Professional Documents

Culture Documents

Sop SRTC Cal Sop T 05 (Temp. Gauge) - Lab

Sop SRTC Cal Sop T 05 (Temp. Gauge) - Lab

Uploaded by

sureshcal131Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop SRTC Cal Sop T 05 (Temp. Gauge) - Lab

Sop SRTC Cal Sop T 05 (Temp. Gauge) - Lab

Uploaded by

sureshcal131Copyright:

Available Formats

Sigma Test & Research Centre

Issue No : 01 Issue Date:05/09/2013 Standard Operating Procedure TEMPERATURE GAUGE (At Lab) Revision No :00 Revision Date :

PURPOSE SCOPE RESPONSIBILITY

: : :

To define procedure for calibration of Temperature Gauge Range -80 to 1100 C at Lab Calibration Engineer

MASTER EAQUIPMENT USED ENVIROMENTAL CONDITION

Standard PRT sensor, Digital Thermometer Readout (chub-4), Liquid Temperature Bath, Dry Block Temperature - (25 3) C Humidity - (50 10) % RH

PROCEDURE 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Temperature Gauge is visually checked for no any physical damage. Temperature Gauge under calibration is attached an under calibration tag .The type, Range, S.No, Make & other details of the temperature gauge are recorded in observation Sheet Format No. STRC/5.8/TH/F-01. Switch on the Liquid Temperature Bath OR Dry Block for temperature source and set it at a desired range for the calibration Point of Temperature Gauge. PRT and Temperature Gauge under calibration are put into the Liquid Temperature Bath. Record Temperature during calibration in Observation Data Sheet. Ensure all the connectivity of reference sensor with digital thermometer readout is correct. Allow sufficient time to stability of equilibrium temperature at the set value and ensure before taking the measurement of the PRT as well as Temperature Gauge under calibration. Wait for 15 to 20 minutes at the set temperature so that the dry block stabilise at set temperature. On Stabilization the set temperature of PRT &Temperature Gauge under calibration is record the temperature on the observation sheet. Five measurements are observed and recorded the temperature for each calibration set point repeat the above step for other temperature set points and cover the range as per customer request.

Prepared By Calibration Engr.

Checked By Manager Technical

Approved By Manager Technical

Doc No : STRC/CAL/SOP-T05 Page 1 of 3

Sigma Test & Research Centre

Issue No : 01 Issue Date:05/09/2013 Standard Operating Procedure TEMPERATURE GAUGE (At Lab) Revision No :00 Revision Date :

11. 12. 13. 14.

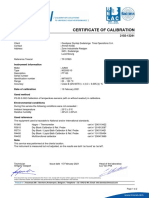

After Calibration the Temperature Gauge are not to be removed immediately, allowed sufficient time to cool the ambient temperature is reached. Calculate the uncertainty of measurement by taking 5 repeated readings at same Measurement point & as per N.A.B.L.-141. Affix the calibration sticker on the Temperature Gauge. Prepare the Calibration certificate in the format SRTC/5.10/TH/F-01.

16. REFERENCE: 1. SOP of calibration of Temperature Gauge STRC/CAL/SOP-T-05. 2. Observation Sheet no. STRC/5.8/TH/F-01. 3. Calibration Certificate format no. SRTC/5.10/TH/F-01. 4. ITS: 90 is referred. 5. Operating Manual & Calibration Certificate of PRT, Digital Thermometer Readout (chub-4), high precision bath. 6. NABL-141for uncertainty evaluation. 17. RECORDS: 1. 2. 3. Calibration data Observation Sheet. Uncertainty Evaluation Record sheet. Copy of Calibration Certificate.

Prepared By Calibration Engr.

Checked By Manager Technical

Approved By Manager Technical

Doc No : STRC/CAL/SOP-T05 Page 2 of 3

Sigma Test & Research Centre

Issue No : 01 Issue Date:05/09/2013 Standard Operating Procedure TEMPERATURE GAUGE (At Lab) Revision No :00 Revision Date :

Prepared By Calibration Engr.

Checked By Manager Technical

Approved By Manager Technical

Doc No : STRC/CAL/SOP-T-05 Page 3 of 3

You might also like

- Wilhelm Schulze StudyDocument11 pagesWilhelm Schulze Studyإلياس بن موسى بوراس100% (2)

- 4 SOP-Tank Farm Final Sent To ZonesDocument37 pages4 SOP-Tank Farm Final Sent To ZonesVijayNo ratings yet

- SOP For Inhouse CalibrationDocument7 pagesSOP For Inhouse Calibrationvasudeva yasas80% (5)

- 5 Things Successful People Do Before 8 AMDocument6 pages5 Things Successful People Do Before 8 AMRichard Regidor0% (1)

- Procedure Waterdraw Calibration CEC FMC PRD en 0005Document18 pagesProcedure Waterdraw Calibration CEC FMC PRD en 0005TahirNo ratings yet

- Chris Mills 2020Document17 pagesChris Mills 2020AminNo ratings yet

- hw1 Spring2016Document2 pageshw1 Spring2016Qu XunjieNo ratings yet

- Magdalena Zegarlińska - The Application of Mikhail Bakhtin's Concepts of Dialogism, Polyphony and Heteroglossia in Film AnalysisDocument9 pagesMagdalena Zegarlińska - The Application of Mikhail Bakhtin's Concepts of Dialogism, Polyphony and Heteroglossia in Film AnalysisInesAmoura26No ratings yet

- AllCeram Instructions enDocument36 pagesAllCeram Instructions enFabio WenoNo ratings yet

- Calibration Thermometer PDFDocument7 pagesCalibration Thermometer PDFGilberto Andrés Jurado100% (1)

- CAT CP 1 (T) Calibration of RTDDocument4 pagesCAT CP 1 (T) Calibration of RTDAmar Singh100% (2)

- Thermometer CalibrationDocument8 pagesThermometer CalibrationGeroldo 'Rollie' L. Querijero100% (1)

- SOP-51 v0 Calibration Procedure ManualDocument10 pagesSOP-51 v0 Calibration Procedure ManualHeni MehrezNo ratings yet

- Analytical Balance SOPDocument2 pagesAnalytical Balance SOPdivine productionNo ratings yet

- Certificate of Calibration: HTLS/DPG/04Document2 pagesCertificate of Calibration: HTLS/DPG/04Umang SOdhiNo ratings yet

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 page02-Calibration & Control of Measuring & Monitoring DeviceskitekNo ratings yet

- Temperature Calibrator - GuidelinessDocument2 pagesTemperature Calibrator - GuidelinessShanmugamoorthyNo ratings yet

- Lascar Calibration-Certificate Temperature-Humidity PDFDocument2 pagesLascar Calibration-Certificate Temperature-Humidity PDFMiguel Angel Pacahuala CristobalNo ratings yet

- Calibration of LPG ProversDocument19 pagesCalibration of LPG ProversanafadoNo ratings yet

- F 05 KDI QHSE 17a Environmental Inspection ChecklistDocument4 pagesF 05 KDI QHSE 17a Environmental Inspection ChecklistArsh AlamNo ratings yet

- Work Instruction FOR: Spectro AnalysisDocument3 pagesWork Instruction FOR: Spectro AnalysismahendraNo ratings yet

- TSC - 22-23 - 5490-1 TachometerDocument2 pagesTSC - 22-23 - 5490-1 TachometerDebabrata MajhiNo ratings yet

- Comprehensive: Comprehensive Calibration Lab PackagesDocument8 pagesComprehensive: Comprehensive Calibration Lab Packagessusanth_sukumaranNo ratings yet

- NMS FT 78 Calibration Certificate Format SoundDocument1 pageNMS FT 78 Calibration Certificate Format SoundYeswe calNo ratings yet

- Kosaka Lab Scope CC 2611Document50 pagesKosaka Lab Scope CC 2611kumarNo ratings yet

- Worksheet For Calibration CTMDocument1 pageWorksheet For Calibration CTMvasudeva yasasNo ratings yet

- BelzDocument24 pagesBelzrohanmanimaniNo ratings yet

- 29-Stop Watch Calibration CartificateDocument1 page29-Stop Watch Calibration CartificateCustomer SupportNo ratings yet

- Accreditation No: LAB 131Document9 pagesAccreditation No: LAB 131Doulat RamNo ratings yet

- SOP For Calibration of Temperature GaugesDocument3 pagesSOP For Calibration of Temperature Gaugesget_engineer0550% (2)

- Barton Automatic Tank Gauging System User ManualDocument12 pagesBarton Automatic Tank Gauging System User ManualSatit hunsaNo ratings yet

- Kejriwal Castings Limited: (Testing Lab, DGP)Document1 pageKejriwal Castings Limited: (Testing Lab, DGP)Aniruddha ChatterjeeNo ratings yet

- Calibration and Verification OF Spherical Tanks: Antwerp Februari 2001Document6 pagesCalibration and Verification OF Spherical Tanks: Antwerp Februari 2001m1c2rNo ratings yet

- Safety Understand The Requirement Calibration Documentation Calibration Procedure For Various InstrumentDocument6 pagesSafety Understand The Requirement Calibration Documentation Calibration Procedure For Various Instrumentkrishna kumarNo ratings yet

- Method Statement For PH MeterDocument2 pagesMethod Statement For PH MeterMuhamed RasheedNo ratings yet

- 002 Pressure Calibration, Master Gauges and Pressure Indicator PDFDocument9 pages002 Pressure Calibration, Master Gauges and Pressure Indicator PDFManzoor AhmadNo ratings yet

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoNo ratings yet

- Standard Calibration Procedure Pressure Switch Doc. No. Call/SCP/015 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Pressure Switch Doc. No. Call/SCP/015 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- QSP - 07 Quality Assurance ProcedureDocument4 pagesQSP - 07 Quality Assurance ProcedureMark BuendiaNo ratings yet

- Terms of Calibration Service (Rev. 7, May 2014)Document1 pageTerms of Calibration Service (Rev. 7, May 2014)John Paul RosNo ratings yet

- Htytdjhfjgk LJ K JKFTDRGBNDocument45 pagesHtytdjhfjgk LJ K JKFTDRGBNDeepak HoleNo ratings yet

- Samsung Swf-p12 Service ManualDocument2 pagesSamsung Swf-p12 Service ManualAivar JanessooNo ratings yet

- 5800 - 10 Pressure Gauge 6000 PsiDocument2 pages5800 - 10 Pressure Gauge 6000 PsiNizar AlifNo ratings yet

- Ertl NorthDocument18 pagesErtl NorthSharath KarnatiNo ratings yet

- ShackleDocument8 pagesShackleAJITH VSNo ratings yet

- Wfp291338 For Quality and Quantity Inspection of FoodsDocument14 pagesWfp291338 For Quality and Quantity Inspection of FoodsOzlem MepNo ratings yet

- AMENAG CSS Company ProfileDocument8 pagesAMENAG CSS Company Profilemukhlis100% (1)

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Document2 pagesMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedNo ratings yet

- PH Buffer Solution 4Document2 pagesPH Buffer Solution 4Anil Rawat100% (1)

- Equipment Calibration/Maintenance: APPENDIX D - USFWS QA Program (5/04)Document5 pagesEquipment Calibration/Maintenance: APPENDIX D - USFWS QA Program (5/04)Defry Farhandinata100% (1)

- Fluk Ammeter CalibrationDocument250 pagesFluk Ammeter CalibrationASHUTOSH BHATTNo ratings yet

- 1113 Maintenance of PRVDocument63 pages1113 Maintenance of PRVhardito sussatrioNo ratings yet

- UTI Test CertificateDocument1 pageUTI Test CertificatePavel ViktorNo ratings yet

- Calibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Document4 pagesCalibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Sherwin John Navarro100% (1)

- CP No.601-Hydraulic Type (Pressure) - RevDocument18 pagesCP No.601-Hydraulic Type (Pressure) - Revamelchan_tiqueNo ratings yet

- 074-005 Plain Ring GaugeDocument5 pages074-005 Plain Ring GaugeRavichandran DNo ratings yet

- Certificate of Calibration: Customer InformationDocument2 pagesCertificate of Calibration: Customer InformationSazzath HossainNo ratings yet

- PH Sensor Calibration ProcedureDocument2 pagesPH Sensor Calibration ProcedureRajuNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- E002 For Instrument Acceptance StandardsDocument14 pagesE002 For Instrument Acceptance StandardsSuresh Kumar RanaNo ratings yet

- Required File Name Reaffirmed Title EquivalentDocument22 pagesRequired File Name Reaffirmed Title Equivalenthtutswe100% (1)

- AC Yoke Cal 11Document2 pagesAC Yoke Cal 11John Dolan100% (1)

- 00 Op C0038Document25 pages00 Op C0038pchakkrapaniNo ratings yet

- U 897 DWM 600Document1 pageU 897 DWM 600Amit KumarNo ratings yet

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DNo ratings yet

- Riding 2002Document69 pagesRiding 2002Elmira RomanovaNo ratings yet

- Research Method in Operations Management: Group 7 PresentsDocument23 pagesResearch Method in Operations Management: Group 7 PresentsanggaNo ratings yet

- Roof Truss Details: Proposed Reinforcement and Roof of Existing Parapet at Roof Deck Thru: Engr. Sergio Mellejor JRDocument1 pageRoof Truss Details: Proposed Reinforcement and Roof of Existing Parapet at Roof Deck Thru: Engr. Sergio Mellejor JRSbftechnical StaffNo ratings yet

- Math Worksheet - 3Document4 pagesMath Worksheet - 3Abinaya ParthasarathyNo ratings yet

- Combined VariationDocument3 pagesCombined VariationB01 BASILIO, MICHAEL ANGELO L.No ratings yet

- Lesson Plan WavefrontDocument6 pagesLesson Plan Wavefrontafifahyuliani100% (1)

- Data Will Set You FreeDocument1 pageData Will Set You FreeAnand AroraNo ratings yet

- Crop Tool and Lasso Tool Lesson PlanDocument2 pagesCrop Tool and Lasso Tool Lesson PlanJorene ApuyaNo ratings yet

- FT50 Journals Used in FT Research Rank - Financial TimesDocument3 pagesFT50 Journals Used in FT Research Rank - Financial TimesgalatimeNo ratings yet

- Ict Literacy Skills Development Training of TrainersDocument3 pagesIct Literacy Skills Development Training of TrainersAmir M. Villas100% (2)

- 2008JCECapillary PDFDocument4 pages2008JCECapillary PDFshaileshNo ratings yet

- Etimology of Techical Vocabulary in EnglishDocument6 pagesEtimology of Techical Vocabulary in Englishkewin_walterNo ratings yet

- Vehicles TacticsDocument21 pagesVehicles TacticseremeevionNo ratings yet

- Anthropometric ProceduresDocument4 pagesAnthropometric ProceduresdrkrishnaswethaNo ratings yet

- Detail Advt. - 08.12.20231703045475079-2Document35 pagesDetail Advt. - 08.12.20231703045475079-2chandrajeetmaurya25No ratings yet

- Guides in Using The Measurement Package On DiscernmentDocument16 pagesGuides in Using The Measurement Package On DiscernmentHelen LomahanNo ratings yet

- What Illusions Teach Us PDFDocument4 pagesWhat Illusions Teach Us PDFDr JoseNo ratings yet

- Books Thermo ElectricityDocument7 pagesBooks Thermo ElectricityAmma Muliya RomadoniNo ratings yet

- Lesson 2 HardwareDocument35 pagesLesson 2 HardwareJeff ErniNo ratings yet

- Attitudes of Children Toward Singing and Choir Participation and Assessed Singing SkillDocument13 pagesAttitudes of Children Toward Singing and Choir Participation and Assessed Singing Skillli manniiiNo ratings yet

- People Pleasing Patterns Are Learned When Needs Are Not Met PDFDocument10 pagesPeople Pleasing Patterns Are Learned When Needs Are Not Met PDFPamela RodriguezNo ratings yet

- DOW UF Case Study For High Turbid WaterDocument5 pagesDOW UF Case Study For High Turbid WaterWendyNo ratings yet

- Feasibility 3Document10 pagesFeasibility 3Renz JacalanNo ratings yet

- English - The Global LanguageDocument7 pagesEnglish - The Global LanguageMrigakhi Sandilya0% (1)