Professional Documents

Culture Documents

Us 20120047866

Us 20120047866

Uploaded by

alecandro_90Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20120047866

Us 20120047866

Uploaded by

alecandro_90Copyright:

Available Formats

US 20120047866A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0047866 A1 Fuechtling (43) Pub. Date: Mar. 1, 2012

(54) HEADER

(52) Us. or. ........................................................ .. 56/153

(76) Inventor:

Christian Fuechtling, Ascheberg

(57)

ABSTRACT

(DE)

(21) Appl. No.:

(22) Filed:

A header has a middle section disposed on a base frame, and

at least tWo side sections disposed adjacent the middle section

and comprising a ?exible cutter bar and at least one conveyor

13/215,335

Aug. 23, 2011

device located downstream of the cutter bar, Which, on the respective side sections, is in the form of an endless belt

(30)

Foreign Application Priority Data

(DE) .................... .. 10 2010 0371319

Aug. 24, 2010

Publication Classi?cation

(51)

Int. Cl. A01D 43/06

(2006.01)

disposed adjacent the middle section in order to transport crop cut by the cutter bar parallel to the longitudinal axis of the header in the direction of the middle section, Wherein the side sections comprise a large number of supporting arms Which are pivotably mounted on the base frame, Wherein the supporting arms of the particular side section carry the cutter bar, and at least one supporting element is provided Which carries at least one belt, thereby enabling them to move inde pendently of one another.

Patent Application Publication

Mar. 1, 2012 Sheet 1 0f 5

US 2012/0047866 Al

Patent Application Publication

Mar. 1, 2012 Sheet 2 0f 5

US 2012/0047866 A1

Patent Application Publication

Mar. 1, 2012 Sheet 3 0f 5

US 2012/0047866 A1

Patent Application Publication

Mar. 1, 2012 Sheet 4 0f 5

US 2012/0047866 A1

Patent Application Publication

Mar. 1, 2012 Sheet 5 0f 5

US 2012/0047866 A1

If)

US 2012/0047866 A1

Mar. 1, 2012

HEADER CROSS-REFERENCE TO RELATED APPLICATION

the form of beltsibeing carried on the side sections, the guidance of the belt and the belt itself remain largely unim paired in this region When one or more adjacent supporting arms undergo vertical de?ection since the supporting element

can move relative to the supporting arms. The supporting

[0001] The invention described and claimed hereinbeloW is also described in German Patent Application DE 10 2010 037 131.9 ?led on Aug. 24, 2010. This German Patent Applica

element is likeWise de?ected vertically and, along With it, the

elements that drive and guide the belt. In this case, in contrast to the aforementioned prior art, the belt is de?ected horizon tally only slightly in order to folloW the movement of the ?oat

arm.

tion, Who se subject matter is incorporated here by reference,

provides the basis for a claim of priority of invention under 35

U.S.C. 119(a)-(d).

BACKGROUND OF THE INVENTION

[0007]

In order to decouple the functions of the cutter bar

being carried by the supporting arms, and of the conveyor

deviceiWhich is in the form of beltsibeing carried on the side sections, the supporting arms and at least one supporting element should each be hinge-mounted on the base frame such that they can sWivel about separate pivot axes. Since the pivot axes are separated, the pivot axes of the supporting arms

and at least one supporting element can orient themselves

[0002]

The present invention relates to a header.

[0003]

AheaderisknoWn fromU.S. Pat. No. 7,478,521 B2,

Which comprises a middle section disposed on a frame, and at

least tWo side sections disposed on the frame, adjacent the

middle section, Which enclose a ?exible cutter bar and at least one conveyor device disposed doWnstream of the cutter bar.

freely, Whereby their positioning can be optimally adapted to

the particular function of the cutter bar and the belt. [0008] The at least one supporting element can be in the form of a large number of carrier arms arranged in parallel With the supporting arms Which carry the cutter bar. They can be aligned With the supporting arms in the vertical direction.

Likewise, the carrier arms can also be offset relative to the supporting arms as seen in the horiZontal direction of the side

On each of the side sections, the conveyor device is in the form of at least one endless belt disposed adjacent the middle section in order to transport crop cut by the cutter bar parallel to the longitudinal axis of the header in the direction of the middle section. The middle section is equipped With a belt conveyor Which circulates transversely to the longitudinal axis in order to convey the crop transferred from the lateral

transverse belt conveyor to a feeder housing of a combine harvester on Which the header can be mounted. In the case of

this header, the cutter bar and the endless belts of the side sections are carried jointly by ?oat arms Which are arranged

parallel to one another, lie in a plane, and are mounted on a base frame of the header such that they can rotate about a

section. [0009] In a preferred development, at least one supporting element can be in the form of a framework. Optimal belt

guidance can be attained as a result since continuous belt

contact Without interruptions is ensured. Furthermore, belt

single common pivot axis in order to enable ground contours to be compensated for via partial de?ection of the header. [0004] The disadvantage of this header is that, upon vertical

de?ection of one or more of the ?oat arms, the belt is pressed

guidance is improved by the frameWork design of the sup

porting element in that none of the conveyance ?ns provided on the surface of the belt bend in the center, because the belt rests on the supporting element, Which is in the form of a

in sections in the direction of the base frame because the pivot

axis of the ?oat arms is situated at a distance from the belt.

frameWork, at nearly every point. Another advantage is that

the end-face seal of the transition betWeen cutter bar and belt

The movement of the belt in the horiZontal direction caused

is simpli?ed.

[0010] To this end, at least tWo carrier arms of one side section can be interconnected by at least one crossmember. At least one crossmember can extend largely across the entire

by the great distance thereof from the pivot axis results in increased Wear of the belt. The partial de?ection of the belt by the ?oat arm that changes position With respect to the adjacent

?oat arms also makes guidance of the belt dif?cult since the

Width of the side section and thereby interconnect all carrier

arms of the side section. To ensure that the at least one cross

position of the belt is changed With respect to the rollers by Which it is driven and guided, and Which extend transversely

to the pivot axis of the ?oat arm. The partial de?ection of the

belt induced by the vertical de?ection of one or more ?oat arms causes the belt to become de?ected in both the vertical

member has the ?exibility required to undergo a horiZontal

compensatory movement, it is made of an elastic material such as plastic or rubber, for example, or is designed as a

metal rail Which has appropriate ?exibility and is secured at

direction and the horiZontal direction, Whereby the guidance

of the belt in this region is negatively affected for the duration of the de?ection.

SUMMARY OF THE INVENTION

only one point of the particular side section, thereby enabling

the crossmemberiWhich is in the form of a metal railito undergo a relative movement With respect to the carrier arms in the horiZontal direction. Other structural measures and

embodiments of the at least one crossmember that ensure that

[0005]

The problem addressed by the invention is that of

providing a header of the initially stated type, Which reacts to

ground contours in a ?exible manner, Wherein secure and

the at least one crossmember has the necessary ?exibility upon partial vertical de?ection of the side section are also feasible. [0011] Alternatively, a large number of crossmembers can

loW-Wear guidance of the belts and optimal adaptation of the

cutter bar to the ground are given.

be provided, each of Which interconnects at least tWo adjacent

carrier arms. The individual crossmembers can be aligned in

[0006]

According to the invention, the supporting arms of

the longitudinal direction of the side section, or they can be

offset one behind the other across the Width of the side sec

the particular side section carry the cutter bar, and at least one supporting element is provided Which carries at least one belt, thereby enabling them to move independently of one another.

By decoupling the functions of the cutter bar being carried by

the supporting arms, and of the conveyor deviceiWhich is in

tion. To attain the ?exibility for a horiZontal compensatory movement, the large number of crossmembers are also designed in the manner described above for the continuous crossmembers.

US 2012/0047866 A1

Mar. 1, 2012

[0012]

Preferably, the supporting arms can include means

for reducing the Weight exerted by the cutter bar on the ground. A large number of header skid shoes are mounted on

the cutter bar, doWnstream of the cutter bar on the side of the

[0019] To improve the guidance, the groove can extend approximately Without interruption across the Width of the

particular side section.

[0020] The novel features Which are considered as charac teristic for the present invention are set forth in particular in the appended claims. The invention itself, hoWever, both as to

header facing the ground, Which sense the ground in order to

folloW the course thereof. The course of the ground is trans mitted by the header skid shoes to the cutter bar Which folloWs the course via corresponding vertical compensatory move ments. The means for reducing the Weight can be in the form of springs or hydraulic cylinders, for example, and serve to

its construction and its method of operation, together With additional objects and advantages thereof, Will be best under stood from the folloWing description of speci?c embodiments When read in connection With the accompanying draWings.

BRIEF DESCRIPTION OF THE DRAWINGS

reduce the Weight applied to the ground via the header skid

shoes, Which are used to sense and folloW the ground, to

prevent the cutter bar from pushing soil in front of it. [0013] Inparticular, the supporting arms and the at least one

supporting element can be interconnected via at least one

[0021]

[0022]

FIG. 1 shoWs a vieW of a schematically depicted

FIG. 2 shoWs a vieW of the header according to FIG.

header from above;

sliding joint. As a result, relative movement betWeen the

supporting arms and the at least one supporting element is

1, from beloW;

[0023] FIG. 3 shoWs a perspective vieW of the header according to FIG. 1, in a ?rst embodiment; [0024] FIG. 4 shoWs a perspective vieW of the header according to FIG. 1, in a second embodiment; [0025] FIG. 5 shoWs a perspective vieW of the header according to FIG. 1, in a third embodiment.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

[0026] FIG. 1 shoWs a schematic vieW of a header 1 from above. Header 1 comprises a base frame 2 on Which a middle section 3 and at least tWo side sections 4 adjacent to middle section 3 are disposed. A continuous, ?exible cutter bar 6 Which extends across approximately the entire Width of header 1 is disposed on middle section 3 and side sections 4 on the front side of header 1 opposite base frame 2. Reels 5 are disposed on base frame 2 of header 1, Which extend across the Width of one side section 4 and across part of the Width of middle section 3. Reels 5 serve to improve the take-up of the crop by cutter bar. The crop that is cut by cutter bar 6 is supplied to a conveyor device Which is disposed doWnstream of cutter bar 6 and is in the form of at least one endlessly

attained, and the sliding joint is also used for the mutual

guidance of the supporting arm and the at least one supporting element. [0014] Furthermore, the middle section can include a header auger and a ?oor plate comprising a guide element

disposed thereon, Wherein the ?oor plate is pivotably

mounted on the base frame. The ?oor plate, Which is pivot ably mounted on the base frame, results in a ?atter design of the header and, therefore, a better ?oW of crop material With out losses. The guide element located on the ?oor plate makes it possibleiin combination With the header augerito draW in the crop in a direct, forced manner, Whereby the middle section is also suited for high crop quantities. [0015] Alternatively, the middle section can comprise an

intake device Which is in the form of a feed belt and conveys the crop transversely to the conveyance direction of the side belts.

[0016]

As an advantage, the pivot axis of the supporting

arm can be disposed axially parallel to the pivot axis of at least one supporting element. Compared to a coaxial arrangement

of the pivot axes, the axially parallel con?guration has the advantage that the position of the pivot axis of the supporting

arm carrying the cutter bar having loW clearance from the ground can be selected, and therefore the line of force betWeen the cutter bar and the pivot axis extends in the ?attest

circulating belt 7 on respective side sections 4.

[0027] Endlessly circulating belts 7 are disposed adjacent

to middle section 3 in order to transport the crop cut by cutter

angle possible relative to the ground. In respect to the position of the pivot axis of the supporting element, the advantage

results that the pivot axis is located at a slight distance behind the conveyor device, and therefore the belt moves only slightly on the side thereof facing the base frame When under

bar 6 parallel to the longitudinal axis of header 1 in the

direction of middle section 3, and to supply same to an intake device. Middle section 3 comprises an intake device Which is

going a compensatory motion, Whereby the belt guidance is

improved considerably and a horizontal de?ection of the belt that could occur upon vertical de?ection of the supporting

in the form of driveable header auger 8 and supplies the crop delivered by endless belts 7 laterally to middle section 3 to an

opening provided in base frame 2 and disposed doWnstream

of header auger 8, through Which the crop is transferred via a feeder housing located on a combine harvester, Which is not

element is largely prevented.

[0017] In particular, in order to guide the belt, the at least

one supporting element can comprise a groove Which extends

depicted, to the combine harvester for further processing. [0028] Middle section 3 comprises a ?oor plate 9 Which has

a contoured design on the top side thereof facing header auger

axially parallel to the base frame, into Which a circumferential projection on the inner side of the belt having a shape corre sponding to that of the groove engages.

[0018]

Preferably, the groove can be disposed directly adja

cent to the upper pivot axis. This con?guration has the advan tage that, upon vertical de?ection of at least one of the sup

8, Which is disposed above ?oor plate 9, While the diametri cally opposed underside of ?oor plate 9 is largely planar. The contoured top side of ?oorplate 9 comprises a Wedge-shaped, raised projection 10. Projection 10 tapers from the front edge

of header 1 in the direction of header auger 8, and terminates in a tip facing header auger 8. Projection 10 serves to forcibly redirect material in order to redirect the crop delivered by belts 7 into the intake region of header auger 8. The height of

projection 10 can vary in order to ensure that material is

porting elements, the horiZontal position of the belt changes only slightly on the side thereof facing the base frame, Whereby the stability of the largely form-?t guidance is not

impaired by the groove in the at least one supporting element and the projection on the belt.

suf?ciently de?ected. As a result, the cut crop that is supplied

US 2012/0047866 A1

Mar. 1, 2012

laterally to middle section 3 via belts 7 of side sections 4 is forcibly de?ected in the direction of header auger 8 in order to

and is carried by carrier arms 14 Which can be sWivelled about

improve material take-up.

[0029] The depiction in FIG. 2 shoWs header 1 according to FIG. 1 in a vieW from beloW. Contoured ?oorplate 9 is largely planar on the underside thereof. Floor plate 9 is hinge

mounted on base frame 2 such that it can sWivel about an axis

upper pivot axis 16. The con?guration of upper pivot axis and loWer pivot axis 15, 16 is selected such that they both lie substantially in a plane With belt 7 and the cutter bar, respec

tively.

[0033] FIG. 4 shoWs a perspective vieW of a header 1 according to FIG. 1, in a second embodiment. This embodi ment differs from that shoWn in FIG. 3 in that the at least one supporting element 13 is in the form of a framework. To this

end, carrier arms 14 of one side section 4 are interconnected

11 that is axially parallel to the longitudinal axis of header 1,

and therefore ?oor plate 9 can be de?ected in the vertical direction only across the entire Width thereof. The depiction in FIG. 2 furthermore shoWs that side sections 4 comprise a large number of supporting arms 12 Which are pivotably hinge-mounted on base frame 2, and Which carry cutter bar 6 on their ends facing aWay from base frame 2. A large number of header skid shoes 23 Which sense the ground and therefore folloW the course of the ground are disposed on respective side sections 4 parallel to cutter bar 6. Via header skid shoes 23, ground contours are sensed and transmitted to cutter bar 6 Which undergoes a de?ection in the vertical direction, at least in sections, due to the pivotable de?ection of supporting arms 12 on base frame 2, in order to folloW the course of the ground

contours.

by at least one crossmember 21 Which extends substantially across the entire Width of side section 4 of header 1. In the embodiment shoWn, a plurality of crossmembers 21 are dis posed in parallel on carrier arms 14 of side section 4 and form a type of table that carries belt 7, and on Which belt 7 lies With a large surface area, thereby resulting in continuous contact of belt 7 on frameWork-type supporting element 13. Belt 7 is guided via a continuous groove 22 Which is disposed directly adjacent upper pivot axis 16 on crossmember 21. A circum

ferential projection having a shape corresponding to that of

groove 22 and disposed on the inner side of belt 7 facing

carrier arms 14 engages in continuous groove 22.

[0030] According to the invention, supporting arms 12 of particular side section 4 carry cutter bar 6, While endless belts

7 of side sections 4 are carried by at least one additional supporting element 13, and therefore cutter bar 6 can move

[0034] FIG. 5 shoWs a perspective vieW of header 1 accord ing to FIG. 1, in a third embodiment. In this embodiment, a

plurality of crossmembers 21 disposed axially parallel to base

frame 2 are provided, Wherein one crossmember 21 intercon nects at least tWo adjacent carrier arms 14 in each case.

independently of endless belts 7 of corresponding side sec tion 4. By decoupling the functions of cutter bar 6 being

carried by supporting arms 12, and of the conveyor devicei

Which is in the form of belts 7ibeing carried on side sections

4 by the at least one supporting element 13, the guidance of belt 7 remains largely unimpaired in this region When one or more adjacent supporting arms 12 undergo vertical de?ection since supporting element 13 can move relative to supporting

arms 12.

Individual crossmembers 21 are preferably disposed one behind the other in a roW, thereby resulting in a con?guration With a continuous crossmember 21 that corresponds to the second embodiment. LikeWise, individual crossmembers 21

are offset relative to one another as seen in the longitudinal

[0031]

The depiction in FIG. 3 shoWs a perspective vieW of

header 1 according to FIG. 1 in a ?rst embodiment. In the depiction according to FIG. 3, a side section 4 of header 1 is

partially exposed in order to shoW the structure of header 1 located underneath belt 7. As shoWn in FIG. 3, base frame 2 comprises a rear panel 18 Which extends vertically relative to the direction of motion of belts 7, and Which is enclosed

direction of header 1. Belt 7 is guided in a manner described With reference to the second embodiment. A large number of crossmembers 21 are aligned, one behind the other, parallel to upper pivot axis 16. Crossmembers 21 each comprise a groove 22 Which, due to the aligned con?guration of cross members 21, form one continuous groove 22 Which is approximately free of interruptions, as in the ?rst embodi ment. The continuous design of groove 22 simpli?es the

guidance of belt 7.

[0035] A feature common to all of the embodiments is that

betWeen tWo preferably holloW-cylindrical pro?led elements

19, 20. In middle section 3, driveable header auger 8 is retained on pro?led elements 19, 20 of base frame 2. [0032] In the ?rst embodiment of header 1 according to the invention, as shoWn in FIG. 3, supporting element 13 is in the form of a large number of separate carrier arms 14. Carrier arms 14 are disposed in pairs parallel to supporting arms 12,

loWer pivot axis 15 of supporting arm 12 is disposed axially

parallel to upper pivot axis 16 of the at least one supporting element 13. Compared to a coaxial arrangement of pivot axes

15, 16, the axially parallel con?guration has the advantage

that the position of loWer pivot axis 15 of supporting arm 12

carrying cutter bar 6 can be selected to have loW clearance

preferably directly above them and in alignment thereWith in

the vertical direction. Supporting arms 12, Which are dis

posed in pairs, and carrying arms 14 are hinge-mounted to base frame 2 such that they can pivot about a separate loWer pivot axis 15 and an upper pivot axis 16. LoWer pivot axis 15

and upper pivot axis 16 are disposed on the base frame at a

distance from each other. Upper pivot axis 16 is disposed directly adjacent to belt 7. Actively driven or passive guide rollers 17 Which drive or guide, respectively, the particular

endlessly circulating belt 7 of a side section 4 are disposed at

least on carrier arms 14 disposed on the ends of side sections

from the ground, and therefore the line of force betWeen cutter bar 6 and loWer pivot axis 15 extends in a ?at angle relative to the ground. In respect to the position of upper pivot axis 16 of supporting element 13, the advantage results that upper pivot axis 16 is located at a slight distance behind the conveyor device, Which is in the form of belt 7, and therefore belt 7 moves only slightly in the horiZontal direction on the side thereof facing base frame 2 When undergoing a compen satory movement, Whereby the guidance of belt 7 in a groove ZZiWhICh extends axially parallel to upper pivot axis 16 and

is directly adjacent theretoiis improved considerably.

[0036] It Will be understood that each of the elements

described above, or tWo or more together, may also ?nd a

4. Particular belt 7 of a side section 4 only encloses carrier

arms 14, and therefore a vertical de?ection of one or more

supporting arms 12 about loWer pivot axis 15 largely does not affect the guidance of belt 7 Which extends parallel thereto

useful application in other types of constructions differing

from the types described above.

US 2012/0047866 A1

Mar. 1, 2012

[0037]

While the invention has been illustrated and

5. The header as de?ned in claim 4, and further comprising

at least one crossmember which interconnects at least two of said carrier arms of one of said side sections.

described as embodied in a header, is not intended to be

limited to the details shown, since various modi?cations and structural changes may be made without departing in any way

from the spirit of the present invention. [0038] Without further analysis, the foregoing will so fully reveal the gist of the present invention that others can, by

6. The header as de?ned in claim 4, and further comprising a plurality of crossmembers each interconnecting at least two

adjacent ones of said carrier arms.

applying current knowledge, readily adapt it for various applications without omitting features that, from the stand point of prior art, fairly constitute essential characteristics of

the generic or speci?c aspects of this invention.

What is claimed as new and desired to be protected by Letters Patent is set forth in the appended claims: 1. A header, comprising a base frame; a middle section disposed on said base frame; at least two side sections dis

7. The header as de?ned in claim 1, wherein said support ing arms include means for reducing a weight exerted by said

cutter bar on a ground.

8. The header as de?ned in claim 1, and further comprising at least one sliding joint interconnecting said supporting arms

and said at least one supporting element. 9. The header as de?ned in claim 1, wherein said middle section has a header auger and a ?oor plate having a guide

posed adjacent said middle section and comprising a ?exible

cutter bar and at least one conveyor device located down stream of said cutter bar, and formed, on a respective one of

element disposed thereon, wherein said ?oor plate is pivot

ably mounted on said base frame. 10. The header as de?ned in claim 1, wherein said middle

section has an intake device formed as a feed belt.

said side sections, as an endless belt disposed adjacent said middle section to transport crop cut by said cutter bar parallel

to a longitudinal axis of the header in a direction of said

middle section, wherein said side sections have a plurality of

supporting arms which are pivotably mounted on said base frame, and wherein said supporting arms of a respective one of said side sections carry said cutter bar, and at least one

supporting element is provided and carries said belt, thereby

enabling them to move independently of one another. 2. The header as de?ned in claim 1, wherein said support ing arms and said at least one supporting element are each

11. The header as de?ned in claim 1, wherein said support ing arms and said at least one supporting element are posi tioned so that a position of a lower pivot axis of said support ing arms is independent of a position of a upper pivot axis of said at least one supporting element. 12. The header as de?ned in claim 11, wherein said at least one supporting element has a groove extending axially par allel to said base frame, and wherein saidbelt has an inner side

provided with a circumferential projection having a shape corresponding to a shape of said groove and engaging in said

groove. 13. The header as de?ned in claim 12, wherein said groove

hinge-mounted on said base frame such that they are pivot able about separate pivot axes.

3. The header as de?ned in claim 1, wherein said at least

is disposed directly adjacent to said upper pivot axis.

14. The header as de?ned in claim 13, wherein said groove extends substantially without interruption across a width of a respective one of said side sections.

* * * * *

one supporting element is formed by a plurality of carrier

arms which are disposed parallel to said supporting arms

carrying said cutter bar.

4. The header as de?ned in claim 3, wherein said at least

one supporting element is formed as a framework.

You might also like

- TNG Release Notes 502Document14 pagesTNG Release Notes 502alecandro_90No ratings yet

- Rudder and PropellerDocument5 pagesRudder and PropellerSumit SinhaNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Fujifilm Cr-Ir341, FCR 500Document1,472 pagesFujifilm Cr-Ir341, FCR 500jab_arx1No ratings yet

- Drag Conveyors MartinDocument15 pagesDrag Conveyors MartinKalai SelvanNo ratings yet

- Idlers - Medium To Heavy Duty PDFDocument28 pagesIdlers - Medium To Heavy Duty PDFEd Ace100% (1)

- Pack Expo International 2002 PDFDocument432 pagesPack Expo International 2002 PDFMagdalenaRosenberg0% (1)

- Us 20140311650Document8 pagesUs 20140311650rashom0099088No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1DANESINo ratings yet

- United States Patent: Gow (10) Patent N0.: (45) Date of PatentDocument5 pagesUnited States Patent: Gow (10) Patent N0.: (45) Date of PatentAdam SalehNo ratings yet

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- Us 20080264323Document26 pagesUs 20080264323ASeaSlugNo ratings yet

- Camera Slider PatentDocument19 pagesCamera Slider PatentjaimepajarolocoNo ratings yet

- TEPZZ - 4 - 45 A - T: European Patent ApplicationDocument10 pagesTEPZZ - 4 - 45 A - T: European Patent ApplicationdaveNo ratings yet

- Belt Aligning RevisitedDocument6 pagesBelt Aligning RevisitedfNo ratings yet

- (Gina Carol Barney) Elevator Traffic Handbook The (BookFi)Document7 pages(Gina Carol Barney) Elevator Traffic Handbook The (BookFi)AdiyNo ratings yet

- Tm. VC: May 13, 1969 E. F. CielaszykDocument3 pagesTm. VC: May 13, 1969 E. F. CielaszykjoycebaylonNo ratings yet

- United States Patent (19) : Harris (451 Oct. 21, 1975Document10 pagesUnited States Patent (19) : Harris (451 Oct. 21, 1975FernandoNo ratings yet

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuNo ratings yet

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocument15 pages915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelNo ratings yet

- Applications: Linear PlaningDocument4 pagesApplications: Linear PlaningSingh KitarpNo ratings yet

- Us4173933 PDFDocument10 pagesUs4173933 PDFRizki Fajar NovantoNo ratings yet

- Ijmet: ©iaemeDocument6 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- EP20161688NWA1Document20 pagesEP20161688NWA1Dilshan PriyadarshanaNo ratings yet

- 6.intro To Photo of Dual Side Shaper Using Scotch Yoke MechanismDocument36 pages6.intro To Photo of Dual Side Shaper Using Scotch Yoke Mechanismvijay vijay33% (3)

- UntitledDocument15 pagesUntitledAjay NishadNo ratings yet

- European Patent Application - VoidmeterDocument9 pagesEuropean Patent Application - Voidmeterazlan.shareNo ratings yet

- United States Patent (19) : Cruise Et Al. (11) Patent NumberDocument8 pagesUnited States Patent (19) : Cruise Et Al. (11) Patent NumberOmkar SharmaNo ratings yet

- CH10Document17 pagesCH10ylj dsNo ratings yet

- July 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1Document7 pagesJuly 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1rte678No ratings yet

- GB2575465ADocument20 pagesGB2575465APaola PinedaNo ratings yet

- 0045 7949 (72) 90047 8Document18 pages0045 7949 (72) 90047 8S S Reddy SomuNo ratings yet

- EP2369289A1Document10 pagesEP2369289A1awe234100% (1)

- Ulllted States Patent (10) Patent N0.: US 7,931,139 B2Document15 pagesUlllted States Patent (10) Patent N0.: US 7,931,139 B2Ion BumbuNo ratings yet

- US Patent 7090236 Land SailingDocument8 pagesUS Patent 7090236 Land SailingDimas MaulanaNo ratings yet

- European Patent Application F04B 27/08, F04B 27/10: Swash Plate Type CompressorDocument19 pagesEuropean Patent Application F04B 27/08, F04B 27/10: Swash Plate Type CompressorSelvaraji MuthuNo ratings yet

- RR PatentsDocument7 pagesRR PatentsAlan SmartNo ratings yet

- ConveyorDocument81 pagesConveyorhaymanotNo ratings yet

- 23mm", @722 GOZ067g: Automobile Side Bumper Filed Nov. 9. 1923Document3 pages23mm", @722 GOZ067g: Automobile Side Bumper Filed Nov. 9. 1923akomocarNo ratings yet

- EP09166154NWA1Document10 pagesEP09166154NWA1maes.daan1No ratings yet

- Concave Attachment ReportDocument35 pagesConcave Attachment ReportMeena SivasubramanianNo ratings yet

- Overland Belt ConveyorsDocument13 pagesOverland Belt ConveyorsRodrigo GarcíaNo ratings yet

- United States Patent (19) : Johnston (11) Patent Number: (45) Date of PatentDocument9 pagesUnited States Patent (19) : Johnston (11) Patent Number: (45) Date of Patentsanjay0910No ratings yet

- Lathe TurretDocument17 pagesLathe TurretLove ReloadedNo ratings yet

- Pipe Conveyor System: Effective Solutions For Long DistancesDocument8 pagesPipe Conveyor System: Effective Solutions For Long DistancesEugenepaccelli Kolandai SamyNo ratings yet

- Construction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill BitsDocument8 pagesConstruction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill Bitsviruz2_09No ratings yet

- US Patent 6,884,932, Entitled "Stringed Instrument Truss Assembly" To Wrona and Miller, Issued Apr. 26, 2005.Document14 pagesUS Patent 6,884,932, Entitled "Stringed Instrument Truss Assembly" To Wrona and Miller, Issued Apr. 26, 2005.Anonymous a7S1qyXNo ratings yet

- Shafts and Shaft Components: Axle Is A Nonrotating Member That Carries No Torque and Is Used ToDocument12 pagesShafts and Shaft Components: Axle Is A Nonrotating Member That Carries No Torque and Is Used ToalhaggagiNo ratings yet

- Us 7367619Document11 pagesUs 7367619P ANo ratings yet

- Rudder and PropellersDocument7 pagesRudder and Propellersantariksa pramudidanNo ratings yet

- Optimizing Screw ConveyorDocument6 pagesOptimizing Screw ConveyorChem.Engg100% (1)

- Universal JointDocument17 pagesUniversal Jointakmalzuhri96No ratings yet

- United States Patent 1191Document13 pagesUnited States Patent 1191ddeeff715No ratings yet

- United States Patent (16) Patent N6 US 8,226,291 B2: Zamirowski Et Al. (45) Date of Patent: Jul. 24, 2012Document26 pagesUnited States Patent (16) Patent N6 US 8,226,291 B2: Zamirowski Et Al. (45) Date of Patent: Jul. 24, 2012Soma GhoshNo ratings yet

- Metal LatheDocument25 pagesMetal Lathebogesz68No ratings yet

- Cutting MachinesDocument6 pagesCutting MachinesDinesh dhakarNo ratings yet

- BELTSDocument7 pagesBELTSPàrtërø Pàrtøh MdàdïcNo ratings yet

- Cutting MachinesDocument19 pagesCutting MachinesDinesh dhakar100% (1)

- Machine Elements 3-Belt DrivesDocument62 pagesMachine Elements 3-Belt Drivesimam hanafiNo ratings yet

- Fabrication Methods of The Polygonal Masonry of Large Tightly Fitted Stone - 21-29Document9 pagesFabrication Methods of The Polygonal Masonry of Large Tightly Fitted Stone - 21-29Alejandro O. LunaNo ratings yet

- Rudder and PropellersDocument9 pagesRudder and PropellerssbdmanNo ratings yet

- Combined GearboxDocument8 pagesCombined Gearboxkats2404No ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Frame Saw Manual 1902Document111 pagesFrame Saw Manual 1902wolf143No ratings yet

- 02 - Posicionar-eje-Horizontal - 001 - KUKA Positioners ENDocument5 pages02 - Posicionar-eje-Horizontal - 001 - KUKA Positioners ENalecandro_90No ratings yet

- Fig. A Fig. B Fig. CDocument1 pageFig. A Fig. B Fig. Calecandro_90No ratings yet

- V BeltsDocument3 pagesV Beltsalecandro_90No ratings yet

- Sca3000 Demo Kit User ManualDocument21 pagesSca3000 Demo Kit User Manualalecandro_90No ratings yet

- An00008642930101 000201Document4 pagesAn00008642930101 000201alecandro_90No ratings yet

- P 1 Acf 3 J 9 J 0 R 2 CT 23 LHG 7 Be 77 V 2Document8 pagesP 1 Acf 3 J 9 J 0 R 2 CT 23 LHG 7 Be 77 V 2alecandro_90No ratings yet

- Toradex & NXP - AI Vision Starter Kit - Solution Brief - FINALDocument2 pagesToradex & NXP - AI Vision Starter Kit - Solution Brief - FINALalecandro_90No ratings yet

- Sllu 158Document15 pagesSllu 158alecandro_90No ratings yet

- VBB4449 SpecificationDocument3 pagesVBB4449 Specificationalecandro_90No ratings yet

- CAT 2023 Laser AmadaDocument35 pagesCAT 2023 Laser Amadaalecandro_90No ratings yet

- Total Solution For Gear MachiningDocument12 pagesTotal Solution For Gear Machiningalecandro_90No ratings yet

- ESPRIT EDGE - Release - Notes - 2023 - 1Document20 pagesESPRIT EDGE - Release - Notes - 2023 - 1alecandro_9050% (2)

- RIVKLE Blindnietmuttern Edelstahl Senkkopf Rundschaft Offen enDocument2 pagesRIVKLE Blindnietmuttern Edelstahl Senkkopf Rundschaft Offen enalecandro_90No ratings yet

- Gearpro eDocument1 pageGearpro ealecandro_90No ratings yet

- Messprotokoll Gear Pro BevelDocument2 pagesMessprotokoll Gear Pro Bevelalecandro_90No ratings yet

- Spna 088Document14 pagesSpna 088alecandro_90No ratings yet

- Marvell Phys Transceivers Alaska 88e1548 88e1548p Product Brief 2015 08Document2 pagesMarvell Phys Transceivers Alaska 88e1548 88e1548p Product Brief 2015 08alecandro_90No ratings yet

- DPRNTDocument4 pagesDPRNTalecandro_90No ratings yet

- Tooling Form A Zak SDocument11 pagesTooling Form A Zak Salecandro_90No ratings yet

- Typical Applications: Radial Adjustment (Off-Center Drilling)Document1 pageTypical Applications: Radial Adjustment (Off-Center Drilling)alecandro_90No ratings yet

- PD.02.22 Release NotesDocument14 pagesPD.02.22 Release Notesalecandro_90No ratings yet

- Bevel Gear BlanksDocument3 pagesBevel Gear Blanksalecandro_90No ratings yet

- WenzelDocument4 pagesWenzelalecandro_90No ratings yet

- Camfix Std.Document1 pageCamfix Std.alecandro_90No ratings yet

- 1.EIMA 2022 ProgrammeDocument7 pages1.EIMA 2022 Programmealecandro_90No ratings yet

- AMADA MIYACHI To Newly Release ML-6811C / ML-6810C Fiber Laser WeldersDocument3 pagesAMADA MIYACHI To Newly Release ML-6811C / ML-6810C Fiber Laser Weldersalecandro_90No ratings yet

- Release Notes MTB 4.4Document1 pageRelease Notes MTB 4.4alecandro_90No ratings yet

- DHI ASM202 Fingerprint-Enrollment-Reader Users-Manual V1.0.0Document14 pagesDHI ASM202 Fingerprint-Enrollment-Reader Users-Manual V1.0.0alecandro_90No ratings yet

- Yale Assure Install TemplateDocument1 pageYale Assure Install Templatealecandro_90No ratings yet

- Lafarge - TA Grinding VRM v1 (Final)Document62 pagesLafarge - TA Grinding VRM v1 (Final)elwathig bakhiet100% (1)

- MFA-4P Motion Failure Alarm 1Document6 pagesMFA-4P Motion Failure Alarm 1Kirk WaterworthNo ratings yet

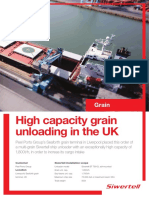

- Casesheet 154 Siwertell MerseyDocks UK Grain UnloaderDocument2 pagesCasesheet 154 Siwertell MerseyDocks UK Grain UnloaderersNo ratings yet

- 1 PDFDocument15 pages1 PDFnicolasNo ratings yet

- Asfaltoukladch 1900 2 enDocument14 pagesAsfaltoukladch 1900 2 enThanh CongNo ratings yet

- Selection of Material Handling EquipmentDocument6 pagesSelection of Material Handling EquipmentAkif ZubairNo ratings yet

- Design GuideDocument30 pagesDesign Guiderapidindustries100% (6)

- JPK-SLDN-PK01 - Borang Perakuan Proses Kerja Syarikat Berdasarkan NOSSDocument3 pagesJPK-SLDN-PK01 - Borang Perakuan Proses Kerja Syarikat Berdasarkan NOSSAnonymous kjzSohZ100% (1)

- Conveyor Pulleys PDFDocument8 pagesConveyor Pulleys PDFDhirendraRaviNo ratings yet

- The Visual FactoryDocument4 pagesThe Visual FactoryOtavio Valente FilhoNo ratings yet

- Topic Inspection Pack Noise: Revised May 2008Document22 pagesTopic Inspection Pack Noise: Revised May 2008Ramadan KareemNo ratings yet

- HORIZON BQ470 - eDocument5 pagesHORIZON BQ470 - eГеоргий ПрокофьевNo ratings yet

- Presentacion ISA Graphic Febrero 2015Document28 pagesPresentacion ISA Graphic Febrero 2015Ileana ContrerasNo ratings yet

- Hino 500 Ranger FG 235 JJ Fire Truck 5500 Water Foam, Double Cabin, SNI Standart PROTEKTA FIREFORT VATORDocument8 pagesHino 500 Ranger FG 235 JJ Fire Truck 5500 Water Foam, Double Cabin, SNI Standart PROTEKTA FIREFORT VATORKasidinNo ratings yet

- Coal Mill Flow SheetDocument3 pagesCoal Mill Flow Sheethamedmustafa093No ratings yet

- Alcon Metal Detector For Alu Foil PackagedDocument2 pagesAlcon Metal Detector For Alu Foil PackagedPrima AdyNo ratings yet

- RFKG Chain Conveyor PDFDocument4 pagesRFKG Chain Conveyor PDFDwi AndreNo ratings yet

- ACS380 Product Presentation RevfDocument44 pagesACS380 Product Presentation RevfEléctrica Ingeniería y ServiciosNo ratings yet

- Belt Conveyors For Bulk Materials Conveyor: Traducir Esta PáginaDocument4 pagesBelt Conveyors For Bulk Materials Conveyor: Traducir Esta PáginaDIEGO FERNANDO CADENA ARANGONo ratings yet

- Drafting q4 Mr.-TalattadDocument17 pagesDrafting q4 Mr.-TalattadJoven AddatuNo ratings yet

- Tna French Fries Brochure (EN)Document3 pagesTna French Fries Brochure (EN)Bindu PanickerNo ratings yet

- Ps2600 BrochureDocument8 pagesPs2600 BrochureMochamad HafidzNo ratings yet

- Advancement in Vegetable Transplanting: Mechanization, Challenges and OpportunitiesDocument7 pagesAdvancement in Vegetable Transplanting: Mechanization, Challenges and OpportunitiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Glavni Katalog MinitecDocument625 pagesGlavni Katalog MinitecrcaletaNo ratings yet

- Belt Conveyor Quotation WorksheetDocument1 pageBelt Conveyor Quotation WorksheetAmit ChauhanNo ratings yet

- Ramsey Weiight ScaleDocument4 pagesRamsey Weiight ScaleIkram Hisan AkbarNo ratings yet