Professional Documents

Culture Documents

Control Charts For Variables

Control Charts For Variables

Uploaded by

Jassfer AlinaCopyright:

Available Formats

You might also like

- Weather Prediction: Project 1 ReportDocument42 pagesWeather Prediction: Project 1 ReportDhruv Goyal88% (16)

- Chapter 5. Control Charts For VariablesDocument38 pagesChapter 5. Control Charts For VariablesJigar Patel's100% (2)

- Control Charts For Variables and AttributesDocument43 pagesControl Charts For Variables and AttributesTARUN MAHAWERNo ratings yet

- Control Charts For Variables: HapterDocument71 pagesControl Charts For Variables: Haptervimal NegiNo ratings yet

- MEC462B-IQC-Control Charts For VariablesDocument21 pagesMEC462B-IQC-Control Charts For VariablesANH NGUYỄN ĐỨCNo ratings yet

- Xbar and R Chart Formula and ConstantsDocument13 pagesXbar and R Chart Formula and ConstantsklausgreatevilNo ratings yet

- Statistical Quality Control: Simple Applications of Statistics in TQMDocument57 pagesStatistical Quality Control: Simple Applications of Statistics in TQMHarpreet Singh PanesarNo ratings yet

- Statistical QCDocument57 pagesStatistical QCJigar NagvadiaNo ratings yet

- Statistical Quality Control Charts For VariablesDocument15 pagesStatistical Quality Control Charts For VariablesChetal BharaiNo ratings yet

- Following Are The Measurement Values in Control Phase of The ProjectDocument9 pagesFollowing Are The Measurement Values in Control Phase of The ProjectSai Rama VizagNo ratings yet

- Satistical Quality ControlDocument21 pagesSatistical Quality Controladitya v s sNo ratings yet

- Metrology Control ChartsDocument14 pagesMetrology Control ChartsRaghu KrishnanNo ratings yet

- WB SpcxbarandrintroDocument4 pagesWB SpcxbarandrintromitiwanaNo ratings yet

- Control Charts For VariablesDocument15 pagesControl Charts For VariablesZahurul IslamNo ratings yet

- Lecture On C - ChartDocument20 pagesLecture On C - Chart191329No ratings yet

- Control Charts: Walter ShewartDocument7 pagesControl Charts: Walter ShewartAli RazaNo ratings yet

- Variables Control ChartDocument22 pagesVariables Control Chartbobby510No ratings yet

- Table Used in Control ChartDocument10 pagesTable Used in Control ChartRonillo PormonNo ratings yet

- Control Charts For The Mean and RangeDocument2 pagesControl Charts For The Mean and RangeRabia ZulqarnainNo ratings yet

- Name: Sub: STD: Roll No: : Chandni K Jadav ARA 14Document15 pagesName: Sub: STD: Roll No: : Chandni K Jadav ARA 14Nirav JadavNo ratings yet

- 5.2 Process Capability Analysis Rev2ADocument8 pages5.2 Process Capability Analysis Rev2APollyNo ratings yet

- Analysis Quality Control ChartsDocument5 pagesAnalysis Quality Control Chartsnaviyo8081No ratings yet

- Controlchart: SyntaxDocument6 pagesControlchart: SyntaxSaidur Rahman SajibNo ratings yet

- Unit - 2: Statistical Process Control in IndustryDocument103 pagesUnit - 2: Statistical Process Control in IndustrySUJITHA NNo ratings yet

- Process CapabilityDocument5 pagesProcess CapabilityLibyaFlowerNo ratings yet

- Chap06 CC VarDocument68 pagesChap06 CC Varryan pramanda unsamNo ratings yet

- PQT TP 1F PDFDocument21 pagesPQT TP 1F PDFToastedBaconNo ratings yet

- Iem PDFDocument11 pagesIem PDFNalabolu Eshwari EshwariNo ratings yet

- X-Bar R ChartDocument3 pagesX-Bar R ChartShanmugam BalasubramaniamNo ratings yet

- X-Bar and S Charts: NCSS Statistical SoftwareDocument26 pagesX-Bar and S Charts: NCSS Statistical Softwareanon_123371106100% (1)

- X Bar Chart: Key ApproachesDocument3 pagesX Bar Chart: Key ApproachesSajid SarwarNo ratings yet

- Calculation of Control Limits For The ChartDocument3 pagesCalculation of Control Limits For The ChartRobinson ANo ratings yet

- PR 4-6Document9 pagesPR 4-6mech bhabhaNo ratings yet

- Control ChartDocument10 pagesControl Chartfbise12345sargodhaNo ratings yet

- Control Charts: Production and Operations ManagementDocument37 pagesControl Charts: Production and Operations ManagementNeelima AjayanNo ratings yet

- 3 - Control Charts For VariablesDocument54 pages3 - Control Charts For VariablesWilliam BautistaNo ratings yet

- 0510552-Chapter 6 Charts in The Analytical Laboraqtory-FinalDocument128 pages0510552-Chapter 6 Charts in The Analytical Laboraqtory-FinalRadwan AjoNo ratings yet

- Normal Distribution and Regression NotesDocument71 pagesNormal Distribution and Regression Notescassandraolson.kya07No ratings yet

- Lecture 17 Control ChartsDocument26 pagesLecture 17 Control Chartstanveer_buitemsNo ratings yet

- IQC1Document12 pagesIQC1Jom Gonzales SantillanNo ratings yet

- Control CharsDocument11 pagesControl CharsbasslaborielNo ratings yet

- A Concise Presentation: Mr. Deepak SarangiDocument20 pagesA Concise Presentation: Mr. Deepak SarangiGAJENDRA KUMARNo ratings yet

- Control ChartsDocument25 pagesControl ChartsIsza Marie N. SocorinNo ratings yet

- A Concise Presentation: Mr. Deepak SarangiDocument20 pagesA Concise Presentation: Mr. Deepak SaranginikunjNo ratings yet

- SQC-SS, ModulesDocument15 pagesSQC-SS, ModulesSumon KumarNo ratings yet

- Method For Computing R-CHARTDocument14 pagesMethod For Computing R-CHARTSURYAPRAKASH GNo ratings yet

- Chapter Four Control Charts For Variables-I: Implementing SPC in A Quality Improvement ProgramDocument10 pagesChapter Four Control Charts For Variables-I: Implementing SPC in A Quality Improvement ProgramComputer Maintainance Hardware and softwareNo ratings yet

- TQM Unit 3Document106 pagesTQM Unit 3Shibamay MitraNo ratings yet

- Statistical Quality Control 2Document34 pagesStatistical Quality Control 2Tech_MXNo ratings yet

- Chapter 3 Control Chart For VariablesDocument66 pagesChapter 3 Control Chart For VariablesRitam PalNo ratings yet

- Statistical Quality Control: Dr. Eng. Mohamed ElwakilDocument60 pagesStatistical Quality Control: Dr. Eng. Mohamed ElwakilOmar Abdelsameia GalAllahNo ratings yet

- Statistical Quality Control PDFDocument82 pagesStatistical Quality Control PDFInshal KhanNo ratings yet

- Chapter 4 Statistial Process Control (SPC)Document22 pagesChapter 4 Statistial Process Control (SPC)Yousab CreatorNo ratings yet

- Statistical Quality ControlDocument82 pagesStatistical Quality ControlShahmirBalochNo ratings yet

- Attribute Control ChartDocument26 pagesAttribute Control ChartRohit JanardananNo ratings yet

- Quality Control, Basic Control ChartsDocument20 pagesQuality Control, Basic Control Chartsmalyduzy0% (1)

- Class 3 NotesDocument209 pagesClass 3 NotesJason FischerNo ratings yet

- Chapter 4 Statistial Process Control (SPC)Document22 pagesChapter 4 Statistial Process Control (SPC)Yousab CreatorNo ratings yet

- A Study On The False Alarm Rates Of, EWMA and CUSUM Control Charts When Parameters Are EstimatedDocument5 pagesA Study On The False Alarm Rates Of, EWMA and CUSUM Control Charts When Parameters Are Estimatedvista10No ratings yet

- (Progress in Soil Science) Viliam Novák (Auth.) - Evapotranspiration in The Soil-Plant-Atmosphere System-Springer Netherlands (2012)Document262 pages(Progress in Soil Science) Viliam Novák (Auth.) - Evapotranspiration in The Soil-Plant-Atmosphere System-Springer Netherlands (2012)Nicolás Alberto Pereira LawrenceNo ratings yet

- 302 Blom - 0127130504 Final Paper 4 18 13 PDFDocument9 pages302 Blom - 0127130504 Final Paper 4 18 13 PDFBro EdwinNo ratings yet

- Plant Analysis ProceduresDocument187 pagesPlant Analysis ProceduresAnastry Galuh KhusikaNo ratings yet

- DDDDDDDocument2 pagesDDDDDDapi-254428474No ratings yet

- The Geology of European Coldwater Coral Carbonate MoundsDocument33 pagesThe Geology of European Coldwater Coral Carbonate MoundsTuw DasNo ratings yet

- SOCI115 Summary 5Document5 pagesSOCI115 Summary 5Muhd ZahinNo ratings yet

- Past Tense Contrast WorkshopDocument3 pagesPast Tense Contrast WorkshopJose OvaexNo ratings yet

- EnergyPrimer LRDocument185 pagesEnergyPrimer LRbblianceNo ratings yet

- Comparatives and Superlatives PDFDocument4 pagesComparatives and Superlatives PDFLenapsNo ratings yet

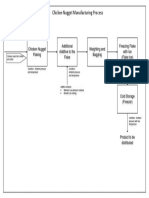

- Chicken Nugget Manufacturing ProcessDocument1 pageChicken Nugget Manufacturing ProcessFitriahFindiatiNo ratings yet

- Corrosion Protection: General Information: Industry AirDocument1 pageCorrosion Protection: General Information: Industry AirMAI_QualityNo ratings yet

- FreeteeDocument14 pagesFreeteemantascitaNo ratings yet

- Confidence IntervalsDocument16 pagesConfidence IntervalsMuaiena Khatun RunaNo ratings yet

- Weather Physics PDFDocument2 pagesWeather Physics PDFAnti CorruptionNo ratings yet

- We Are Not Afraid To DieDocument4 pagesWe Are Not Afraid To Diesai mithraNo ratings yet

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNo ratings yet

- Cymbopogon Winterianus:: An Important Species For Essential Java Citronella Oil and Medicinal ValueDocument4 pagesCymbopogon Winterianus:: An Important Species For Essential Java Citronella Oil and Medicinal ValueKaran Kumar VermaNo ratings yet

- Cloud PhysicsDocument13 pagesCloud PhysicsJatin SoniyaNo ratings yet

- FIGHTING FANTASY Caverns of The Snow WitchDocument45 pagesFIGHTING FANTASY Caverns of The Snow Witchjasc0_hotmail_it100% (4)

- Lab 20exp 200 PDFDocument4 pagesLab 20exp 200 PDFCherieCheungNo ratings yet

- CH02 Precipitation 2020Document53 pagesCH02 Precipitation 2020SUNNYWAY CONSTRUCTIONNo ratings yet

- WeatherDocument12 pagesWeathersnehamanepatil1819No ratings yet

- Synagro Nuisance Mitigation and Control Plan For Plainfield Township Biosolids Plant Land Development PlanDocument135 pagesSynagro Nuisance Mitigation and Control Plan For Plainfield Township Biosolids Plant Land Development PlanDickNo ratings yet

- Sustainable Development and Environmental IssuesDocument6 pagesSustainable Development and Environmental IssuesAbhijit JadhavNo ratings yet

- WallerDocument23 pagesWallerZain ZearkNo ratings yet

- Song Sheet o SusannaDocument3 pagesSong Sheet o SusannaXohy Wade0% (1)

- Trench WarfareDocument28 pagesTrench Warfareapi-300259780No ratings yet

- Block 1Document96 pagesBlock 1Smriti SaxenaNo ratings yet

- U4S - 3. WeatherDocument2 pagesU4S - 3. WeatherMaru C.No ratings yet

Control Charts For Variables

Control Charts For Variables

Uploaded by

Jassfer AlinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Charts For Variables

Control Charts For Variables

Uploaded by

Jassfer AlinaCopyright:

Available Formats

Control Charts for Variables

Introduction

A quality characteristic that is measured on a numerical scale is called a variable. dimension length, width weight temperature volume

A quality characteristic that is a variable, it is usually necessary to monitor both the mean value of the quality characteristic and its variability. Control of the process average or mean quality level is usually done with the control chart for means or x chart. Process variability can be monitor with either a control chart for the standard deviation, called the s chart, or a control chart for the range, called an R chart.

The need for controlling both process mean and process variability

CONTROL CHART FOR x AND R

Statistical Basis of the Charts Suppose that a quality characteristic is normally distributed with mean and standard deviation , where both and are known. If x1, x2, ......, xn is a sample of size n, the average of this sample is

we know that x is normally distributed with mean and standard deviation x = / n . The probability is 1- that any sample mean will fall between

In practice, we usually will no know and . They must be estimated from preliminary samples or subgroups taken when the process is thought to be in control. These estimates should usually be based on at least 20 to 25 samples. Suppose that m samples are available, each containing n observations on the quality characteristic. Typically, n will be small, often either 4, 5, or 6.

The best estimator of , the process average, is the grand average,

We may estimate from either the standard deviations or the ranges of the m samples. Let R1, R2, ....., Rm be the ranges of the m samples. The average range is

The formulas for constructing the control limits on the x chart are as follows:

The formulas for constructing the control limits on the R chart are as follows:

Example Piston for automotive engine are produced by a forging process. We wish to establish statistical control of inside diameter of the ring manufactured by this process using x and R charts. Twenty-five samples, each of size five, have been taken when we think the process is in control. The inside diameter measurement data from these samples are shown in table.

x chart

R chart

CONTROL CHART FOR x AND S

x AND S charts are preferable to their more familiar Counterparts, x and R charts, when either 1. 2. The sample size n is moderately large, n > 10 or 12 The sample size n is variable.

The construction of x and S charts Setting up and operating control charts for x and S requires about the same sequence of step as those for the x and R charts, except that for each sample we must calculate the sample average x and sample standard deviation S.

The sample variance :

The formulas for constructing the control limits on the S chart are as follow : For given

For not given

Example Construction of x and S charts using the pistonring inside diameter measurements in table.

Revise the Control Limits

Suppose that one or more of the values of either x and R plot out of control. It is necessary to revise the control limit by examining each of the out of control points, looking for an assignable cause. If an assignable cause is found, the point is discarded and an the control limits are recalculated, using only the remaining points.

You might also like

- Weather Prediction: Project 1 ReportDocument42 pagesWeather Prediction: Project 1 ReportDhruv Goyal88% (16)

- Chapter 5. Control Charts For VariablesDocument38 pagesChapter 5. Control Charts For VariablesJigar Patel's100% (2)

- Control Charts For Variables and AttributesDocument43 pagesControl Charts For Variables and AttributesTARUN MAHAWERNo ratings yet

- Control Charts For Variables: HapterDocument71 pagesControl Charts For Variables: Haptervimal NegiNo ratings yet

- MEC462B-IQC-Control Charts For VariablesDocument21 pagesMEC462B-IQC-Control Charts For VariablesANH NGUYỄN ĐỨCNo ratings yet

- Xbar and R Chart Formula and ConstantsDocument13 pagesXbar and R Chart Formula and ConstantsklausgreatevilNo ratings yet

- Statistical Quality Control: Simple Applications of Statistics in TQMDocument57 pagesStatistical Quality Control: Simple Applications of Statistics in TQMHarpreet Singh PanesarNo ratings yet

- Statistical QCDocument57 pagesStatistical QCJigar NagvadiaNo ratings yet

- Statistical Quality Control Charts For VariablesDocument15 pagesStatistical Quality Control Charts For VariablesChetal BharaiNo ratings yet

- Following Are The Measurement Values in Control Phase of The ProjectDocument9 pagesFollowing Are The Measurement Values in Control Phase of The ProjectSai Rama VizagNo ratings yet

- Satistical Quality ControlDocument21 pagesSatistical Quality Controladitya v s sNo ratings yet

- Metrology Control ChartsDocument14 pagesMetrology Control ChartsRaghu KrishnanNo ratings yet

- WB SpcxbarandrintroDocument4 pagesWB SpcxbarandrintromitiwanaNo ratings yet

- Control Charts For VariablesDocument15 pagesControl Charts For VariablesZahurul IslamNo ratings yet

- Lecture On C - ChartDocument20 pagesLecture On C - Chart191329No ratings yet

- Control Charts: Walter ShewartDocument7 pagesControl Charts: Walter ShewartAli RazaNo ratings yet

- Variables Control ChartDocument22 pagesVariables Control Chartbobby510No ratings yet

- Table Used in Control ChartDocument10 pagesTable Used in Control ChartRonillo PormonNo ratings yet

- Control Charts For The Mean and RangeDocument2 pagesControl Charts For The Mean and RangeRabia ZulqarnainNo ratings yet

- Name: Sub: STD: Roll No: : Chandni K Jadav ARA 14Document15 pagesName: Sub: STD: Roll No: : Chandni K Jadav ARA 14Nirav JadavNo ratings yet

- 5.2 Process Capability Analysis Rev2ADocument8 pages5.2 Process Capability Analysis Rev2APollyNo ratings yet

- Analysis Quality Control ChartsDocument5 pagesAnalysis Quality Control Chartsnaviyo8081No ratings yet

- Controlchart: SyntaxDocument6 pagesControlchart: SyntaxSaidur Rahman SajibNo ratings yet

- Unit - 2: Statistical Process Control in IndustryDocument103 pagesUnit - 2: Statistical Process Control in IndustrySUJITHA NNo ratings yet

- Process CapabilityDocument5 pagesProcess CapabilityLibyaFlowerNo ratings yet

- Chap06 CC VarDocument68 pagesChap06 CC Varryan pramanda unsamNo ratings yet

- PQT TP 1F PDFDocument21 pagesPQT TP 1F PDFToastedBaconNo ratings yet

- Iem PDFDocument11 pagesIem PDFNalabolu Eshwari EshwariNo ratings yet

- X-Bar R ChartDocument3 pagesX-Bar R ChartShanmugam BalasubramaniamNo ratings yet

- X-Bar and S Charts: NCSS Statistical SoftwareDocument26 pagesX-Bar and S Charts: NCSS Statistical Softwareanon_123371106100% (1)

- X Bar Chart: Key ApproachesDocument3 pagesX Bar Chart: Key ApproachesSajid SarwarNo ratings yet

- Calculation of Control Limits For The ChartDocument3 pagesCalculation of Control Limits For The ChartRobinson ANo ratings yet

- PR 4-6Document9 pagesPR 4-6mech bhabhaNo ratings yet

- Control ChartDocument10 pagesControl Chartfbise12345sargodhaNo ratings yet

- Control Charts: Production and Operations ManagementDocument37 pagesControl Charts: Production and Operations ManagementNeelima AjayanNo ratings yet

- 3 - Control Charts For VariablesDocument54 pages3 - Control Charts For VariablesWilliam BautistaNo ratings yet

- 0510552-Chapter 6 Charts in The Analytical Laboraqtory-FinalDocument128 pages0510552-Chapter 6 Charts in The Analytical Laboraqtory-FinalRadwan AjoNo ratings yet

- Normal Distribution and Regression NotesDocument71 pagesNormal Distribution and Regression Notescassandraolson.kya07No ratings yet

- Lecture 17 Control ChartsDocument26 pagesLecture 17 Control Chartstanveer_buitemsNo ratings yet

- IQC1Document12 pagesIQC1Jom Gonzales SantillanNo ratings yet

- Control CharsDocument11 pagesControl CharsbasslaborielNo ratings yet

- A Concise Presentation: Mr. Deepak SarangiDocument20 pagesA Concise Presentation: Mr. Deepak SarangiGAJENDRA KUMARNo ratings yet

- Control ChartsDocument25 pagesControl ChartsIsza Marie N. SocorinNo ratings yet

- A Concise Presentation: Mr. Deepak SarangiDocument20 pagesA Concise Presentation: Mr. Deepak SaranginikunjNo ratings yet

- SQC-SS, ModulesDocument15 pagesSQC-SS, ModulesSumon KumarNo ratings yet

- Method For Computing R-CHARTDocument14 pagesMethod For Computing R-CHARTSURYAPRAKASH GNo ratings yet

- Chapter Four Control Charts For Variables-I: Implementing SPC in A Quality Improvement ProgramDocument10 pagesChapter Four Control Charts For Variables-I: Implementing SPC in A Quality Improvement ProgramComputer Maintainance Hardware and softwareNo ratings yet

- TQM Unit 3Document106 pagesTQM Unit 3Shibamay MitraNo ratings yet

- Statistical Quality Control 2Document34 pagesStatistical Quality Control 2Tech_MXNo ratings yet

- Chapter 3 Control Chart For VariablesDocument66 pagesChapter 3 Control Chart For VariablesRitam PalNo ratings yet

- Statistical Quality Control: Dr. Eng. Mohamed ElwakilDocument60 pagesStatistical Quality Control: Dr. Eng. Mohamed ElwakilOmar Abdelsameia GalAllahNo ratings yet

- Statistical Quality Control PDFDocument82 pagesStatistical Quality Control PDFInshal KhanNo ratings yet

- Chapter 4 Statistial Process Control (SPC)Document22 pagesChapter 4 Statistial Process Control (SPC)Yousab CreatorNo ratings yet

- Statistical Quality ControlDocument82 pagesStatistical Quality ControlShahmirBalochNo ratings yet

- Attribute Control ChartDocument26 pagesAttribute Control ChartRohit JanardananNo ratings yet

- Quality Control, Basic Control ChartsDocument20 pagesQuality Control, Basic Control Chartsmalyduzy0% (1)

- Class 3 NotesDocument209 pagesClass 3 NotesJason FischerNo ratings yet

- Chapter 4 Statistial Process Control (SPC)Document22 pagesChapter 4 Statistial Process Control (SPC)Yousab CreatorNo ratings yet

- A Study On The False Alarm Rates Of, EWMA and CUSUM Control Charts When Parameters Are EstimatedDocument5 pagesA Study On The False Alarm Rates Of, EWMA and CUSUM Control Charts When Parameters Are Estimatedvista10No ratings yet

- (Progress in Soil Science) Viliam Novák (Auth.) - Evapotranspiration in The Soil-Plant-Atmosphere System-Springer Netherlands (2012)Document262 pages(Progress in Soil Science) Viliam Novák (Auth.) - Evapotranspiration in The Soil-Plant-Atmosphere System-Springer Netherlands (2012)Nicolás Alberto Pereira LawrenceNo ratings yet

- 302 Blom - 0127130504 Final Paper 4 18 13 PDFDocument9 pages302 Blom - 0127130504 Final Paper 4 18 13 PDFBro EdwinNo ratings yet

- Plant Analysis ProceduresDocument187 pagesPlant Analysis ProceduresAnastry Galuh KhusikaNo ratings yet

- DDDDDDDocument2 pagesDDDDDDapi-254428474No ratings yet

- The Geology of European Coldwater Coral Carbonate MoundsDocument33 pagesThe Geology of European Coldwater Coral Carbonate MoundsTuw DasNo ratings yet

- SOCI115 Summary 5Document5 pagesSOCI115 Summary 5Muhd ZahinNo ratings yet

- Past Tense Contrast WorkshopDocument3 pagesPast Tense Contrast WorkshopJose OvaexNo ratings yet

- EnergyPrimer LRDocument185 pagesEnergyPrimer LRbblianceNo ratings yet

- Comparatives and Superlatives PDFDocument4 pagesComparatives and Superlatives PDFLenapsNo ratings yet

- Chicken Nugget Manufacturing ProcessDocument1 pageChicken Nugget Manufacturing ProcessFitriahFindiatiNo ratings yet

- Corrosion Protection: General Information: Industry AirDocument1 pageCorrosion Protection: General Information: Industry AirMAI_QualityNo ratings yet

- FreeteeDocument14 pagesFreeteemantascitaNo ratings yet

- Confidence IntervalsDocument16 pagesConfidence IntervalsMuaiena Khatun RunaNo ratings yet

- Weather Physics PDFDocument2 pagesWeather Physics PDFAnti CorruptionNo ratings yet

- We Are Not Afraid To DieDocument4 pagesWe Are Not Afraid To Diesai mithraNo ratings yet

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNo ratings yet

- Cymbopogon Winterianus:: An Important Species For Essential Java Citronella Oil and Medicinal ValueDocument4 pagesCymbopogon Winterianus:: An Important Species For Essential Java Citronella Oil and Medicinal ValueKaran Kumar VermaNo ratings yet

- Cloud PhysicsDocument13 pagesCloud PhysicsJatin SoniyaNo ratings yet

- FIGHTING FANTASY Caverns of The Snow WitchDocument45 pagesFIGHTING FANTASY Caverns of The Snow Witchjasc0_hotmail_it100% (4)

- Lab 20exp 200 PDFDocument4 pagesLab 20exp 200 PDFCherieCheungNo ratings yet

- CH02 Precipitation 2020Document53 pagesCH02 Precipitation 2020SUNNYWAY CONSTRUCTIONNo ratings yet

- WeatherDocument12 pagesWeathersnehamanepatil1819No ratings yet

- Synagro Nuisance Mitigation and Control Plan For Plainfield Township Biosolids Plant Land Development PlanDocument135 pagesSynagro Nuisance Mitigation and Control Plan For Plainfield Township Biosolids Plant Land Development PlanDickNo ratings yet

- Sustainable Development and Environmental IssuesDocument6 pagesSustainable Development and Environmental IssuesAbhijit JadhavNo ratings yet

- WallerDocument23 pagesWallerZain ZearkNo ratings yet

- Song Sheet o SusannaDocument3 pagesSong Sheet o SusannaXohy Wade0% (1)

- Trench WarfareDocument28 pagesTrench Warfareapi-300259780No ratings yet

- Block 1Document96 pagesBlock 1Smriti SaxenaNo ratings yet

- U4S - 3. WeatherDocument2 pagesU4S - 3. WeatherMaru C.No ratings yet