Professional Documents

Culture Documents

Passive UHF RFID in Paper Industry Challenges Benefits and The Application Environment-rUB

Passive UHF RFID in Paper Industry Challenges Benefits and The Application Environment-rUB

Uploaded by

instrengCopyright:

Available Formats

You might also like

- PPTDocument69 pagesPPTAjit MishraNo ratings yet

- Thesis RFIDDocument51 pagesThesis RFIDAjinkya Wagh0% (1)

- Smart RFID Tags: Nadine Pesonen, Kaarle Jaakkola, Jerome Lamy, Kaj Nummila and Jouko MarjonenDocument20 pagesSmart RFID Tags: Nadine Pesonen, Kaarle Jaakkola, Jerome Lamy, Kaj Nummila and Jouko MarjonenBasharNo ratings yet

- Survey of RFIDDocument21 pagesSurvey of RFIDmgollarzaNo ratings yet

- Final Rfid Report1Document35 pagesFinal Rfid Report1priyaNo ratings yet

- I Jcs It 20150602122Document19 pagesI Jcs It 20150602122AkhilaNo ratings yet

- 144-Article Text-337-1-10-20230617Document7 pages144-Article Text-337-1-10-20230617ajtorres852No ratings yet

- Radio Frequency Identification TechnologDocument10 pagesRadio Frequency Identification TechnologMisaelNo ratings yet

- RFID Project ReportDocument53 pagesRFID Project Reportchhavigupta168933% (3)

- RFID Modules & Guideline For Selecting Appropriate RFID Module For IndustriesDocument4 pagesRFID Modules & Guideline For Selecting Appropriate RFID Module For IndustriesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Abcs of RfidDocument6 pagesAbcs of RfidGeny KucherNo ratings yet

- Design of Antennas For Uhf Rfid TagsDocument11 pagesDesign of Antennas For Uhf Rfid Tagschandrakant chaudhariNo ratings yet

- WMC Seminar ReportDocument11 pagesWMC Seminar ReportVijit SinghNo ratings yet

- An Introduction To RFID Technology: Sanjay Ahuja, Pavan PottiDocument4 pagesAn Introduction To RFID Technology: Sanjay Ahuja, Pavan PottiAstaNo ratings yet

- Radio Frequency Identification RFIDDocument41 pagesRadio Frequency Identification RFIDmtawba100% (4)

- Rfid Technology in Supply Chain Management: State of The Art and PerspectivesDocument12 pagesRfid Technology in Supply Chain Management: State of The Art and PerspectivesHadi P.No ratings yet

- Integration of RFID and Wireless Sensor Networks: 1.2 Tags and Frequency RangesDocument6 pagesIntegration of RFID and Wireless Sensor Networks: 1.2 Tags and Frequency RangesMahmoud El-tabeyNo ratings yet

- Abhilasha Ojha: Seminar Report ONDocument32 pagesAbhilasha Ojha: Seminar Report ONPragya SharmaNo ratings yet

- Sensor Design and Applications Is Intended For A Wide Range ofDocument1 pageSensor Design and Applications Is Intended For A Wide Range ofFernando-Pierre GPNo ratings yet

- RFID Applications: An Introductory and Exploratory StudyDocument7 pagesRFID Applications: An Introductory and Exploratory StudyDorothy BrewerNo ratings yet

- Simple Low Cost Iot Uhf Rfid Based Lab Equipment Identification and Tracking SystemDocument16 pagesSimple Low Cost Iot Uhf Rfid Based Lab Equipment Identification and Tracking SystemAgam KurniawanNo ratings yet

- AStudyonthe Componentsusedin RFIDSystemandits ChallengesDocument8 pagesAStudyonthe Componentsusedin RFIDSystemandits Challengesorekihoutaro252004No ratings yet

- AStudyonthe Componentsusedin RFIDSystemandits ChallengesDocument7 pagesAStudyonthe Componentsusedin RFIDSystemandits ChallengesCat SkullNo ratings yet

- Rfid PDFDocument7 pagesRfid PDFdamaharibabuNo ratings yet

- A Phase-Based Technique For Localization of UHF-RFID Tags Moving On A Conveyor Belt Performance Analysis and Test-Case MeasurementsDocument10 pagesA Phase-Based Technique For Localization of UHF-RFID Tags Moving On A Conveyor Belt Performance Analysis and Test-Case MeasurementsAlexis TNo ratings yet

- Report On RFIDDocument14 pagesReport On RFIDA.s.jNo ratings yet

- Economical Assessment of The Impact of RDocument23 pagesEconomical Assessment of The Impact of RGlicheria LesanNo ratings yet

- Innovative RFID Sensors For Internet of Things ApplicationsDocument11 pagesInnovative RFID Sensors For Internet of Things ApplicationsPäül PärïċötöNo ratings yet

- Plos 2008Document13 pagesPlos 2008alexanderfortis8628No ratings yet

- Rfid-Ta 2018 8552767Document4 pagesRfid-Ta 2018 8552767sayaliNo ratings yet

- Application Article: Localization and Tracking of Passive RFID Tags Based On Direction EstimationDocument9 pagesApplication Article: Localization and Tracking of Passive RFID Tags Based On Direction EstimationRamalingNo ratings yet

- RFID Sensor Placement Algorithm in Ubiquitous ComputingDocument4 pagesRFID Sensor Placement Algorithm in Ubiquitous ComputingvinsenNo ratings yet

- Elsevier ELAHMAR Latifa V4Document8 pagesElsevier ELAHMAR Latifa V4oukairaNo ratings yet

- A Survey and Tutorial of RFID Anti-Collision Protocols: Research OnlineDocument24 pagesA Survey and Tutorial of RFID Anti-Collision Protocols: Research OnlineChokri AjroudNo ratings yet

- Sensors: The Design of RFID Conveyor Belt Gate Systems Using An Antenna Control UnitDocument12 pagesSensors: The Design of RFID Conveyor Belt Gate Systems Using An Antenna Control UnitHarshal PatilNo ratings yet

- Radio Frequency IdentificationDocument21 pagesRadio Frequency Identificationbiss vargheseNo ratings yet

- Example Thesis About RfidDocument7 pagesExample Thesis About Rfidoaehviiig100% (1)

- Review of Various Aspects of Radio Frequency Identification (Rfid) TechnologyDocument6 pagesReview of Various Aspects of Radio Frequency Identification (Rfid) TechnologyInternational Organization of Scientific Research (IOSR)No ratings yet

- 3D RFID Simulation and Design - Factory Automation: Wei Liu and Ming Mao WongDocument23 pages3D RFID Simulation and Design - Factory Automation: Wei Liu and Ming Mao WongAbohicham AbhNo ratings yet

- InkJet-Printed Humidity SensorDocument10 pagesInkJet-Printed Humidity SensorAngel LagrañaNo ratings yet

- Rfid Ism Antennas ArrayDocument5 pagesRfid Ism Antennas Arrayamar rouibahNo ratings yet

- Rfid-Based Secured Access System Using 8051 Microcontroller (AT89C51)Document30 pagesRfid-Based Secured Access System Using 8051 Microcontroller (AT89C51)Karl Neil Jay AgnoNo ratings yet

- Security Challenges For User-Oriented RFID Applications Within The Internet of Things'Document7 pagesSecurity Challenges For User-Oriented RFID Applications Within The Internet of Things'lcchooNo ratings yet

- Verification of RFID System Usability in Silage Bale Life Cycle ManagementDocument11 pagesVerification of RFID System Usability in Silage Bale Life Cycle ManagementCleaver BrightNo ratings yet

- Employee Monitoring System PDFDocument4 pagesEmployee Monitoring System PDFNinad SamelNo ratings yet

- Advanced RFID Measurements: Basic Theory To Protocol Conformance TestDocument10 pagesAdvanced RFID Measurements: Basic Theory To Protocol Conformance TestMitchell DanielsNo ratings yet

- Materials-Sensor Fabric 2020Document18 pagesMaterials-Sensor Fabric 2020TerritoryManNo ratings yet

- RFID Based Prepaid Energy MeterDocument38 pagesRFID Based Prepaid Energy MeterSaad Ali100% (1)

- Antenna Design For UHF RFID TagsDocument7 pagesAntenna Design For UHF RFID TagsReza Pour KiaNo ratings yet

- Overview of RFID-Based Indoor Positioning TechnologyDocument10 pagesOverview of RFID-Based Indoor Positioning TechnologyArthurNo ratings yet

- Radio Frequency Identification TechnologDocument10 pagesRadio Frequency Identification Technologsushmithanayak40No ratings yet

- Chapter 2Document17 pagesChapter 2dhiaa ahmedNo ratings yet

- RFID Based Prepaid Energy MeterDocument7 pagesRFID Based Prepaid Energy MeterBilal KhanNo ratings yet

- Rfid Based Telemedicine SystemDocument18 pagesRfid Based Telemedicine SystemTilottama DeoreNo ratings yet

- Overview of RFID Technology and Its Applications in The Food IndustryDocument6 pagesOverview of RFID Technology and Its Applications in The Food IndustryMarulina StewartNo ratings yet

- C C C C CCC !"#"#$% !Document9 pagesC C C C CCC !"#"#$% !Milin PatelNo ratings yet

- RFID Handbook: Fundamentals and Applications in Contactless Smart Cards, Radio Frequency Identification and Near-Field CommunicationFrom EverandRFID Handbook: Fundamentals and Applications in Contactless Smart Cards, Radio Frequency Identification and Near-Field CommunicationNo ratings yet

- RFID Systems: Research Trends and ChallengesFrom EverandRFID Systems: Research Trends and ChallengesRating: 5 out of 5 stars5/5 (1)

- Microwave and Millimeter Wave Circuits and Systems: Emerging Design, Technologies and ApplicationsFrom EverandMicrowave and Millimeter Wave Circuits and Systems: Emerging Design, Technologies and ApplicationsNo ratings yet

- Reconfigurable Radio Systems: Network Architectures and StandardsFrom EverandReconfigurable Radio Systems: Network Architectures and StandardsNo ratings yet

- Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts267 Manifold D Piping Iso View A1 1:100 1 1Document1 pagePetrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts267 Manifold D Piping Iso View A1 1:100 1 1instrengNo ratings yet

- PEDWPITS999230Document1 pagePEDWPITS999230instrengNo ratings yet

- PEDWPITS999227Document1 pagePEDWPITS999227instrengNo ratings yet

- Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Stairs, Ladders & Handrail Typical Details A1Document1 pagePetrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Stairs, Ladders & Handrail Typical Details A1instrengNo ratings yet

- Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts077 Pancake Main Structure Construction Drawing 1 A1 1:75 1 1Document1 pagePetrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts077 Pancake Main Structure Construction Drawing 1 A1 1:75 1 1instrengNo ratings yet

- Description of Revision Date (dd-MMM-yy)Document1 pageDescription of Revision Date (dd-MMM-yy)instrengNo ratings yet

- Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts077 Pancake Main Structure Arrangement A1 1:75 1 1Document1 pagePetrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts077 Pancake Main Structure Arrangement A1 1:75 1 1instrengNo ratings yet

- Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts077 Flare Ko Drum Module Equipment & Escape Route Layout A1 1:100 1 1Document1 pagePetrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Ts077 Flare Ko Drum Module Equipment & Escape Route Layout A1 1:100 1 1instrengNo ratings yet

- General Notes: Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Piping Layout (Below El. +105.000) A0 1:50 1 1Document1 pageGeneral Notes: Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Piping Layout (Below El. +105.000) A0 1:50 1 1instrengNo ratings yet

- Pedwstts004001 006V2Document1 pagePedwstts004001 006V2instrengNo ratings yet

- Petrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Stairs, Ladders & Handrail Typical Details A1Document1 pagePetrobras Netherlands BV Fpso Cidade de Ilhabela Topsides Stairs, Ladders & Handrail Typical Details A1instrengNo ratings yet

- Project: FT Catcher Fpso Feed: Hvac - Heater Load CalculationDocument7 pagesProject: FT Catcher Fpso Feed: Hvac - Heater Load CalculationinstrengNo ratings yet

- iF111S iF121S iF211S iF221S: Instruction ManualDocument20 pagesiF111S iF121S iF211S iF221S: Instruction ManualMiguel PerezNo ratings yet

- Cm2esp Xritdecoder InfoDocument4 pagesCm2esp Xritdecoder InfovluftmallmannNo ratings yet

- TDQ 182020DE 65Fv01Document1 pageTDQ 182020DE 65Fv01Юлия Абоймова100% (1)

- v150NX Quick Installation GuideDocument2 pagesv150NX Quick Installation GuideRega PrimastaNo ratings yet

- Series-Fed Aperture-Coupled Microstrip Antennas and ArraysDocument160 pagesSeries-Fed Aperture-Coupled Microstrip Antennas and ArraysKaushik ManjanbailNo ratings yet

- Planning of SIAEDocument205 pagesPlanning of SIAEThiago Andrade Rangel100% (1)

- Galaxy Owners Manual dx94hpDocument11 pagesGalaxy Owners Manual dx94hpbellscb100% (1)

- Nano PDFDocument404 pagesNano PDFKavi YaNo ratings yet

- Aoxvbll06 - 43 A A20Document4 pagesAoxvbll06 - 43 A A20Claudia MendesNo ratings yet

- Dual-Band Base Station Antenna Array With Cross-Band Scattering and In-Band Coupling SuppressionDocument9 pagesDual-Band Base Station Antenna Array With Cross-Band Scattering and In-Band Coupling Suppressiondtvt2006No ratings yet

- CollantDocument2 pagesCollantpogee752No ratings yet

- Xu Ly Nhieu U900Document36 pagesXu Ly Nhieu U900Maverick24No ratings yet

- EE 418 Exam IIDocument4 pagesEE 418 Exam IIMMhammed AlrowailyNo ratings yet

- Antenna and Wave Propagation Two Marks Question and AnswersDocument13 pagesAntenna and Wave Propagation Two Marks Question and AnswerskarthikcoolmsdsacNo ratings yet

- Contoh GA Report 1Document4 pagesContoh GA Report 1Asyrani AsariNo ratings yet

- AvddadaddDocument447 pagesAvddadaddNahum Martinez GarciaNo ratings yet

- TAGC1 de 1Document120 pagesTAGC1 de 1Firas KACHROUDINo ratings yet

- 21.1 Mb-4w8x33vb1-01-I3Document2 pages21.1 Mb-4w8x33vb1-01-I3YarinaNo ratings yet

- A New Antenna Feed Having Equal: E-And H-Plane PatternsDocument7 pagesA New Antenna Feed Having Equal: E-And H-Plane PatternsJulio CesarNo ratings yet

- 60 GHZ Wideband Antena With Air Filled Stacked Patch StructureDocument4 pages60 GHZ Wideband Antena With Air Filled Stacked Patch StructureKewin KusterNo ratings yet

- MPR Quick Start Guide For Powering and Installation 3db20024caaatnzza Ics01Document2 pagesMPR Quick Start Guide For Powering and Installation 3db20024caaatnzza Ics01Omar sameerNo ratings yet

- Anritsu 2015Document826 pagesAnritsu 2015ach47228No ratings yet

- 3X-V65A-3XR Antenna Product SpecificationDocument3 pages3X-V65A-3XR Antenna Product SpecificationMuamer DuricNo ratings yet

- Samsung 6G VisionDocument46 pagesSamsung 6G Visionstart-up.roNo ratings yet

- HW2017 WinProp LetterDocument2 pagesHW2017 WinProp LetterGiorgi PapavaNo ratings yet

- Satellite Communications Presentation MaterialDocument90 pagesSatellite Communications Presentation MaterialJohn Dexter RealizoNo ratings yet

- TX Int180kugDocument2 pagesTX Int180kugRobertito MenesesNo ratings yet

- Distributed Antenna SystemDocument5 pagesDistributed Antenna SystemAqeel HasanNo ratings yet

- Cambridge Audio Stereo Receiver Type Topaz SR20 - Users ManualDocument13 pagesCambridge Audio Stereo Receiver Type Topaz SR20 - Users ManualNorlec HiFiNo ratings yet

- Antenas AllgonDocument49 pagesAntenas AllgonhectorVRNo ratings yet

Passive UHF RFID in Paper Industry Challenges Benefits and The Application Environment-rUB

Passive UHF RFID in Paper Industry Challenges Benefits and The Application Environment-rUB

Uploaded by

instrengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passive UHF RFID in Paper Industry Challenges Benefits and The Application Environment-rUB

Passive UHF RFID in Paper Industry Challenges Benefits and The Application Environment-rUB

Uploaded by

instrengCopyright:

Available Formats

66 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO.

1, JANUARY 2009

Passive UHF RFID in Paper Industry: Challenges,

Benets and the Application Environment

Arttu Lehto, Jussi Nummela, Student Member, IEEE, Leena Ukkonen, Member, IEEE,

Lauri Sydnheimo, Member, IEEE, and Markku Kivikoski, Member, IEEE

AbstractRadio frequency identication (RFID) systems for the

paper industry is an emerging research topic due to the need for

an automated identication system for the paper industry which

would carry on the identication codes of paper and board reels

throughout their life cycle. This paper discusses the application of

passive ultra-high frequency (UHF) RFID systems to the paper in-

dustry. Challenges, benets, and the application environment of

using passive UHF RFID systems in the paper industry are pre-

sented and discussed. The major challenges are development of

globally operable tag antenna designs and integration of reader

units and reader antennas to paper handling machinery. To con-

front and solve these challenges, this paper presents novel tag an-

tenna designs for paper and board reel identication and proposes

solutions for reader and reader antenna integration to paper han-

dling machinery. In addition, the identication locations within the

paper reel supply chain and the effects of RFID systems to supply

chain visibility are presented and discussed. In addition, test results

of using passive UHF RFID systems in the paper industry environ-

ment are presented.

Note to PractitionersAn automated identication system,

which would carry on the identication code of a specied paper

or board reel throughout its life cycle, is needed in the paper

industry. Nowadays when barcode identication systems are used

the identity of the reels disappear when the wrapping of the reel

and at the same time the barcode are removed. The RFID tag,

however, would be attached to the paper reel core and thereby the

identication code of the reel is restored throughout its life cycle.

RFID systems would benet the paper industry by enhancing

the supply chain visibility and providing a more automated

identication system than barcode identication. In the future,

paper reels will be identied with clamp truck-integrated reader

units which, on the other hand, enables adding more real-time

information about the locations of the paper reels to information

databases but also sets challenges for paper reel tag performance

and integration of RFID reader units and reader antennas to

paper handling machinery. This paper concentrates on passive

UHF RFID systems and their application to the paper industry.

Challenges and benets of RFIDsystems in the specic application

environment of the paper industry are presented and discussed.

Manuscript received October 31, 2007. First published December 02, 2008;

current version published December 30, 2008. This paper was recommended

for publication by Associate Editor S. Sarma and Editor N. Viswanadham upon

evaluation of the reviewers comments.

J. Nummela, L. Ukkonen, L. Sydnheimo, and M. Kivikoski are with

the Department of Electronics, Rauma Research Unit, Tampere University

of Technology, FI-26100 Rauma, Finland (e-mail: jussi.nummela@tut.;

leena.ukkonen@tut.).

A. Lehto is with Rauma Stevedoring Ltd., 26101 Rauma, Finland (e-mail:

arttu.lehto@raumasteve.).

Digital Object Identier 10.1109/TASE.2008.2007269

Index TermsPaper industry, radio frequency identication

(RFID), tag antenna designs.

I. INTRODUCTION

T

HE PAPER industry needs an automated identication

system which would carry on the identication code of a

specied reel throughout the whole life cycle and supply chain

of paper and board reels. At the moment, when barcode identi-

cation systems are used, the identication code and thereby the

information about the specic reel disappears when the wrap-

ping and the barcode are removed. However, with radio fre-

quency identication (RFID) systems, it would be possible to

identify the individual reels from cradle to grave. In this case,

the safest place for the tag would be on the surface of the reel

core between the core and the paper. This way the identication

code is restored throughout the lifecycle of the reel from paper

or board mill to the end user, for example, in printing companies

[1], [2]. The outside surface of the core under the wrapped paper

is the best place for the tag because some reel handling machines

have a shaft that goes through the core. In this case, a tag that is

placed on the inside surface of the reel core would very likely

be damaged. RFID systems would benet the paper industry by

providing real-time information, for example, about handling

locations of the reel. Also, since the origin of the reel is known

throughout its life cycle, the use of RFID systems would im-

prove the quality control and the supply chain visibility [1][3].

The application of RFID in paper industry has been under

research and development for the past decade. Pilot tests have

been carried out to study the operability of different types of

RFID systems in paper reel identication. Considering the

high frequency (HF) RFID systems operating at 13.56 MHz,

the problems have been achieving sufcient read range and

the integration of large HF RFID reader antennas to paper

reel handling machinery, such as clamp trucks. Also, the use

of semi-passive UHF RFID systems with a battery which is

supporting the backscattering process have been proposed to

paper reel identication due to increased read range [4]. Com-

pared with passive systems, semi-passive systems are more

expensive and the durability of the tags battery, for example,

in very cold environments is also an issue to consider. This

paper concentrates on analyzing the use of passive UHF RFID

systems in paper reel identication. Recently, promising results

of identifying paper and board reels with passive ultra-high

frequency (UHF) RFID technology have been achieved [2],

1545-5955/$25.00 2008 IEEE

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 67

Fig. 1. Paper reel supply chain [10].

[5], [6]. After these studies, the development of passive UHF

RFID systems has been carried forward. This paper presents

the most recent results of the research work concentrating

on tag antenna development for paper and board reels and

performance testing of passive UHF RFID systems in the paper

industry environment.

The benets of this technology are sufcient read range of the

paper reels fromdesired orientations, cost-effective microchips,

possibilities for different tag antenna variations, relatively com-

pact reader antenna sizes for clamp-truck integrated readers, and

the possibility to use globally standardized RFID technology

due to EPC Gen2 specication [7].

Before passive UHF RFID systems can efciently be applied

to paper reel identication, a number of challenges have to be

confronted and solved. The application environment within the

supply chain of paper reels is very complicated, and paper and

board reels are complex objects with several boundaries and var-

ious material properties.

The placement of the tag between the core and the paper

or board sets challenges for passive UHF RFID. The lack of

a well-functioning, application specic tag antennas for identi-

cation of paper and board reels has been the major issue ob-

structing the application of RFID systems in the paper industry.

Tags that carry on the identication code consist of an antenna

and a microchip. Tag microchips in passive RFIDsystems do not

have an internal source of energy. Passive tags get all the energy

for functioning from the electromagnetic radiation transmitted

by the reader. The communication in passive UHF RFID sys-

tems is based on backscattering of modulated electromagnetic

wave: reader transmits energy, commands and data to tag which

then responds by backscattering its identication data that is

modulated to the carrier wave back to the reader [8], [9].

In addition to tag antenna development, many issues have to

be addressed: the identication locations of reels in the supply

chain have to be planned, the data content of the tags microchip

has to be dened, the RFID systems have to be integrated into

the existing data management systems and clamp-truck inte-

grated reader units and reader antennas have to be developed.

This paper presents and analyses the challenges, benets, and

the application environment of the use of passive UHF RFID

systems in the paper industry. The paper reel supply chain is

presented and the effects of RFIDon the paper reel supply chain

management and visibility are discussed. The application of

passive UHF RFID in the paper industry is also discussed and

analyzed with performance testing in the paper industry envi-

ronment. This paper addresses the major challenges of applying

passive UHF RFIDin the paper industry, which are development

of an omnidirectional tag antenna and integrating the reader

units and reader antennas to paper handling machinery.

II. PAPER REEL SUPPLY CHAIN

This section describes the structure of the basic supply chain

of paper reels and claries the role of barcode identication

systems that are in use in paper reel identication at the mo-

ment. The paper reel supply chain from the paper mill to the

end user includes several stages. An example of a supply chain

68 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO. 1, JANUARY 2009

Fig. 2. Bar code label afxed to the end of the paper reel core.

Fig. 3. Paper reel label.

of paper reels is presented in Fig. 1 [10]. The need for identi-

cation starts after the slitter machine where each reel is cut out

from the parent reel and trimmed to have a specied width and

web length. Nowadays, when barcode identication systems are

used, the rst barcode label is afxed on the other end of the reel

core after the reel comes out from the slitter machine. The bar-

code label afxed to the reel core is presented in Fig. 2. This

barcode includes the reel identication number. The identi-

cation numbers are given for each reel when the specic reel

widths and other parameters of the reels are planned. The infor-

mation about the reelwidth, weight, paper quality, etc.are

connected to the reel identication number and stored in the

database. After the slitter machine, the reel is automatically car-

ried forward to the packing plant using conveyor belts.

In the packing plant, the reel is shielded using wear-resistant

and waterproof wrapping paper. The wrapping paper is carefully

folded around the reel and over the inner end disk which is a cor-

rugated board disk that is shielding the ends of the reel. After

that, the outer end disk is xed. Nowadays, when barcode sys-

tems are used in paper reel identication labels including such

information as the weight of the reel, paper quality, length of the

wound paper, manufacturer mill, reel width and diameter, reel

identication number and the corresponding barcode are afxed

on the outer surface of the reel. The label can also indicate the

paper reel clamp pressure which can be used when the reel is

lifted with a clamp truck. Fig. 3 presents the paper reel label.

Fig. 4. The AGV carrying a paper reel.

This information is also saved to a database with the barcode

information and the identication number of the reel. Normally,

two labels are attached on the reel: one on the other end of the

reel and one on the belly of the reel. After this phase, the reel is

carried forward to the warehouse using conveyor belts.

Paper reels are normally stored at the mill and at their end des-

tination. In some cases, on the way fromthe mill to the end user,

the reels are stored by middlemen: stockists, export merchants,

and wholesalers. Warehousing should be efcient and the reels

should be stored in the warehouse or in the pressroom so that

each reel is readily available in the rst inrst out principle so

that the stock turnover can be followed. Electronic warehouse

management systems are used for optimizing the rotation of the

stocks and the storage plan.

In many countries, paper reels are transported on roadways

using trucks or on railways. Road and railway transportation

is also used for carrying reels from the mills to the sea ports.

Occasionally, the reels are delivered directly fromthe mill to the

ship and fromthe ship to the customer. In seaports, specic ma

trailers are used to transfer reels to and from the ship. Planned

loading reduces costs and delays in delivery.

Inside the printing house, automated guided vehicles (AGVs)

carry out the feeding of paper reels for continuous printing ma-

chines. Fig. 4 presents an AGV carrying a paper reel.

By means of a call key system, the printing machine operator

requests new paper reels on demand. From this electronic

request, the control system generates a transport order. The

AGV carries the paper reel of the desired paper quality from

the stock where the reels are prepared and stored and takes it to

the printing machine that is requesting it.

III. APPLICATION OF PASSIVE UHF RFID

IN THE PAPER INDUSTRY

Many issues have to be considered when passive UHF RFID

systems are planned to be applied in the paper industry. This

section concentrates on analyzing the attachment of the tag on

the reel core, the possible identication locations of the reels, the

data content of the tags microchip, and the desired read range

and reading directions of the reels.

A. Attachment of the Tag on the Reel Core

Reel cores are usually made of berboard, which can contain

recycled and newmaterial. The thickness of the berboard layer

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 69

varies between 1015 mm. For example, a 15-mm thick ber-

board layer contains 32 individual layers of 0.50.6-mm thick

berboard. These berboard layers are clued tightly together.

The inner diameter of reel core can be 3 inches (76.2 mm) or 6

inches (152.4 mm). In addition, 9 inch (228.6 mm) and 12 inch

(304.8 mm) reel cores are used, for example, in board mills.

The widths of the full reel core rods depend on the widths of

the slitter machines used in the individual paper mills. At the

paper mill, the reel core rod is cut into cores of individual reels

according to the customer order.

The tag should be attached to the individual reel core after it

has been cut to its nal width. This is because the tag should be

placed at the middle of the width of the reel core. In addition, the

tag should be afxed tightly to the core because the tag has to

endure the rolling process of paper at the slitter machine. At this

point, when the tag has been attached to the reel core, the reel

identication number can be programmed to the tag microchips

memory.

As noted above, nowadays reel cores are cut to their nal

width at the paper mill. In the future, when the RFID tags have

to be placed on the reel cores, precutting the reel cores and at-

taching the tags before the cores are shipped to the paper mill is

one possible new business process.

B. Identication Locations of Paper Reels

This section presents a description of possible paper reel

identication locations within the supply chain. The paper reel

supply chain is presented in Fig. 1.

The rst identication location for the reel would be right

after the slitter machine. At this point, the reel has been issued an

identication number. The identication would take place when

the reels are moved towards the packing plant on a conveyor

belt. In this paper, Section V-Apresents identication test results

of reels moving on a conveyor belt.

The second time for reel identication would be the arrival

to the packing plant. At this point, the reel identication would

indicate which reels have arrived for packaging. Third, the reels

should be identied when leaving the packing plant.

After leaving the packing plant, the reels are transported to a

warehouse using, for example, road transport. In the next stage,

the reels are moved to the warehouse with, for example, a clamp

truck. At this point, the reels should be identied with a clamp

truck-integrated reader unit. When the reels are identied with

a clamp truck-integrated reader unit, information, for example,

about the clamp truck lifting pressure and the location of the

reel in the warehouse could be saved to the database. In this

paper, Section V-B presents identication test results of paper

reels using a clamp-truck integrated reader unit.

From the warehouse, the reels are moved to transportation.

The paper reels are transported by boat, by road truck, or

using railways. Nevertheless, the reels have to be identied

when moved from the warehouse to the specic transportation

vehicle to ensure that the loading is carried out according to

the cargo plan. Section V-C in this paper presents identication

test results of paper reels placed on a moving ma trailer which

transports the reels to the sea ship.

Arrival of the reels to the end user is the next identication

location in this model. The reels are moved from the transporta-

tion vehicle to the end user warehouse using, for example, clamp

Fig. 5. The concept of omnidirectional reading.

trucks. From the end user warehouse, the reels are taken into

use. Moving the reels, for example, in the printing house can

be carried out with AGVs that should thereby have an onboard

reader unit. When some special paper qualities are used in small

printing batches, the reel can be moved back to the warehouse.

At this point, RFID gives a special feature compared to bar-

codes: the reel with an RFID tag maintains its identity and it

can be identied when the reel is again taken into use. Reels

with barcodes lose their identity when the wrapping is removed

at the point of using the reel for the rst time. After this it is very

challenging to identify the reels seamlessly.

All this identication information would be stored to a data-

base which authorized users, such as the manufacturer and the

client, would have access to. These kinds of databases already

exist and thereby the integration of RFID systems to the paper

industry should be relatively straightforward fromthe viewpoint

of information systems. RFID would enable more visible, ef-

cient and automated paper reel supply chain by enabling au-

tomated reel identication with clamp truck-integrated reader

units and by restoring the reel identity throughout the supply

chain from the paper mill to the end user.

C. Requirements for the Read Range With Passive UHF RFID

Systems

Due to the requirement of identication of the reels with a

clamp truck-integrated reader unit, the reels have to be identi-

ed omnidirectionally, i.e., 360 around the reel in horizontal

plane. When reels are identied with a clamp truck-integrated

RFID reader unit, the reel is clamped from arbitrary direction,

and despite of that fact the reel has to be identied reliably. In

addition, reading from any direction is a requirement also when

the reels are identied at any other location in the paper reel

supply chain, for example, on a conveyor belt. In practice, om-

nidirectional reading means that there is no need to turn the reel

for desired identication orientation. The concept of omnidirec-

tional reading is presented in Fig. 5.

Also, certain requirements are set for the read range of paper

reels. In the following specication, the read range is measured

from the center point of the reel, and thereby the actual read

range includes the paper reel radius and the distance in free air

from the paper reel surface. Read range from the center of the

reel should be at least 1500 mmdespite the radius of the reel and

70 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO. 1, JANUARY 2009

paper or board quality. In this specication, the maximumthick-

ness for paper or board layer is 900 mm. The remaining reading

distance will be an in-air distance measured from the paper or

board layer surface. However, currently the maximum diameter

for board reels is 2100 mm. In this case, the sufcient read range

measured from the board layer surface is 300400 mm.

The read ranges presented above are sufcient for reel iden-

tication because much longer read ranges would not give sig-

nicant benets to the supply chain management. In identica-

tion of paper and board reels, it is important to know which reel

is identied in the readers interrogation zone. Read ranges of

several meters might disturb the identication process because

generally only one reel at a time is needed to be identied. In

addition, when reels are identied with a clamp truck-integrated

reader unit the reader antenna will be brought very close to the

identied reel.

D. The Information Content of the Microchip

Depending on the memory size and type of the RFID mi-

crochip, different amounts of data can be written and stored

on the microchip. In its most minimalist form, the microchip

memory contains the identication code, which in this case is

usually the 14-character reel identication number. Also, for

example, the electronic product code (EPC) in its basic form

contains 96 bits. On the contrary, some microchips can contain

for example 2000 bits user-programmable information [11].

In the case of paper reel identication, the preferable infor-

mation content of the microchip would be only the reel iden-

tication number. All the other real-time information, for ex-

ample, about the handling locations of the reel would be stored

to the database. Due to the attenuating properties of paper, the

probability for bit error is high. If the bit-error rate is, for ex-

ample , which means that every 100th bit is lost, the 96 bit

identication code is read quite reliably despite the challenging

environment. However, if a 2000 bit identication code has to

be read through paper, multiple queries are needed to interro-

gate the whole identication data of the tag. This increases the

reading time and makes the identication more unreliable [11].

It should also be noted that though tags can be read through

paper, writing information to tags memory correspondingly

through paper is even a more challenging task. This also speaks

for using 96 bit read-only tags in paper reels and storing the

further information to a suitable database.

IV. CHALLENGES IN APPLYING PASSIVE UHF RFID

IN THE PAPER INDUSTRY

The paper industry is a very challenging application environ-

ment for passive UHF RFID systems. This section presents two

of these challenges: the challenges in paper reel tag antenna de-

sign and clamp truck-integrated reader unit and reader antenna

development.

A. Designing an Omnidirectional Tag Antenna

Due to the placement of the tag, the tags antenna has to be de-

signed to operate through paper or board. When an electromag-

netic wave propagates through paper or board, its wavelength,

speed and amplitude decrease. The decreased wavelength is de-

ned as the ratio of the free-space wavelength at the specied

frequency and the square root of the dielectric constant of paper,

and it affects the electrical dimensions of the tag antenna inside

the reel [2], [11], [12]. Thereby the tag antenna has to be tuned

to radiate at the right frequency when it is placed between the

core and the paper. In addition, since paper attenuates the elec-

tromagnetic wave the tag antenna must have enough surface area

to harvest energy for the microchip and to backscatter its iden-

tication data back to the reader.

In addition to the ability to read the tag through paper or

board, the biggest challenge has been developing a tag antenna

that would be readable omnidirectionally. This means that the

vertically orientated reel can be identied horizontally 360

around it. The concept of omnidirectional reading is explained

in Fig. 5. This feature is crucial, for example, in clamp truck

handling of the reels.

At the moment there is a variety of commercial passive UHF

RFID tags available. We have previously tested these usually

dipole-type tags in paper reel identication by attaching the tag

on the reel core after which the paper was wrapped around it [2].

With standardized UHF RFID equipment, it is possible to iden-

tify commercial tags through an industrial paper reel on some

directions but omnidirectional reading around the reel is not pos-

sible with these commercial tags [2]. Commercial tags are usu-

ally based on small dipole antennas and thereby their radiation

properties, for example radiation pattern and radar cross sec-

tion (RCS) are not suitable for omnidirectional reading through

a thick layer of attenuating material. The ability to identify the

tag from any direction around the reel is indispensable in clamp

truck handling: the truck driver has to be able to grab the reel

with the truck clamps from any direction, and the reel must

be identied automatically with a clamp truck-integrated reader

unit. This way the time stamps of handling the reel in different

locations can be saved to the database and tracked.

Achieving optimal performance of tags in paper industry ap-

plications requires careful designing of tag antennas taking into

account the effects of paper and board on the antenna perfor-

mance. Board is dened as a heavyweight sheet generally made

from waste paper and has a thickness of more than 0.15 mm.

Whereas paper contains one main material layer, board typically

has several layers. The dielectric properties of paper and board

have a paramount effect on designing tag antennas for paper reel

identication. One of the most important parameters is permit-

tivity . Permittivity describes the polarizability of the mate-

rial in an external electric eld. Since the values of are in the

order of , it is more practical to use the dielectric

constant , which is the ratio of the permittivity of the mate-

rial and the permittivity of vacuum

(1)

The dielectric constant of paper varies typically from 2 to 4 de-

pending on density, ller content, ber furnish, etc. Also, mois-

ture content has some effect on the dielectric constant of paper.

Dielectric constant is also frequency dependent decreasing with

frequency [2], [12], [13].

The dielectric constant of paper increases with increasing

density and the behavior follows with reasonable accuracy the

ClausiusMossotti relation:

(2)

where is the real part of the complex dielectric constant and

is the density of paper. Fillers, for example, and

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 71

kaolin, increase the density of paper, and also the dielectric con-

stant of llers is usually higher than the dielectric constant of

wood bers. For example, the dielectric constant of

is approximately 8.5. Due to these two issues, llers increase

the dielectric constant of paper. Also, the loss tangent of paper

, and thereby the dielectric losses of paper, increases lin-

early with density [13].

Dielectric properties of paper are also affected by the

moisture in paper. Typically, the moisture content of paper is

3%7%. When board reels come out of the slitter machine, their

moisture content can be up to 10%. However, the change in the

moisture content does not signicantly change the dielectric

constant of paper itself, although the dielectric constant of

water is nearly 80. This high dielectric constant is due to the

permanent dipole moment of water molecules. However, in

paper, water molecules are attached to cellulose chains, and

therefore they cannot rotate freely. A water molecule attached

to cellulose chain is free to orientate itself parallel to the electric

eld only if the eld is parallel to the orientation of the cellulose

chain. Since the chain orientations in paper are random, only

a small fraction of the water molecules have perfect alignment

with the electric eld. Therefore, the effect of water on the

dielectric constant of paper is smaller than would be expected

if the water molecules were free. However, the increase in

moisture content increases the dielectric losses of paper [2],

[13].

The dielectric properties of paper have a direct inuence

on the wavelength of the electromagnetic wave propagating

through paper and therefore on the electrical dimensions of the

tag antenna itself. The tag antenna is placed on the reel core

between the reel and the paper. The decrease in the wavelength

inside the paper layer wrapped around the core can be dened

with

(3)

where is wavelength in paper, is free-space wavelength and

is the dielectric constant of paper [2], [11], [12]. Since the di-

mensions of tag antennas at UHF frequencies are proportional

to the wavelength of the RFID system frequency, this decreased

wavelength has to be considered when the tag antenna is de-

signed to operate through paper.

Different reel and reel core diameters also cause challenges

for paper reel identication. Generally, reel diameters vary be-

tween 4001800 mm. Reel core inner diameters are either 3, 6,

9, or 12 inches. The tag antenna design should be functioning

with all paper and board qualities. However, the dimensions of

the tag antenna can be varied according to the reel core diameter.

The tag should be placed at the middle of the reel width. This

way, the location of the tag inside the reel is known and this

arrangement also encourages the clamp truck drivers to handle

the reels in the right way. The reels should always be lifted by

grabbing the reel from the middle of the reel width to prevent

damages.

In addition, the worldwide UHF RFID bandwidth covers fre-

quencies from 865 to 960 MHz. Thereby, the tag has to be func-

tioning within this bandwidth.

1) Omnidirectional Tag Antenna Designs for Paper Reels:

The lack of a well-functioning, omnidirectional tag antenna for

paper reels is a major issue impeding the application of RFID

systems to paper industry. Therefore, the suitable tag antenna

design has to be developed rst to enable the identication of

the reels according to the specied read range requirements.

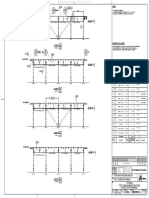

Fig. 6. Geometry of the C-tag antenna design at and mounted on the reel core.

Fig. 7. Geometry of the array tag design at.

As examples of omnidirectional tag antenna designs for paper

reels that are under research and development are the C-tag an-

tenna [2], [5] and the array tag antenna design [6]. The geometry

of the C-tag at and mounted around the reel core is presented

in Fig. 6. It is a modication of a bow-tie antenna with larger

area and a length that is proportional to the wavelength of the

electromagnetic wave inside paper or board. The larger area of

the C-tag increases the RCS of the antenna design, and thereby

increases the area for harvesting energy to the microchip and

backscattering the identication data back to the reader [14]. In

other words, the larger surface area of the C-tag compared with

the commercial tags and its mounting around the reel core en-

ables the omnidirectional reading around the paper reel [2]. The

rst version of the C-tag design is presented in [2]. The geom-

etry of the C-tag has then been further developed and the results

of the following version have been presented in [5]. This paper

presents the most recent C-tag geometry with reading perfor-

mance results. The presented C-tag design has enough reading

performance for application testing in paper industry environ-

ment.

The geometry of the three-element array tag design is pre-

sented in Figs. 7 and 8. Fig. 7 presents the array tag design at.

The antenna design has one antenna element (the middlemost

in Fig. 7) to which the microchip is connected and two reector

elements to enable the omnidirectional reading. Length of the

bow-tie elements was 100 mm.

2) Read Range Measurements: To verify the functioning of

the C-tag antenna design and the three-element array design

in practice and to study their parameters, measurements at the

paper mill were carried out. The purpose of the measurements

was to study the read range of the C-tag and the three-element

array tag when they were placed on the core of the paper reel

72 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO. 1, JANUARY 2009

Fig. 8. Array tag design mounted on the reel core.

Fig. 9. The measurement directions around the paper reel.

under the paper layer. The paper quality used in the measure-

ments of the C-tag was coated offset printing paper and the di-

ameter of the paper reel was 960 mm. The paper quality used

in the measurements of the three-element array was newsprint

paper and the reel diameter was 1000 mm.

Read ranges of the C-tag and three-element array were mea-

sured with 915 MHz FCC compatible Gen 2 reader unit and

linearly polarized reader antennas from eight directions, as pre-

sented in Fig. 9. Read ranges of the C-tag were measured also

with 866 MHz ETSI compatible reader unit to compare the read

ranges with both of the frequency bands. The gain of the reader

antennas was 6 dBi. Figs. 1012 present the measured omni-

directional read ranges. The read ranges are measured from the

center point of the reel, i.e., the presented read range includes the

reel radius (for example, 0.48 m) and the free air distance from

the paper reel surface. These read ranges can be compared to

the read range requirement presented in Section III-C. The reel

core outer diameter was 105 mm (3 inch core). S in Figs. 1012

indicates the direction of the IC chip, which is equivalent to di-

rection 1 in Fig. 9.

The results show that both the C-tag antenna and the three-el-

ement array design can be read omnidirectionally through an

industrial paper reel with standardized RFID equipment. The

performance of the C-tag antenna design is conrmed within

both ETSI and FCC frequency bands and regulations. With the

Fig. 10. Omnidirectional read ranges of the C-tag antenna design measured

with FCC compliant 915 MHz reader unit.

Fig. 11. Omnidirectional read ranges of the C-tag antenna design measured

with ETSI compliant 866 MHz reader unit.

Fig. 12. Omnidirectional read ranges of the three-element array tag antenna

design measured with FCC compliant 915 MHz reader unit.

tested reel diameter, C-tag antenna complies with reading re-

quirements presented in Section III-C.

3) RFID Signal Analysis: Read range measurements pre-

sented in the previous section shows the practical performance

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 73

Fig. 13. Measurement system at paper mill.

of the tag antenna designs. However, for research work in fur-

ther developing the tag antenna designs, it is important to gain

knowledge about the identication process in the signal level.

Threshold power level and backscattered signal strength are im-

portant characterization parameters of tag functioning.

Very often the limiting factor for tag read range is the de-

livery of power to the IC chip of the tag. The transmitted power

by the reader is determined in the communication regulations,

and thereby the power delivery to the IC chip at a given distance

is determined by the tag antenna design. The IC chip requires

a certain amount of power to operate, and the tag antenna de-

sign and its matching structures determine how efciently the

power is delivered to the IC chip. In addition, the materials in

the vicinity of the tag affect the properties of the antenna and

the IC chip. We studied the threshold power level, which means

the minimum transmission power required to activate the tag at

a specied distance, of the C-tag inside the industrial paper reel.

The threshold power levels were measured omnidirectionally at

eight measurement directions, which are presented in Fig. 9.

However, the operating range and the reading reliability of

the tag depends also on the backscattered signal strength which

is detected at the receiver of the reader. The minimum signal

strength which the reader can reliably detect and decode is usu-

ally presented as the sensitivity of the reader (a power level in

dBm). Typically, the sensitivity of a commercial reader unit is

around 70 to 90 dBm. A typical method for measuring the

backscattered signal from the tag is using a signal source at-

tached to a transmitting antenna to send a query command to

the tag. The strength of the backscattered signal is then mea-

sured with a vector signal analyzer. The measurement can be

carried out with different transmission frequencies and power

levels for further tag characterization.

In the threshold power and backscattered signal mea-

surements conducted for this paper, we used Tagformance

measurement system [15]. Fig. 13 presents the measurement

setup at paper mill. The gain of the transmitting and receiving

antennas was 9 dBi and their polarization was linear. The

10 dB S11 bandwidth of the antennas was from 824 to

896 MHz. In this case, the measurement distance from the tag

was 0.60 m, of which 0.44 m was paper and 0.16 m was air.

Figs. 14 and 15 present the (i) threshold power level and

(ii) backscattered signal strength at threshold power level mea-

Fig. 14. (i) Measured threshold power level and (ii) backscattered signal

strength at threshold power level measured at 866 MHz.

Fig. 15. (i) Measured threshold power level and (ii) backscattered signal

strength at threshold power level measured at 915 MHz.

sured at 866 and 915 MHz. The results show that the achieved

read range is affected by the two factors, and also the environ-

mental conditions, such as reections and multipath propagation

which take place at the practical paper mill reading environment.

Generally, the threshold power levels and the backscattering

signal strength is feasible, taking into account that the measure-

ments have been carried out through the attenuating paper layer.

B. Integrating Reader Units and Reader Antennas to Paper

Handling Machinery

Seamless integration of reader units and reader antennas to

paper handling machinery is crucial for reliable and efcient

identication of paper reels. When paper reels are moving on a

conveyor belt inside the paper mill, one or more reader antennas

can be used in identication in a gate conguration. However,

integrating readers and reader antennas to clamp trucks is more

challenging.

As noted earlier, in clamp truck handling the tag has to be

readable from all the directions horizontally around the paper

reel when the reel is in vertical orientation. Omnidirectional

74 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO. 1, JANUARY 2009

Fig. 16. Perpendicular beam scanning applied to a clamp truck.

reading ability eliminates the direction dependence of reading

the tag. The reel can then be crabbed fromany direction with the

truck clamps and the tag is then read with the integrated clamp

truck RFID reader unit [2], [11]. In addition, when the tag can

be read omnidirectionally, only one reader antenna instead of

two or more reader antennas in a gate conguration can be used

at all identication locations, for example, in the paper mill.

There are three possibilities to integrate an RFID system to

the clamp trucks. One can use existing reader units, which are

relatively compact, and connect the reader antenna to the reader

unit with coax cabling. Identication information would be

transferred to the user terminal inside the truck with IO-cabling.

However, since the clamp trucks are working in harsh environ-

ments and, for example, a signicant amount of shaking occurs

when the truck is moving, general-purpose RFID readers and

the coax cabling is not a durable solution for this application.

Nowadays, there are reader units that are specically de-

signed for forklift use [16]. In many of these readers, the

reader antenna and the RF front end of the reader are integrated

together and the identication information is transferred to

the user terminal inside the truck with IO-cabling or wireless

connection. This would be a preferable solution also for paper

reel clamp trucks.

In addition, in the future, the clamp truck integrated reader

unit could be totally wireless: the identication information

would be transferred wirelessly using, for example, Bluetooth

and the reader unit would have a rechargeable power source.

The problem in this solution is the power source of the reader.

There should be found an ample time in the process to recharge

the batteries. Thereby, research should also be carried out to

study the possibilities of energy scavenging from the kinetic

energy of the clamp truck [17].

Since the reader antenna would be afxed to the paper reel

clamps, special challenges arise also for the development of the

reader antenna. Beam steering with antenna arrays [18] offer

a possibility to search for the tag antennas in paper or board

reels when the reader unit is integrated into a clamp truck. As

an improvement to beam steering, perpendicular beamscanning

that is presented in Fig. 16 can be used in clamp truck-integrated

Fig. 17. Reader unit set up next to the conveyor belt at the paper mill.

readers to minimize the signal path from reader to tag and vice

versa. Perpendicular beam scanning also gives aid in avoiding

the reections on the air-paper boundary. In addition, relatively

narrow beam reader antennas should be used in perpendicular

beam scanning to minimize the effect of noise originating from

the surrounding wireless communication systems [11].

V. PERFORMANCE TESTING IN THE

APPLICATION ENVIRONMENT

A. Conveyor Belt Reading Tests

The purpose of the conveyor belt reading testing was to verify

identication of moving reels on the conveyor belt at paper mill.

Identication took place right after the slitter machine. Figs. 17

and 18 present the measurement environment and measurement

set up. Alien Technologys ETSI and FCC compliant reader

units with linearly polarized antennas (6 dBi gain) were used in

the testing. The distance between the reels outer surface and the

reader antenna was 0.30 m. The reader antennas were placed on

only one side of the conveyor belt to verify the omnidirectional

reading. Also, multiple reader antennas in gate conguration on

both sides of the conveyor belt can be used in this application.

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 75

TABLE I

READING RESULTS OF THE CONVEYOR BELT TESTING

Fig. 18. Reels passing the reader unit.

Twenty reels with the newest version of C-tag were used in

the testing. Fig. 6 presents the C-tag design. The width of the

reels was 880 mm and the diameter was 960 mm. Paper quality

was offset printing paper. All 20 tags had different EPC codes

which was then linked with the reel number of each reel. The

tag microchip used in the testing was Alien Technologys Higgs

Gen 2 microchip.

Table I presents the results of the conveyor belt testing. All the

reels were identied with both of the reader units. As presented

in Table I, the orientation of the tags microchip relative to the

reader antenna was also noted. The reader antenna was on the

left side of the arrow in Table I (i.e., this sign points towards

the reader antenna). The results show that at 0.30 m reading

distance the orientation of the tags microchip does not have an

effect on the reading reliability.

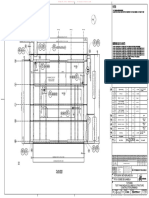

B. Reading Tests on the Clamp Truck

The purpose of the clamp truck testing was to verify the iden-

tication of paper reels grabbed by clamp truck. In this testing

existing commercial reader units and antennas were used. The

reader unit was placed in the cabin of the truck. The measure-

ments were performed with three different kinds of reader an-

tennas, with six paper reels. Diameter of all reels was 1250 mm.

Widths of the reels were 1440 mm (reel 1), 1290 mm (reel 2),

856 mm (reel 3), 1440 mm (reel 4), 1290 mm (reel 5), and

856 mm (reel 6). Paper quality was coated offset printing paper.

All reels were grabbed once with the clamp truck, and the iden-

tication with all antennas was then veried separately. Reel

number 6 was stacked on top of reel number 3, and they were

grabbed together fromthe center point of the stack. Reel number

2 was grabbed from all the eight different directions (directions

seen in Fig. 9) and the identication was again veried for all

antennas separately. Reels were located on a ma trailer, and

their locations and tag directions can be seen in Fig. 19.

The grabbing point of the paper reel should always be in

the middle of the reel width, where the grip is most stable and

durable. Then, the identication process is stable and the re-

sults are reliable. In these tests, the grab was always made in the

middle of the reel, to get the reliable results.

The antennas were attached to the clamp truck forks, as pre-

sented in Fig. 20. Antenna 1 was placed in the center, above the

clamps, and antennas 2 and 3 were placed between the clamps

on each side. Antenna 1 was Intermec IA39B circularly polar-

ized antenna, with 10.5 dBi gain and rugged berglass radome.

Antenna 2 was smaller Intermec IA33D circularly polarized an-

tenna with 6.0 dBi gain and metal cell specically designed

for lift truck applications. Antenna 3 was Huber+Suhner SPA

860/65/9/0/V linearly polarized planar antenna, with 9 dBi gain

76 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO. 1, JANUARY 2009

TABLE II

READING RESULTS OF CLAMP TRUCK INTEGRATED READER WITH THREE ANTENNAS, WHEN REELS WERE ON A MAFI TRAILER

Fig. 19. Reel locations and tag directions on a ma trailer, when grabbed from

side with clamp truck.

Fig. 20. Three tested antennas attached to paper reel clamps.

and regular plastic cover. The RFID reader used in testing was

Impinj ETSI compliant reader unit.

The results of separate reel identication with each antenna

can be seen fromTable II. In single reel cases (reel 1, 2, 4, and 5),

Fig. 21. Two stacked reels 3 and 6 grabbed together in truck clamps.

each antenna was able to identify the grabbed reel every time, re-

gardless of tag direction. When two stacked reels were grabbed

together to truck clamps, as seen in Fig. 21, antenna 1 and an-

tenna 3 identied upper reel, and antenna 2 identied the lower

reel. The presented values are average succeeded identications

per second.

In addition, reel number 2 was grabbed from eight different

directions, and the identication was veried with each antenna.

The results can be seen from Table III. The presented values are

average succeeded identications per second.

C. Reading Tests on the Ma Trailer

The purpose of the testing was to nd out how efciently the

paper reels tagged with the C-type tag could be identied when

they were pulled on a carriage through an RFID gate. The width

of the reels was 880 mm and the diameter was 960 mm. Paper

quality was offset printing paper. All the 14 tags had different

EPCcode which was then linked with the reel number. The tests

were performed in the port environment and as a transportation

eet there were used a terminal tractor with a ma trailer (SWL

50 tons). Fourteen reels were unitized onto the ma trailer and

they were put to a certain loading pattern, which is presented in

Fig. 22. Fig. 23 presents the setup of the RFID gate.

During the identication tests the distance of the RFIDreader

antenna from the surface of the moving reels was changed to

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 77

TABLE III

READING RESULTS OF CLAMP TRUCK INTEGRATED READER WITH THREE ANTENNAS, WHEN GRABBING THE REEL NUMBER 2 FROM EIGHT DIRECTIONS

TABLE IV

MAFI TRAILER READING RESULTS WITH FEIG ELECTRONICS ETSI COMPLIANT READER UNIT

Linearly polarized ETSI frequency band reader antennas with 9 dBi gain and 12-m long cables between the reader unit

and the antennas were used (cable losses are larger than usually).

Fig. 22. Identied reels on the ma trailer and the order of the reels.

clarify how the reading distance affects the identication reli-

ability. The tests were performed by changing the reading dis-

tances between 0.352.25 m from the antennas to the surface of

the reels. Each reading test was repeated 24 times. Different

RFID reader units were used: Impinj FCC compliant and Feig

Electronics, ETSI compliant reader unit. The reader antennas

were linearly polarized.

Tables IV and V present the results of RFID gate testing with

different types of reader units and antennas. With ETSI com-

pliant reader unit one reader antenna at each side of the gate

was used (a total of two reader antennas). It should be noted

that in this case 12-m long cables between the reader unit and

Fig. 23. The setup of the RFID gate in the port warehouse.

reader antennas were used which leads to larger power losses

than usually. Only one reader antenna on the other side of the

gate was used with the FCC compliant reader unit and FCC

compliant reader antenna. Thereby the maximum number of

identied reels was 7.

It was found out that with increasing reading distance the di-

rection of the IC chip relative to the reader antenna has an effect

on the identication of the reels. The most challenging identi-

cation case occurs when the ICchip points away fromthe reader

unit (direction 5 in Fig. 9).

78 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 6, NO. 1, JANUARY 2009

TABLE V

MAFI TRAILER READING RESULTS WITH IMPINJ FCC COMPLIANT READER UNIT

Linearly polarized FCC frequency band reader antenna with 6 dBi gain was used.

D. Summary of the Testing Results

The performance of C-tag for paper reel identication was

tested in three different identication locations in paper reel

supply chain: on conveyor belt after slitter machine, with paper

reel clamp truck-integrated reader units and reader antennas

on moving ma trailer. Paper quality in the testing was coated

offset printing paper, which is more attenuating than, for ex-

ample, newsprint paper due to higher ller content.

On conveyor belt, all the moving reels were identied at

0.30 m identication distance which is practical in many cases.

On clamp truck, identication depended on reader antenna

polarization and position relative to the crabbed reel and tag

inside the reel. However, with the combination of antennas

used in the testing identication was reliable and verication

of identifying paper reels on clamp truck was achieved. On the

ma trailer, the reliable identication distances in this testing

varied from 0.75 m (ETSI) to 1.75 m (FCC) from the reel

surface. In this testing case, the conguration and components

of the RFID gate have a large effect on reading reliability.

Generally, the testing results are promising and give a good

base for further testing and development of, for example, clamp

truck-integrated reader units and reader antennas.

VI. CONCLUSION

This paper presents the benets and challenges of applying

passive UHF RFID in the paper industry. The industrial appli-

cation environment in the paper reel supply chain is challenging

for the RFID system performance development. Efcient appli-

cation of passive UHF RFID systems to paper and board reel

identication requires development of novel tag and reader an-

tenna designs, development of reader units that can be integrated

to paper handling machinery, and integration of RFID systems

to the existing information management databases.

This paper presents the paper reel supply chain and discusses

the possibilities of RFID in paper reel supply chain manage-

ment. The application of passive UHF RFID in the paper in-

dustry is discussed and analyzed with performance testing in the

paper industry environment. This paper also presents novel tag

antenna designs for paper and board reel identication and pro-

poses solutions for integrating reader units and reader antennas

to paper handling machinery.

Reading test veried that identication can be reliably carried

out on conveyor belt inside the paper mill, on paper reel clamp

truck and ma trailer.

In the near future, the main emphasis of the research will be

on verifying and improving the performance of passive UHF

RFID systems in paper industry applications. Novel reader an-

tennas for clamp trucks based on the idea of perpendicular beam

scanning which is presented in this paper will be developed.

Identication of paper reels will also be tested with AGV in-

tegrated reader unit. Paper reel tags will be further optimized to

facilitate identication of reels with differently sized reel cores.

In addition, the information management architectures in paper

reel supply chain and integration of reader units and reader an-

tennas to paper handling machinery will be studied further.

REFERENCES

[1] M. Schaffrath, L. Ukkonen, L. Sydnheimo, and M. Kivikoski, RFID

tag antenna designs for paper industry applications: Passive bow-tie

transponder performance analysis, in Proc. 2nd IASTED Conf. An-

tenna, Radar Wave Propag., Jul. 2005, pp. 348353.

[2] L. Ukkonen, M. Schaffrath, J. Kataja, L. Sydnheimo, and M.

Kivikoski, Evolutionary RFID tag antenna design for paper industry

applications, Int. J. Radio Frequency Identif. Technol. Appl. Inder-

science, vol. 1, no. 1, pp. 107122, Oct. 2006.

[3] K. Michael and L. McCathie, The pros and cons of RFID in supply

chain management, in Proc. IEEE Int. Conf. Mobile Business, 2005,

pp. 623629.

[4] Power Paper, PowerR: Battery-Assisted Passive RFID for Paper

Reel Tracking. [Online]. Available: http://www.power-id.com/ last

accessed, Oct. 30, 2007

[5] L. Ukkonen, L. Sydnheimo, and M. Kivikoski, Design and perfor-

mance of passive UHF RFID tag antenna for industrial paper reels,

in Proc. IEEE Antennas and Propag. Soc. Int. Symp., Jun. 2007, pp.

54795482.

[6] L. Ukkonen, A. Yu, L. Sydnheimo, F. Yang, A. Elsherbeni, and M.

Kivikoski, Analysis of bow tie array RFID tag antenna for paper reel

identication systems, in Proc. IEEE Antennas and Propag. Soc. Int.

Symp., Jun. 2007, pp. 27452748.

[7] Alien Technology, EPCGlobal Class 1 Gen 2 RFID Specication.

White Paper. [Online]. Available: http://www.alientechnology.com/

docs/AT_wp_EPCGlobal_WEB.pdf, last accessed, Oct. 30, 2007

[8] K. Finkenzeller, RFD Handbook, 2nd ed. New York: Wiley, 2003.

[9] K. V. S. Rao, An overview of backscattered radio frequency identi-

cation system (RFID), in Proc. IEEE Asia Pacic Microw. Conf., Dec.

1999, vol. 3, pp. 746749.

[10] M. Keskilammi, P. Salonen, L. Sydnheimo, and M. Kivikoski,

Radio wave propagation modeling in paper reel for novel radio

frequency identication system, in Proc. IEEE JamCon, Technol.

Econ. Develop., Aug. 2000, 6 pp..

[11] L. Sydnheimo, Studies towards advanced mobile systems in indus-

trial applications, Ph.D. dissertation, Tampere Univ. Technol., Rauma,

Finland, Dec. 2005, ISBN 952-15-1492-2.

[12] C. A. Balanis, Advanced Engineering Electromagnetics. New York:

Wiley, 1989.

[13] S. Simula, T. Varpula, S. Iklinen, H. Sepp, A. Paukku, and K.

Niskanen, Measurement of the dielectric properties of paper, J.

Imaging Sci. Technol., vol. 43, no. 5, pp. 472477, 1999.

[14] E. F. Knott, J. F. Schaeffer, and M. T. Tuley, Radar Cross Section, 2nd

ed. Norwood, MA: Artech House, 1993.

LEHTO et al.: PASSIVE UHF RFID IN PAPER INDUSTRY: CHALLENGES, BENEFITS AND THE APPLICATION ENVIRONMENT 79

[15] Tagformance Measurement System. [Online]. Available: http://www.

voyantic.com, last accessed, Oct. 30, 2007

[16] [Online]. Available: http://www.symbol.com/rd5000.last accessed,

Oct. 30, 2007

[17] J. A. Paradiso and T. Starner, Energy scavenging for mobile and wire-

less electronics, IEEE Pervasive Computing, vol. 4, no. 1, pp. 1827,

Jan.Mar. 2005.

[18] P. Salonen, M. Keskilammi, L. Sydnheimo, and M. Kivikoski, An

intelligent 2.45 GHz beam scanning array for modern RFID reader, in

Proc. IEEE Int. Conf. Phased Array Syst. Technol., 2000, pp. 407410.

Arttu Lehto was born in Tampere, Finland, in 1972.

He received the M.Sc. degree in 2000 and the Li-

cenciate of Technology in 2006 in industrial man-

agement from the Tampere University of Technology

(TUT), Rauma, Finland. He is currently working to-

wards the Ph.D. degree in the RFID Research Group,

TUT, Department of Electronics Rauma Research

Unit.

He works as a Technical Manager of Rauma Steve-

doring Ltd., the port operator in the Port of Rauma.

Jussi Nummela (S07) was born in Rauma, Finland,

in 1977. He received the M.Sc. degree in telecom-

munications from the Tampere University of Tech-

nology (TUT), Rauma, Finland, in 2006. He is cur-

rently working towards the Ph.D. degree and working

as a Research Scientist in the RFID Research Group,

TUT, Department of Electronics Rauma Research

Unit.

His research focus is in telecommunications and

RFID.

Leena Ukkonen (M04) was born in Tampere,

Finland, in 1980. She received the M.Sc. and Ph.D.

degrees in electrical engineering from the Tampere

University of Technology (TUT), Rauma, Finland,

in 2003 and 2006, respectively.

She is currently working at the TUT, Department

of Electronics Rauma Research Unit as a Senior Re-

search Scientist and RFID Research Group Manager.

Her research interests are focused on passive UHF

radio frequency identication (RFID) antenna devel-

opment for tags and readers.

Lauri Sydnheimo (M02) was born in Tampere,

Finland, in 1959. He received the M.Sc. and Ph.D.

degrees in electrical engineering from the Tampere

University of Technology (TUT), Rauma, Finland,

in 1997 and 2005, respectively.

He is currently a Professor with the Department

of Electronics, TUT, and works as the Research

Director of Tampere University of Technologys

Rauma Research Unit. He has authored over 120

publications in the eld of RFID tag and reader

antenna design and RFID system performance im-

provement. His research interests are focused on wireless data communication

and radio frequency identication (RFID).

Markku Kivikoski (M94) was born in Tampere,

Finland, in 1952. He received the M.Sc., the Licen-

ciate of Technology, and the Doctor of Technology

degrees in electrical engineering from the Tampere

University of Technology (TUT), Rauma, Finland,

in 1976, 1980, and 1985, respectively.

In 1994, he was appointed by invitation to the

Professor Chair of Industrial Electronics at TUT.

He has served in the Research Council for Natural

Sciences and Engineering, Academy of Finland.

He is currently a Director of the Department of

Electronics, TUT, the Vice Rector and was elected to be the Rector of TUT in

August 2008. His research interests include wireless data transfer in industrial

environment, electromagnetic compatibility, embedded real-time systems,

mechatronics, and radio frequency identication (RFID).

You might also like