Professional Documents

Culture Documents

2010 Impreg Brochure - Lubricants

2010 Impreg Brochure - Lubricants

Uploaded by

varundodhiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2010 Impreg Brochure - Lubricants

2010 Impreg Brochure - Lubricants

Uploaded by

varundodhiaCopyright:

Available Formats

IMPREGNATING OILS & GELS

Premium Lubrication for Sintered Metal Bearings

IMPREGNATING OILS & GELS

Introduction

Ultrachem is well known worldwide for its unique formulations of synthetic impregnating oils designed for use in vacuum impregnated powder metal (sintered) sleeve bearings, often used in sub-fractional hp electric motors. These are the motors that consumers nd every day in their automobiles (window lift motors, car seat motors, wiper motors, blower motors, etc.), in all kinds of appliances including power tools, garbage disposals, ceiling fans, fans and blowers used in business machines, range hoods, garage door openers and so on. Any small motor not using ball bearings will likely use powder metal sleeve bearings. Many of these bearings also have a felt wick or reservoir in the shape of a donut around the outer perimeter of the bearing. The bearings are porous due to their make-up of powder metal. Popular choices are usually bronze bearings or iron/graphite bearings. Proprietary blends of many different metals are also found. They are then sintered or red in high temperature ovens until the powders begin to melt together. The bearings are then sized and placed in baskets in a vacuum impregnator with the impregnating oil. Typically, the oil is heated to ~150 F. As the vacuum is formed, the oil lls the many pores in the bearing structure. As the motor shaft starts to spin on the inner diameter (id) of the bearing the heat draws the oil out to form a boundary of lubrication. When properly sized and lubricated the shaft is actually spinning on a lm of oil. Therefore, the selection of the oil is of the utmost importance. When the motor is turned off, the bearing cools down and capillary action draws the oil back into the bearing until the next time the motor is turned on. Ultrachem has pioneered the use of unique additives in impregnating oils to control oil migration and spread, as well as performance and long life. Let Ultrachem formulate an oil to meet your specic needs. Graphite (Denoted by G or 5P) Ultrachem has been instrumental in developing impregnating oils fortied with solid lubricant additives such as colloidal graphite. The properly sized graphite particles will actually travel through the porous structure of the bearing and provide a physical solid lubricant on the id of the bearing on cold start-up conditions. Studies have shown that the average pore size of a pm bearing to be 20 to 40 microns in size. The average particle size of our colloidal graphite is approximately 1.0 micron. The addition of graphite has proven of importance in many automobile applications where most motors are required to start at 40. Additional benets can be found at high speeds associated with motors used in applications such as vacuum cleaners, routers and others. Hand held power tools also benet, as any other motor that may sit idle for long periods of time. The Pressure/Velocity value can also be increased when using colloidal graphite with many of our impregnating oils. The graphite can stay in suspension for many months in most of our oils. Some of the heavier Omnilubes may require agitation prior to impregnation. That will not affect the nal quality of the product once it is impregnated. Ultrachem also manufactures an UltraGel that is designed for use in a pm bearing as a lubricant and an OmniGel and SynGel that are designed for use outside the bearing as back-up lubricant for the impregnating oil.

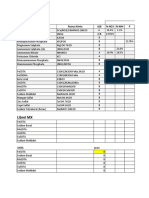

TYPE OF SERVICE Economical Performance General Performance

Fans, Blowers, Vacuum Cleaners, Power Tools

SERVICE 1) TEMPERATURES

99C to -10C 210F to 15F

BASE OIL

Mineral Oil

PRODUCT

A-110, A-110-5P A-121, A-121-5P

155C to -40C 310F to 40F

Synthetic Hydrocarbon

Omnilube 180, 300, 350

Low Temperature Performance

Refrigerator Defroster Fans, Ice Maker Motors

105C to -50C 220F to -60F

Synthetic Hydrocarbon

Omnilube 60, 100

High Temperature Performance

Ovens, Vertical Shaft Designs, Slow Bearing Speed Applications, Power Tools

Up to 177C Up to 350F

Synthetic Hydrocarbon

Omnilube 550, 850

Food Grade Applications

Processors, Blenders, Blowers, Reduced Starting Torque

Various

Synthetic Hydrocarbon

Omnilube 60, 100 Omnilube Non-Tox 520, 280, 370

General Performance

Economical & Versatile

163C to -29C 325F to -20F

Synthetic Hydrocarbon/Ester

Chemlube 626, 626G

General Performance

The Original Synthetic Impregnating Fluids, Wide Application Range

177C to -51C 350F to -60F

Ester

Chemlube 201, 207, 645

Premium High Temperature Performance

Widely Used in Automotive Applications, Wiper Motors, Seat Motors, Window Lift Motors, Radiator Fans, Fireplace Inserts

Up to 205C Up to 400F

Ester

Chemlube 209, 217, 5072 Syntroil 220, 330, 440, 555

High Load Performance

Gear Sets, High Load Applications

205C to -35C 400F to -30F

PAG

Chemlube 62, 90, 128 180, 650

IMPREGNATING OILS & GELS

PERFORMANCE BENEFITS

Economical Widely Used for Over 40 Years Available with Graphite

PERFORMANCE BENEFITS

Omnilube Impregnating Fluids Offer: Good Compatibility with Plastics2) and Elastomers Qualied for Either USDA H-1 (Incidental Contact) or H-2 (No Direct Contact) for Food Grade Applications Compatible with All Sintered Bearing Materials Most Omnilube Products are Available with Graphite to Prevent Dry Start-Up Superior Anti-Corrosion Protection Wide Viscosity Range Available

Polar Tendencies for Metal Surface Protection High VI Leading to Reduced Viscosity Change with Temperature Excellent Low-Friction Torque Generally Not Recommended For Use with Plastics or Elastomers5) Excellent Performance Over a Wide Temperature Range Polar Tendency to Wet Metal Surface Excellent Anti-Wear Protection Superior Anti-Corrosion Protection The Industry Standard for Performance in High-Temperature Applications Highest Load-Carrying Capabilites Superior Anti-Corrosion Protection and Resistance to Deposit Formation Will Not Mix with Petroleum Oils; Limited Synthetic Compatibility

ULTRACHEM PRODUCT

RESERVOIR LUBRICANT

BASE OIL/GEL

Omnilube Oil4)

OmniGel 300-1, 300-2

Synthetic Hydrocarbon/Silicate

Chemlube or Syntroil Oil

SynGel 217-1, 217-2

Ester/Silicate

Omnilube Oil

UltraGel 300-00

Synthetic Hydrocarbon/ Aluminum Complex

Footnotes: 1) Service temperatures are dependent on many variables and are intended for help in selecting a suitable product. 2) The Omnilube oils have been tested with a large variety of plastics over the years, but it is always best to test them on your particular plastic. We can provide a sample free of cost for evaluations conducted by you or your plastic vendor. 3) The addition of our graphite to some oils helps provide a solid lubricant to prevent dry start-up where a lot of wear can occur. Graphite is intended for bearings only and not bearing reservoirs. Best if used in bearings with no free graphite. 4) Not for use with Chemlube PAG oils. 5) Contact us for our ester compatibility guide.

IMPREGNATING OILS & GELS

OmniGels and SynGels are specially thickened versions of our impregnating oils. They are specically designed for use as replacements for felt wicks and greases used previously as back-up lubrication for sintered metal; bearings. They purposely release lubricant as required to the outside diameter of the bearing and replenish bearing oil lost through migration or evaporation. These gels extend the life of the bearing and are excellent for automated high speed reservoir injection.

UltraGel is specically intended to be impregnated into the bearing to control the release of the oil to the inner diameter of the bearing without releasing excess oil that may be lost down the motor shaft and not recovered.

Contact Info: Ultrachem, Inc. 900 Centerpoint Blvd. New Castle, DE 19720 P: 302.325.9880 F: 302.325.0335 E: info@ultracheminc.com W: www.ultracheminc.com

6

FOOD GRADE LUBRICANTS

Premium Synthetic Lubricants for the Food Manufacturing & Processing Industry

GAS COMPRESSION LUBRICANTS

Premium Synthetic Lubricants for Gas Compression & Engine Applicaiton

HIGH PRESSURE COMPRESSOR LUBRICANTS

Premium Synthetic Lubricants for High Pressure Compression Applications

You might also like

- 8.4 HW PropertiesRectRhomSquPracticeDocument2 pages8.4 HW PropertiesRectRhomSquPracticeERVIN DANCANo ratings yet

- Basic GreaseDocument20 pagesBasic Greasefahreez100% (3)

- Drop and Hardness Tests of GreasesDocument17 pagesDrop and Hardness Tests of GreasesJohn Mace VidamoNo ratings yet

- Stats Tools PackageDocument44 pagesStats Tools PackageMuhammad Asif Khan100% (1)

- Bearing Importance of LubricationDocument5 pagesBearing Importance of LubricationgeppaNo ratings yet

- Mobil Glygoyle Series PDFDocument4 pagesMobil Glygoyle Series PDFKui KimNo ratings yet

- GL XX Mobil Glygoyle SeriesDocument5 pagesGL XX Mobil Glygoyle SeriesignaciovidalNo ratings yet

- 118 Worm Gear LubesDocument4 pages118 Worm Gear LubesWajahat RasoolNo ratings yet

- Importance of LubricationDocument14 pagesImportance of LubricationBijendra PrajapatiNo ratings yet

- C1 - 2014 GS OilDocument2 pagesC1 - 2014 GS OilNathan KornNo ratings yet

- LE Pyroshield 9011 XHDocument4 pagesLE Pyroshield 9011 XHSanjeev SharmaNo ratings yet

- Elsvare Gas Turbine Lube OilDocument36 pagesElsvare Gas Turbine Lube Oilshaonaa100% (1)

- Lubrication Selection For Enclosed Gear DrivesDocument16 pagesLubrication Selection For Enclosed Gear DrivesGian TeryNo ratings yet

- 5354 Greases 2010 03Document6 pages5354 Greases 2010 03Gajendra SorenNo ratings yet

- Klübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsDocument8 pagesKlübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsFabrizzio_ValerNo ratings yet

- Gearbox LubricationDocument5 pagesGearbox LubricationTaranpreet Singh100% (1)

- Turbine LubricationDocument3 pagesTurbine Lubricationpeach5100% (1)

- Lubricants - Always Important-Sometimes EssentialDocument2 pagesLubricants - Always Important-Sometimes EssentialGordinhorsNo ratings yet

- Mobil - Glygoyle - 460Document3 pagesMobil - Glygoyle - 460the anhNo ratings yet

- Guide To Electric Motor Bearing LubricationDocument7 pagesGuide To Electric Motor Bearing LubricationUber_Konstruktor100% (2)

- Lubrication of Rolling Bearings Tips and AdviceDocument44 pagesLubrication of Rolling Bearings Tips and AdvicealanrinNo ratings yet

- Tribology in Marine ApplicationsDocument19 pagesTribology in Marine ApplicationsNeeraj RajpalNo ratings yet

- Mobil SHC™ Gear SeriesDocument4 pagesMobil SHC™ Gear SeriesJeefNo ratings yet

- Lubricants For Elactric Appli.Document6 pagesLubricants For Elactric Appli.Hariharan JayaramanNo ratings yet

- Worm Gear LubricationDocument4 pagesWorm Gear LubricationEr Mishal GandhiNo ratings yet

- Guide To EM Bearing LubricationDocument12 pagesGuide To EM Bearing LubricationAnonymous alQXB11EgQ100% (1)

- LM BrochureDocument52 pagesLM BrochureShylesh RaveendranNo ratings yet

- Rust X Brouser PDFDocument4 pagesRust X Brouser PDFPradeep KatiyarNo ratings yet

- Understanding Vacuum Pump LubricantsDocument21 pagesUnderstanding Vacuum Pump LubricantsengrsurifNo ratings yet

- UntitledDocument28 pagesUntitledapi-133947076No ratings yet

- Bearing SpecificationDocument6 pagesBearing SpecificationMuhammad Munirul AlamNo ratings yet

- TEXOL Brochure 2023Document8 pagesTEXOL Brochure 2023Texol BangladeshNo ratings yet

- Chevron Sri Grease NL Gi 2Document2 pagesChevron Sri Grease NL Gi 2msharathsNo ratings yet

- Speciality Lubricants For Machine ToolsDocument15 pagesSpeciality Lubricants For Machine ToolsDarmawan PutrantoNo ratings yet

- PSC Oilfield Lubrication RangeDocument27 pagesPSC Oilfield Lubrication RangeProject Sales CorpNo ratings yet

- Lubrication GuideDocument28 pagesLubrication GuideVarun PineamaneniNo ratings yet

- ENB 04 0555 Rev B Bearing Lubrication PDFDocument5 pagesENB 04 0555 Rev B Bearing Lubrication PDFIrwan SyahNo ratings yet

- Steel Industry PackageDocument9 pagesSteel Industry Packagebatung144100% (1)

- Klüber Klubersynth Gh6-680Document8 pagesKlüber Klubersynth Gh6-680Chiranjeevi VijayaraghavanNo ratings yet

- Klbersynth - GH - 6-460 - 012163 - PI - EN - enDocument8 pagesKlbersynth - GH - 6-460 - 012163 - PI - EN - enChiranjeevi VijayaraghavanNo ratings yet

- Approved Lubrication DDocument2 pagesApproved Lubrication DMostafa MohamedNo ratings yet

- Presentation On GreaseDocument29 pagesPresentation On GreaseAshishNo ratings yet

- What You Need To Know When Selecting Gear OilsDocument5 pagesWhat You Need To Know When Selecting Gear OilsmarciofelipessantosNo ratings yet

- CHY1005 Module 02 - TRIBOLOGY Class NotesDocument77 pagesCHY1005 Module 02 - TRIBOLOGY Class Notessrikar princeNo ratings yet

- Guide To Electric Motor Lubrication ExxonDocument0 pagesGuide To Electric Motor Lubrication Exxont_syamprasad100% (1)

- Grease Girth GearDocument32 pagesGrease Girth Gearsatfas100% (2)

- Transaxle OilDocument11 pagesTransaxle OilSunilkumar ReddyNo ratings yet

- SKF LGMT 3 - Excellent Rust Inhibiting PropertiesDocument2 pagesSKF LGMT 3 - Excellent Rust Inhibiting PropertiesArnold StevenNo ratings yet

- HR Idol Press Gear 680Document2 pagesHR Idol Press Gear 680Shital PatelNo ratings yet

- The Castrol Range of Industrial Lubricants High - 1Document40 pagesThe Castrol Range of Industrial Lubricants High - 1Shan Rana100% (1)

- Oils & LubricationDocument24 pagesOils & Lubricationntshilamulele51No ratings yet

- A Study of Automotive Gear LubesDocument28 pagesA Study of Automotive Gear LubesgerardoctavaraNo ratings yet

- The How and Why of Lubricant Selection and Consolidation For Rotating MachineryDocument7 pagesThe How and Why of Lubricant Selection and Consolidation For Rotating MachineryRepositorio MantenimientoNo ratings yet

- Lubricants WPS OfficeDocument2 pagesLubricants WPS OfficePanguisa Omas FeNo ratings yet

- Pennzoil Premium Wheel Bearing Grease 707lDocument2 pagesPennzoil Premium Wheel Bearing Grease 707lMohd Firdaus IsmailNo ratings yet

- GREASEDocument12 pagesGREASEKarthikeyanNo ratings yet

- Ko En093eupDocument2 pagesKo En093eupEmir MuslićNo ratings yet

- WWWDocument56 pagesWWWChaiwat PhollookinNo ratings yet

- USL Fluid 101 EbookDocument8 pagesUSL Fluid 101 EbookWilliam NasserNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Taiwan Panorama 2023 NovDocument128 pagesTaiwan Panorama 2023 NovKwang HwaNo ratings yet

- Eaton Fuller FRO 15210C Transmission Parts ManualDocument34 pagesEaton Fuller FRO 15210C Transmission Parts ManualCamiloNo ratings yet

- Ivf NiceDocument22 pagesIvf NiceDianne LabisNo ratings yet

- Cheng 2021Document13 pagesCheng 2021Karen GarzónNo ratings yet

- Power of The BloodDocument14 pagesPower of The BloodEturnal BrandsNo ratings yet

- Clean Room CatalogueDocument20 pagesClean Room CatalogueKISHANSINGH YADAVNo ratings yet

- QuadraPure Metal Scavengers User GuideDocument6 pagesQuadraPure Metal Scavengers User Guidehomo_erosNo ratings yet

- CBSE Sample Papers For Class 3 English - Mock Paper 1Document6 pagesCBSE Sample Papers For Class 3 English - Mock Paper 1Rita KumariNo ratings yet

- Solid State Physics JEST 2012-2019Document7 pagesSolid State Physics JEST 2012-2019Biswajit BhowmickNo ratings yet

- Sabbaba MenuDocument8 pagesSabbaba Menuaresha6881No ratings yet

- 10 Most Powerful Greek GodsDocument4 pages10 Most Powerful Greek GodsIris Milagro MembreñoNo ratings yet

- Excel Meracik Nutrisi Bandung 11 Feb 2018Document30 pagesExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNo ratings yet

- Instruments Obs & Gynea PDFDocument19 pagesInstruments Obs & Gynea PDFVibes Usmlee100% (1)

- Prof. D. Pulla RaoDocument20 pagesProf. D. Pulla RaoAppan Kandala VasudevacharyNo ratings yet

- Sig Decomp MproxDocument60 pagesSig Decomp MproxOri CarmiNo ratings yet

- Novice DocumentsDocument100 pagesNovice DocumentsD G Mattichak, Jr100% (3)

- The Effect of Elevated Temperature On ConcreteDocument204 pagesThe Effect of Elevated Temperature On Concretexaaabbb_550464353100% (1)

- Addition of Green Tea Extract in Fructose Egg Yolk Milk Diluter On The Quality and Antioxidant ContenDocument9 pagesAddition of Green Tea Extract in Fructose Egg Yolk Milk Diluter On The Quality and Antioxidant Conten3129 NashihahNo ratings yet

- Precast Concrete Technician Study GuideDocument37 pagesPrecast Concrete Technician Study Guidefree4bruceNo ratings yet

- Analysis and Optimization of Spiral Plate Heat Exchanger Using Computational Fluid DynamicsDocument10 pagesAnalysis and Optimization of Spiral Plate Heat Exchanger Using Computational Fluid DynamicsIJRASETPublicationsNo ratings yet

- Floor 76: Sword Art Online: Infinity Moment - Guide (Uncompleted)Document30 pagesFloor 76: Sword Art Online: Infinity Moment - Guide (Uncompleted)Sony Kasujaya100% (1)

- 36 - 4 - New York - 08-91 - 1478Document8 pages36 - 4 - New York - 08-91 - 1478Ovo OjasNo ratings yet

- Slag Splashing Technique in Converter OperationDocument3 pagesSlag Splashing Technique in Converter Operationrabikant_25No ratings yet

- Numerical Analysis of A Bisection-Exclusion Method To Find Zeros of Univariate Analytic FunctionsDocument39 pagesNumerical Analysis of A Bisection-Exclusion Method To Find Zeros of Univariate Analytic FunctionsLucas SantosNo ratings yet

- WiproDocument21 pagesWiproAnu TanjaNo ratings yet

- TXP® BTC: GeometryDocument2 pagesTXP® BTC: GeometryLeonardo BarriosNo ratings yet

- Mens TshirtDocument15 pagesMens TshirtTrung Hieu NguyenNo ratings yet

- Christology in The Political Theology of Oliver O'Donovan PDFDocument16 pagesChristology in The Political Theology of Oliver O'Donovan PDFsemiteologicoNo ratings yet