cracks became visible and the optimization of the concrete mix for successive pours. Confirmed the excellent adherence between the old and new concrete. Follow the long-term shrinkage of concrete and the seasonal deformations due to temperature changes.

Verify the amount of pre-stressing effectively given to the slab. During the push phase it was possible to observe the deformations induced in the caisson as its support conditions changed, for example when passing on a support. The sensors embedded in concrete were used to determine the amount of shrinkage and pre-stressing that was transferred from the concrete slab to the steel caisson. Verify the structural response of the beams wrapped with FRP. Continuous monitoring of prefabricated beams before transportation on-site, during transportation and during the pouring of the deck. Measure the local deformations of concrete and reconstruct the radial displacements during scaffolding removal and during the freestanding period of the arch. Daily temperature influence on the arch is particularly large and should be taken into account when performing pointmeasurements like triangulation. Monitoring the behavior of old columns during under traffic before and after repair. Deformation of the bridge during the construction phases and for the whole life cycle. Temperature monitoring and correlation with the measured strains. Pre-stress load transfer identification after deck completion, dead load deformation monitoring. Detection of fatigue crack onset in steel girders. Verify that no damage is induced in a bridge which is laterally moved form the construction location to the final location. Measure the dynamic amplification factors. Measure modal frequencies and mode shapes. Verify that the piers are not having excessive relative movements due to foundation instability. Verify that no damage is induced to a bridge due to nearby construction. Preserve bridge of historical value. Verify effect of thermal changes in the deformation of stays and main cables. Verify the distribution of live loads among individual wires in a cable bundle.

For additional details, please refer to the papers cited in the references and covering individual projects. APPLICATION EXAMPLE: I35W BRIGE This application example is a good example of a truly integrated structural health monitoring system, combining different sensing technologies to achieve the desired level of monitoring.

the structural behavior of the bridge, and contribute to the intelligent transportation system as well as to the bridge security. The design of the system was an integral part of the overall bridge design process allowing the SHM system to both receive and provide useful information about the bridge performance, behavior and expected lifetime evolution. Monitoring instruments on the new St Anthony Falls Bridge measure dynamic and static parameter points to enable close behavioral monitoring during the bridges life span. Hence, this bridge can be considered to be one of the first 'smart bridges of this scale to be built in the United States.

Figure 6: New I35W Bridge in Minneapolis The collapse of the old I35W Bridge in Minneapolis in 2007 shook the confidence of the public in the safety of the infrastructure that we use every day. As a result, the construction of the replacement bridge (see Figure 6) must rebuild this confidence, by demonstrating that a high level of safety can not only be attained during construction, but also maintained throughout the projected 100-year life-span of the bridge. One of the central factors contributing to this is the design and installation of a comprehensive structural health monitoring system, which incorporates many different types of sensors measuring parameters related to the bridge performance and ageing behavior. This system continuously gathers data and allows, through appropriate analysis, to obtain actionable data on the bridge performance and health evolution. The data provided is be used for operational functions, as well as for the management of ongoing bridge maintenance, complementing and targeting the information gathered with routine inspections. The monitoring system was designed and implemented through a close cooperation between the designer, the owner, the instrumentation supplier and University of Minnesota. The main objectives of the system are to support the construction process, record Long-gauge SOFO fiber optic sensor Vibrating Wire Strain Gauge

Concrete humidity and corrosion

Accelerometer

SOFO Fiber Optic Sensor Datalogger

Vibrating wire and temperature sensors datalogger

Figure 7: Sensing components The system includes a range of sensors which are capable of measuring various parameters to enable the behavior of the bridge to be monitored. Strain gauges measure local static strain, local curvature and concrete creep and shrinkage; thermistors measure temperature, temperature gradient and thermal strain, while linear potentiometers measure joint movements. At the mid-spans, accelerometers are incorporated to measure traffic-induced vibrations

and modal frequencies (Eigen frequencies). SensCore corrosion sensors are installed to measure the concrete resistivity and corrosion current. Meanwhile there are long-gauge SOFO fiber optic sensors which measure a wide range of parameters, such as average strains, strain distribution along the main span, average curvature, deformed shape, dynamic strains, dynamic deformed shape, vertical mode shapes and dynamic damping they also detect crack formation. Some of the installed sensors are shown in Figure 7. The sensors are located throughout the two bridges, the northbound and southbound lanes, and are in all spans. However, a denser instrumentation is installed in the southbound main span over the Mississippi river, as depicted in Figure 8. This span will therefore serve as sample to observe behaviors that are considered as similar in the other girders and spans.

REFERENCES

Fibre Optic Methods for Structural Health Monitoring, Branko Glisic and Daniele Inaudi, Johh Wiley & Sons, Ltd, (2007), . Integrity monitoring of old steel bridge using fiber optic distributed sensors based on Brillouin scattering , Branko Glisic, Daniele Posenato, Daniele Inaudi, 14th SPIE Annual Symposium on Smart Structures and Materials & Nondestructive Evaluation and Health Monitoring, San Diego (CA), USA, (2007), 6531-25. Stress measurements in the main cable of a suspension bridge under dead and traffic loads , M. Talbot, J.F. Laflamme, B. Gliic, Experimental Vibration Analysis for Civil Engineering Structures, EVACES 07, Porto, Portugal, October 24-26, (2007), Paper 138, On conference CD. Structural Health Monitoring of Bridges in Sweden , M. Enckell, The 3rd International Conference on Structural Health Monitoring of Intelligent Infrastructure SHMII-3, November 13-16, (2007), On Proceedings CD. Integrated Analysis of Inhomogeneous Structural Monitoring Data of a Monolithic Bridge , W. Lienhart, F. K. Brunner,, The 3rd International Conference on Structural Health Monitoring of Intelligent Infrastructure - SHMII-3, November 13-16, (2007), On Proceedings CD. Monitoring an Interstate Highway Bridge with a Built-In Fiberoptic Sensor System , R. L. Idriss, Z. Liang, 3RD International Conference on Bridge Maintenance, Safety and Management, Porto, Portugal, 16-19 July, 2006, (2006), To be published. Monitoring with Fiber Optic Sensors of a Cable-Stayed Bridge in the Port of Venice , A. Del Grosso, A. Torre, G. Brunetti, D. Inaudi, A. Pietrogrande, IABMAS'06 The Third Int'l Conference on Bridge Maintenance, Safety and Management, 16 - 19 July 2006, Porto, Portugal, (2006), . Continuous monitoring of concrete bridges during construction and service as a tool for data-driven Bridge Health Monitoring , D. Inaudi, B. Glisic, IABMAS'06 The Third Int'l Conference on Bridge Maintenance, Safety and Management, 16 - 19 July, Porto, Portugal, (2006), . Experiences in Data Analysis and Interpretation from Continuous Static Monitoring of Bridges , A. Del Grosso, D. Posenato, D. Inaudi, A. Torre, 4th World Conference on Structural Control and Monitoring, (2006), . Monitoring System for a Cable-Stayed Bridge using static and dynamic Fiber Optic Sensors , A. Del Grosso, A. Torre, D. Inaudi, G. Brunetti, A. Pietrogrande, 2nd International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII-2'2005), Shenzhen, China, November 1618, (2005), . Monitoring the behaviour of the Traneberg bridge during retrofitting, M. Enkell, H. Larsson, 2nd International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII-2'2005), Shenzhen, China, November 16-18, (2005), . In-situ modulus of elasticity for a high performance concrete bridge , Erin A. Hughs, Zhiyong Liang, Rola L. Idriss and Craig M. Newtson, ACI Materials Journal, (2005), Vol. 102, N0.6, pp.458-458.. Interface stresses between soil and large diameter drilled shaft under lateral loading , K. Janoyan, M. Whelan, ASCE Geotechnical Special Publication No. 124, Drilled Shafts, Micropiling, Deep Mixing, Remedial Methods, and Specialty Foundation Systems, (2004), .

Figure 8: Sensor locations This project is one of the first to combine very diverse technologies, including vibrating wire sensors, fiber optic sensors, corrosion sensors and concrete humidity sensors into a seamless system using a single database and user interface. CONCLUSIONS This overview on the monitoring of 40 bridges with optical fiber sensors shows how diverse and multi-faced this domain can be. The projects include everything form a simple short-term test with a couple of sensors to verify a design hypotheses to a large-scale instrumentation project with hundreds of sensors to extend the lifetime of a bridge with known problems. After an initial phase where my projects were driven by the curiosity of both universities and owners towards a new technology, we have now moved to applications where the customer wants to address a specific question or increase safety in the case of known deficiencies or degradations. Those projects show that a well planned and executed monitoring projects can provide actionable information to the owner and the bridge engineer.

Structural Monitoring of Concrete Bridges during Whole Lifespan , Branko Glisic, Daniele Inaudi, 82nd Annual Meeting of the Transportation Research Board (TRB), January 12-16, 2003, Washington DC, USA, (2003), On CD, paper number 033012. Monitoring fo the new Arsta railway bridge using fiber optic and traditional sensor technology , M. EnckellEl Jemli, R. Karoumi, F. Lanaro, SPIE Symposium on Smart Strucutres and Materials, 2-6 March 2003, San Diego, USA, (2003), Vol. 5057. Strain, deformation and crack monitoring in bended structural members using long-gauge fiber optic sensors, B. Glisic, D. Inaudi, Test 2003, 13-15 May 2003, Nurenberg, Germany, (2003), paper A3.4 on conference CD. Monitoring of Bridge Deformations Using Embedded Fiber Optical Sensors , W. Lienhart, F. K. Brunner, In Stiros, St. and Pytharouli, St. (Eds.) Proc. 11th International Symp. on Deformation Measurements, Santorini, Greece, (2003), 555-561. Long-gage optical fiber sensors monitoring on deteriorated structure deformational properties , S. Sumitro, Y. Okada & K. Saitoh, S. Takanashi, D. Inaudi, First International Conference on Structural Health Monitoring and Intelligent Infrastructure, Tokyo, November 13-15, (2003), . Monitoring of a concrete arch bridge during construction, D. Inaudi, A. Rfenacht, B. von Arx, H. P. Noher, S. Vurpillot, B. Glisic, SPIE, International Symposium on Smart Structures and Materials, 1721.3.2002, San Diego, USA, (2002), Vol 4696, p 146-153. Complex Measurement System for Long-Term Monitoring of Pre-stressed Railway Bridges of the New Lehrter Bahnhof in Berlin., W. Habel, H. Kohlhoff, J. Knapp, R. Helmerich, H. Hnichen, D. Inaudi, SPIE, International Symposium on Smart Structures and Materials, 17-21.3.2002, San Diego, USA, (2002), Vol 4694, p 236-241. Overview of European Activities in the Health Monitoring of Bridges , Andrea Del Grosso, Daniele Inaudi, Livia Pardi, First International conference on Bridge Maintenance, Safety and Managment, IABMAS'02, (2002), CIMNE, Barcellona. Monitoring System for Long-term evaluation of prestressed railway bridges in the new Lehrter Bahnhof in Berlin , W. Habel, H. Kohlhoff, J. Knapp, R. Helmerich, Third World Conference on Strucutral Control, 7-12.4.2002, Como, Italy, (2002), . Monitoring Of A Smart Bridge With Embedded Sensors During Manufacturing, Construction And Service , Rola L. Idriss, Third International Conference on Health Monitoring, Stanford California, September, (2001), . Monitoring Of A High Performance Prestressed Concrete Bridge With Embedded Optical Fiber Sensors During Fabrication, Construction And Service , Rola L. Idriss, Structural Faults and Repair Conference, London, England, July 2001, (2001), . Monitoring of bridges and concrete structures with fiber optic sensors in Europe, A. Del Grosso, K. Bergmeister, D. Inaudi, U. Santa, IABSE conference on cable-supported bridges, Seoul, invited paper, (2001), . Global monitoring concepts for bridges, K. Bergmeister, U. Santa, Structural concrete, (2001), Vol 2, No 1, p 29-39. Early age behaviour of concrete and limitation of hybride structures cracking P. Mivelaz, S. Wolf, B. Glisic, J.-P. Lebet, O. Bernard, MCS, ICOM and IMAC - DGC- EPFL, Lausanne, Switzerland, (2001), .

Bridge spatial displacement monitoring with fiber optic deformation sensors , S. Vurpillot, P. Kronenberg, D. Inaudi, ACI/KCI 2000 International Conference Repair, Rehabilitation and Maintenance of Concrete, Seoul, Korea Structures, and Innovations in Design and Construction, (2000), SP193-54. Deformation monitoring during bridge refurbishment under traffic , D. Inaudi, N. Casanova, S. Vurpillot, B. Glisic, P. Kronenberg, S. Lloret, 16th Congress of IABSE, Luzern, Switzerland, (2000), on CD. Long-term monitoring of a concrete bridge with 100+ fiberoptic long-gage sensors , D. Inaudi, P. Kronenberg, S. Vurpillot, B. Glisic, S. Lloret, SPIE, Conf. Nondestructive Evaluation Techniques for Aging Infrastructure & Manufacturing, Newport Beach, USA, (1999), Vol 3587, p 50-59. Monitoring of concrete bridges with long-gage fiber optic sensors , D. Inaudi, S. Vurpillot, Journal of intelligent material systems and structures, (1999), Vol 10, No 4, p 280-292. Vertical displacement of bridges using the SOFO system: a fiber optic monitoring method for structures , N. Perregaux, S. Vurpillot, J.-S. Tosco, D. Inaudi, O. Burdet, 12th Engineering Mechanical Conference, La Jolla, USA, (1998), p 833 - 836. Quasi-static strain monitoring during the Push phase of a box-girder bridge using fiber bragg grating sensors , S.T. Vohra, B. Althouse, G. Johnson, S. Vurpillot, D. Inaudi, European Workshop on Optical Fibre Sensors, Peebls Hydro, Scotland, UK, (1998), p 1-4. Vertical deflection of a pre-stressed concrete bridge obtained using deformation sensors and inclinometer measurements , S. Vurpillot, G. Krueger, D. Benouaich, D. Clment, D. Inaudi, ACI Structural Journal, (1998), Vol 95, No 5, p 518 - 526. Railway bridge monitoring during construction and bridge sliding , D. Inaudi, N. Casanova, P. Kronenberg, S. Vurpillot, SPIE, Smart Structures and materials, San Diego, USA, (1997), Vol 3043, p. 58 64. Bridge monitoring by fiber optic deformation sensors: design, emplacement and results , S. Vurpillot, D. Inaudi, J.-M. Ducret, SPIE, Smart Structures and materials, San Diego, USA, (1996), Vol 2719, p 141 - 149.

You might also like

- Dept of Civil Engineering KLS GIT, Belagavi 2GI17CSE02Document20 pagesDept of Civil Engineering KLS GIT, Belagavi 2GI17CSE02Sanket NaikNo ratings yet

- Client Guide To Instrumentation and MonitoringDocument28 pagesClient Guide To Instrumentation and MonitoringChristo DunstonNo ratings yet

- Long-Term Monitoring of High-Rise Buildings Using Long-Gage Fiber Optic SensorsDocument13 pagesLong-Term Monitoring of High-Rise Buildings Using Long-Gage Fiber Optic SensorsittovoNo ratings yet

- SHM at The Civil Infrastructure - Applications, Recent ... - BRIMOSDocument8 pagesSHM at The Civil Infrastructure - Applications, Recent ... - BRIMOSMariana GarsteaNo ratings yet

- 10-Year SHM PunggolDocument16 pages10-Year SHM PunggolThanh NguyenNo ratings yet

- Technology Developments in Structural Health Monitoring of Large-Scale BridgesDocument11 pagesTechnology Developments in Structural Health Monitoring of Large-Scale BridgesSai Vijaya Krishna ThattaiNo ratings yet

- Life-Cycle Monitoring of Long-Span PSC Box-Girder Bridges Through Distributed Sensor Network: Strategies, Methods and ApplicationsDocument14 pagesLife-Cycle Monitoring of Long-Span PSC Box-Girder Bridges Through Distributed Sensor Network: Strategies, Methods and ApplicationsDave ThompsonNo ratings yet

- Life Cycle Management Model For TunnelsDocument6 pagesLife Cycle Management Model For TunnelsIrina StipanovicNo ratings yet

- Static and Dynamic Testing of Highway Bridges A BeDocument15 pagesStatic and Dynamic Testing of Highway Bridges A Beshibu samsonNo ratings yet

- Modelling of Intelligent Wells Forecasting Life Cycle CostsDocument9 pagesModelling of Intelligent Wells Forecasting Life Cycle Costssaladinayubi1234No ratings yet

- Test Methods: Integrated System For Monitoring Bridge StructuresDocument7 pagesTest Methods: Integrated System For Monitoring Bridge Structurescerbu_bass_cdcNo ratings yet

- 1 s2.0 S0141029623006582 MainDocument19 pages1 s2.0 S0141029623006582 Mainandremax11asNo ratings yet

- Bridge MaintenenceDocument41 pagesBridge MaintenenceFriansyah BudiNo ratings yet

- Chapter 1Document22 pagesChapter 1CharleneKronstedtNo ratings yet

- Instrumentation-Keystone of Dam MonitoringDocument30 pagesInstrumentation-Keystone of Dam MonitoringAnonymous ep7LE5ZdP5No ratings yet

- PP - Building Inspection System 2018Document23 pagesPP - Building Inspection System 2018Jaser Khalaf MahasnehNo ratings yet

- SPE/IADC-189403-MS Well Integrity - Next DevelopmentsDocument15 pagesSPE/IADC-189403-MS Well Integrity - Next DevelopmentsMahfoud AMMOURNo ratings yet

- Life-Cycle Considerations in The Selection and Use of Bridge Expansion JointsDocument8 pagesLife-Cycle Considerations in The Selection and Use of Bridge Expansion Joints정주호No ratings yet

- Li Et Al-2018-The Structural Design of Tall and Special BuildingsDocument22 pagesLi Et Al-2018-The Structural Design of Tall and Special Buildingsscri_kkNo ratings yet

- Bridges & Culverts: Field Investigation & ProposalsDocument27 pagesBridges & Culverts: Field Investigation & ProposalsS SathiyarubanNo ratings yet

- Journal of Civil Structural Health MonitoringDocument20 pagesJournal of Civil Structural Health MonitoringShubham RathodNo ratings yet

- Smart Bridges, Smart Tunnels: Transforming Wireless Sensor Networks From Research Prototypes Into Robust Engineering InfrastructureDocument30 pagesSmart Bridges, Smart Tunnels: Transforming Wireless Sensor Networks From Research Prototypes Into Robust Engineering InfrastructureRakesh Kumar Mandal sec-B,128No ratings yet

- Bridge Management From Design To Maintenance: July 1996Document25 pagesBridge Management From Design To Maintenance: July 1996Sanket NaikNo ratings yet

- Rohit Mourya (Structural Health Monitoring System)Document17 pagesRohit Mourya (Structural Health Monitoring System)Rohit Mourya100% (1)

- The General Architecture of A European Bridge ManagementDocument23 pagesThe General Architecture of A European Bridge ManagementLaurentiu PavelescuNo ratings yet

- Research Proposal (TELESPHORE)Document10 pagesResearch Proposal (TELESPHORE)TELESPHORE NDAYISABANo ratings yet

- Assessment of Existing Steel Bridges: Codes and Standard: IOP Conference Series: Materials Science and EngineeringDocument10 pagesAssessment of Existing Steel Bridges: Codes and Standard: IOP Conference Series: Materials Science and Engineeringjuan diazNo ratings yet

- Design and Inspection of Long Span Suspension Bridges - Bridge Information ModellingDocument10 pagesDesign and Inspection of Long Span Suspension Bridges - Bridge Information ModellingTuan PnNo ratings yet

- Design Guidelines For Bridge Size CulvertsDocument32 pagesDesign Guidelines For Bridge Size CulvertsWing MacNo ratings yet

- Managing Tunnel Infrastructure A New GuidelineDocument7 pagesManaging Tunnel Infrastructure A New GuidelineDeyuan GuoNo ratings yet

- Dam Safety and Monitoring InstrumentationDocument4 pagesDam Safety and Monitoring Instrumentationina_criNo ratings yet

- LAteral BucklingDocument12 pagesLAteral Bucklingabhi1648665No ratings yet

- BrInspectionManual 2011-2 PDFDocument619 pagesBrInspectionManual 2011-2 PDFBinodNo ratings yet

- Bridge Engineering: Maintenance: Bridge Maintenance TechniquesDocument36 pagesBridge Engineering: Maintenance: Bridge Maintenance TechniquesRam NepaliNo ratings yet

- PDRI Infraestructure ProjectsDocument156 pagesPDRI Infraestructure ProjectsArturo Sempértegui100% (1)

- Durability Design of Concrete Structures - Part 2: Modelling and Structural AssessmentDocument22 pagesDurability Design of Concrete Structures - Part 2: Modelling and Structural AssessmentnemanjakokoNo ratings yet

- Common Pathologies in RC Bridge Structures - A Statistical AnalysisDocument8 pagesCommon Pathologies in RC Bridge Structures - A Statistical AnalysisbrelightsNo ratings yet

- Long Term Health Monitoring of Post-Tensioning Box Girder BridgesDocument14 pagesLong Term Health Monitoring of Post-Tensioning Box Girder BridgesSetyo Hardono100% (1)

- Final ProjectDocument18 pagesFinal Projectavijeet sethiNo ratings yet

- Integrity Lessons LearntDocument27 pagesIntegrity Lessons LearntRene ParedeschaconNo ratings yet

- Benefit of The Instrumentation, Monitoring and Control System (IMC) of Bridges in Colombia From An Economic Point of View Through A Case StudyDocument11 pagesBenefit of The Instrumentation, Monitoring and Control System (IMC) of Bridges in Colombia From An Economic Point of View Through A Case Studyihsan tamrinNo ratings yet

- Ug 3Document20 pagesUg 3api-301328164No ratings yet

- Vol 2 Onshore Pipelines The Road To Success 3rd EditionDocument418 pagesVol 2 Onshore Pipelines The Road To Success 3rd EditionAli Hammouda100% (1)

- Extend Life Aging PipelinesDocument20 pagesExtend Life Aging PipelinesPar MadNo ratings yet

- Fast Construction - Segmental and Launched BridgesDocument36 pagesFast Construction - Segmental and Launched BridgesBuvanendran Sanjeevan100% (1)

- Research Paper On Structural Health MonitoringDocument7 pagesResearch Paper On Structural Health Monitoringgw1gnz6b100% (1)

- Ipc2012 90730Document8 pagesIpc2012 90730Marcelo Varejão CasarinNo ratings yet

- Bridge Erection Techniques and Construction EquipmDocument2 pagesBridge Erection Techniques and Construction EquipmAbderrahmane SaidNo ratings yet

- Applied Sciences: Modular and Offsite Construction of Piping: Current Barriers and RouteDocument16 pagesApplied Sciences: Modular and Offsite Construction of Piping: Current Barriers and Routebashar sharqawiNo ratings yet

- Review of Pipeline Integrity ManagementDocument8 pagesReview of Pipeline Integrity ManagementTaib Anwar100% (2)

- Riopipeline2019 1090 201906111002ibp1090 19 The Rol PDFDocument9 pagesRiopipeline2019 1090 201906111002ibp1090 19 The Rol PDFMarcelo Varejão CasarinNo ratings yet

- Use of Gaming Technology To Bring BridgeDocument17 pagesUse of Gaming Technology To Bring BridgeAbdullah AhmedNo ratings yet

- Amended Interim Report Richard Chomba1Document14 pagesAmended Interim Report Richard Chomba1richard chombaNo ratings yet

- Report119 - Part5 of 5 InspectionsDocument11 pagesReport119 - Part5 of 5 InspectionshjdNo ratings yet

- Pipeline Leak Detection Study - OTH94Document58 pagesPipeline Leak Detection Study - OTH94ElcioDiasJrNo ratings yet

- Chapter 9Document27 pagesChapter 9Fuad AhmedinNo ratings yet

- Research Review 010312lrDocument37 pagesResearch Review 010312lrVenkata Raju KalidindiNo ratings yet

- Bridge InspectionDocument5 pagesBridge Inspectiondarelsharq77No ratings yet

- Wireless Vibration Sensorfor Tunnel ConstructionDocument8 pagesWireless Vibration Sensorfor Tunnel ConstructionParvatha Vardhan GandrakotaNo ratings yet

- قواعد اللغة العربية -حفني ناصف واخوانهDocument201 pagesقواعد اللغة العربية -حفني ناصف واخوانهrwaidaabbasNo ratings yet

- 2015 470245 On-TheDocument154 pages2015 470245 On-TherwaidaabbasNo ratings yet

- الأعمال الشعرية سليم بركات 99854Document565 pagesالأعمال الشعرية سليم بركات 99854rwaidaabbasNo ratings yet

- Zahef Books 1649194942Document106 pagesZahef Books 1649194942rwaidaabbasNo ratings yet

- Retrofitting Shear Cracks in Reinforced Concrete Pier Caps Using Carbon Fiber Reinforced PolymersDocument240 pagesRetrofitting Shear Cracks in Reinforced Concrete Pier Caps Using Carbon Fiber Reinforced PolymersrwaidaabbasNo ratings yet

- Advance Analysis Iqra LiaqatDocument222 pagesAdvance Analysis Iqra LiaqatrwaidaabbasNo ratings yet

- SCC - TB - Enu Scia - Esa PT Steel Code CheckDocument265 pagesSCC - TB - Enu Scia - Esa PT Steel Code CheckrwaidaabbasNo ratings yet

- Proceedings of Nano Macro Mechanics 2012Document276 pagesProceedings of Nano Macro Mechanics 2012rwaidaabbasNo ratings yet

- 06 PlateTheory 02 MomentCurvatureDocument15 pages06 PlateTheory 02 MomentCurvaturerwaidaabbasNo ratings yet

- IDARC 2D Version 4.0 A Program For The Inelastic Damage Analysis of BuildingsDocument206 pagesIDARC 2D Version 4.0 A Program For The Inelastic Damage Analysis of BuildingsrwaidaabbasNo ratings yet

- The American Astronomical Society. All Rights Reserved. Printed in U.S.A. (Document12 pagesThe American Astronomical Society. All Rights Reserved. Printed in U.S.A. (rwaidaabbasNo ratings yet

- 01 - 144251-1.pdfلسان العربDocument496 pages01 - 144251-1.pdfلسان العربrwaidaabbasNo ratings yet

- Seismic Behaviour and Analysis of Continuous Reinforced Concrete BridgesDocument356 pagesSeismic Behaviour and Analysis of Continuous Reinforced Concrete BridgesrwaidaabbasNo ratings yet

- Background To Fatigue Load ModelsDocument11 pagesBackground To Fatigue Load ModelsrwaidaabbasNo ratings yet

- Or 06010Document82 pagesOr 06010rwaidaabbasNo ratings yet

- PC Bridge Design ManualDocument41 pagesPC Bridge Design ManualrwaidaabbasNo ratings yet

- DL Infos Maurer MSM Sliding BearingsDocument14 pagesDL Infos Maurer MSM Sliding BearingsrwaidaabbasNo ratings yet

- Ga and OylDocument3 pagesGa and Oyljuad87No ratings yet

- Astm F 13608Document4 pagesAstm F 13608Riesma TasomaraNo ratings yet

- CM 425 - Properties of Fresh Concrete PDFDocument14 pagesCM 425 - Properties of Fresh Concrete PDFTran Huynh NamNo ratings yet

- Christa Esl Methods Thematic Unit Lesson Plan 4 Grade 3Document2 pagesChrista Esl Methods Thematic Unit Lesson Plan 4 Grade 3api-439006276No ratings yet

- Bluetooth, IEEE 802.11, WIMAXDocument30 pagesBluetooth, IEEE 802.11, WIMAXMukesh71% (7)

- Stem To Steam Visual Art Signature Program References Education Trends Subscribe To RssDocument3 pagesStem To Steam Visual Art Signature Program References Education Trends Subscribe To Rssapi-221015864No ratings yet

- Shais 168Document3 pagesShais 168Mohammed gNo ratings yet

- 8BK88PLUSDocument8 pages8BK88PLUSSwapnil PatilNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

- VT Ratio Measurement With 12KVDocument9 pagesVT Ratio Measurement With 12KVmanikandanNo ratings yet

- Communication SkillsDocument2 pagesCommunication SkillspandyaniravNo ratings yet

- Kajian WacanaDocument6 pagesKajian WacanaPutri FatinNo ratings yet

- 36 มยผ.8116-52 มาตรฐานแผงควบคุมเครื่องสูบน้ำดับเพลิงDocument21 pages36 มยผ.8116-52 มาตรฐานแผงควบคุมเครื่องสูบน้ำดับเพลิงappril26No ratings yet

- Computer Aided Logistic SystemsDocument26 pagesComputer Aided Logistic SystemsMehmet FİDANCINo ratings yet

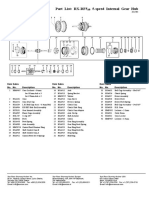

- Part List: RX-RF5 5-Speed Internal Gear HubDocument2 pagesPart List: RX-RF5 5-Speed Internal Gear HubTomislav KoprekNo ratings yet

- Atlas Copco Boomer L2D Component and Signallists RCS4Document34 pagesAtlas Copco Boomer L2D Component and Signallists RCS4Hai Van100% (4)

- SGP 6Document7 pagesSGP 6Soumajit PoddarNo ratings yet

- Injection Molding Mold DesignDocument26 pagesInjection Molding Mold DesignDiligence100% (1)

- Shrinkkomp GroutDocument6 pagesShrinkkomp GroutSridhar TholasingamNo ratings yet

- 2018 Catalogue ChillersDocument123 pages2018 Catalogue ChillersИлия ГеоргиевNo ratings yet

- Seisgram2K PQL Datawiewer Winscp Teraterm: Monitoring The EarthDocument2 pagesSeisgram2K PQL Datawiewer Winscp Teraterm: Monitoring The EarthLuna FitrianaNo ratings yet

- Hashtag GuideDocument11 pagesHashtag GuideChithra ShineyNo ratings yet

- Text Mining Applications and TheoryDocument5 pagesText Mining Applications and Theorynokhaha5100% (1)

- VAFS-T Series-1Document14 pagesVAFS-T Series-1Ditya GufronoNo ratings yet

- Different Types of HAZOPDocument16 pagesDifferent Types of HAZOPNg Joshua67% (3)

- Pioneer Deh-X1680ub Crt5450 PartsDocument4 pagesPioneer Deh-X1680ub Crt5450 PartsCarlos EstaraNo ratings yet

- Full Circle Magazine - Issue 57 ENDocument57 pagesFull Circle Magazine - Issue 57 ENRoman SukochevNo ratings yet

- Configuring VTP: Finding Feature InformationDocument26 pagesConfiguring VTP: Finding Feature InformationBui Hong MyNo ratings yet

- COBOL (Common Business Oriented Language)Document2 pagesCOBOL (Common Business Oriented Language)christine booduanNo ratings yet

- Pediatric Laparoscopic Inguinal Hernia Repair - A Review of Techniques - A SAGES Wiki ArticleDocument30 pagesPediatric Laparoscopic Inguinal Hernia Repair - A Review of Techniques - A SAGES Wiki ArticleAndri Feisal NasutionNo ratings yet