Professional Documents

Culture Documents

Laboratory Manual MEC224 Mechanical Engineering Workshop

Laboratory Manual MEC224 Mechanical Engineering Workshop

Uploaded by

Sunil SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laboratory Manual MEC224 Mechanical Engineering Workshop

Laboratory Manual MEC224 Mechanical Engineering Workshop

Uploaded by

Sunil SharmaCopyright:

Available Formats

1

LABORATORY MANUAL MEC224 MECHANICAL ENGINEERING WORKSHOP

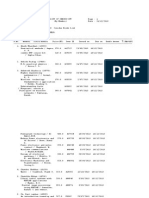

TABLE OF CONTENTS S. No. 1 2 3 4 5 6 7 8 Title of the Experiment To perform taper turning using tailstock offset method To make a job of eccentric turning on lathe machine. To make a job with drilling and boring operation on lathe machine To prepare a job on Surface Grinder / Cylindrical Grinder and measure the various parameters of the finished piece. To make a job on lathe machine with internal threading and external threading Exercise on milling machine to produce a spur gear Graph plotting of variation in hardness at different zones of job after welding with TIG and MIG welding To join two metal sheets of 1.5 mm thickness through the spot welding Page No. 3 7 10 14 17 21 24 27

JOB 1:- To perform taper turning using tailstock offset method. MACHINES/EQUIPMENTS/TOOLS USED:MACHINE USED: - Lathe machine MATERIAL USED: - M.S round bar 25mm diameter. TOOLS USED: - Marking block, facing tool, steel rule, vernier calipers and out side caliper. LEARNING OBJECTIVE: - To learn taper turning operation on lathe machine using tail stock offset method

OUTLINE OF PROCEDURE:1. Take a circular bar of diameter 25mm and 65mm length and hold it in 4 jaw chuck. 2. Turn diameter as 22mm and according to dimensions given turn required diameters. 3. For taper turning set the tail stock off-center (adjusting the axis of rotation)

REQUIRED RESULTS:1. To know the nomenclature of single point cutting tool. 2. To analyze the turning operation on lathe machine.

CAUTIONS:1. Do not change the gear while running the machine. 2. Concentrate on job while machining. 3. Do not check the size of job while machine is running. 4. Set the speed as per required. LEARNING OUTCOME:- to be written by the students in 50-70 words.

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

JOB 2:-To make a job of eccentric turning on lathe machine. MACHINES/EQUIPMENTS/TOOLS USED:- Machine used: - Centre lathe MATERIAL USED: - Mild steel TOOL USED: - Surface gauge, steel foot rule, odd leg calliper, turning tool, smooth file, dot punch LEARNING OBJECTIVE: - To learn eccentric turning on lathe machine.

BEFORE MACHINING

AFTER MACHINING

PROCEDURE:Take MS round piece of 32mm and cut the piece of 62mm. Face & turn the job 30mm &length 60 mm. Now mark the dot punch at the centre of the faced side and paste the chalk on that side and with the help of divider make a circle of 15mm at side of chalk paste. Now hold the job in four jaw chuck lathe for eccentric turning aligns it with help of surface gauge and scribe around the dotted circle. Now turn the work piece at the centre of work piece i.e up to 30mm. SCOPE OF RESULTS TO BE REPORTED:1. To know the operation of eccentric turning on lathe machine. PRECAUTIONS 1. 2. 3. 4. 5. 6. Align the job properly in the 4 jaw chuck. Set the cutting tool in the centre height of job. The depth of cut should be minimum; it should not be more than 0.5 mm. Do not change gear while lathe is running. Lock the compound slide for the threading operations. Clean the machine after the completion of job.

LEARNING OUTCOME:- to be written by the students in 50-70 words.

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

10

JOB3:- To make a job with drilling and boring operation on lathe machine. MACHINES/EQUIPMENTS/TOOLS USED: - Lathe machine MATERIAL USED: - M.S round bar 25mm diameter. TOOLS USED: - Marking block, facing tool, steel rule, vernier calipers, out side caliper, drill (12.7mm), boring bar and depth gauge LEARNING OBJECTIVE: - To learn about drilling and boring operation on lathe machine.

OUTLINE PROCEDURE:1. Hold the job in 4 jaw chuck and align it properly. 2. Set the facing tool and maintain the job length as 40mm. 3. Set the drill in tail stock and start drilling operation. 4. Make a hole throughout the job and set the boring tool and start boring operation. 5. Maintain size as per drawing. REQUIRED RESULTS:1. To know the nomenclature of single point cutting tool. 2. To analyze the turning operation on lathe machine. CAUTIONS:1. Do not change the gear while running the machine. 2. Concentrate on job while machining. 3. Do not check the size of job while machine is running. 4. Set the speed as per required. LEARNING OUTCOME:To be written by the students in 50-70 words.

11

12

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

13

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

14

JOB4: - To prepare a job on Surface Grinder / Cylindrical Grinder and measure the various parameters of the finished piece. MATERIAL USED: - M S sq. 65mm X 16mm X 16mm. MACHINES/EQUIPMENT/TOOLS USED: - Surface grinder, Micrometer, diamond dresser, vernier caliper. LEARNING OBJECTIVES: - To perform different operations on surface grinder Machines, cutting of specimen, measuring marking and product finishing on grinder Machines. Sketch:-

OUTLINE PROCEDURE: - Hold the job in the center of magnetic chuck and take a sketch of the specimen and work upon it by measuring the dimensions as per sketch. List down the steps of operations and then used different tools as per the requirement. SCOPE OF RESULT TO BE REPORTED:i. Observed dimensions as per sketch. ii. To know how to perform different operations on Machines. PRECAUTI ONS:i. ii. iii. iv. v.

Clean the magnetic chuck before starting the operation. Set the job firmly in the center of the magnetic chuck. Depth of cut should be minimum 0.02mm. Sprinkle the coolant at tool and wok piece interface. During working, never wear loose clothes.

LEARNING OUTCOME: - Student will know how to perform different operations on surface grinder machines.

15

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

16

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

17

JOB 5:- To make a job on lathe machine with internal threading and external threading. MACHINES/EQUIPMENTS/TOOLS USED:-Lathe machine MATERIAL USED- M.S. pipe 50 mm, and M.S. round 25 mm TOOL USED:- Surface gauge, facing tool, boring tool, threading tools, screw pitch gauge, steel foot rule, and vernier calliper. LEARNING OBJECTIVE: - To learn internal and external threading on lathe machine

BEFORE MACHINING PROCEDURE

AFTER MACHINING

Take a MS. pipe 2*40 mm. Hold in 4 jaw chucks and align it properly with the help of surface gauge. Set the boring tool and maintain the size mm. Set the threading tool and leaver of lead screw at 11 T.P.I (B.S.W). Set the depth of cut and threading is done until you get the required depth. Unload the job. Reset the job from face side and mark of length 35mm. Face the job up to length 35mm.

18

FOR EXTERNAL THREADS: -

PROCEDURE:Take a MS Round . 25mm*115 mm. Hold in 4 jaw chucks and align it properly with the help of surface gauge. Set the turning and maintain the size as per drawing and set the drill chuck in tail stock spindle and do centering operation . Set the threading tool and leaver of lead screw at 8 T.P.I (square). Set the depth of cut and threading is done until you get the required depth. Unload the job. SCOPE OF RESULTS TO BE REPORTED:1. To know geometry of boring tool. 2. To know internal and external threading operation on lathe machine PRECAUTIONS 1. Align the job properly in the 4 jaw chuck. 2. Set the cutting tool in the centre height of job. 3. The depth of cut should be minimum; it should not be more than 0.5 mm. 4. Do not change gear while lathe is running. 5. Lock the compound slide for the threading operations. 6. Clean the machine after the completion of job.

19

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

20

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

21

JOB-6 Exercise on milling machine to produce a spur gear. MATERIAL USED:- Cast iron. MACHINES/EQUIPMENTS/TOOLS USED: Horizontal milling machine with dividing head, Involute cutter 16 DP -o3, Vernier caliper, Dog carrier, Spanner set, Depth gauge. LEARNING OBJECTIVES:-To produce gear teeth using milling machine

OUTLINE PROCEDURE:- Hold the job in mandrel and adjust the table in the centre of slotting cutter then set the depth of cut, feed the job against rotating cutter and take a sketch of the specimen and work upon it by measuring the dimensions as per sketch. List down the steps of operations and then used different tools as per the requirement. SCOPE OF RESULT TO BE REPORTED:Observed dimensions as per sketch. To know how to perform different operations on milling m/c. PRECAUTIONS:Do not carry tool in your pockets. Follow the operative instructions given strictly. Always remove chips by brush, Do not remove by hand. During working, never wear loose clothes. Always wear fitting clothes. Always use correct speed & feed. LEARNING OUTCOME:- To perform gear cutting operation on milling machine.

22

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

23

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

24

JOB 7:- Graph plotting of variation in hardness at different zones of job after welding with TIG and MIG welding EQUIPMENT REQUIRED: MIG and TIG welding machines, Hardness tester MATERIAL REQUIRED: M.S flat LEARNING OBJECTIVES: The objective of this work is to identify the part of a weld joint that exhibited irradiated weld joint tensile specimen and investigate the mechanisms occurring by analyzing the corresponding microstructure. PROCEDURE AND OUTLINES a First of all we will take the mild steel pieces and weld the mild steel pieces with the TIG and MIG welding. b The various effects will be read out with welding in the different zones. c Then take the readings at different zones. d Then again check the regions after the welding.their are various HAZ after welding with TIG and MIG we check the hardness at various regions. e Then plot the variations of hardness at different zones. SCOPE OF THE RESULTS TO BE REPORTED: To understand the working of various operations by TIG and MIG and analyze the hardness at various levels. CAUTIONS: a Always wear shoes while performing the practical. b Do not wear bangles, bracelets, rings, chains, and even neck tie. c Turn off all equipment when not in use. d Do not drape cables over your body.

LEARNING OUTCOMS: To be written by the students in 50-70 words.

25

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

26

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

27

JOB 8:- To join two metal sheets of 1.5 mm thickness through the spot welding MACHINES/EQUIPMENTS:- Spot welding machine. MATERIAL USED: - Two metal sheet of thickness 1.5 mm and length 100 mm. TOOLS USED: - Marking block, Hammer, Chisel, , and sand paper LEARNING OBJECTIVE: - To learn spot welding a sheet metal OUTLINE OF PROCEDURE:1. Initially cut two mild steel sheets of length 100 mm each using a hammer and chisel. 2. Clean using a hammer and chisel. 3. The face surface of the sheet are being finally rubbed with a sand paper. 4. Then the welding parameters according to the thickness of the sheet are calculated. 5. Then the two sheets are made to overlap up to correct length and finally the overlap region is placed between the electrodes. 6. As the electrodes are being pressed with the help of paddle the circuit gets completed and a nugget is ground due to heat offered due to resistance between the sheets. REQUIRED RESULTS:The mild steel sheets have been perfectly joined by the spot welding process. CAUTIONS:1. Welding parameters play an important role in deciding the quality of weld, so must be calculated properly. 2. The paddle faces at the sheet must be properly cleaned with the help of sand paper 3. The paddle must be kept pressed until whole of the nugget formation takes place. LEARNING OUTCOME:- to be written by the students in 50-70 words.

28

Process Sheet

Workshop Name: Name of Student: Roll No.: Job: Drawing:

Date: Section: Registration No.:

S. No.

Job Operations Specification / Dimension

Tools Used

Equipment/Machine Remark Used

29

Learning Outcome:

To be filled in by Faculty Parameter (Scale from 1-10, 1 for very poor and S.No. 10 Marks excellent) obtained Understanding of the student about the 1 procedure/apparatus. (process sheet) Dimensional Accuracy, Finishing and Learning Outcome. Completion of experiment/job, Discipline and Cleanliness Signature of Faculty Total marks obtained

Max. Marks 20

2 3

20 10

30

You might also like

- Lathe Report Sem 1 DegDocument9 pagesLathe Report Sem 1 DegTarmizi Bahari74% (27)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Fitting ReportDocument18 pagesFitting ReportAriff Azizi67% (3)

- JJ 103 Fitting ReportDocument12 pagesJJ 103 Fitting ReportNasrul Haziq Murad55% (20)

- Workshop Hammer ReportDocument14 pagesWorkshop Hammer ReportJoshua Chong67% (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Workshop Report 2Document6 pagesWorkshop Report 2Muhd Ariff100% (1)

- Lab Sheet MillingDocument5 pagesLab Sheet MillingLalang Laut BestNo ratings yet

- Report of Milling Project Lab 2Document12 pagesReport of Milling Project Lab 2Mohd Danial H100% (2)

- Machining Report (Lathe)Document11 pagesMachining Report (Lathe)Syah KlAte67% (3)

- Hammer Full ReportDocument9 pagesHammer Full ReportVince Ong100% (3)

- FittingDocument7 pagesFittingAniz Farznor SariffuddinNo ratings yet

- Set Out Masonry StructureDocument18 pagesSet Out Masonry StructureDawit Awash80% (5)

- Substation Design PDFDocument115 pagesSubstation Design PDFDoly0% (1)

- "School of Mechanical Engineering" Laboratory Manual MEC 332 Machine Tools and Machining LaboratoryDocument37 pages"School of Mechanical Engineering" Laboratory Manual MEC 332 Machine Tools and Machining LaboratoryAnupam AdarshNo ratings yet

- Laboratory Manual: Computer Aided Manufacturing LaboratoryDocument32 pagesLaboratory Manual: Computer Aided Manufacturing Laboratoryzeya_12345No ratings yet

- MFT Lab Manual 2017-18 Even UpdatedDocument63 pagesMFT Lab Manual 2017-18 Even UpdatedPrakash ThangavelNo ratings yet

- Machine Shop Lab Manual 2018Document16 pagesMachine Shop Lab Manual 2018S B MALLURNo ratings yet

- Shop Exercise 5Document7 pagesShop Exercise 5marisonNo ratings yet

- MFT2 Lab 2Document48 pagesMFT2 Lab 2dellibabu509No ratings yet

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்No ratings yet

- Workshop Report Zainab AliDocument15 pagesWorkshop Report Zainab Aliapi-287774894No ratings yet

- Vsa Scholl of Engineering: Iv Semester Mechanical EngineeringDocument43 pagesVsa Scholl of Engineering: Iv Semester Mechanical EngineeringDmj Anbu RajNo ratings yet

- Laboratory Manual: MEC 317 Manufacturing Technology LaboratoryDocument27 pagesLaboratory Manual: MEC 317 Manufacturing Technology LaboratorySunil SharmaNo ratings yet

- FORMATOALUMNOTRABAJOFINALDocument11 pagesFORMATOALUMNOTRABAJOFINALEduardo Cristian Tarapaqui FloresNo ratings yet

- Manual 14Document14 pagesManual 14JAINTONYNo ratings yet

- MT-II LAB ManualDocument44 pagesMT-II LAB ManualGANESH KUMARNo ratings yet

- Shop Exercise 5Document16 pagesShop Exercise 5Athena GrotesqueNo ratings yet

- Lab Manual - BWPDocument23 pagesLab Manual - BWPAneesh KumarNo ratings yet

- Universiti Tun Hussein Onn Malaysia Centre For Diploma StudiesDocument8 pagesUniversiti Tun Hussein Onn Malaysia Centre For Diploma StudiesAbbyNo ratings yet

- Workshop Practice PDFDocument7 pagesWorkshop Practice PDFAhmed Azad40% (5)

- Mec 123 PracticalDocument41 pagesMec 123 Practicalsanialiu2711No ratings yet

- Production Technology: Department of Mechanical EngineeringDocument17 pagesProduction Technology: Department of Mechanical Engineeringrahul bhattNo ratings yet

- Report MillingDocument5 pagesReport MillingHarith AzrinNo ratings yet

- WeldingDocument64 pagesWeldingLiyana100% (1)

- Lathe Workshop Practice 1 FINALDocument11 pagesLathe Workshop Practice 1 FINALMacrey BwaleiNo ratings yet

- MachinistDocument28 pagesMachinistabyzenNo ratings yet

- Report - MillingDocument8 pagesReport - MillingMaarij Anjum50% (2)

- Work Shop Practice-Ii: Diploma in Mechanical EngineeringDocument36 pagesWork Shop Practice-Ii: Diploma in Mechanical EngineeringLEAGUE OF WARLORDSNo ratings yet

- Workshop ManualDocument37 pagesWorkshop ManualSai Swaroop Mandal0% (1)

- Milling Report Section 5Document9 pagesMilling Report Section 5AbbyNo ratings yet

- Lap Report TemplateDocument7 pagesLap Report TemplateMd Sajib SheikhNo ratings yet

- Chapter-1 Manufacturing TechnologyDocument39 pagesChapter-1 Manufacturing TechnologyKarthickNo ratings yet

- ABES Engineering College, Ghaziabad: Department of Mechanical EngineeringDocument4 pagesABES Engineering College, Ghaziabad: Department of Mechanical EngineeringShivam JhaNo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument8 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaThaneswaran BaluNo ratings yet

- Fittinga Sfs CCDocument4 pagesFittinga Sfs CCAryan AroraNo ratings yet

- Shop Practice Number 6Document9 pagesShop Practice Number 6JantzenCaliwliwNo ratings yet

- Experiment 2Document7 pagesExperiment 2bobcrysto100% (2)

- Shop-4-Cross Peen Hammer HeadDocument8 pagesShop-4-Cross Peen Hammer HeadJag MasterNo ratings yet

- WS Manual 2023Document27 pagesWS Manual 2023ANSHUL SINGHNo ratings yet

- First Year Fall Semester 2020: Ie-115: Material Workshop Report File: Lab WorkDocument45 pagesFirst Year Fall Semester 2020: Ie-115: Material Workshop Report File: Lab WorkMuhammadtayyabaziz KhanNo ratings yet

- 7.machine Shop IDocument2 pages7.machine Shop IVikram RaoNo ratings yet

- MT-2 Lab Manual Rajalaksmi PDFDocument11 pagesMT-2 Lab Manual Rajalaksmi PDFlenojerin3486No ratings yet

- Faculty of Mechanical and Manufacturing Engineering Department of Mechanical EngineeringDocument10 pagesFaculty of Mechanical and Manufacturing Engineering Department of Mechanical EngineeringEzzuan RaesNo ratings yet

- c1 PDFDocument56 pagesc1 PDFAnjaana PrashantNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Shop Theory (Henry Ford Trade School)From EverandShop Theory (Henry Ford Trade School)No ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Grinding Overview: Machinist Grinder Interview Questions and AnswersFrom EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNo ratings yet

- Biomimicry: Exploring Research, Challenges, Gaps and Tools (Paper ID 102)Document15 pagesBiomimicry: Exploring Research, Challenges, Gaps and Tools (Paper ID 102)Sunil SharmaNo ratings yet

- Training Calendar For The M/o May 2014 Topic/Area Programme Code Trainer/Resource Person Time Date of Training Name Designation Division/School Sr. No Target Audience (As Per List Attached)Document18 pagesTraining Calendar For The M/o May 2014 Topic/Area Programme Code Trainer/Resource Person Time Date of Training Name Designation Division/School Sr. No Target Audience (As Per List Attached)Sunil SharmaNo ratings yet

- Arbitrary Axis RotationDocument6 pagesArbitrary Axis RotationSunil SharmaNo ratings yet

- Sop 2Document2 pagesSop 2Sunil SharmaNo ratings yet

- Time Table For Registration Number: 11601081 Home SectionDocument2 pagesTime Table For Registration Number: 11601081 Home SectionSunil SharmaNo ratings yet

- MTE ANALYSIS-Student Feedback Form: S.No Student Name Regd - NO MM 40 Reason For Low Performance SignatureDocument1 pageMTE ANALYSIS-Student Feedback Form: S.No Student Name Regd - NO MM 40 Reason For Low Performance SignatureSunil SharmaNo ratings yet

- Civ339:Hydraulics and Hydraulic Machinery Laboratory: Course OutcomesDocument1 pageCiv339:Hydraulics and Hydraulic Machinery Laboratory: Course OutcomesSunil SharmaNo ratings yet

- Faculty's Time Table: Sunil Sharma 16727Document1 pageFaculty's Time Table: Sunil Sharma 16727Sunil SharmaNo ratings yet

- PopularScience of NoblePhysics2016 PDFDocument5 pagesPopularScience of NoblePhysics2016 PDFSunil SharmaNo ratings yet

- LS Srinath Four Chapters CompleteDocument137 pagesLS Srinath Four Chapters CompleteSunil SharmaNo ratings yet

- PCC AC NewDocument1 pagePCC AC NewSunil SharmaNo ratings yet

- T AmountDocument5 pagesT AmountSunil SharmaNo ratings yet

- Faculty's Time Table: Sumeet Nagar 11588Document1 pageFaculty's Time Table: Sumeet Nagar 11588Sunil SharmaNo ratings yet

- 22 - Research Projects - Sanctioned TDocument1 page22 - Research Projects - Sanctioned TSunil SharmaNo ratings yet

- Effect of Chromium Powder Mixed Dielectric On Performance Characteristic of Aisi D2 Die Steel Using EDMDocument15 pagesEffect of Chromium Powder Mixed Dielectric On Performance Characteristic of Aisi D2 Die Steel Using EDMSunil SharmaNo ratings yet

- Friday Name of The School Saturday Name of The School First Friday First SaturdayDocument2 pagesFriday Name of The School Saturday Name of The School First Friday First SaturdaySunil SharmaNo ratings yet

- R PT Timetable StudentDocument2 pagesR PT Timetable StudentSunil SharmaNo ratings yet

- List of Coaches: S No Name Designation Id No Contact No. VenueDocument2 pagesList of Coaches: S No Name Designation Id No Contact No. VenueSunil SharmaNo ratings yet

- NDT - Non Destructive TestingDocument2 pagesNDT - Non Destructive TestingSunil Sharma100% (1)

- Form 4 ChemistryDocument15 pagesForm 4 ChemistryKia LisaNo ratings yet

- Proler Steel International and Liebherr Mining & Construction Reach Settlement in LawsuitDocument2 pagesProler Steel International and Liebherr Mining & Construction Reach Settlement in LawsuitPR.comNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Swisspump Nds 50hzDocument96 pagesSwisspump Nds 50hzNour Nour El IslamNo ratings yet

- Metal FabricationDocument8 pagesMetal FabricationEdbert TulipasNo ratings yet

- Us - Tsubaki - Sprocket - Catalog 2Document199 pagesUs - Tsubaki - Sprocket - Catalog 2Jairo Andrés FANo ratings yet

- Understanding Ferronickel Smelting From Laterites Through Computational Thermodynamics ModellingDocument15 pagesUnderstanding Ferronickel Smelting From Laterites Through Computational Thermodynamics Modellingفردوس سليمانNo ratings yet

- Elkhart Products Corporation: Welding, Cutting, & BurningDocument14 pagesElkhart Products Corporation: Welding, Cutting, & BurningVictor VieiraNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesNo ratings yet

- 1 Introduction To Iron Chemistry: SilverDocument29 pages1 Introduction To Iron Chemistry: SilverΟΔΥΣΣΕΑΣ ΓΚΑΖΕΛΗΣNo ratings yet

- Norsok PC Systems GuideDocument14 pagesNorsok PC Systems Guidea_c_eNo ratings yet

- Alumbrado Appleton Atx AtexDocument138 pagesAlumbrado Appleton Atx AtexAnder H. CaulfieldNo ratings yet

- A 194 - A 194m - 03 Qte5nc9bmtk0ts1sruqDocument16 pagesA 194 - A 194m - 03 Qte5nc9bmtk0ts1sruqfadjarNo ratings yet

- Aws RT SpecificDocument30 pagesAws RT SpecificphanthanhhungNo ratings yet

- AAV ThermaxDocument2 pagesAAV Thermax123habib123fikriNo ratings yet

- Tig - Mig Welding ConsumablesDocument2 pagesTig - Mig Welding ConsumablesandyhaggerNo ratings yet

- Smaw TestDocument2 pagesSmaw TestTalakag Tnhs100% (2)

- FERULA ESCO USA DioDocument1 pageFERULA ESCO USA DioWilliam ContrerasNo ratings yet

- DescalingChemicals PDFDocument2 pagesDescalingChemicals PDFsanjay ukalkarNo ratings yet

- Bolts ReferencesDocument8 pagesBolts ReferencesvinnuzNo ratings yet

- Unit-III Railway EngineeringDocument208 pagesUnit-III Railway EngineeringShanmugaraj Muthuraj100% (2)

- Avesta Welding Manual - 2009-03-09 PDFDocument312 pagesAvesta Welding Manual - 2009-03-09 PDFkamals55No ratings yet

- Solid Circular SystemDocument6 pagesSolid Circular SystemSanjay LohodasanNo ratings yet

- 830 SpecDocument2 pages830 Specmonarchy1103No ratings yet

- Maraging SteelsDocument19 pagesMaraging SteelsAjeshSomanPulladNo ratings yet

- Catalog REAMERSDocument68 pagesCatalog REAMERSpashaNo ratings yet

- RISO371Document157 pagesRISO371Bhavin SukhadiyaNo ratings yet

- B Ia110-LDocument9 pagesB Ia110-LYang WuNo ratings yet

- Mil STD 2073 1d (Appendix A)Document32 pagesMil STD 2073 1d (Appendix A)mtcengineeringNo ratings yet