Professional Documents

Culture Documents

Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is More

Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is More

Uploaded by

anca mariaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is More

Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is More

Uploaded by

anca mariaCopyright:

Available Formats

W O R K S H O P

Simple Elegance

B Y L A R R Y O K R E N D

A table with few parts and uncomplicated joinery proves that less is more

This mahogany drop-leaf console table is ideal for placement behind a sofa or in an entryway. Because the design consists of simple joinery and few parts, you can easily adjust the size to suit your setting.

urniture thats easy to make can tend to be visually clunky, and graceful furniture has a reputation for being too difficult for the home woodworker to build. With that in mind, our design team accepted the challenge to create a table that featured flowing lines but simple construction. Starting with straight lines and pleasing proportions, we simply added a few curves and tapers to various pieces. The result is a table that requires only moderate skill to build, but everyone who sees it will think youre a woodworking genius.

Preliminary pointers

Although we used mahogany for our table, other common species such as maple, oak and cherry are also good choices.

12

HANDY NOVEM B ER u DECEM B ER 2007

Adjust the amount of material you purchase (see Shopping List, p. 14) depending on the quality of the wood. Knots, splits and warps may require you to buy more stock. Weve included a little extra in our recommendations for waste and test pieces. We employed a Festool Domino to cut all of the table mortises. This mortising system is significantly faster (more than 75 percent faster, in my experience) than a router and uses manufactured floating tenons. The Domino has become a shop favorite among the editors and is a HANDY Innovation Award winner (see p. 26). However, this expensive tool isnt required for this project; you can make the mortise-and-tenon joints with a router and use

P H OTO S B Y L A R R Y O K R E N D ; I L L U S T R AT I O N B Y G A B R I E L G R A P H I C S ; D E S I G N B Y DA N C A R Y, V E R N G R A S S E L A N D L A R R Y O K R E N D ; C O N S T R U C T I O N B Y V E R N G R A S S E L

DROP-LEAF CONSOLE TABLE

E

1/2" radius

B

1/4" Hinge mortise 1/2"

DETAIL 1 B A

4"

1-1/2 x 3-1/4" drop-leaf hinge (see Detail 1)

1"

C

5-5/8"

10"

F G B E D A 1 2

3-1/2" 1" flat

19" 1-1/2" flat 4" C L 12-3/8"

14-1/4" (start taper)

H C

C L

Taper both inner faces to 1" square DETAIL AT SIDE

2 x 2-1/2" leaf hinge

Mortise hinge flush (2 left-hand and 2 right-hand req'd.)

F

1/8" 6x40 Dominoes

C D

5x30 Dominoes 3/8"

5-3/4" 1" 3/8" 3"

H

Tabletop fastener 1-1/2"

D A

1/2" DETAIL AT APRONS

DETAIL AT STRETCHERS

1-5/8" DETAIL LEAF SUPPORT H

1/2"

DETAIL 2

MATERIALS AND CUTTING LIST

KEY NO. DESCRI PTION (All parts mahogany) A 1 Top B 2 Drop leaves C 4 Legs D 2 Front/back aprons E 2 Side aprons F 2 Long stretchers G 2 Short stretchers H 4 Leaf supports SIZE 3/4 x 14-1/8 x 48 in. 3/4 x 8 x 48 in. 1-1/2 x 1-1/2 x 29-1/4 in. 3/4 x 6 x 43-1/2 in. 3/4 x 6 x 9-5/8 in. 3/4 x 1-1/4 x 44-1/4 in. 3/4 x 1-1/4 x 9-5/8 in. 3/4 x 3 x 5-3/4 in.

SHOPPING LIST

4/4 mahogany (24 bf.) 8/4 mahogany (7 bf.) 5x30 Dominoes (8) 6x40 Dominoes (24) 2 x 2-1/2-in. leaf hinges (4; Rockler No. 57124) 1-1/2 x 3-1/4-in. drop-leaf hinges (4; Rockler No. 29256) Tabletop fasteners (6; Rockler No. 34215) Finishing supplies (sandpaper, steel wool, stain, varnish, etc.)

To learn how to build and use a tapering jig, go to

www.HandymanClub.com/FromHandy

14

HANDY NOVEM B ER u DECEM B ER 2007

Featherboard

1

Bend a flexible wood strip to lay out the curves on the drop leaves; then saw close to the line with a jigsaw. Either sand or use a router and template to smooth the edge to the pencil line.

Router-cut cove

Cut the matching drop-leaf profile with standard 1/2-in. cove and roundover router bits. Youll get the best results using a router table. Use scrap pieces to set up the cuts, and use featherboards to keep the workpiece firmly against the table.

floating or fixed tenons. If youd prefer simpler joinery methods, other good options are dowels, biscuits and pocket screws. (However, keep in mind that the latter two are not suitable for joining the stretchers.) Depending on the type of wood you use and its cost, youll spend about $200 to $400 for materials, hardware and finishing supplies. Theres nothing special about the hardware; most home centers will have what you need. (See SOURCES ONLINE for a hardware source and the Shopping List, opposite, for catalog numbers.)

Preparing stock and parts

As with any furniture project, the best way to get the flat, consistent stock necessary to achieve the most precise joinery is to joint and plane rough stock. But if you dont have a jointer and a planer, you can purchase milled stock at most home centers and lumberyards. At 14-1/8 in., the top is a fairly wide piece, so you may need to edge-join two narrower pieces together. You should be able to make all of the remaining parts from single boards. Once youve cut all of the parts to length and width, lay out the curves on the drop leaves and aprons and the tapers on the legs. You can cut these before or after cutting the mortises. Just be sure to mark the parts clearly to avoid mistakes, such as the position of the leg tapers. Theres nothing complicated about laying out the curves for the drop leaves. Bend a long 1/8 x 1-in. strip of wood to form a curve; then trace the curve onto the workpiece. Use a band saw or jigsaw to cut the curves just outside the pencil line (photo 1, above). To save time, you can stack pieces, sticking them together with carpet tape, and cut them at once. You can also cut the leaf supports this way. After cutting,

sand the edges smooth to the marked line. (An oscillating spindle sander is a great tool for this task.) Rout the concave/convex drop-leaf joint (often called a rule joint) on the leaves and top with 1/2-in. roundover and cove bits (photo 2). A router table will afford better control and smoother cuts than a handheld router. Each leg has two tapered sides that are oriented toward the inside of the table. Using a table saw and tapering jig to make the leg tapers (see WEB EXTRA) is the fastest and most accurate method (photo 3, p.16). Be sure to make the cuts in a sequence so the cut sides face up to prevent the workpiece from rocking on the tapering jig. The legs must be securely clamped or fastened to the jig. You could also use a band saw to cut the tapers and then sand or plane off the saw marks.

Joinery matters

Although we used Domino tenons to join our table (photo 4), the procedure for laying out conventional mortise and tenons (or most other types of joints) is basically the same. Here are a few tips to set you on the right path. Allow at least 1/2 in. from the top and bottom edges to the first joints on the legs and aprons. The tenons should be no more than one-third the thickness of the stock, so in this case, the tenons are 1/4 in. thick. Be sure the tenons that extend from the aprons into the legs arent too long so they dont intersect with each other. Use two or three tenons rather than one long one this will allow for seasonal wood movement. Its always a good idea to cut the mortises a little deeper than the length of the tenons to accommodate excess glue that may be squeezed to the bottom of the joint. If you opt for pocket screws or dowels, use three for each apron/leg joint and one for each stretcher joint. Biscuits are

N O V E M B E R u D E C E M B E R 2 0 0 7 HandymanClub.com

15

Workpiece Tapering jig

4

Although we used a Festool Domino to cut all of the tables mortises, you could opt to use conventional mortiseand-tenon joints or dowels for all of the joints and use biscuits or pocket screws for the aprons.

We used a table saw tapering jig to cut the leg tapers (see Web Extra). The leg was fastened to the jig with carpet tape. You could also use a band saw or a jigsaw and then sand the cut sides smooth.

too large for the stretchers, but theyre a good choice for the apron/leg joints. Use either No. 10 or No. 20 biscuits.

Fit and finish

Once youve finished the joinery, dry-fit the table-base parts to check the fit. Then cut the grooves for the tabletop fasters (see drawing, p.14) using a table saw. Glue the base together in stages (photo 5, opposite) to keep the process from becoming too complicated and time-consuming and to

ensure that the base is square. Lay out the mortise positions for the drop-leaf hinges on the top and on the drop leaves (see drawing and photo 6). You can use a small router and a straight bit to cut the mortises, or you can cut them by hand with a chisel. The hinge mortises in the leaf supports are best cut with a band saw. These parts are too small to safely cut on a table saw. Install the leaf hinges and the support hinges; then attach the top with the tabletop fasteners to check the fit. Disassemble the

16

HANDY

NOVEM B ER u DECEM B ER 2007

Hinge-knuckle centerline

5

To glue together the table, first make subassembly pairs of legs and front/back aprons, and assemble the long and short stretchers. Then add the side aprons and stretcher assembly to one leg/apron assembly. Finally, add the remaining leg/apron assembly as shown here.

6

The drop-leaf hinge centerline should be positioned 1/2 in. from the bottom edge of the top to allow the leaves to swing freely. Mortise the hinges so theyre flush with the table surface.

table and remove all of the hardware before final sanding. Ease all sharp edges with a sanding block or a router and a small (1/8- or 1/4-in.) roundover bit. Sand the entire table with 220-grit paper before finishing. Check for any unwanted surface glue by wiping the table with mineral spirits. Areas contaminated with glue will appear lighter. Of course, the finish you apply depends on your preference and skill and the type of wood used. An oil-base stain and wipe-on polyurethane is always a good low-hassle

choice. For a truly smooth, lustrous finish, sand with 320-grit paper between coats; then buff the final coat with 0000 steel wool followed by a soft cotton cloth rubbed in the direction of the grain. u

SOURCES ONLINE

For online information, go to www.HandymanClub.com/FromHandy and click on SOURCES ONLINE. Festool (Domino), 888-337-8600 Rockler (hardware), 800-279-4441

N O V E M B E R u D E C E M B E R 2 0 0 7 HandymanClub.com

17

You might also like

- Treasured Chest Build A Jewelry BoxDocument9 pagesTreasured Chest Build A Jewelry BoxThanasis KyrgiazoglouNo ratings yet

- Oriental Box of Drawers PDFDocument10 pagesOriental Box of Drawers PDFAleksandar Nikolic100% (2)

- Domino Zigzag ChairDocument6 pagesDomino Zigzag ChairAlex Johnston0% (1)

- Cherry Dresser: How To Build A Classic 5-Drawer DresserDocument9 pagesCherry Dresser: How To Build A Classic 5-Drawer DresserriverbendfcNo ratings yet

- Bench - Classic Cedar Garden PDFDocument11 pagesBench - Classic Cedar Garden PDFmarianrkwNo ratings yet

- Simple Stool: Take A Load Off Your Feet and Reach New Heights With This Easy-To-Build PieceDocument3 pagesSimple Stool: Take A Load Off Your Feet and Reach New Heights With This Easy-To-Build PieceJvlValenzuela100% (1)

- Trestle Coffee TableDocument7 pagesTrestle Coffee Table- yAy3e -No ratings yet

- WJ140 Hoosier Step StoolDocument7 pagesWJ140 Hoosier Step Stoolmtejadacoll100% (1)

- Dresser PlanDocument11 pagesDresser PlanGsmHelpNo ratings yet

- Banco Escalera PDFDocument3 pagesBanco Escalera PDFluanbagonNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Anniversary Desk: Celebrate 100 Years of PM With The Fourth in Our Furniture SeriesDocument11 pagesAnniversary Desk: Celebrate 100 Years of PM With The Fourth in Our Furniture SeriesШиша ШишулінNo ratings yet

- Japanese Inspired CabinetDocument12 pagesJapanese Inspired Cabinetrhinorod100% (1)

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- How To Make A Meat SafeDocument5 pagesHow To Make A Meat SafeChristian Theriault100% (1)

- How To Build Modern Barstools Like A ProDocument17 pagesHow To Build Modern Barstools Like A Progerman100% (1)

- How To Build A Double Chair Bench With TableDocument27 pagesHow To Build A Double Chair Bench With TablebearyuyuNo ratings yet

- Mission Style Open Shelf Bathroom Vanity: AdvancedDocument22 pagesMission Style Open Shelf Bathroom Vanity: AdvancedMaricruz Valdivieso de PalaciosNo ratings yet

- A Round Kitchen Classic - Bent Laminated Cherry TableDocument8 pagesA Round Kitchen Classic - Bent Laminated Cherry TableJainar BerlianaNo ratings yet

- Bench - Mendocino BenchDocument5 pagesBench - Mendocino BenchvdbrogerNo ratings yet

- WOOD Store: Thank You!Document12 pagesWOOD Store: Thank You!lacroitoruNo ratings yet

- Porch Swing: Project 16258EZDocument5 pagesPorch Swing: Project 16258EZBSulli100% (1)

- Coffe TableDocument15 pagesCoffe TableJun Vargas100% (1)

- DIY Outdoor Chair - Angela Marie MadeDocument10 pagesDIY Outdoor Chair - Angela Marie MademrcongamanNo ratings yet

- PostarA Bench Built To LastDocument6 pagesPostarA Bench Built To Lastbonte01100% (2)

- ParquetDocument4 pagesParquetFernando FrayreNo ratings yet

- Creating A Ring HolderDocument3 pagesCreating A Ring Holderapi-522254901No ratings yet

- ChippendaleLeg FWW0135Document7 pagesChippendaleLeg FWW0135TAANGTAWAN007100% (1)

- SIX-CANDLE CENTERPIECE - Woodsmith ShopDocument5 pagesSIX-CANDLE CENTERPIECE - Woodsmith ShopEricsNo ratings yet

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- Adirondack Rocking Chair PlansDocument19 pagesAdirondack Rocking Chair PlansMoises BarbosaNo ratings yet

- Children's Bunkhouse LoftDocument7 pagesChildren's Bunkhouse Loft- yAy3e -100% (3)

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliNo ratings yet

- Dining Room ChairsDocument16 pagesDining Room Chairsrhinorod100% (1)

- Broken Arch Mantel Clock Plans: © 2005 by Robert E. Reedy All Rights ReservedDocument25 pagesBroken Arch Mantel Clock Plans: © 2005 by Robert E. Reedy All Rights ReservedLinNo ratings yet

- The Lutyens Garden BenchDocument8 pagesThe Lutyens Garden BenchAdrian CocisNo ratings yet

- Concorde TableDocument2 pagesConcorde Table- yAy3e -No ratings yet

- Barn Door Baby GateDocument17 pagesBarn Door Baby GateNovitates1No ratings yet

- WJ088 Garden BenchDocument13 pagesWJ088 Garden BenchOsvaldo Moraes100% (1)

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Adirondack ChairDocument11 pagesAdirondack ChairMoises Martins Rocha100% (1)

- Bed and Storage BoxesDocument9 pagesBed and Storage Boxespoimandres100% (1)

- Nesting Tables: REQUIREMENTS FOR THIS PROJECT-I Made The Tables As They Are ShownDocument11 pagesNesting Tables: REQUIREMENTS FOR THIS PROJECT-I Made The Tables As They Are Shown- yAy3e -No ratings yet

- Country Dry SinkDocument4 pagesCountry Dry SinkjcpolicarpiNo ratings yet

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68No ratings yet

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 pagesLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNo ratings yet

- Folding Stool: I Can Do ThatDocument3 pagesFolding Stool: I Can Do ThatSergio PazNo ratings yet

- Woodsmith 184 Avoiding Router Table TearoutDocument2 pagesWoodsmith 184 Avoiding Router Table TearoutPaul LauNo ratings yet

- Firewood GarbageShedDocument13 pagesFirewood GarbageShedJeremy SmathersNo ratings yet

- Bench - Build A Classic Porch Glider - PopMecDocument8 pagesBench - Build A Classic Porch Glider - PopMecvdbroger100% (1)

- Bench - Langcrest - LoveseatDocument5 pagesBench - Langcrest - LoveseatvdbrogerNo ratings yet

- The Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Document2 pagesThe Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Exartis GeorgeNo ratings yet

- Pano PDFDocument121 pagesPano PDFjuanNo ratings yet

- Deluxe Router TableDocument27 pagesDeluxe Router TableNebojša JovanovNo ratings yet

- David de Lossy/Photodisc/Getty ImagesDocument15 pagesDavid de Lossy/Photodisc/Getty ImagesasiasiNo ratings yet

- Porch SwingDocument3 pagesPorch SwingManuel RomeroNo ratings yet

- Spindle Turning: Fine Points For The BeginnerDocument6 pagesSpindle Turning: Fine Points For The Beginnerapi-25885411No ratings yet

- Plan Bed Heirloom Arts and CraftsDocument13 pagesPlan Bed Heirloom Arts and Craftspoimandres0% (1)

- Ex No - 1 RECTANGULAR TRAY MAKINGDocument5 pagesEx No - 1 RECTANGULAR TRAY MAKINGANISH PATIL (RA2111029010064)No ratings yet

- Doc655294263 647999315Document14 pagesDoc655294263 647999315mariifernandez1100% (3)

- Plat Milho 04Document54 pagesPlat Milho 04Thiago FredyNo ratings yet

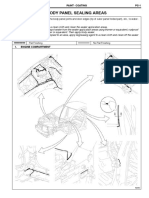

- Body Panel Sealing AreasDocument6 pagesBody Panel Sealing AreasMilton Poma CabasNo ratings yet

- Corgi DogDocument21 pagesCorgi DogReceitas amigurumi100% (4)

- Amigurumi FreeDocument71 pagesAmigurumi FreeAlice WCM100% (2)

- Processing TENCEL® LF / Cotton BlendsDocument32 pagesProcessing TENCEL® LF / Cotton Blendskona100% (1)

- HexForce 00120 1200 Z6040Document1 pageHexForce 00120 1200 Z6040quyet ngo100% (1)

- Orbit Part2Document9 pagesOrbit Part2DaxxiiNo ratings yet

- Springback Ledger Bindings PDFDocument10 pagesSpringback Ledger Bindings PDFCibele AndradeNo ratings yet

- Production Technology R10 JntukDocument4 pagesProduction Technology R10 JntukSrimanthula SrikanthNo ratings yet

- Lesson Sixteen TextDocument12 pagesLesson Sixteen TextVignesh WaranNo ratings yet

- Atr42 600 Papercraft ManualDocument7 pagesAtr42 600 Papercraft ManualDina HishamNo ratings yet

- American Woodworker #142 Jun-Jul 2009 PDFDocument58 pagesAmerican Woodworker #142 Jun-Jul 2009 PDFАлександр АлександровичNo ratings yet

- Cotton Lace Ponchette: Pattern NoteDocument2 pagesCotton Lace Ponchette: Pattern NoteMarlen MicuNo ratings yet

- Management Process IIDocument200 pagesManagement Process IIPeeka Prabhakara RaoNo ratings yet

- Arnold The SpiderDocument7 pagesArnold The SpiderKhánh Ninh Nghiêm100% (1)

- Reto Misterioso AmigurumiDocument15 pagesReto Misterioso AmigurumiPatricia López RasteuNo ratings yet

- Bedding - Bed Coverings Part IIDocument118 pagesBedding - Bed Coverings Part IIThe 18th Century Material Culture Resource Center88% (8)

- Boq Items TilesDocument1 pageBoq Items TilesAbd-Elaal Mohamed AmerNo ratings yet

- Lulu's Crafts Giraffe Hat PatternDocument5 pagesLulu's Crafts Giraffe Hat PatternSulis Setiya NingsihNo ratings yet

- GGB Herborth 01Document16 pagesGGB Herborth 01artus_agvNo ratings yet

- English PDF Bunnies en V2Document6 pagesEnglish PDF Bunnies en V2Cornelia Mirica100% (2)

- L40140 DownloadableDocument5 pagesL40140 DownloadableGeorgiana BusuiocNo ratings yet

- Valentines Cupid English Free PatternDocument11 pagesValentines Cupid English Free PatterngleselgeseNo ratings yet

- LPObjects Trophy Owl Head Manual PDFDocument3 pagesLPObjects Trophy Owl Head Manual PDFHuam Cas Jhonatan0% (4)

- WS24830 - Heavy Duty Miter Saw StationDocument8 pagesWS24830 - Heavy Duty Miter Saw StationJasmine Vaaltyn100% (3)

- Costing Sheet Format FormulaDocument4 pagesCosting Sheet Format FormulaDeny ArisandiNo ratings yet

- Landscape Photography Cheat SheetDocument1 pageLandscape Photography Cheat SheetAlessandra MigueisNo ratings yet

- The Little Deer-Elizabeth KamalinaDocument21 pagesThe Little Deer-Elizabeth Kamalinaadvokatandrienko100% (1)