Professional Documents

Culture Documents

Banner Qs30

Banner Qs30

Uploaded by

alen_c405833Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Banner Qs30

Banner Qs30

Uploaded by

alen_c405833Copyright:

Available Formats

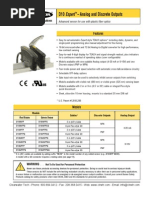

QS30 Series

Diffuse-Mode Laser Sensors

QS30 Laser Features

Visible laser beam for diffuse sensing Available with Class 1 or long-range Class 2 laser Excellent optical performance throughout sensing range, even close up Easy-to-set Expert-style TEACH options including Static, Dynamic, and SinglePoint programming plus manual adjustment for fine-tuning Easy-to-read operating status indicators, with 8-segment bargraph display Bipolar discrete outputs, PNP and NPN Selectable 30 millisecond OFF-delay Models available with 2 m or 9 m (6.5' or 30') cable or integral quick-disconnect Compact housing, mounting versatility popular 30 mm threaded nose or side-mount

U.S. Patent #5,808,296

QS30 Laser Models

Model Laser Class Range Spot Size at Focus Cable* 2 m (6.5') 5-wire Cable Supply Voltage Output Type

1000

Excess Gain

E X C E S S G A I N

QS30

6 mm Diffuse Mode Laser 4 mm 2 mm 0 2 mm 10 4 mm 6 mm 0 10 mm .4 in 100 mm 4 in 1000 mm 40 in

Beam Pattern

0.24 in

QS30LD

QS30

Diffuse Mode

Class 1

QS30LDQ

400 mm (16")

Approx. 1 mm at 400 mm (0.039" at 16")

0.16 in 0.08 in 0 0.08 in 0.16 in 0.24 in

100

Integral 5-pin Euro-style QD

1 1 mm .04 in

100 mm 200mm 300 mm 400 mm 4.0 in 8.0 in 12.0 in 16.0 in

DISTANCE

10 30V dc

Bipolar NPN/PNP

1000

DISTANCE

QS30LDL

Class 2

QS30LDLQ

800 mm (32")

Approx. 1 mm at 800 mm (0.039" at 32")

2 m (6.5') 5-wire Cable

E X C E S S G A I N

QS30

Diffuse Mode Laser

6 mm 4 mm 2 mm 0 2 mm

0.24 in

QS30

Diffuse Mode

0.16 in 0.08 in 0 0.08 in 0.16 in 0.24 in

100

Integral 5-pin Euro-style QD

10

4 mm 6 mm 0 10 mm .4 in 100 mm 4 in 1000 mm 40 in

1 1 mm .04 in

200 mm 400mm 600 mm 800 mm 8.0 in 16.0 in 24.0 in 32.0 in

DISTANCE

DISTANCE

*9 m (30') cables are available by adding suffix W/30 to the model number of any cabled sensor (e.g., QS30LD W/30). A model with a QD connector requires a mating cable (see page 10).

WARNING . . .

Not To Be Used for Personnel Protection

Never use this product as a sensing device for personnel protection. Doing so could lead to serious injury or death.

This product does NOT include the self-checking redundant circuitry necessary to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Printed in USA

09/04

P/N 109027 rev. C

QS30 Series Diffuse-Mode Laser Sensor

QS30 Laser Overview

The QS30 is an easy-to-use, high-performance laser sensor whose many configuration options make it suitable for demanding applications. It provides high-performance sensing in low-contrast applications at relatively long range. It features static, dynamic and single-point TEACH-mode programming, in addition to manual fine adjustment, remote programming and security lockout options. A SETUP mode also may be used to change the sensors output response (see page 8). The sensor features two identically configured outputs, one each NPN and PNP. The sensors compact housing has a large, easy-to-see bar graph display plus bright LEDs for easy programming and status monitoring during operation. The sensor can be side-mounted, using its integral mounting holes, or frontmounted, via its 30 mm threaded barrel.

Yellow Output Conducting Indicator Green Power ON Indicator Programming Push Buttons

Bargraph Display

Switching Threshold

SETUP Status Indicators: Delay Dark Operate Light Operate

Figure 1. QS30 features

QS30 Laser Specifications

Sensing Beam Beam Size at Aperture Laser Classification Supply Voltage Supply Protection Circuitry Delay at Power Up Output Configuration Class 1: 650 nm visible red Class 2: 658 nm visible red Approx. 2 mm Class 1 or Class 2, depending on model (see page 3) 10 to 30V dc (10% max. ripple @ 10% duty cycle) @ 35 mA max current, exclusive of load Protected against reverse polarity, over voltage, and transient voltages 1 second max.; outputs do not conduct during this time Bipolar: 1 current sourcing (PNP) and 1 current sinking (NPN) 150 mA maximum load OFF-state leakage current: < 10 A at 30V dc ON-state saturation voltage: NPN: < 1.0V @ 150 mA load PNP: < 2.0V @ 150 mA load Protected against output short-circuit, continuous overload, transient over-voltages, and false pulse on power up 500 microseconds 70 microseconds 2 push buttons and remote wire Expert Teach programming (two-point static, dynamic, and single-point static) Manually adjust (+/) thresholds (from buttons only) LO/DO and OFF-delay configuration options Push-button lockout (from remote wire only) 8-segment red bargraph: Signal strength relative to switch-point Green LED: Power ON Yellow LED: Output conducting ABS plastic housing; acrylic lens cover IP67, NEMA 6 5-conductor 2 m (6.5') PVC cable, 9 m (30') PVC cable, or 5-pin integral Euro-style quick-disconnect fitting -10 to +50C, 90% relative humidity @ 50C (non-condensing) All models meet Mil. Std. 202F requirements. Method 201A (Vibration: 10 to 60Hz max. double amplitude 0.06", maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G, 11 ms duration, half sine wave.

Output Rating

Output Protection Output Response Time Repeatability

Adjustments

Indicators Construction Environmental Rating Connections Operating Temperature Vibration and Mechanical Shock Certifications

Banner Engineering Corp. Minneapolis, MN U.S.A.

P/N 109027 rev. C

www.bannerengineering.com Tel: 763.544.3164

QS30 Series Diffuse-Mode Laser Sensor

Description of Laser Classes

Class 1 Lasers that are safe under reasonably foreseeable conditions of operation, including the use of optical instruments for intrabeam viewing. Reference 60825-1 Amend. 2 IEC:2001(E), section 8.2. Class 2 Lasers that emit visible radiation in the wavelength range from 400 nm to 700 nm where eye protection is normally afforded by aversion responses, including the blink reflex. This reaction may be expected to provide adequate protection under reasonably foreseeable conditions of operation, including the use of optical instruments for intrabeam viewing. Reference 60825-1 Amend. 2 IEC:2001(E), section 8.2. Class 2 Laser Safety Notes: Low-power lasers are, by definition, incapable of causing eye injury within the duration of the blink (aversion response) of 0.25 seconds. They also must emit only visible wavelengths (400 - 700 nm). Therefore, an ocular hazard can exist only if an individual overcomes their natural aversion to bright light and stares directly into the laser beam. For safe laser use: Do not permit a person to stare at the laser from within the beam. Do not point the laser at a persons eye at close range. Terminate the beam emitted by a Class 2 laser product at the end of its useful path. Locate open laser beam paths either above or below eye level, where practical.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure; per EN 60825. Do NOT attempt to disassemble this sensor for repair. A defective unit must be returned to the manufacturer.

Banner Engineering Corp. Minneapolis, MN U.S.A.

www.bannerengineering.com Tel: 763.544.3164 P/N 109027 rev. C

QS30 Series Diffuse-Mode Laser Sensor

Sensor Programming

Sensor configuration is accomplished through TEACH-mode programming and SETUP mode. After TEACH mode has defined the sensing parameters, SETUP mode may be used to add an OFF-delay or change the light/dark operate status. Manual Adjust may be used to fine-tune the thresholds (see page 7). Two push buttons, Dynamic (+) and Static (-), or the remote wire, may be used to access and set programming parameters. Sensor programming may be accomplished using any of three TEACH methods. A single switching threshold may be programmed using either dynamic (on-the-fly) or static TEACH. In addition, Single-Point Static TEACH may be used to define a sensing window, centered on a single taught condition. Single-Point TEACH programming may be accomplished only statically.

Remote Programming

The Remote Programming function may be used to program the sensor remotely or to disable the push buttons for security. Connect the gray wire of the sensor to ground (0V dc), with a remote programming switch connected between them. Pulse the remote line according to the diagrams in the programming procedures. The length of the individual programming pulses is equal to the value T: 0.04 seconds T 0.8 seconds

Returning to RUN Mode

TEACH and SETUP modes each may be exited either after the 60-second time-out, or by exiting (cancelling out of) the process: In Static TEACH mode, press and hold the Static (-) button (or hold the remote line) for 2 seconds to exit. The sensor returns to RUN mode without saving any new settings. In SETUP mode, press and hold both the Static (-) and Dynamic (+) buttons (or hold the remote line) for 2 seconds to exit. The sensor returns to RUN mode and saves the current setting.

Banner Engineering Corp. Minneapolis, MN U.S.A.

P/N 109027 rev. C

www.bannerengineering.com Tel: 763.544.3164

QS30 Series Diffuse-Mode Laser Sensor

2nd Taught Condition 1st Taught Condition

Two-Point Static TEACH

Two-point TEACH Sets a single switching threshold Threshold is adjustable using + and - buttons (Manual Adjust)

Sensor positions threshold midway between taught conditions

Output OFF Darkest (no signal) Position adjusted by Manual Adjust

Output ON Most Light (saturated signal)

Figure 2. Two-Point TEACH (Light Operate shown) Bargraph LED Number

6 to 8 4 to 5 2 to 3 1

Two-Point Static TEACH is the traditional setup method, used when two conditions can be presented by the user. The sensor locates a single sensing threshold (the switch point) midway between the two taught conditions, with the Output ON condition on one side, and the Output OFF condition on the other (see Figure 2). The first condition taught is the ON condition.The Output ON and OFF conditions can be reversed by changing Light/Dark Operate status in SETUP mode. Two-Point TEACH and Manual Adjust Using Manual Adjust with Two-Point TEACH moves the switching threshold. The lighted LED on the light bar will move to exhibit the relative amount of received signal.

Relative Contrast/ Recommendation

Excellent: Very stable operation. Good: Minor sensing variables will not affect sensing reliability. Low: Minor sensing variables will affect sensing reliability. Marginal: Consider an alternate sensing scheme.

Push Button Access TEACH Mode

Press and Hold

Remote Line

Display Shows

No action required; sensor is ready for 1st TEACH condition.

Power LED: OFF Output LED: ON Bargraph: #5 & 6 Flashing

Learn Output ON Condition

Present Output ON Present Output ON condition condition Click Single-pulse remote line

Power LED: OFF Output LED: OFF Bargraph: #5 & 6 Flashing

T

Present Output OFF condition Click Present Output OFF condition Single-pulse remote line Teach Accepted Power LED: ON Bargraph: One LED flashes to show relative contrast (good contrast shown; see table above) Sensor returns to RUN mode Teach Unacceptable Power LED: OFF Bargraph: #1, 3, 6, 8 flash to show fail Sensor returns to Learn Output ON condition

Learn Output OFF Condition

Banner Engineering Corp. Minneapolis, MN U.S.A.

www.bannerengineering.com Tel: 763.544.3164 P/N 109027 rev. C

QS30 Series Diffuse-Mode Laser Sensor

Dynamic TEACH and Adaptive Thresholds

Teach on-the-fly Sets a single switching threshold Threshold position is adjustable using + and - buttons (Manual Adjust) Dynamic TEACH is best used when a machine or process may not be stopped for teaching. A variation of two-point TEACH, it programs the sensor during actual machine run conditions, taking multiple samples of the light and dark conditions and automatically setting the threshold at the optimum level (see Figure 3). Dynamic TEACH activates the sensors adaptive threshold system, which continuously tracks minimum and maximum signal levels, and automatically maintains centering of the switch point between the light and dark conditions. The adaptive threshold system remains in effect during RUN mode. The adaptive routine saves to non-volatile memory at least once per hour. When Dynamic TEACH mode is used, the Output ON state (light or dark operate) will remain as it was last programmed. To change the Output ON state, use SETUP mode (see page 8). The sensing set point may be adjusted (fine-tuned) whenever the sensor is in RUN mode by clicking the + and - buttons. However, when a manual adjustment is made, the adaptive threshold system is disabled (cancelled).

Darkest (no signal) Darkest Taught Condition Lightest Taught Condition

Sensor positions threshold midway between taught conditions

Output OFF Position adjusted by Manual Adjust

Output ON Most Light (saturated signal)

Figure 3. Two-Point Dynamic TEACH (Light Operate shown) Bargraph LED Number

6 to 8 4 to 5 2 to 3 1

Relative Contrast/ Recommendation

Excellent: Very stable operation. Good: Minor sensing variables will not affect sensing reliability. Low: Minor sensing variables will affect sensing reliability. Marginal: Consider an alternate sensing scheme.

Push Button Access TEACH Mode

Press and Hold

Remote Line

Hold remote line low (to ground) Power LED: OFF Bargraph: #7 & 8 flashing

Display Shows

Learn Output ON and OFF

Present Output ON and OFF conditions Continue to hold

Present Output ON and OFF conditions Continue to hold remote line low (to ground)

Power LED: OFF Bargraph: #7 & 8 flashing

Release

Release remote line/switch

Finish Learning

Teach Accepted Power LED: ON Bargraph: One LED flashes to show relative contrast (good contrast shown; see table above) Sensor returns to RUN mode with new settings Teach Unacceptable Power LED: OFF Bargraph: #1, 3, 6, 8 flash to show fail Sensor returns to RUN mode without changing settings

Banner Engineering Corp. Minneapolis, MN U.S.A.

P/N 109027 rev. C

www.bannerengineering.com Tel: 763.544.3164

QS30 Series Diffuse-Mode Laser Sensor

Sensing window size adjusted by Manual Adjust Output OFF Darkest (no signal) Output ON Single taught point Output OFF Most Light (saturated signal)

Single-Point Static TEACH (Sensing Window)

Sets a single ON condition All other conditions (lighter or darker) result in OFF output Sensing window size (sensitivity) is adjustable using + and - buttons (Manual Adjust) Single-Point TEACH is most useful when a product may not always appear in the same place, or when other signals may appear. Single-Point TEACH programs a sensing window, with the Output ON condition inside the window, and the Output OFF conditions outside the window (see Figure 4). Output ON and OFF conditions can be reversed by changing Light/Dark Operate status in SETUP mode. Single-Point TEACH programming may be accomplished only using Static TEACH. The sensor learns a single sensing condition, and adds switching thresholds above and below the taught condition to create a sensing window. Single-Point TEACH and Manual Adjust Using Manual Adjust with Single-Point TEACH expands or contracts the size of the window. The lighted LEDs on the light bar separate to a greater or lesser extent to exhibit the relative sensing window size.

Figure 4. Single-Point TEACH (Light Operate shown)

Push Button

Remote Line Present Output ON condition Single-pulse remote line Power LED: OFF Output LED: ON (Push Button) Output LED: OFF (Remote) Bargraph: #5 & 6 flashing

Display Shows

Access TEACH Mode

Press and Hold

T

Present Output ON condition Double-click Double-pulse remote line Teach Accepted Power LED: ON Bargraph: #3 & 6 flash to show Single-Point TEACH Sensor returns to RUN mode with new settings Teach Unacceptable Power LED: OFF Bargraph: #1, 3, 6, 8 flash to show fail, then #5 & 6 begin to flash Sensor waits for valid Teach condition

Learn Set Point (Output ON) Condition

T T T

Banner Engineering Corp. Minneapolis, MN U.S.A.

www.bannerengineering.com Tel: 763.544.3164 P/N 109027 rev. C

QS30 Series Diffuse-Mode Laser Sensor

SETUP Mode

SETUP mode is used to change sensor output response for: Light or Dark operate 30-millisecond pulse stretcher (OFF delay), if required. The status LEDs, active only during SETUP mode, indicate the output response configuration when the sensor will be in RUN mode. Four combinations are possible: Light Operate, No Delay Dark Operate, No Delay Dark Operate, 30 ms Delay Light Operate, 30 ms Delay To access SETUP mode and change the output response settings: 1) 2) 3) Press and hold BOTH push buttons (or double-pulse Remote line) until the green LED indicator turns OFF. Click EITHER push button (or pulse Remote line) to toggle through the four possible setting combinations. Press and hold both push buttons (or hold Remote line) until the green LED indicator turns ON, indicating return to RUN mode.

SETUP Status Indicators Press and hold both push buttons to access SETUP mode

Figure 5. SETUP mode

NOTES: If SETUP mode programming is interrupted and remains inactive for 60 seconds, the sensor returns to RUN mode with the most recent settings (i.e., exits and saves current selection). SETUP mode operates in the background, while the outputs are active.

Manual Adjust

Use during RUN mode, accomplished via push buttons only. Two-Point TEACH (Static or Dynamic): Fine-tunes sensing threshold set-point value Press + to increase; press - to decrease Single-Point TEACH: Adjusts sensing window size (tolerance) for the single-point target condition Press + to increase; press - to decrease The lighted bargraph LEDs move to reflect the increase or decrease.

Push Button Disable

In addition to its programming function, Remote Programming may be used to disable the push buttons for security. Disabling the push buttons prevents undesired tampering with the programming settings. Connect the gray wire of the sensor as described on page 4, and four-pulse to either enable or disable the push buttons:

T T T T T T T

Banner Engineering Corp. Minneapolis, MN U.S.A.

P/N 109027 rev. C

www.bannerengineering.com Tel: 763.544.3164

QS30 Series Diffuse-Mode Laser Sensor

Dimensions

Cabled Models QD Models

35.0 mm (1.38") 32.5 mm (1.28")

QS30LD

22.0 mm (0.87")

3.5 mm (0.14")

12.5 mm (0.49")

1.3 mm (0.05")

CLASS 1 LASER PRODUCT

10-30 VDC

5.0 mm (0.20")

Complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50, dated 7-26-01.

33.0 mm (1.30")

44.0 mm (1.73")

2 x 3.3 mm (0.125") max. torque 0.7 Nm (6 in lbs)

M30 x 1.5 Thread max. torque 6 Nm (53 in lbs) with included 30 mm mounting nut

13.0 mm (0.51")

Hookups

Cabled Models

bn bu wh bk gy + 10 - 30V dc 150 mA max. load Remote Teach

QD Models

bn bu wh Load bk Load gy + 10 - 30V dc 150 mA max. load Remote Teach

Load Load

Banner Engineering Corp. Minneapolis, MN U.S.A.

www.bannerengineering.com Tel: 763.544.3164 P/N 109027 rev. C

QS30 Series Diffuse-Mode Laser Sensor

Quick-Disconnect Cables

Style

5-pin Euro-style

straight

Model

MQDC1-506 MQDC1-515 MQDC1-530

Length

2 m (6.5') 5 m (15') 9 m (30')

Dimensions

15 mm (0.6") 44 mm max. (1.7") 38 mm max. (1.5") M12 x 1

Pin-out

White Wire Brown Wire Blue Wire Black Wire Gray Wire

5-pin Euro-style

right-angle

MQDC1-506RA MQDC1-515RA MQDC1-530RA

2 m (6.5') 5 m (15') 9 m (30')

M12 x 1 15 mm (0.6")

38 mm max. (1.5")

Banner Engineering Corp. Minneapolis, MN U.S.A.

10

P/N 109027 rev. C

www.bannerengineering.com Tel: 763.544.3164

QS30 Series Diffuse-Mode Laser Sensor

Brackets

SMBQS30L 14-gauge, stainless steel right-angle bracket for cable models Clearance for M4 (#8) hardware 12 tilt adjustment

20

SMBQS30LT

14-gauge stainless steel for QD models with rightangle cables Tall right-angle mounting bracket 8 Tilt adjustment

20

R35.0mm [R1.38"] 4.3mm [0.17"] 4.5mm [0.18"] 24.0mm [0.95"] 11.0mm [0.43"]

R35.0mm [R1.38"] 44.0mm [1.73"] 4.5mm [0.18"] 24.0mm [0.95"] 22.0mm [0.87"] 4.3mm [0.17"] 11.0mm [0.43"] 44.0mm [1.73"]

22.0mm [0.87"] R1.7mm [R0.07"]

33.0mm [1.3"] 64.4mm [2.54"] R33.0mm [R1.3"] 59.4mm [2.4"]

91.4mm [3.60"]

R33.0mm [R1.3"] 16 86.4mm [3.4"]

24

1.9mm [0.07"]

1.9mm [0.07"]

SMBQS30Y

Heavy-duty die-cast bracket M18 vertical mounting option 8 tilt adjustment with cabled units Nuts and lockwasher included

2 X R 33.0 mm (1.30")

17.0 mm (0.67") 7.0 mm (0.28")

4 X 3.3 mm (0.13")

Other Compatible Mounting Brackets:

56 mm (2.20") 33 mm (1.30")

SMB30MM SMB30SC SMB30A

18.0 mm (0.71") 16.35 mm (0.64") 13.3 mm (0.52") 24.0 mm (0.94") 35.0 mm (1.38")

M18 X 1 26.5 mm (1.04")

Banner Engineering Corp. Minneapolis, MN U.S.A.

www.bannerengineering.com Tel: 763.544.3164 P/N 109027 rev. C

11

QS30 Series Diffuse-Mode Laser Sensor

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or implied.

P/N 109027 rev.C

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 Phone: 763.544.3164 www.bannerengineering.com Email: sensors@bannerengineering.com

You might also like

- Detailed Lesson Plan in EIM 2023Document6 pagesDetailed Lesson Plan in EIM 2023Lester Conztantine100% (2)

- R8605B M300 V2Document268 pagesR8605B M300 V2Rinda_Rayna100% (2)

- NEMA TS2 - OverviewDocument22 pagesNEMA TS2 - OverviewAdalberto MesquitaNo ratings yet

- Q10 Series: FeaturesDocument4 pagesQ10 Series: FeaturesAbdalla FarisNo ratings yet

- World-Beam QS30 Diffuse-Mode Laser Sensor: DatasheetDocument12 pagesWorld-Beam QS30 Diffuse-Mode Laser Sensor: DatasheetrajeevvshishodiNo ratings yet

- LX Series Part-Sensing Light Screen: FeaturesDocument4 pagesLX Series Part-Sensing Light Screen: Featuresduonghieu8xNo ratings yet

- Sensor Banner - BarreiraDocument4 pagesSensor Banner - BarreiraAdailton FreitasNo ratings yet

- Gold Spectrumlab 54Document17 pagesGold Spectrumlab 54Korsarito100% (1)

- Installation Instructions Series 9000 Lasersight Photoelectric SensorsDocument4 pagesInstallation Instructions Series 9000 Lasersight Photoelectric Sensorsy0o0o0No ratings yet

- Banner D10 Analog Discrete OutputsDocument15 pagesBanner D10 Analog Discrete OutputsMemik TylnNo ratings yet

- Installation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDocument4 pagesInstallation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDiauoliver RendersNo ratings yet

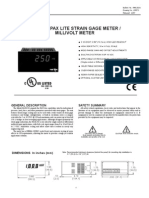

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocument8 pagesModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosNo ratings yet

- Banner SM312DQD DatasheetDocument8 pagesBanner SM312DQD DatasheetemersonmarquezveNo ratings yet

- Banner R GAGE Radar SensorsDocument4 pagesBanner R GAGE Radar SensorsMemik TylnNo ratings yet

- MODEL 6300 & 6320D Visible Range Spectrophotometers: Operating ManualDocument18 pagesMODEL 6300 & 6320D Visible Range Spectrophotometers: Operating ManualHadil HibaNo ratings yet

- LT7 Series Banner OKDocument24 pagesLT7 Series Banner OKThomas CampbellNo ratings yet

- R Series RP RH AnalogDocument14 pagesR Series RP RH AnaloghaggNo ratings yet

- Kew Snap: Instruction ManualDocument24 pagesKew Snap: Instruction ManualClaudio CostaNo ratings yet

- World-Beam QS30ELVC Series: FeaturesDocument12 pagesWorld-Beam QS30ELVC Series: FeaturespopagrioNo ratings yet

- Operator'S Manual: DMXA-Series and DMHA-Series Digital RadiometersDocument14 pagesOperator'S Manual: DMXA-Series and DMHA-Series Digital RadiometersFaculainNo ratings yet

- Function GeneratorDocument37 pagesFunction GeneratorRoberto Angel Lora MartinezNo ratings yet

- Devicenet: T SensorsDocument18 pagesDevicenet: T SensorsEswar Kiran ReddyNo ratings yet

- Banner PICO AMP MD14 AmplifiersDocument8 pagesBanner PICO AMP MD14 AmplifiersMemik TylnNo ratings yet

- 39408, CP25QXVT80 Wengler Level SensorDocument19 pages39408, CP25QXVT80 Wengler Level SensorVigneshkumar JagannathanNo ratings yet

- Instruction Manual: LX2 (W) SeriesDocument20 pagesInstruction Manual: LX2 (W) Series1976gt500No ratings yet

- Inductive Proximity Sensors: GeneralDocument4 pagesInductive Proximity Sensors: GeneralJack Agung SihombingNo ratings yet

- Distance SensorDocument5 pagesDistance Sensortuyetden613No ratings yet

- MS4600 Datasheet en 201507 F266I-E-01Document7 pagesMS4600 Datasheet en 201507 F266I-E-01Eliezer DominguezNo ratings yet

- D12 ExpertDocument12 pagesD12 ExpertaeduardocgNo ratings yet

- Power Meter E51C2Document29 pagesPower Meter E51C2atereñoneNo ratings yet

- ZX Series (ZX-L-N) : Ordering InformationDocument29 pagesZX Series (ZX-L-N) : Ordering Informationkavin22No ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- Banner Q3X Laser Contrast SensorDocument33 pagesBanner Q3X Laser Contrast SensorMark R.No ratings yet

- MeasurIT Quadbeam MSSD53 Transmitter 0803Document2 pagesMeasurIT Quadbeam MSSD53 Transmitter 0803cwiejkowskaNo ratings yet

- RM st60Document2 pagesRM st60Hồ ThànhNo ratings yet

- Magnetic Switches and AccessoriesDocument13 pagesMagnetic Switches and AccessoriesMarko NedicNo ratings yet

- LR-TB5000 IM 96M12739 GB WW 1034-3aDocument12 pagesLR-TB5000 IM 96M12739 GB WW 1034-3aregiomontanus5423No ratings yet

- BEAM355 and BEAM355S: Single-Ended, Reflected-Type Addressable Beam Smoke DetectorsDocument4 pagesBEAM355 and BEAM355S: Single-Ended, Reflected-Type Addressable Beam Smoke DetectorsWilliam DiasNo ratings yet

- EearDocument14 pagesEearOswald NgNo ratings yet

- Sensors: SA6A: Ultrasonic Analog Distance Detection SensorsDocument5 pagesSensors: SA6A: Ultrasonic Analog Distance Detection SensorsRamadhan Adi NugrohoNo ratings yet

- CD732 en CatalogDocument1 pageCD732 en CatalogsigithvacNo ratings yet

- Instalation ManualDocument9 pagesInstalation Manualjoseluisrosglz1678No ratings yet

- Yk 35uv SpecDocument2 pagesYk 35uv SpecHồ ThànhNo ratings yet

- M Series SPEX MonochromatorDocument20 pagesM Series SPEX Monochromatorstre0539100% (1)

- NX-CIF Datasheet en 201506 P55I-E-02 Rev3 1Document14 pagesNX-CIF Datasheet en 201506 P55I-E-02 Rev3 1Lizbeth Soto CastilloNo ratings yet

- Basicos de Caterpillar 3208Document16 pagesBasicos de Caterpillar 3208Elinton De Jesus SarmientoNo ratings yet

- Renishaw OmpsystemDocument2 pagesRenishaw OmpsystemRelu ChiruNo ratings yet

- Sensors Trainers ST 9000 07.06.2023Document2 pagesSensors Trainers ST 9000 07.06.2023Scienscope SDN BHDNo ratings yet

- TMP 8479-LR-ZB250AN AP IM 96M12305 GB WW 1014-1b-796519325Document4 pagesTMP 8479-LR-ZB250AN AP IM 96M12305 GB WW 1014-1b-796519325Isra MarNo ratings yet

- Sie20174 - Reltest 1000Document12 pagesSie20174 - Reltest 1000Royyan Hasmi FadhillahNo ratings yet

- 5 UltrasonicDocument50 pages5 UltrasonicbuturcasNo ratings yet

- CRO 30 MHZDocument31 pagesCRO 30 MHZilesh22No ratings yet

- SecureDocument19 pagesSecureumairkhan2197151No ratings yet

- Banner SL-30 Series PDFDocument6 pagesBanner SL-30 Series PDFdirkz26No ratings yet

- Onkyo CR 305X SMDocument25 pagesOnkyo CR 305X SMRobert JohnsonNo ratings yet

- Long Distance Square Inductive Proximity SensorDocument6 pagesLong Distance Square Inductive Proximity SensorNico SantiNo ratings yet

- LVDT Displacement SensorsDocument8 pagesLVDT Displacement SensorslelixNo ratings yet

- GFG 8219a Doc 1Document20 pagesGFG 8219a Doc 1alexjx65No ratings yet

- Seismic CompressorsDocument6 pagesSeismic CompressorsnauticasmexicoNo ratings yet

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- On The Eurocode 8 Limited Damage Criteria For Non-Structural Elements - Analysis and RequirementsDocument10 pagesOn The Eurocode 8 Limited Damage Criteria For Non-Structural Elements - Analysis and RequirementsSoós MártiNo ratings yet

- First Quarter-Gr4-Ww-Pt-With-Answers-KeyDocument35 pagesFirst Quarter-Gr4-Ww-Pt-With-Answers-KeyEurika LimNo ratings yet

- Linux CommandsDocument9 pagesLinux Commandsprat jariwala100% (1)

- Defining Reservoir Drive MechanismsDocument2 pagesDefining Reservoir Drive MechanismsJuan Daniel SidaurukNo ratings yet

- Structural Engineering Other Technical Topics - Eng-TipsDocument2 pagesStructural Engineering Other Technical Topics - Eng-TipsMohammad AasimuddinNo ratings yet

- Book of Best PracticesDocument117 pagesBook of Best PracticesMoeen Khan Risaldar100% (2)

- Small Scale FadingDocument83 pagesSmall Scale FadingAshu1803No ratings yet

- VSL Primary Gas StandardsDocument59 pagesVSL Primary Gas Standards分析室信箱No ratings yet

- PM TLB 315SJ MKII RevBDocument594 pagesPM TLB 315SJ MKII RevBHANNESNo ratings yet

- Airnet Catalog enDocument54 pagesAirnet Catalog enJoseNo ratings yet

- Clap Switch Circuit Electronic Project Using 555 TimerDocument2 pagesClap Switch Circuit Electronic Project Using 555 TimerZnutTunz100% (1)

- Doosan DBC130 Alarms ManualDocument223 pagesDoosan DBC130 Alarms ManualDarryl Hardt100% (3)

- Loss of Anchorage of Miniscrews: A 3-Dimensional Assessment: Original ArticleDocument8 pagesLoss of Anchorage of Miniscrews: A 3-Dimensional Assessment: Original ArticlePrevita NindaNo ratings yet

- Photo R280-R285-R290Document125 pagesPhoto R280-R285-R290SattittecInfomática100% (1)

- Atoms and MoleculesDocument12 pagesAtoms and MoleculesKshithij R KikkeriNo ratings yet

- 920 vpm2Document54 pages920 vpm2Wasim ShahzadNo ratings yet

- Electrical Diagrams and DrawingsDocument3 pagesElectrical Diagrams and DrawingsAnto JcNo ratings yet

- FX Stiff Debug Log FileDocument8 pagesFX Stiff Debug Log Filegman4dx266No ratings yet

- Manual Dark LegionsDocument31 pagesManual Dark Legionskrycov100% (2)

- Rohit Maheshwari: Carrer ObjectiveDocument2 pagesRohit Maheshwari: Carrer ObjectiverohitkotaNo ratings yet

- Laboratory Assessment ChecklistDocument28 pagesLaboratory Assessment ChecklistPanneer Selvam100% (2)

- Different Types of MillsDocument39 pagesDifferent Types of Millsrashm006ranjan100% (1)

- CP 1Document1 pageCP 1shameer bashaNo ratings yet

- Technical Schedule A To D & H Pkg-2Document69 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

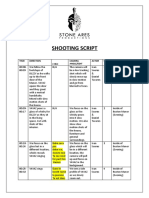

- Unit 8 - Shooting ScriptDocument5 pagesUnit 8 - Shooting Scriptapi-660822705No ratings yet

- CGa Series 3 Boiler Manual 0520Document68 pagesCGa Series 3 Boiler Manual 0520Sonaina KhanNo ratings yet