Professional Documents

Culture Documents

Powermax Powerpac GB

Powermax Powerpac GB

Uploaded by

ghodghod123Copyright:

Available Formats

You might also like

- SSP 652 Audi 40l v8 Tdi Engine of Ea898 SeriesDocument48 pagesSSP 652 Audi 40l v8 Tdi Engine of Ea898 SeriesJose Ramón Orenes ClementeNo ratings yet

- Project On CSRDocument40 pagesProject On CSRghodghod12383% (47)

- Electrocraft EAD BLDC CatalogDocument16 pagesElectrocraft EAD BLDC CatalogElectromateNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 2016 Backward Design Unit Plan TemplateDocument23 pages2016 Backward Design Unit Plan Templateapi-311086670100% (1)

- Kollmorgen Powermax II CatalogDocument4 pagesKollmorgen Powermax II CatalogElectromateNo ratings yet

- Kollmorgen Nema23 PowermaxII CatalogDocument12 pagesKollmorgen Nema23 PowermaxII CatalogElectromateNo ratings yet

- Stepper Catalog en-US RevC enDocument148 pagesStepper Catalog en-US RevC enJorge JuarezNo ratings yet

- Nema P2 Stepper System TBDocument4 pagesNema P2 Stepper System TBRomulo Cardoso100% (1)

- Stepper Motors Catalog en-US RevADocument146 pagesStepper Motors Catalog en-US RevAYazeed MomaniNo ratings yet

- Ametek MCG Stepper CatalogDocument34 pagesAmetek MCG Stepper CatalogElectromateNo ratings yet

- CG 3 Phase MotorDocument76 pagesCG 3 Phase MotorSaravanan Mani100% (1)

- Kollmorgen N&K Series Nema 42 SpecsheetDocument4 pagesKollmorgen N&K Series Nema 42 SpecsheetElectromateNo ratings yet

- Electrocraft Legacy CatalogDocument59 pagesElectrocraft Legacy CatalogElectromateNo ratings yet

- Caracteristicas Motores PDFDocument60 pagesCaracteristicas Motores PDF0ZKRCITHONo ratings yet

- Kollmorgen Nema23 Special Purpose SpecsheetDocument3 pagesKollmorgen Nema23 Special Purpose SpecsheetElectromateNo ratings yet

- Actuator CatalogDocument71 pagesActuator CatalogaquinorickyNo ratings yet

- BrushlessDocument141 pagesBrushlessalysonmicheaalaNo ratings yet

- Electrocraft Stepper CatalogDocument41 pagesElectrocraft Stepper CatalogElectromateNo ratings yet

- Stepper Catalog en-US RevC EN PDFDocument148 pagesStepper Catalog en-US RevC EN PDFGuillermo Chuquillanqui PradoNo ratings yet

- Dyadics SCN6 DatasheetDocument2 pagesDyadics SCN6 DatasheetElectromateNo ratings yet

- Kollmorgen Nema 34 N3 K3 Stepper Systems TB SpecsheetDocument4 pagesKollmorgen Nema 34 N3 K3 Stepper Systems TB SpecsheetElectromateNo ratings yet

- N23 Industrial Grade MotorsDocument5 pagesN23 Industrial Grade Motorszhifeng yanNo ratings yet

- MotorDocument48 pagesMotorHernan CuevasNo ratings yet

- Dynasyn Hightorque-Servomotors DT: Dynamic. Compact. PowerfulDocument34 pagesDynasyn Hightorque-Servomotors DT: Dynamic. Compact. PowerfulMoumene Djafer BeyNo ratings yet

- Electrocraft PMDC CatalogDocument42 pagesElectrocraft PMDC CatalogElectromateNo ratings yet

- Stepper Catalog PDFDocument36 pagesStepper Catalog PDFCano VoyNo ratings yet

- SM Series Stepper MotorsDocument7 pagesSM Series Stepper MotorsPham LongNo ratings yet

- Servo-Motor Selection-Guide en-US 2006 PDFDocument48 pagesServo-Motor Selection-Guide en-US 2006 PDFIsaac Gutierrez PayanNo ratings yet

- Mosfets: Product GuideDocument63 pagesMosfets: Product Guideihodiputah_510No ratings yet

- YEG2 SDocument2 pagesYEG2 Swpt_meNo ratings yet

- Uc 3843 Data SheetDocument56 pagesUc 3843 Data Sheetmeepow100% (1)

- Dynamatic Technologies LTD® Hydraulic Gear Motor, Model:1DR: Salient FeaturesDocument12 pagesDynamatic Technologies LTD® Hydraulic Gear Motor, Model:1DR: Salient FeatureskottaNo ratings yet

- Dc02en PDFDocument42 pagesDc02en PDFKaya EmanuelNo ratings yet

- CAT DC Motors en PDFDocument38 pagesCAT DC Motors en PDFMaria IlieNo ratings yet

- Nos RamDocument32 pagesNos RamSocial Path100% (1)

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogElectromateNo ratings yet

- Sony Dsr-11 Ver-1.1 SMDocument173 pagesSony Dsr-11 Ver-1.1 SMsaul64No ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogServo2GoNo ratings yet

- Dyadics SCN5 DatasheetDocument2 pagesDyadics SCN5 DatasheetElectromateNo ratings yet

- Freedom Series DataDocument120 pagesFreedom Series Datahockey_36No ratings yet

- 3G3JXDocument8 pages3G3JXrwciriloNo ratings yet

- Powerpak HandbookDocument0 pagesPowerpak HandbookPehr HedströmNo ratings yet

- Rad Torque CatalogDocument16 pagesRad Torque CatalogJesus CcoylloNo ratings yet

- Yeg2 3Document2 pagesYeg2 3wpt_meNo ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogElectromateNo ratings yet

- Vexta Motor BrochureDocument56 pagesVexta Motor BrochureSandy KohlndorferNo ratings yet

- Electrocraft Linear Motors CatalogDocument37 pagesElectrocraft Linear Motors CatalogElectromateNo ratings yet

- R Series.255131941Document4 pagesR Series.255131941Rajabhau VaidyaNo ratings yet

- Kollmorgen PMA Series CatalogDocument6 pagesKollmorgen PMA Series CatalogElectromateNo ratings yet

- Magnetic Particle Equipment Selection GuideDocument16 pagesMagnetic Particle Equipment Selection GuideWellington S. FrançaNo ratings yet

- De DriveDocument6 pagesDe DriveEdgar RdzNo ratings yet

- Alteradores MarathonDocument8 pagesAlteradores MarathonSalineñoApasionadoNo ratings yet

- Marine Alternators: Up To 2500 kVA 50Hz / 3000kVA 60HzDocument5 pagesMarine Alternators: Up To 2500 kVA 50Hz / 3000kVA 60HzxxxxxAMSNo ratings yet

- Ie3 Pa Pe SeriesDocument16 pagesIe3 Pa Pe SeriesshakibNo ratings yet

- Cartepillar C32 Diesel Oilfield Generator SetDocument4 pagesCartepillar C32 Diesel Oilfield Generator SetJesus Enrique Figueroa GilNo ratings yet

- Regal SGA CatDocument40 pagesRegal SGA CatIee XpNo ratings yet

- SPECTRA - NEMA Molded Case Circuit Breakers - Application andDocument51 pagesSPECTRA - NEMA Molded Case Circuit Breakers - Application andnaufrago69aNo ratings yet

- Vol06 Tab02Document250 pagesVol06 Tab02r2d2zpNo ratings yet

- Basf Brand Guide Directrices de Identidad CorporativaDocument27 pagesBasf Brand Guide Directrices de Identidad Corporativaghodghod123No ratings yet

- ConicsDocument3 pagesConicsghodghod123No ratings yet

- Berkeley Campaign Style 09Document79 pagesBerkeley Campaign Style 09ghodghod123No ratings yet

- BSA Brand IdentityDocument34 pagesBSA Brand IdentityJoe DonahueNo ratings yet

- EasyGroup Brand ManualDocument36 pagesEasyGroup Brand Manualghodghod123No ratings yet

- Carnegie Mellon Writers Style GuideDocument13 pagesCarnegie Mellon Writers Style Guideghodghod123No ratings yet

- Channel4 C4StyleGuide1.1Document46 pagesChannel4 C4StyleGuide1.1ghodghod123No ratings yet

- Restaurants: Tung Fong Harvey's World CuisineDocument1 pageRestaurants: Tung Fong Harvey's World Cuisineghodghod123No ratings yet

- Nightlife: Little Italy (Little High) Bluzz - Lounge BarDocument2 pagesNightlife: Little Italy (Little High) Bluzz - Lounge Barghodghod123No ratings yet

- Thomas Telford BooksDocument16 pagesThomas Telford Booksghodghod123No ratings yet

- Bigdata Analytics in Energy UtilitiesDocument24 pagesBigdata Analytics in Energy UtilitiesDeepak Panguluri100% (2)

- An Overview of Nitinol Medical ApplicationsDocument12 pagesAn Overview of Nitinol Medical Applicationsgulangyu2019No ratings yet

- Corrosion StudyDocument1 pageCorrosion Studygeoff-ayton-7603No ratings yet

- 967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)Document41 pages967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)AbysmalNo ratings yet

- Interpretations To Asme b31 3Document17 pagesInterpretations To Asme b31 3Phornlert WanaNo ratings yet

- Motors - Installation, Operation, MaintenanceDocument20 pagesMotors - Installation, Operation, MaintenanceVlada JelenićNo ratings yet

- PVM (X) Series: Vertical Multistage PumpsDocument11 pagesPVM (X) Series: Vertical Multistage PumpsNelson IglesiasNo ratings yet

- Microwave TubesDocument139 pagesMicrowave TubesGopichand DasariNo ratings yet

- Thermodynamics States A Set of Four Laws Which Are Valid For All Systems That Fall Within The Constraints Implied by EachDocument2 pagesThermodynamics States A Set of Four Laws Which Are Valid For All Systems That Fall Within The Constraints Implied by EachKevin Alberto Tejera PereiraNo ratings yet

- MKE Bab 5 1 Turbin Aksi Dan ReaksiDocument2 pagesMKE Bab 5 1 Turbin Aksi Dan ReaksiMariaulfadamayantiNo ratings yet

- 20 C32 1000 KW 480VDocument6 pages20 C32 1000 KW 480VDIEGO PEÑALOZANo ratings yet

- DL - AP21-1019 - SpecSheet - IFF50 - en-EU PrimusDocument2 pagesDL - AP21-1019 - SpecSheet - IFF50 - en-EU Primuskato davidNo ratings yet

- Build-a-ma-Jigs Aeroplane BX1322Document2 pagesBuild-a-ma-Jigs Aeroplane BX1322Alex IvanovNo ratings yet

- PRINTED ChemT4HLQDocument18 pagesPRINTED ChemT4HLQtaengooNo ratings yet

- Course Curriculum Course: Thermal Engineering-II Course Code: 3351901Document12 pagesCourse Curriculum Course: Thermal Engineering-II Course Code: 3351901rushibmr19785604No ratings yet

- Petroleum Refining IWW Case Study - FinalDocument9 pagesPetroleum Refining IWW Case Study - FinalIastra100% (1)

- Chemistry Investigatory Project On Evaporation of LiquidDocument22 pagesChemistry Investigatory Project On Evaporation of LiquidDivyanshu KumarNo ratings yet

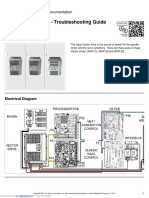

- Vector Drive - Troubleshooting Guide: Haas Technical DocumentationDocument7 pagesVector Drive - Troubleshooting Guide: Haas Technical DocumentationViruzeNo ratings yet

- Organic Review Worksheet and Problem SetDocument20 pagesOrganic Review Worksheet and Problem SetNelNo ratings yet

- Inter 2 Physics Success SeriesDocument12 pagesInter 2 Physics Success SeriesZain AliNo ratings yet

- Alkyl HalidesDocument146 pagesAlkyl HalidesRahmawatirahman7850% (2)

- By Reading and Using The Thesis, The Reader Understands and Agrees To The Following TermsDocument189 pagesBy Reading and Using The Thesis, The Reader Understands and Agrees To The Following TermsAlbert vallejos ariasNo ratings yet

- Nitrous Oxide - Not A Laughing Matter in Electronics Manufacturing - N2O PDFDocument1 pageNitrous Oxide - Not A Laughing Matter in Electronics Manufacturing - N2O PDFdanNo ratings yet

- Seismic Response of Wind Turbines: Remi André KjørlaugDocument167 pagesSeismic Response of Wind Turbines: Remi André Kjørlaugnachopi2005No ratings yet

- Assignment of Electrical Machines by Ndatimana J.PDocument6 pagesAssignment of Electrical Machines by Ndatimana J.PIsaac P PlanNo ratings yet

- Concept Recapitulation Test II/Advanced/PAPER-1/Question/QuestionDocument25 pagesConcept Recapitulation Test II/Advanced/PAPER-1/Question/Questionullasagw100% (1)

- Tokyo Power Opens New Biomass Plant in MahiyanganayaDocument2 pagesTokyo Power Opens New Biomass Plant in MahiyanganayaPathmavel ManickasivamNo ratings yet

- Rickmeier 34Document12 pagesRickmeier 34carlosNo ratings yet

Powermax Powerpac GB

Powermax Powerpac GB

Uploaded by

ghodghod123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Powermax Powerpac GB

Powermax Powerpac GB

Uploaded by

ghodghod123Copyright:

Available Formats

High performance Step Motors

POWERMAX II Series P and M POWERPACTM Series N and K

Product Manual Edition 05/2007

As part of the product, you should keep the manual for the product's entire service life. Give the manual to the next owner or user of the product.

File stepmotor_pmnk_e.***

Technical Data Version History: Edition/Date 10/2004 05/2007 Reason for Revision Initial release Design

05/07

Danaher Motion

Printed in Germany. All rights reserved. Subject to technical modifications introduced to improve the equipment! No part of this document may be reproduced in any way (by print, photocopy, microfilm or any other procedure) without written consent nor may it be processed, reproduced or disseminated using electronic systems.

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

Table of Contents

1. General ....................................................................................................................................................4 1.1. Motor Design ......................................................................................................................................4 1.1.1. Sigmax Technology ..........................................................................................................................4 1.1.2. Design POWERMAX II Series P and M ..........................................................................................5 1.1.3. Design POWERPAC Series N and K .............................................................................................5 1.2. General Technical Features ...............................................................................................................6 1.3. Frame Sizes and Torque Ranges.......................................................................................................7 1.4. Standard Version ................................................................................................................................7 1.5. Options ...............................................................................................................................................7 1.6. Type Code ..........................................................................................................................................8 2. Technical Data.........................................................................................................................................9 2.1. Powermax II Series P and M ............................................................................................................9 2.1.1. Data P Series (Standard), NEMA 23 ..................................................................................................9 2.1.2. Data M Series (Sigmax), NEMA 23 ...............................................................................................10 2.1.3. Torque Characteristics POWERMAX II .........................................................................................11 2.1.4. Dimensions POWERMAX II Series P and M..................................................................................12 2.2. POWERPAC Series N and K........................................................................................................13 2.2.1. Data N Series (Standard), NEMA 34................................................................................................13 2.2.2. Data K Series (Sigmax), NEMA 34................................................................................................15 2.2.3. Data N Series (Standard), NEMA 42................................................................................................17 2.2.4. Data K Series (SIGMAX) - NEMA 42.............................................................................................18 2.2.5. Torque Characteristics POWERPAC............................................................................................20 2.2.6. Dimensions POWERPAC, NEMA 34............................................................................................21 2.2.7. Dimensions POWERPAC, NEMA 42............................................................................................22 3. Electrical Connections ...........................................................................................................................23

Step Motor Series M, P, N, K

Technical Data

05/07

Danaher Motion

1. General

1.1. Motor Design

The POWERPAC and POWERMAX II Step motors provide an excellent torque to frame size ratio. Optimized magnetic design in combination with a new rotor/stator design produce more torque and a higher acceleration. This unique design also reduces the detent torque for smoother microstepping. The motors are available in several frame sizes and offer holding torques of 0,42 Nm up to 40,2 Nm. The motors of the M and K series incorporate the patented flux focusing technology (Sigmax ) and provide a performance increase of 20% to 30% at identical motor size.

TM

1.1.1. Sigmax Technology

Due to their unique stator construction the Sigmax motors produce a higher torque rate than comparably sized standard motors. Thin rare-earth-magnets are embedded into the stator gashes. The polarization concentrates the flux which is produced in the rotor magnets onto the stator teeth. Thus the flux leakage that occurs on certain rotor-tostator positions is inhibited. Standard Hybrid Step Motor (Series P and N) Sigmax Hybrid Step Motor (Series M and K)

Typical path of flux transfer in an energized conventional hybrid step motor. Some flux leakage occurs in normal operation.

Patented Sigmax technology redirects magnetic flux to inhibit leakage and optimize torque production.

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

1.1.2. Design POWERMAX II Series P and M

The motors in size NEMA 23 have an octagonal housing. In standard version all motors have an 8-pole connector.

1.1.3. Design POWERPAC Series N and K

The motors in size NEMA 34 and 42 have a square housing. In standard version all motors have an 8-pole flying lead connection.

standard: fyling leads, 300 mm optional: terminal box with terminal board or MS connector

standard: NEMA mounting

rugged stator

NEMA shaft with straight key Optionally available: customized shaft and flange design

optional: integrated encoder

Rare earth magnets provide high demagne-tization resistance Large diameter rotor coupled with optimum magnetic design for high trque and acceleration

oversized long life bearings withstand high radial and axial forces Sigmax technology (K series) for optimized torque

Step Motor Series M, P, N, K

Technical Data

05/07

Danaher Motion

1.2. General Technical Features POWERMAX II Series P and M

Motor Type: P series: Hybrid step motors M series: Hybrid step motors with rare-earthmagnets stator Rotor Construction: laminanted (hoher Wirkungsrad bei hohen Drehzahlen) Phases: 2 Full Steps: 200 pro revolution Full Step Angle: 1,8 Angular Accuracy: M series: 1,5% of one full step, no load P series: 3% of one full step, no load Operating Temperature: -20 C to +40 C Insulation: NEMA class B, 130C Protection Class: IP 23 Insulation Resistance: 100 M at 500 VDC and 25C Shaft Loading: Max. radial load (regarding to half the shaft length distance to the bearing) = 90 N Max. axial load = 60 N

L

POWERPAC Series N and K

Motor Type: N series: Hybrid step motors K series: Hybrid step motors with rare-earthmagnets stator Rotorkonstruktion: laminiert (hoher Wirkungsrad bei hohen Drehzahlen) Phases: 2 Full Steps: 200 pro revolution Full Step Angle: 1,8 Angular Accuracy: K series: 1,5% of one full step, no load N series: 3% of one full step, no load Operating Temperature: -20 C to +40 C Insulation: NEMA class B, 130C Protection Class: IP 44, optional IP 65 Insulation Resistance: 100 M at 500 VDC and 25C Shaft Loading: *) Motor size Max. axial load Max. radial load 31, 32 1355 N 290 N 33, 34 1355 N 490 N 41 1800 N 560 N 42, 43 1800 N 490 N ) * regarding to half the shaft length distance to the bearing (s.

drawing on the left)

Lifetime of Bearings: At least 10.000 hours at speeds up to 10.000 full steps per second, if the motor is used within the above mentioned radial and axial shaft load ranges.

Lifetime of Bearings: At least 10.000 hours at speeds up to 10.000 full steps per second, if the motor is used within the above mentioned radial and axial shaft load ranges

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

1.3. Frame Sizes and Torque Ranges

Motor Type Powermax P-Series (Standard) M-Series (Sigmax

)

Powerpac

N-Series (Standard)

K-Series (Sigmax )

Size Stack 1 Stack 2 Stacks 1 Stack 2 Stacks 1 Stack 2 Stacks 3 Stacks 4 Stacks 1 Stack 2 Stacks 3 Stacks 4 Stacks

NEMA 23 0,42 - 0,43 Nm 0,77 - 0,82 Nm 1,39 - 1,51 Nm 0,95 - 1,02 Nm 1,62 - 1,79 Nm

NEMA 34

NEMA 42

4,5 - 4,7 Nm 8,4 - 8,8 Nm 12,1 - 13,0 Nm 14,36 - 15,4 Nm 5,7 - 6,0 Nm 10,7 - 11,15 Nm 15,1 -16,5 Nm 18,2 - 19,7 Nm

11,5 - 11,7 Nm 21,8 - 22,2 Nm 30,0 - 30,8 Nm 14,8 - 15,1 Nm 27,8 - 28,4 Nm 39,7 - 40,23 Nm

Page 8 8 9 9 10 12/16 12/16 13/17 13 14/17 14/18 15/18 15

1.4. Standard Version POWERMAX II Series P and M

NEMA 23 8 lead connector for serial or parallel connection Single shaft end, smooth shaft 6,35 mm Connector cable KAB.300 has to be ordered separately

POWERPAC Series N and K

NEMA 34 or NEMA 42 8 flying leads for serial or parallel connection Single shaft end with straight keyway CE certification (EN60034-1) UL certification (motor insulation class B, File E103510

1.5. Options

Various encoders Various gearboxes Brake Rear shaft extension Various hook-up versions Low inertia rotor (Powermax only)

Further types and options for this series as well as stepper drives and other accessories are available upon request.

Step Motor Series M, P, N, K

Technical Data

05/07

Danaher Motion

1.6. Type Code

N 3 3 H C H J - L

Series

P M N K Standard (Powermax) Sigmax version (Powermax) Standard (Powerpac) Sigmax version (Powerpac)

K - N S - 0 1

Special Sequence

00 01 xx - Standard motor, no shaft seal - Standard motor with shaft seal (Powerpac only) - Numbers assigned for special motors (upon request)

Encoder Options Size

2 3 4 - NEMA 23 (57,15 mm ) (Powermax only) - NEMA 34 (96,52 mm ) (Powerpac only) - NEMA 42 (109,85 mm ) (Powerpac only) NS xx M1 M2 SS No feedback Several encoders available (upon request) Encoder mounting provision (Powermax only) Encoder mounting provision (Powerpac only) Special (upon request)

Number of Rotor Stacks

H 1 2 3 4 1/2 stack (Powermax only) 1 stack 2 stack 3 stack (Powerpac only) 4 stack (Powerpac only)

Shaft Modifications

N F K S Smooth (Powermax only) Flat Straight key (Powerpac only) Special (upon request)

Mounting Configuration

N H S - NEMA (Powermax only) - Heavy Duty NEMA (Powerpac only) - Special (upon request)

Shaft Configuration

N D E S Single Double (R and C construction only) Double ended for encoder Special (upon request)

Construction/Hookup

R C L M S - Regular - System MS connector (Powerpac only) - Splashproof/to terminal board via conduit connector: 1/2" NPS pipe thread (Powerpac only) - Splashproof/to terminal board via conduit connector: metric PG11 pipe thread (Powerpac only) - Special (upon request)

Rotor Types

L J - Laminated - Low inertia (Powermax only, n/a for 1/2 stack)

Winding Types

A-N - Refer to winding data S - Special (upon request)

Winding/Leads

x F L H E Receptacle (Powermax only) - Please order cable separately! 8 lead (n/a C construction) 4 lead series 4 lead parallel 6 lead (n/a C construction) (Powerpac only)

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

2. Technical Data

2.1. Powermax II Series P and M 2.1.1. Data P Series (Standard), NEMA 23

P2HNRXx-LNN-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full Step Step angle Angular accuracy Phases Winding resistance Winding inductance Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

F

0,42 1,6

C

0,43 2,5

H

0,42 5,2

% Rph Lph MP mH Nm

200 per revolution 1,8 1,8 1,8 3 3 3 2 2 2 3,8 1,68 0,44 5,1 2,3 0,5 0,018 0,018 0,018 B B B 100M @ 500VDC 500VDC 1min

-3

J m Lmax

Kgm *10 kg mm C C

0,007 0,45 40,7

0,007 0,007 0,45 0,45 40,7 40,7 -20 to +40 95 IP 23

* Please replace the x in the item number with the letter of the requested winding.

P21NRXx-LNN-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

D

0,77 1,5

C

0,82 3,5

B

0,79 4,6

A

0,81 5,6

% Rph Lph MP mH Nm

1,8 3 2 5,22 10,3 0,03 B

200 per revolution 1,8 1,8 3 3 2 2 1,06 0,64 2,3 1,1 0,03 0,03 B B 100M @ 500VDC 500VDC 1min 0,012 0,012 0,68 0,68 52,4 52,4 -20 to +40 95 IP 23

1,8 3 2 0,46 0,8 0,03 B

J m Lmax

Kgm *10 kg mm C C

-3

0,012 0,68 52,4

0,012 0,68 52,4

* Please replace the x in the item number with the letter of the requested winding.

Step Motor Series M, P, N, K

Technical Data

05/07

Danaher Motion

P22NRXx-LNN-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

D

1,43 2,5

C

1,43 3,1

B

1,51 4,6

A

1,39 6,5

% Rph Lph MP mH Nm

1,8 3 2

200 per revolution 1,8 1,8 3 3 2 2

1,8 3 2

2,44 6,2 0,05

B

1,56 3,9 0,05

0,76 2,1 0,05

0,42 0,8 0,05

B

B B 100M @ 500VDC 500VDC 1min 0,025 0,025 1,13 1,13 78,8 78,8 -20 to +40 95 IP 23

J m Lmax

Kgm *10 kg mm C C

-3

0,025 1,13 78,8

0,025 1,13 78,8

* Please replace the x in the item number with the letter of the requested winding.

2.1.2. Data M Series (Sigmax), NEMA 23

M21NRXx-LNN-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

D

0,95 1,5

C

1,02 3,5

B

0,97 4,6

A

1,00 5,6

% Rph Lph MP mH Nm

1,8 1,5 2 5,22 8,7 0,066 B

200 per revolution 1,8 1,8 1,5 1,5 2 2 1,06 0,64 2,0 1,0 0,066 0,066 B B 100M @ 500VDC 500VDC 1min 0,012 0,012 0,68 0,68 52,4 52,4 -20 to +40 95 IP 23

1,8 1,5 2 0,46 0,7 0,066 B

J m Lmax

Kgm *10 kg mm C C

-3

0,012 0,68 52,4

0,012 0,68 52,4

* Please replace the x in the item number with the letter of the requested winding.

10

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

M22NRXx-LNN-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

D

1,68 2,5

C

1,68 3,1

B

1,79 4,6

A

1,62 6,5

% Rph Lph MP mH Nm

1,8 1,5 2 2,44 5,0 0,12 B

200 per revolution 1,8 1,8 1,5 1,5 2 2 1,56 0,76 3,1 1,7 0,12 0,12 B B 100M @ 500VDC 500VDC 1min 0,025 0,025 1,13 1,13 78,8 78,8 -20 to +40 95 IP 23

1,8 1,5 2 0,42 0,7 0,12 B

J m Lmax

Kgm *10 kg mm C C

-3

0,025 1,13 78,8

0,025 1,13 78,8

* Please replace the x in the item number with the letter of the requested winding.

2.1.3. Torque Characteristics POWERMAX II

1,2 1

Torque (Nm) Drehmoment (Nm)

0,8 0,6 0,4 0,2 0 0

P21-L-B (67V/4,6A)

P22-L-A (67V/4,6A)

P Series selected windings connection bipolar, parallel, with drive DSM5-70

P2H-L-H (67V/4,6A)

2000

4000

6000

8000

10000

12000 14000

16000

Frequenz (full (Vollschritte/s) Frequency steps/s)

1,2 1

Torque (Nm) Drhemoment (Nm)

M22-L-A (67V/4,6A) M21-L-B (67V/4,6A)

0,8 0,6 0,4 0,2 0 0

M Series selected windings connection bipolar, parallel, with drive DSM5-70

2000

4000

6000

8000

10000

12000

14000

16000

Frequency (Vollschritte/s) (full steps/s) Frequenz

Step Motor Series M, P, N, K

11

Technical Data

05/07

Danaher Motion

2.1.4. Dimensions POWERMAX II Series P and M

(incl. mating plugs)

all dimensions in mm

Motor type Length

P2H 40,7

P21/M21 P22/M22 52,4 78,8

Note! The 8core cable of 300mm length which is need for the Powermax motors has to be ordered separately (order no. KAB.300).

12

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

2.2. POWERPAC Series N and K 2.2.1. Data N Series (Standard), NEMA 34

N31HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

H

4,5 2,8

J

4,5 5,5

K

4,7 6,6

L

4,6 8,6

% Rph Lph MP mH Nm

1,8 3 2 3,1 12,5 0,13 B

200 per revolution 1,8 1,8 3 3 2 2 0,84 0,58 3,5 2,6 0,13 0,13 B B 100M @ 500VDC 500VDC 1min 0,14 0,14 2,3 2,3 112,8 112,8 -20 to +40 95 IP 44

1,8 3 2 0,36 1,4 0,13 B

J m L

Kgm *10 kg mm C C

-3

0,14 2,3 112,8

0,14 2,3 112,8

* Please replace the y in the item number with the letter of the requested winding.

N32HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

J

8,4 5,1

K

8,8 6,1

L

8,5 8,1

M

8,6 10,0

% Rph Lph MP mH Nm

1,8 3 2 1,27 6,5 0,25 B

200 per revolution 1,8 1,8 3 3 2 2 0,9 0,52 5,1 2,6 0,25 0,25 B B 100M @ 500VDC 500VDC 1min 0,27 0,27 3,8 3,8 151,4 151,4 -20 to +40 95 IP 44

1,8 3 2 0,35 1,8 0,25 B

J m L

Kgm *10 kg mm C C

-3

0,27 3,8 151,4

0,27 3,8 151,4

* Please replace the y in the item number with the letter of the requested winding.

Step Motor Series M, P, N, K

13

Technical Data

05/07

Danaher Motion

N33HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

J

12,1 5,0

K

12,4 6,1

L

13,0 9,0

M

12,1 9,9

% Rph Lph MP mH Nm

1,8 3 2 1,65 9,0 0,38 B

200 per revolution 1,8 1,8 3 3 2 2 1,12 0,53 6,4 3,4 0,38 0,38 B B 100M @ 500VDC 500VDC 1min 0,4 0,4 5,4 5,4 155,7 155,7 -20 to +40 95 IP 44

1,8 3 2 0,44 2,3 0,38 B

J m L

Kgm *10 kg mm C C

-3

0,4 5,4 155,7

0,4 5,4 155,7

* Please replace the y in the item number with the letter of the requested winding.

N34HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

J

15,3 5,5

K

14,36 6,0

L

15,4 8,7

M

15,1 11,3

% Rph Lph MP mH Nm

1,8 3 2 1,6 11,5 0,4 B

200 per revolution 1,8 1,8 3 3 2 2 1,35 0,66 8,1 4,7 0,4 0,4 B B 100M @ 500VDC 500VDC 1min 0,53 0,53 6,8 6,8 195,1 195,1 -20 to +40 95 IP 44

1,8 3 2 0,41 2,6 0,4 B

J m L

Kgm *10 kg mm C C

-3

0,53 6,8 195,1

0,53 6,8 195,1

* Please replace the y in the item number with the letter of the requested winding.

14

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

2.2.2. Data K Series (Sigmax), NEMA 34

K31HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

H

5,7 2,8 170

J

5,8 5,5 170

K

6,0 6,6 170

L

5,9 8,6 170

P

5,9 2,8 325

% Rph Lph MP mH Nm

1,8 1,5 2 3,1 10,2 0,18 B

200 1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 0,84 0,58 0,36 2,8 2,1 1,2 0,18 0,18 0,18 B B B 100M @ 500VDC 500VDC 1min 0,14 2,3 112,8 0,14 0,14 2,3 2,3 112,8 112,8 -20 to +40 95 IP 44

1,8 1,5 2 1,55 10,2 0,18 B

J m L

Kgm *10 kg mm C C

-3

0,14 2,3 112,8

0,14 2,3 112,8

* Please replace the y in the item number with the letter of the requested winding.

K32HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

J

10,7 5,1 170

K

11,15 6,1 170

L

10,7 8,1 170

M

10,8 10,0 170

P

10,7 3,3 325

% Rph Lph MP mH Nm

1,8 1,5 2 1,27 5,1 0,35 B

1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 0,9 0,52 0,35 4,0 2,0 1,4 0,35 0,35 0,35 B B B 100M @ 500VDC 500VDC 1min 0,27 3,8 151,4 0,27 0,27 3,8 3,8 151,4 151,4 -20 to +40 95 IP 44

1,8 1,5 2 1,5 11,8 0,35 B

J m L

Kgm *10 kg mm C C

-3

0,27 3,8 151,4

0,27 3,8 151,4

* Please replace the y in the item number with the letter of the requested winding.

Step Motor Series M, P, N, K

15

Technical Data

05/07

Danaher Motion

K33HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

J

15,1 5,0 170

K

15,6 6,1 170

L

16,5 9,0 170

M

15,2 9,9 170

P

15,1 3,7 325

% Rph Lph MP mH Nm

1,8 1,5 2 1,65 7,0 0,53 B

1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 1,12 0,53 0,44 5,0 2,6 1,2 0,53 0,53 0,53 B B B 100M @ 500VDC 500VDC 1min 0,4 5,4 155,7 0,4 0,4 5,4 5,4 155,7 155,7 -20 to +40 95 IP 44

1,8 1,5 2 1,5 14,9 0,53 B

J m L

Kgm *10 kg mm C C

-3

0,4 5,4 155,7

0,4 5,4 155,7

* Please replace the y in the item number with the letter of the requested winding.

K34HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

J

19,6 5,5 170

K

18,2 6,0 170

L

19,7 8,7 170

M

19,2 11,3 170

P

19,2 3,7 325

% Rph Lph MP mH Nm

1,8 1,5 2 1,6 8,9 0,5 B

1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 1,35 0,66 0,41 6,3 3,6 2,0 0,5 0,5 0,5 B B B 100M @ 500VDC 500VDC 1min 0,53 6,8 195,1 0,53 0,53 6,8 6,8 195,1 195,1 -20 to +40 95 IP 44

1,8 1,5 2 1,8 18,4 0,5 B

J m L

Kgm *10 kg mm C C

-3

0,53 6,8 195,1

0,53 6,8 195,1

* Please replace the y in the item number with the letter of the requested winding.

16

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

2.2.3. Data N Series (Standard), NEMA 42

N41HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

J

11,5 5,5

L

11,5 8,7

M

11,7 10,7

% Rph Lph MP mH Nm

1,8 3 2 1,16 10,1 0,3 B

200 per revolution 1,8 1,8 3 3 2 2 0,47 0,31 3,9 2,8 0,3 0,3 B B 100M @ 500VDC 500VDC 1min 0,55 0,55 5,0 5,0 132,1 132,1 -20 to +40 95 IP 44

J m L

Kgm *10 kg mm C C

-3

0,55 5,0 132,1

* Please replace the y in the item number with the letter of the requested winding.

N42HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

K

21,9 6,4

L

21,8 8,1

M

22,2 9,9

N

22,1 15,8

% Rph Lph MP mH Nm

1,8 3 2 1,2 12,8 0,59 B

200 per revolution 1,8 1,8 3 3 2 2 0,75 0,51 7,8 5,5 0,59 0,59 B B 100M @ 500VDC 500VDC 1min 1,09 1,09 8,3 8,3 183,4 183,4 -20 to +40 95 IP 44

1,8 3 2 0,21 2,1 0,59 B

J m L

Kgm *10 kg mm C C

-3

1,09 8,3 183,4

1,09 8,3 183,4

* Please replace the y in the item number with the letter of the requested winding.

Step Motor Series M, P, N, K

17

Technical Data

05/07

Danaher Motion

N43HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I Nm A

K

30,6 6,2

L

30,0 8,0

M

30,5 9,9

N

30,8 15,4

% Rph Lph MP mH Nm

1,8 3 2 1,65 19,6 0,75 B

200 per revolution 1,8 1,8 3 3 2 2 0,99 0,66 11,0 7,7 0,75 0,75 B B 100M @ 500VDC 500VDC 1min 1,62 1,62 11,6 11,6 234,4 234,4 -20 to +40 95 IP 44

1,8 3 2 0,28 3,2 0,75 B

J m L

Kgm *10 kg mm C C

-3

1,62 11,6 234,4

1,62 11,6 234,4

* Please replace the y in the item number with the letter of the requested winding.

2.2.4. Data K Series (SIGMAX) - NEMA 42

K41HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

J

14,8 5,5 170

L

14,8 8,7 170

M

15,1 10,7 170

P

15,0 3,4 325

% Rph Lph MP mH Nm

1,8 1,5 2 1,16 7,8 0,46 B

1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 0,47 0,31 1,47 3,1 2,2 20,1 0,46 0,46 0,46 B B B 100M @ 500VDC 500VDC 1min 0,55 5,0 132,1 0,55 0,55 5,0 5,0 132,1 132,1 -20 to +40 95 IP 44

J m L

Kgm *10 kg mm C C

-3

0,55 5,0 132,1

* Please replace the y in the item number with the letter of the requested winding.

18

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

K42HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

K

28,0 6,4 170

L

27,8 8,1 170

M

28,4 9,9 170

N

28,2 15,8 170

P

28,1 4,1 325

% Rph Lph MP mH Nm

1,8 1,5 2 1,2 9,8 0,69 B

1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 0,75 0,51 0,21 6,0 4,2 1,6 0,69 0,69 0,69 B B B 100M @ 500VDC 500VDC 1min 1,09 8,3 183,4 1,09 1,09 8,3 8,3 183,4 183,4 -20 to +40 95 IP 44

1,8 1,5 2 1,47 23,0 0,69 B

J m L

Kgm *10 kg mm C C

-3

1,09 8,3 183,4

1,09 8,3 183,4

* Please replace the y in the item number with the letter of the requested winding.

K43HRFy-LNK-NS-00*

Motor Data Holding Torque (bipolar/parallel 2 phases on) Rated current per winding (bipolar, parallel) Rated voltage Technical Data Full step Step angle Angular accuracy Phases Winding resistance Winding inductivity Detent torque Insulation class Insulation inductance Dielectricity test Mechanical Data Rotor inertia Mass Length Ambient temperature max. surface temperature Protection class MH I UDC Nm A V

K

39,9 6,2 170

L

39,0 8,0 170

M

39,7 9,9 170

N

40,23 15,4 170

P

40,1 4,9 325

% Rph Lph MP mH Nm

1,8 1,5 2 1,65 15,2 0,83 B

1,8 1,8 1,8 1,5 1,5 1,5 2 2 2 0,99 0,66 0,28 8,5 5,9 2,5 0,83 0,83 0,83 B B B 100M @ 500VDC 500VDC 1min 1,62 11,6 234,4 1,62 1,62 11,6 11,6 234,4 234,4 -20 to +40 95 IP 44

1,8 1,5 2 1,33 24,9 0,83 B

J m L

Kgm *10 kg mm C C

-3

1,62 11,6 234,4

1,62 11,6 234,4

* Please replace the y in the item number with the letter of the requested winding.

Step Motor Series M, P, N, K

19

Technical Data

05/07

Danaher Motion

2.2.5. Torque Characteristics POWERPAC

12,00 10,00

N34-K (70V/6,0A)

Drehmoment Torque (Nm) (Nm)

8,00 6,00 4,00 2,00 0,00 0 2000 4000 6000 8000 10000

Frequency(Vollschritte/s) (full steps/s) Frequenz N32-J (70V/5,1A) N31-J (70V/5,5A) N33-K (70V/6,1A)

Size N3 (Standard, NEMA 34) selected windings connection bipolar, parallel, at 70V

12,00 10,00

Torque (Nm)(Nm) Drehmoment

N34-K (140V/6,0A)

8,00 6,00 4,00 2,00 0,00 0

N33-K (140V/6,1A)

Sitze N3 (Standard, NEMA 34) selected windings connection bipolar, parallel, at 70V

2000

4000

6000

8000

10000

Frequency (full steps/s) Frequenz (Vollschritte/s)

25,00 20,00 15,00 10,00 5,00 0,00 0 2000 4000 6000 8000 10000

Frequency (full steps/s) Frequenz (Vollschritte/s) N41-L (140V/8,7A) N43-K (140V/9,9A)

Torque (Nm)(Nm) Drehmoment

N42-L (140V/8,1A)

Size N4 (Standard, NEMA 42) selected windings connection bipolar, parallel, at 70V

Note! Optimized characteristics for the K series motors for the requested phase currents and voltages are available upon request.

20

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

2.2.6. Dimensions POWERPAC, NEMA 34

Standard Version

Type N31 N32 N33 N34

D -0,013 12,7 12,7 15,875 15,875

Keyway

W 23,82 24,61 T 14,1 17,9 K 3,175 4,763

Connector Options

Shaft Options

2x180 - 2-56UNC-2B 5 deep TK 46,03

Type Lmax

N31 112,8

N32 151,4

N33 190,0

N34 228,4

Mounting Options

Note! All dimensions in mm. The above drawings only show the N series, but they are also valid for the K series.

Step Motor Series M, P, N, K

21

Technical Data

05/07

Danaher Motion

2.2.7. Dimensions POWERPAC, NEMA 42

Standard Version

Connector Options

Shaft Options

Mounting Options

Note! All dimensions in mm. The above drawings only show the N series, but they are also valid for the K series.

22

Step Motor Series M, P, N, K

Danaher Motion

05/07

Technical Data

3. Electrical Connections

8 leads parallel

black/white Bipolar Drive A black orange orange/white red/white B /B red yellow yellow/white Step Motor

/A

8 leads serial

black/white Bipolar Drive A black orange orange/white red/white B /B red yellow yellow/white Note! On 4-lead motors the connections are internally bridged and only the black, orange, red and yellow core are lead through. Step Motor

/A

Step Motor Series M, P, N, K

23

You might also like

- SSP 652 Audi 40l v8 Tdi Engine of Ea898 SeriesDocument48 pagesSSP 652 Audi 40l v8 Tdi Engine of Ea898 SeriesJose Ramón Orenes ClementeNo ratings yet

- Project On CSRDocument40 pagesProject On CSRghodghod12383% (47)

- Electrocraft EAD BLDC CatalogDocument16 pagesElectrocraft EAD BLDC CatalogElectromateNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 2016 Backward Design Unit Plan TemplateDocument23 pages2016 Backward Design Unit Plan Templateapi-311086670100% (1)

- Kollmorgen Powermax II CatalogDocument4 pagesKollmorgen Powermax II CatalogElectromateNo ratings yet

- Kollmorgen Nema23 PowermaxII CatalogDocument12 pagesKollmorgen Nema23 PowermaxII CatalogElectromateNo ratings yet

- Stepper Catalog en-US RevC enDocument148 pagesStepper Catalog en-US RevC enJorge JuarezNo ratings yet

- Nema P2 Stepper System TBDocument4 pagesNema P2 Stepper System TBRomulo Cardoso100% (1)

- Stepper Motors Catalog en-US RevADocument146 pagesStepper Motors Catalog en-US RevAYazeed MomaniNo ratings yet

- Ametek MCG Stepper CatalogDocument34 pagesAmetek MCG Stepper CatalogElectromateNo ratings yet

- CG 3 Phase MotorDocument76 pagesCG 3 Phase MotorSaravanan Mani100% (1)

- Kollmorgen N&K Series Nema 42 SpecsheetDocument4 pagesKollmorgen N&K Series Nema 42 SpecsheetElectromateNo ratings yet

- Electrocraft Legacy CatalogDocument59 pagesElectrocraft Legacy CatalogElectromateNo ratings yet

- Caracteristicas Motores PDFDocument60 pagesCaracteristicas Motores PDF0ZKRCITHONo ratings yet

- Kollmorgen Nema23 Special Purpose SpecsheetDocument3 pagesKollmorgen Nema23 Special Purpose SpecsheetElectromateNo ratings yet

- Actuator CatalogDocument71 pagesActuator CatalogaquinorickyNo ratings yet

- BrushlessDocument141 pagesBrushlessalysonmicheaalaNo ratings yet

- Electrocraft Stepper CatalogDocument41 pagesElectrocraft Stepper CatalogElectromateNo ratings yet

- Stepper Catalog en-US RevC EN PDFDocument148 pagesStepper Catalog en-US RevC EN PDFGuillermo Chuquillanqui PradoNo ratings yet

- Dyadics SCN6 DatasheetDocument2 pagesDyadics SCN6 DatasheetElectromateNo ratings yet

- Kollmorgen Nema 34 N3 K3 Stepper Systems TB SpecsheetDocument4 pagesKollmorgen Nema 34 N3 K3 Stepper Systems TB SpecsheetElectromateNo ratings yet

- N23 Industrial Grade MotorsDocument5 pagesN23 Industrial Grade Motorszhifeng yanNo ratings yet

- MotorDocument48 pagesMotorHernan CuevasNo ratings yet

- Dynasyn Hightorque-Servomotors DT: Dynamic. Compact. PowerfulDocument34 pagesDynasyn Hightorque-Servomotors DT: Dynamic. Compact. PowerfulMoumene Djafer BeyNo ratings yet

- Electrocraft PMDC CatalogDocument42 pagesElectrocraft PMDC CatalogElectromateNo ratings yet

- Stepper Catalog PDFDocument36 pagesStepper Catalog PDFCano VoyNo ratings yet

- SM Series Stepper MotorsDocument7 pagesSM Series Stepper MotorsPham LongNo ratings yet

- Servo-Motor Selection-Guide en-US 2006 PDFDocument48 pagesServo-Motor Selection-Guide en-US 2006 PDFIsaac Gutierrez PayanNo ratings yet

- Mosfets: Product GuideDocument63 pagesMosfets: Product Guideihodiputah_510No ratings yet

- YEG2 SDocument2 pagesYEG2 Swpt_meNo ratings yet

- Uc 3843 Data SheetDocument56 pagesUc 3843 Data Sheetmeepow100% (1)

- Dynamatic Technologies LTD® Hydraulic Gear Motor, Model:1DR: Salient FeaturesDocument12 pagesDynamatic Technologies LTD® Hydraulic Gear Motor, Model:1DR: Salient FeatureskottaNo ratings yet

- Dc02en PDFDocument42 pagesDc02en PDFKaya EmanuelNo ratings yet

- CAT DC Motors en PDFDocument38 pagesCAT DC Motors en PDFMaria IlieNo ratings yet

- Nos RamDocument32 pagesNos RamSocial Path100% (1)

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogElectromateNo ratings yet

- Sony Dsr-11 Ver-1.1 SMDocument173 pagesSony Dsr-11 Ver-1.1 SMsaul64No ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogServo2GoNo ratings yet

- Dyadics SCN5 DatasheetDocument2 pagesDyadics SCN5 DatasheetElectromateNo ratings yet

- Freedom Series DataDocument120 pagesFreedom Series Datahockey_36No ratings yet

- 3G3JXDocument8 pages3G3JXrwciriloNo ratings yet

- Powerpak HandbookDocument0 pagesPowerpak HandbookPehr HedströmNo ratings yet

- Rad Torque CatalogDocument16 pagesRad Torque CatalogJesus CcoylloNo ratings yet

- Yeg2 3Document2 pagesYeg2 3wpt_meNo ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogElectromateNo ratings yet

- Vexta Motor BrochureDocument56 pagesVexta Motor BrochureSandy KohlndorferNo ratings yet

- Electrocraft Linear Motors CatalogDocument37 pagesElectrocraft Linear Motors CatalogElectromateNo ratings yet

- R Series.255131941Document4 pagesR Series.255131941Rajabhau VaidyaNo ratings yet

- Kollmorgen PMA Series CatalogDocument6 pagesKollmorgen PMA Series CatalogElectromateNo ratings yet

- Magnetic Particle Equipment Selection GuideDocument16 pagesMagnetic Particle Equipment Selection GuideWellington S. FrançaNo ratings yet

- De DriveDocument6 pagesDe DriveEdgar RdzNo ratings yet

- Alteradores MarathonDocument8 pagesAlteradores MarathonSalineñoApasionadoNo ratings yet

- Marine Alternators: Up To 2500 kVA 50Hz / 3000kVA 60HzDocument5 pagesMarine Alternators: Up To 2500 kVA 50Hz / 3000kVA 60HzxxxxxAMSNo ratings yet

- Ie3 Pa Pe SeriesDocument16 pagesIe3 Pa Pe SeriesshakibNo ratings yet

- Cartepillar C32 Diesel Oilfield Generator SetDocument4 pagesCartepillar C32 Diesel Oilfield Generator SetJesus Enrique Figueroa GilNo ratings yet

- Regal SGA CatDocument40 pagesRegal SGA CatIee XpNo ratings yet

- SPECTRA - NEMA Molded Case Circuit Breakers - Application andDocument51 pagesSPECTRA - NEMA Molded Case Circuit Breakers - Application andnaufrago69aNo ratings yet

- Vol06 Tab02Document250 pagesVol06 Tab02r2d2zpNo ratings yet

- Basf Brand Guide Directrices de Identidad CorporativaDocument27 pagesBasf Brand Guide Directrices de Identidad Corporativaghodghod123No ratings yet

- ConicsDocument3 pagesConicsghodghod123No ratings yet

- Berkeley Campaign Style 09Document79 pagesBerkeley Campaign Style 09ghodghod123No ratings yet

- BSA Brand IdentityDocument34 pagesBSA Brand IdentityJoe DonahueNo ratings yet

- EasyGroup Brand ManualDocument36 pagesEasyGroup Brand Manualghodghod123No ratings yet

- Carnegie Mellon Writers Style GuideDocument13 pagesCarnegie Mellon Writers Style Guideghodghod123No ratings yet

- Channel4 C4StyleGuide1.1Document46 pagesChannel4 C4StyleGuide1.1ghodghod123No ratings yet

- Restaurants: Tung Fong Harvey's World CuisineDocument1 pageRestaurants: Tung Fong Harvey's World Cuisineghodghod123No ratings yet

- Nightlife: Little Italy (Little High) Bluzz - Lounge BarDocument2 pagesNightlife: Little Italy (Little High) Bluzz - Lounge Barghodghod123No ratings yet

- Thomas Telford BooksDocument16 pagesThomas Telford Booksghodghod123No ratings yet

- Bigdata Analytics in Energy UtilitiesDocument24 pagesBigdata Analytics in Energy UtilitiesDeepak Panguluri100% (2)

- An Overview of Nitinol Medical ApplicationsDocument12 pagesAn Overview of Nitinol Medical Applicationsgulangyu2019No ratings yet

- Corrosion StudyDocument1 pageCorrosion Studygeoff-ayton-7603No ratings yet

- 967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)Document41 pages967-0121 Onan DJB DJE Genset Operator's Manual (02-1991)AbysmalNo ratings yet

- Interpretations To Asme b31 3Document17 pagesInterpretations To Asme b31 3Phornlert WanaNo ratings yet

- Motors - Installation, Operation, MaintenanceDocument20 pagesMotors - Installation, Operation, MaintenanceVlada JelenićNo ratings yet

- PVM (X) Series: Vertical Multistage PumpsDocument11 pagesPVM (X) Series: Vertical Multistage PumpsNelson IglesiasNo ratings yet

- Microwave TubesDocument139 pagesMicrowave TubesGopichand DasariNo ratings yet

- Thermodynamics States A Set of Four Laws Which Are Valid For All Systems That Fall Within The Constraints Implied by EachDocument2 pagesThermodynamics States A Set of Four Laws Which Are Valid For All Systems That Fall Within The Constraints Implied by EachKevin Alberto Tejera PereiraNo ratings yet

- MKE Bab 5 1 Turbin Aksi Dan ReaksiDocument2 pagesMKE Bab 5 1 Turbin Aksi Dan ReaksiMariaulfadamayantiNo ratings yet

- 20 C32 1000 KW 480VDocument6 pages20 C32 1000 KW 480VDIEGO PEÑALOZANo ratings yet

- DL - AP21-1019 - SpecSheet - IFF50 - en-EU PrimusDocument2 pagesDL - AP21-1019 - SpecSheet - IFF50 - en-EU Primuskato davidNo ratings yet

- Build-a-ma-Jigs Aeroplane BX1322Document2 pagesBuild-a-ma-Jigs Aeroplane BX1322Alex IvanovNo ratings yet

- PRINTED ChemT4HLQDocument18 pagesPRINTED ChemT4HLQtaengooNo ratings yet

- Course Curriculum Course: Thermal Engineering-II Course Code: 3351901Document12 pagesCourse Curriculum Course: Thermal Engineering-II Course Code: 3351901rushibmr19785604No ratings yet

- Petroleum Refining IWW Case Study - FinalDocument9 pagesPetroleum Refining IWW Case Study - FinalIastra100% (1)

- Chemistry Investigatory Project On Evaporation of LiquidDocument22 pagesChemistry Investigatory Project On Evaporation of LiquidDivyanshu KumarNo ratings yet

- Vector Drive - Troubleshooting Guide: Haas Technical DocumentationDocument7 pagesVector Drive - Troubleshooting Guide: Haas Technical DocumentationViruzeNo ratings yet

- Organic Review Worksheet and Problem SetDocument20 pagesOrganic Review Worksheet and Problem SetNelNo ratings yet

- Inter 2 Physics Success SeriesDocument12 pagesInter 2 Physics Success SeriesZain AliNo ratings yet

- Alkyl HalidesDocument146 pagesAlkyl HalidesRahmawatirahman7850% (2)

- By Reading and Using The Thesis, The Reader Understands and Agrees To The Following TermsDocument189 pagesBy Reading and Using The Thesis, The Reader Understands and Agrees To The Following TermsAlbert vallejos ariasNo ratings yet

- Nitrous Oxide - Not A Laughing Matter in Electronics Manufacturing - N2O PDFDocument1 pageNitrous Oxide - Not A Laughing Matter in Electronics Manufacturing - N2O PDFdanNo ratings yet

- Seismic Response of Wind Turbines: Remi André KjørlaugDocument167 pagesSeismic Response of Wind Turbines: Remi André Kjørlaugnachopi2005No ratings yet

- Assignment of Electrical Machines by Ndatimana J.PDocument6 pagesAssignment of Electrical Machines by Ndatimana J.PIsaac P PlanNo ratings yet

- Concept Recapitulation Test II/Advanced/PAPER-1/Question/QuestionDocument25 pagesConcept Recapitulation Test II/Advanced/PAPER-1/Question/Questionullasagw100% (1)

- Tokyo Power Opens New Biomass Plant in MahiyanganayaDocument2 pagesTokyo Power Opens New Biomass Plant in MahiyanganayaPathmavel ManickasivamNo ratings yet

- Rickmeier 34Document12 pagesRickmeier 34carlosNo ratings yet