Professional Documents

Culture Documents

The Process The Overview: Electroless Nickel

The Process The Overview: Electroless Nickel

Uploaded by

Cindy Montero SerranoCopyright:

Available Formats

You might also like

- Worldwide Engineering Standards: Material Specification Finish GMW4700Document4 pagesWorldwide Engineering Standards: Material Specification Finish GMW4700Miguel Queiros100% (4)

- ElectroplatingDocument18 pagesElectroplatingRahul Pandey100% (2)

- Erector Parts GuideDocument24 pagesErector Parts Guidedomingojs233710No ratings yet

- Zinc CoatingsDocument16 pagesZinc CoatingsShojikuriakoseT100% (2)

- Evaluation of Alternatives To Electrodeposited Cadmium For Threaded Fasteners Applications (III)Document13 pagesEvaluation of Alternatives To Electrodeposited Cadmium For Threaded Fasteners Applications (III)mp87_ingNo ratings yet

- Electroless Nickel PlatingDocument1 pageElectroless Nickel PlatingJosé Emilio Román de AndaNo ratings yet

- Electro PlatingDocument4 pagesElectro PlatingSreedhar Patnaik.MNo ratings yet

- Titanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowDocument19 pagesTitanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowhadeNo ratings yet

- Decorative Nickel PlatingDocument17 pagesDecorative Nickel PlatingKhaledAhmedNo ratings yet

- Electroless Nickel Composite CoatingsDocument1 pageElectroless Nickel Composite CoatingsJosé Emilio Román de AndaNo ratings yet

- Electroless PlatingDocument4 pagesElectroless PlatingFeer PowersNo ratings yet

- Zinc Flake Vs Zinc-Nickel ComparisonDocument7 pagesZinc Flake Vs Zinc-Nickel ComparisonSon NguyenNo ratings yet

- Technical Tidbits April 2002 - Nickel As A Coating MaterialDocument2 pagesTechnical Tidbits April 2002 - Nickel As A Coating MaterialDavid GillNo ratings yet

- Electropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild SteelDocument8 pagesElectropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild Steelqnk7No ratings yet

- QPQ (Salt Bath Ferritic Nitrocarburizing 5898 - BNA Melonite Rev 1 - 0Document2 pagesQPQ (Salt Bath Ferritic Nitrocarburizing 5898 - BNA Melonite Rev 1 - 0Mark JohnsonNo ratings yet

- What Is Che NiAu or ENIGDocument9 pagesWhat Is Che NiAu or ENIGjackNo ratings yet

- SilcoTek Coating Overview Brochure WebDocument6 pagesSilcoTek Coating Overview Brochure WebIker MelladoNo ratings yet

- Supreme Technology 2-Zinc Alloy&ZincDocument6 pagesSupreme Technology 2-Zinc Alloy&ZincTran Duong QuangNo ratings yet

- Gavalnise Vs PaintsDocument35 pagesGavalnise Vs Paintsian1000100% (2)

- Electro-Cleaning Technical Brief: Contact: David BenchoamDocument8 pagesElectro-Cleaning Technical Brief: Contact: David BenchoamMehdiNo ratings yet

- ElectroDocument14 pagesElectronvemanNo ratings yet

- Electropolishing TheBenefitsOfElectropolishingDocument13 pagesElectropolishing TheBenefitsOfElectropolishingAmit PanditaNo ratings yet

- Product Description SheetDocument2 pagesProduct Description SheetFabio ParceroNo ratings yet

- Electroplating TE SEMINARDocument29 pagesElectroplating TE SEMINARArjun R krishnanNo ratings yet

- Zinc Nickel PlatingDocument1 pageZinc Nickel PlatingSiripongTNo ratings yet

- AdvancesInBellowsElectroforming - Advances in Electroformed BellowsDocument12 pagesAdvancesInBellowsElectroforming - Advances in Electroformed BellowsgooogaNo ratings yet

- Dow-Corning - Molykote P-37Document2 pagesDow-Corning - Molykote P-37ramnadh803181No ratings yet

- Metals and How To Weld Nickel Alloys Like Inconel 718Document39 pagesMetals and How To Weld Nickel Alloys Like Inconel 718Erick Hogan100% (1)

- Zer CorDocument4 pagesZer CorVaibhav KhannaNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- Zinc Nickel Plating: Platings & Coatings For IndustryDocument1 pageZinc Nickel Plating: Platings & Coatings For IndustryyağmurNo ratings yet

- GUIDE - Elect Roles Nickel PlatingDocument14 pagesGUIDE - Elect Roles Nickel PlatingratnasdatarNo ratings yet

- AutomotiveDocument2 pagesAutomotivewatnaNo ratings yet

- Electrocleaning Technical BriefDocument8 pagesElectrocleaning Technical BriefSutopoNo ratings yet

- What Is Nelco N4000-29 PCBDocument4 pagesWhat Is Nelco N4000-29 PCBjackNo ratings yet

- Nickle Based SuperalloyDocument25 pagesNickle Based SuperalloyLavesh Kumar100% (1)

- Nickel Hard Chrome PlatingDocument11 pagesNickel Hard Chrome PlatingvrkbkdnhcwjqlvjhxqNo ratings yet

- Accrolube SpecDocument3 pagesAccrolube SpecManuel GarniqueNo ratings yet

- Nelco N4000-13 BC Buried Capacitance, High-Speed Multifunctional Epoxy Laminate and PrepregDocument6 pagesNelco N4000-13 BC Buried Capacitance, High-Speed Multifunctional Epoxy Laminate and PrepregjackNo ratings yet

- New Galvanizing TechnologyDocument4 pagesNew Galvanizing Technologywmaddoxmec100% (1)

- Zinc PlatingDocument2 pagesZinc PlatingSathyaraj M SNo ratings yet

- EutecTrode Manual Metal Arc Electrodes PDFDocument12 pagesEutecTrode Manual Metal Arc Electrodes PDFswapneel_kulkarniNo ratings yet

- The Nickel Advantage in Duplex Stainless SteelsDocument15 pagesThe Nickel Advantage in Duplex Stainless SteelsgullenariNo ratings yet

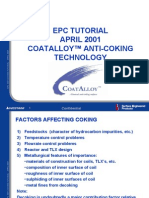

- Epc Tutorial APRIL 2001 Coatalloy™ Anti - Coking TechnologyDocument16 pagesEpc Tutorial APRIL 2001 Coatalloy™ Anti - Coking TechnologyKmajdianNo ratings yet

- Thermomechanical Processing and Properties of Niobium AlloysDocument11 pagesThermomechanical Processing and Properties of Niobium Alloysmariane1982100% (2)

- 589enint Greencoat Pural BTDocument4 pages589enint Greencoat Pural BTkokrasniqiNo ratings yet

- Nickel in Ferritic & Martensitic Stainless Steel PDFDocument23 pagesNickel in Ferritic & Martensitic Stainless Steel PDFhimanshu17121990No ratings yet

- DSM-0329.1 WokaDur NiE ElectrodeDocument4 pagesDSM-0329.1 WokaDur NiE ElectrodeAlireza KhodabandehNo ratings yet

- Stellram Milling Grades Chart InchDocument4 pagesStellram Milling Grades Chart InchTri LilalilulaNo ratings yet

- Comparison Between CPCC FBEC Amp CRSDDocument6 pagesComparison Between CPCC FBEC Amp CRSDSrikanth SrikantiNo ratings yet

- Hot Dipping / Galvanizing Process: Manufacturing Process I S.E. Production Unit-VDocument18 pagesHot Dipping / Galvanizing Process: Manufacturing Process I S.E. Production Unit-Vsample use100% (1)

- Loctite 271Document3 pagesLoctite 271ydwihatmanto123No ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- Hot Solder Dip Prevents RustDocument4 pagesHot Solder Dip Prevents RustDaoud MiourighNo ratings yet

- Under Plate PlatingDocument3 pagesUnder Plate PlatingvkmsNo ratings yet

- Flyer23 12 ZFC Zintek300 Techseal Glossy BlackDocument2 pagesFlyer23 12 ZFC Zintek300 Techseal Glossy BlackSyedMazharAliShahNo ratings yet

- Belzona 1111 (Super Metal) - Epoxy-Based CompositeDocument2 pagesBelzona 1111 (Super Metal) - Epoxy-Based CompositeVALJEANYNo ratings yet

- Woods Nickel Strike - TDS July 2017Document1 pageWoods Nickel Strike - TDS July 2017Aaed DahhamNo ratings yet

- ENPDocument21 pagesENPRizki PerdanaNo ratings yet

- MWC SVM ElectroformedMetalBellowsDocument16 pagesMWC SVM ElectroformedMetalBellowsgooogaNo ratings yet

- Electropolishing WorkbookDocument16 pagesElectropolishing WorkbookAhmet BozgeyikNo ratings yet

- Aws WJ 201502Document141 pagesAws WJ 201502Remmy Torres VegaNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Ss 316 ChemicalcompatibilitychartDocument17 pagesSs 316 ChemicalcompatibilitychartaurinkokelloNo ratings yet

- GT8E Catalog PDFDocument14 pagesGT8E Catalog PDFAnonymous cLCdIbNo ratings yet

- Braided Cable SpecificationDocument32 pagesBraided Cable SpecificationmansurscribdNo ratings yet

- Dalic 11003Document2 pagesDalic 11003zozi6030No ratings yet

- Adhesion Test For PaintDocument44 pagesAdhesion Test For PaintLaughlikesiao HeheNo ratings yet

- PDFDocument974 pagesPDFpeter smith100% (1)

- Ducab Connect 2Document94 pagesDucab Connect 2tony6868No ratings yet

- Electroless Nickel Composite CoatingsDocument1 pageElectroless Nickel Composite CoatingsJosé Emilio Román de AndaNo ratings yet

- Heavy Industries Taxila ReportDocument46 pagesHeavy Industries Taxila ReportAitazaz Ahsan100% (2)

- Fabco Air Multi CylinderDocument28 pagesFabco Air Multi Cylinderzhangwenfeng221No ratings yet

- Delta CatDocument229 pagesDelta Catchristopher.j.morris20.civNo ratings yet

- Metallographic Principles 200-860Document44 pagesMetallographic Principles 200-860marian111100% (4)

- Mil C 14550BDocument4 pagesMil C 14550BKris PathinatherNo ratings yet

- ISRI Publication 2017Document70 pagesISRI Publication 2017Florin Damaroiu50% (2)

- NLG Drag Brace - CMM PN Tp500-E050Document159 pagesNLG Drag Brace - CMM PN Tp500-E050Anderson RamalhoNo ratings yet

- Fenner Keyless - BushingsDocument52 pagesFenner Keyless - BushingspurushothamNo ratings yet

- Nickel Plating PDFDocument40 pagesNickel Plating PDFVeronica CorreaNo ratings yet

- 2020 FrictionCoefficientsDocument12 pages2020 FrictionCoefficientsraaspoy2007No ratings yet

- PATTA Self Drilling Screws Cat2018Document48 pagesPATTA Self Drilling Screws Cat2018Seth Madhusudan RathiNo ratings yet

- Mini SKii PDocument42 pagesMini SKii PFelipe LorenziNo ratings yet

- Kobelco PVD Coating SystemDocument8 pagesKobelco PVD Coating SystemmiatiNo ratings yet

- Shielding Catalog Tech EtchDocument52 pagesShielding Catalog Tech EtchmasoodkamalNo ratings yet

- Brass Product Catalouge - Matrix AlloyDocument7 pagesBrass Product Catalouge - Matrix AlloyBrass FittingsNo ratings yet

- Replacement of Chrome Plating With HVOF GoodrichDocument30 pagesReplacement of Chrome Plating With HVOF GoodrichR2osNo ratings yet

- 1133if 1133A 1133 PCDocument56 pages1133if 1133A 1133 PCIgor221987100% (1)

- Complete Market Report On Electroplating, Nickel Chrome IndiaDocument23 pagesComplete Market Report On Electroplating, Nickel Chrome Indiaharismalak215No ratings yet

The Process The Overview: Electroless Nickel

The Process The Overview: Electroless Nickel

Uploaded by

Cindy Montero SerranoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Process The Overview: Electroless Nickel

The Process The Overview: Electroless Nickel

Uploaded by

Cindy Montero SerranoCopyright:

Available Formats

ELECTROLESS NICKEL

T HE OV ERV IEW THE PROCESS

Pioneers family of electroless nickel plating methods offer a variety of solutions to meet your finishing requirements. Each of our proprietary electroless nickel processes can be engineered to meet different hardness and/or corrosion protection needs.

Process Hardness

Rc Knoop

ELECTROLESS NICKEL

Yielding excellent wear and corrosion resistance, electroless nickel is an autocatalytic plating process resulting in a reflective layer of nickelphosphorous. This plating process provides an extremely uniform coating on all surfaces, making post machining unnecessary when dimensions are accurate.

CLICK HERE TO VIEW IMAGES OF THIS PROCESS

Wear

Suga

Corrosion

Salt Spray (.001)

Lubricity

C.O.F.

Description

Major Benefit

Nor-Last

As Plated Baked 64 70 822 970 7 mg 5 mg 100 hrs 48 hrs 0.18 0.21

Nor-Last offer the best wear protection of our electroless nickel finishes approaching the ability of hard chrome.

Surface hardness and supreme wear resistance increasing tooling longevity 2.5 to 4 times. Hardness and good wear resistance.

RECEPTIVE METALS

Aluminum Stainless Steel Brass Iron Alloys Copper

Nor-Kote I

As Plated Baked 44 68 452 920 900 15 mg 13 mg 13 mg 100 hrs 24 hrs 24 hrs 0.18 0.32 0.157

Pioneer Metal Finishings standard electroless nickel process.

Nor-Kote II 68

Added PTFE surcace treatment.

Improved surface lubricity and release properties. Improved surface lubricity and release properties.

Nor-Kote III 68

900

13 mg

24 hrs

0.187

Combination of proprietary surface pretreatment of the base metal and PTFE surface treatment. Pioneer Metal Finishings most corrosion resistant electroless nickel process.

Nor-Guard

45

466

13 mg

1200 hrs

0.15

Supreme corrosion protection.

THICKNESS

.0001 - .005

Nor-Lube

As Plated Baked 25 44 275 450 53 25 100 hrs 100 hrs 0.116 0.116

Electroless nickel process with occluded PTFE particles.

Offering supreme lubricity.

TOLERANCES

+/- .0001

Pioneer Metal Finishing offer Electroless Nickel processes that are CadmiumFree and Lead-Free and are ELV, RoHs & WEEE compliant.

MAX PART SIZE

12 X 30 x 30

PERFORMANCE BENEFITS

Abrasion & Corrosion Resistance Uniform Plating, No Edge Build Up Natural Surface Lubricity Post Machining Unnecessary Well-suited for Salvage Work Food Grade Approved PRINT PRINTER FRIENDLY PDF

SPECIFICATIONS

ASTM B 733 AMS 2404 TYPE I, III, IV, V CLASSES 1-6 Approved for food grade applications CONTACT A REPRESENTATIVE ABOUT THIS SERVICE

FOR OTHER PIONEER FINISHING SOLUTIONS VISIT

W W W . P I O N E E R M E T A L . C O M

You might also like

- Worldwide Engineering Standards: Material Specification Finish GMW4700Document4 pagesWorldwide Engineering Standards: Material Specification Finish GMW4700Miguel Queiros100% (4)

- ElectroplatingDocument18 pagesElectroplatingRahul Pandey100% (2)

- Erector Parts GuideDocument24 pagesErector Parts Guidedomingojs233710No ratings yet

- Zinc CoatingsDocument16 pagesZinc CoatingsShojikuriakoseT100% (2)

- Evaluation of Alternatives To Electrodeposited Cadmium For Threaded Fasteners Applications (III)Document13 pagesEvaluation of Alternatives To Electrodeposited Cadmium For Threaded Fasteners Applications (III)mp87_ingNo ratings yet

- Electroless Nickel PlatingDocument1 pageElectroless Nickel PlatingJosé Emilio Román de AndaNo ratings yet

- Electro PlatingDocument4 pagesElectro PlatingSreedhar Patnaik.MNo ratings yet

- Titanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowDocument19 pagesTitanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowhadeNo ratings yet

- Decorative Nickel PlatingDocument17 pagesDecorative Nickel PlatingKhaledAhmedNo ratings yet

- Electroless Nickel Composite CoatingsDocument1 pageElectroless Nickel Composite CoatingsJosé Emilio Román de AndaNo ratings yet

- Electroless PlatingDocument4 pagesElectroless PlatingFeer PowersNo ratings yet

- Zinc Flake Vs Zinc-Nickel ComparisonDocument7 pagesZinc Flake Vs Zinc-Nickel ComparisonSon NguyenNo ratings yet

- Technical Tidbits April 2002 - Nickel As A Coating MaterialDocument2 pagesTechnical Tidbits April 2002 - Nickel As A Coating MaterialDavid GillNo ratings yet

- Electropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild SteelDocument8 pagesElectropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild Steelqnk7No ratings yet

- QPQ (Salt Bath Ferritic Nitrocarburizing 5898 - BNA Melonite Rev 1 - 0Document2 pagesQPQ (Salt Bath Ferritic Nitrocarburizing 5898 - BNA Melonite Rev 1 - 0Mark JohnsonNo ratings yet

- What Is Che NiAu or ENIGDocument9 pagesWhat Is Che NiAu or ENIGjackNo ratings yet

- SilcoTek Coating Overview Brochure WebDocument6 pagesSilcoTek Coating Overview Brochure WebIker MelladoNo ratings yet

- Supreme Technology 2-Zinc Alloy&ZincDocument6 pagesSupreme Technology 2-Zinc Alloy&ZincTran Duong QuangNo ratings yet

- Gavalnise Vs PaintsDocument35 pagesGavalnise Vs Paintsian1000100% (2)

- Electro-Cleaning Technical Brief: Contact: David BenchoamDocument8 pagesElectro-Cleaning Technical Brief: Contact: David BenchoamMehdiNo ratings yet

- ElectroDocument14 pagesElectronvemanNo ratings yet

- Electropolishing TheBenefitsOfElectropolishingDocument13 pagesElectropolishing TheBenefitsOfElectropolishingAmit PanditaNo ratings yet

- Product Description SheetDocument2 pagesProduct Description SheetFabio ParceroNo ratings yet

- Electroplating TE SEMINARDocument29 pagesElectroplating TE SEMINARArjun R krishnanNo ratings yet

- Zinc Nickel PlatingDocument1 pageZinc Nickel PlatingSiripongTNo ratings yet

- AdvancesInBellowsElectroforming - Advances in Electroformed BellowsDocument12 pagesAdvancesInBellowsElectroforming - Advances in Electroformed BellowsgooogaNo ratings yet

- Dow-Corning - Molykote P-37Document2 pagesDow-Corning - Molykote P-37ramnadh803181No ratings yet

- Metals and How To Weld Nickel Alloys Like Inconel 718Document39 pagesMetals and How To Weld Nickel Alloys Like Inconel 718Erick Hogan100% (1)

- Zer CorDocument4 pagesZer CorVaibhav KhannaNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- Zinc Nickel Plating: Platings & Coatings For IndustryDocument1 pageZinc Nickel Plating: Platings & Coatings For IndustryyağmurNo ratings yet

- GUIDE - Elect Roles Nickel PlatingDocument14 pagesGUIDE - Elect Roles Nickel PlatingratnasdatarNo ratings yet

- AutomotiveDocument2 pagesAutomotivewatnaNo ratings yet

- Electrocleaning Technical BriefDocument8 pagesElectrocleaning Technical BriefSutopoNo ratings yet

- What Is Nelco N4000-29 PCBDocument4 pagesWhat Is Nelco N4000-29 PCBjackNo ratings yet

- Nickle Based SuperalloyDocument25 pagesNickle Based SuperalloyLavesh Kumar100% (1)

- Nickel Hard Chrome PlatingDocument11 pagesNickel Hard Chrome PlatingvrkbkdnhcwjqlvjhxqNo ratings yet

- Accrolube SpecDocument3 pagesAccrolube SpecManuel GarniqueNo ratings yet

- Nelco N4000-13 BC Buried Capacitance, High-Speed Multifunctional Epoxy Laminate and PrepregDocument6 pagesNelco N4000-13 BC Buried Capacitance, High-Speed Multifunctional Epoxy Laminate and PrepregjackNo ratings yet

- New Galvanizing TechnologyDocument4 pagesNew Galvanizing Technologywmaddoxmec100% (1)

- Zinc PlatingDocument2 pagesZinc PlatingSathyaraj M SNo ratings yet

- EutecTrode Manual Metal Arc Electrodes PDFDocument12 pagesEutecTrode Manual Metal Arc Electrodes PDFswapneel_kulkarniNo ratings yet

- The Nickel Advantage in Duplex Stainless SteelsDocument15 pagesThe Nickel Advantage in Duplex Stainless SteelsgullenariNo ratings yet

- Epc Tutorial APRIL 2001 Coatalloy™ Anti - Coking TechnologyDocument16 pagesEpc Tutorial APRIL 2001 Coatalloy™ Anti - Coking TechnologyKmajdianNo ratings yet

- Thermomechanical Processing and Properties of Niobium AlloysDocument11 pagesThermomechanical Processing and Properties of Niobium Alloysmariane1982100% (2)

- 589enint Greencoat Pural BTDocument4 pages589enint Greencoat Pural BTkokrasniqiNo ratings yet

- Nickel in Ferritic & Martensitic Stainless Steel PDFDocument23 pagesNickel in Ferritic & Martensitic Stainless Steel PDFhimanshu17121990No ratings yet

- DSM-0329.1 WokaDur NiE ElectrodeDocument4 pagesDSM-0329.1 WokaDur NiE ElectrodeAlireza KhodabandehNo ratings yet

- Stellram Milling Grades Chart InchDocument4 pagesStellram Milling Grades Chart InchTri LilalilulaNo ratings yet

- Comparison Between CPCC FBEC Amp CRSDDocument6 pagesComparison Between CPCC FBEC Amp CRSDSrikanth SrikantiNo ratings yet

- Hot Dipping / Galvanizing Process: Manufacturing Process I S.E. Production Unit-VDocument18 pagesHot Dipping / Galvanizing Process: Manufacturing Process I S.E. Production Unit-Vsample use100% (1)

- Loctite 271Document3 pagesLoctite 271ydwihatmanto123No ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- Hot Solder Dip Prevents RustDocument4 pagesHot Solder Dip Prevents RustDaoud MiourighNo ratings yet

- Under Plate PlatingDocument3 pagesUnder Plate PlatingvkmsNo ratings yet

- Flyer23 12 ZFC Zintek300 Techseal Glossy BlackDocument2 pagesFlyer23 12 ZFC Zintek300 Techseal Glossy BlackSyedMazharAliShahNo ratings yet

- Belzona 1111 (Super Metal) - Epoxy-Based CompositeDocument2 pagesBelzona 1111 (Super Metal) - Epoxy-Based CompositeVALJEANYNo ratings yet

- Woods Nickel Strike - TDS July 2017Document1 pageWoods Nickel Strike - TDS July 2017Aaed DahhamNo ratings yet

- ENPDocument21 pagesENPRizki PerdanaNo ratings yet

- MWC SVM ElectroformedMetalBellowsDocument16 pagesMWC SVM ElectroformedMetalBellowsgooogaNo ratings yet

- Electropolishing WorkbookDocument16 pagesElectropolishing WorkbookAhmet BozgeyikNo ratings yet

- Aws WJ 201502Document141 pagesAws WJ 201502Remmy Torres VegaNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Ss 316 ChemicalcompatibilitychartDocument17 pagesSs 316 ChemicalcompatibilitychartaurinkokelloNo ratings yet

- GT8E Catalog PDFDocument14 pagesGT8E Catalog PDFAnonymous cLCdIbNo ratings yet

- Braided Cable SpecificationDocument32 pagesBraided Cable SpecificationmansurscribdNo ratings yet

- Dalic 11003Document2 pagesDalic 11003zozi6030No ratings yet

- Adhesion Test For PaintDocument44 pagesAdhesion Test For PaintLaughlikesiao HeheNo ratings yet

- PDFDocument974 pagesPDFpeter smith100% (1)

- Ducab Connect 2Document94 pagesDucab Connect 2tony6868No ratings yet

- Electroless Nickel Composite CoatingsDocument1 pageElectroless Nickel Composite CoatingsJosé Emilio Román de AndaNo ratings yet

- Heavy Industries Taxila ReportDocument46 pagesHeavy Industries Taxila ReportAitazaz Ahsan100% (2)

- Fabco Air Multi CylinderDocument28 pagesFabco Air Multi Cylinderzhangwenfeng221No ratings yet

- Delta CatDocument229 pagesDelta Catchristopher.j.morris20.civNo ratings yet

- Metallographic Principles 200-860Document44 pagesMetallographic Principles 200-860marian111100% (4)

- Mil C 14550BDocument4 pagesMil C 14550BKris PathinatherNo ratings yet

- ISRI Publication 2017Document70 pagesISRI Publication 2017Florin Damaroiu50% (2)

- NLG Drag Brace - CMM PN Tp500-E050Document159 pagesNLG Drag Brace - CMM PN Tp500-E050Anderson RamalhoNo ratings yet

- Fenner Keyless - BushingsDocument52 pagesFenner Keyless - BushingspurushothamNo ratings yet

- Nickel Plating PDFDocument40 pagesNickel Plating PDFVeronica CorreaNo ratings yet

- 2020 FrictionCoefficientsDocument12 pages2020 FrictionCoefficientsraaspoy2007No ratings yet

- PATTA Self Drilling Screws Cat2018Document48 pagesPATTA Self Drilling Screws Cat2018Seth Madhusudan RathiNo ratings yet

- Mini SKii PDocument42 pagesMini SKii PFelipe LorenziNo ratings yet

- Kobelco PVD Coating SystemDocument8 pagesKobelco PVD Coating SystemmiatiNo ratings yet

- Shielding Catalog Tech EtchDocument52 pagesShielding Catalog Tech EtchmasoodkamalNo ratings yet

- Brass Product Catalouge - Matrix AlloyDocument7 pagesBrass Product Catalouge - Matrix AlloyBrass FittingsNo ratings yet

- Replacement of Chrome Plating With HVOF GoodrichDocument30 pagesReplacement of Chrome Plating With HVOF GoodrichR2osNo ratings yet

- 1133if 1133A 1133 PCDocument56 pages1133if 1133A 1133 PCIgor221987100% (1)

- Complete Market Report On Electroplating, Nickel Chrome IndiaDocument23 pagesComplete Market Report On Electroplating, Nickel Chrome Indiaharismalak215No ratings yet