Professional Documents

Culture Documents

Sustainable Design Information Sheet For 3M™ FASARA™ Glass Finishes

Sustainable Design Information Sheet For 3M™ FASARA™ Glass Finishes

Uploaded by

reflections1272Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sustainable Design Information Sheet For 3M™ FASARA™ Glass Finishes

Sustainable Design Information Sheet For 3M™ FASARA™ Glass Finishes

Uploaded by

reflections1272Copyright:

Available Formats

Sustainable Design Information Sheet for 3M FASARA Glass Finishes

SECTION I. PRODUCT INFORMATION Product Name: 3M Fasara Glass Finishes

March 2012

3M Corporate Environmental Policy SECTION II. ENVIRONMENTAL POLICY Environmental Concerns are integral to 3M and its activities. In 1975 3M became one of the first manufacturing companies to establish a formal Environmental Policy. That same year, we adopted our voluntary 3M Pollution Prevention Pays (3P) program based on the then-novel idea that pollution prevention is both an environmental and a competitive/financial strategy. The 3P program is based on the reality that pollution prevention is more environmentally effective, technically sound and economical than conventional pollution control equipment. In 2002 we revitalized the 3P program to provide more opportunities for participation by our research and development, logistics, transportation and packaging employees with the addition of new award categories and criteria. Beginning in the early 1970s 3Ms environmental programs set forward-looking corporate policies and environmental targets. Time after time our pollution prevention efforts have demonstrated that as we reduce our waste, the environment benefits and we also become a more profitable company. 3M will continue to recognize and exercise its responsibility to: 1. Solve its own environmental pollution and conservation problems. 2. Prevent pollution at the source wherever and whenever possible. 3. Develop products that will have a minimal effect on the environment. 4. Conserve natural resources through the use of reclamation and other appropriate methods. 5. Assure that its facilities and products meet and sustain the regulations of all federal, state and local environmental agencies. 6. Assist, wherever possible, governmental agencies and other official organizations engaged in environmental activities. SECTION III. This credit summary is an Impact Analysis of Fasara glass finishes as it pertains to the LEED Rating System.

Green Building Design and Construction, 2009 (Updated June 2010)

Credit Name Intent Requirement Points Available

SS Credit 8, Light Pollution Reductions

To minimize light trespass from the building and site, reduce sky-glow to increase night sky access, improve nighttime visibility through glare reduction and reduce development impact from lighting on nocturnal environments.

Project teams must comply with 1 of the 2 NC: 1 options for interior lighting AND the requirements Schools: 1 for exterior lighting. Option 1 does not apply. CS: 1 Option 2: All openings in the envelope (transparent or translucent) with a direct line of sight to any nonemergency luminaires must have shielding (controlled/closed by automatic device for a resultant transmittance of less than 10% between 11 pm and 5 am). Depending on the pattern chosen and when used in conjunction with devices designed to limit the transmittance of light from interior spaces, Fasara glass finishes can assist with glare reduction and overall light trespass from buildings. Use existing interior nonstructural elements (e.g., interior walls, doors, floor coverings and ceiling systems) in at least 50% (by area) of the completed building, including additions. If the project includes an addition with square footage more than 2 times the square footage of the existing building, this credit is not applicable. Fasara glass finishes are designed to be applied to existing windows. When a fresh new look is needed, save the cost of scrapping and replacing windows by removing the existing film and applying a new innovative design. Use salvaged, refurbished or reused materials, the sum of which constitutes at least 5% or 10%, based on cost, of the total value of materials on the project. The minimum percentage materials reused for each point threshold is as follows 5% - 1 point 10% - 2 points Fasara glass finishes are designed to be applied to new or existing windows. When a fresh new look is needed, save the cost of scrapping and replacing windows by removing the existing film and applying a new innovative design. NC: 1-2 Schools: 1-2 CS: 1

MR Credit 1.2 Building Reuse Maintain Interior Nonstructural Elements

To extend the life cycle of existing building stock, conserve resources, retain cultural resources, reduce waste and reduce environmental impact of new buildings as they relate to materials manufacturing and transport.

NC: 1 Schools: 1 CS: NA

MR Credit 3 Material Reuse

To reuse building materials and products to reduce demand for virgin materials and reduce waste, thereby lessening impacts associated with the extraction and processing of virgin resources.

Green Interior Design and Construction, 2009

Credit Name Intent Requirement Points Available

MR Credit 1.2, Building Reuse Maintain Interior Nonstructural Elements MR Credit 3.1 Material Reuse

To extend the life cycle of existing building stock, conserve resources, retain cultural resources, reduce waste and reduce environmental impact of new buildings as they relate to materials manufacturing and transport. To reuse building materials and products to reduce demand for virgin materials and reduce waste, thereby lessening impacts associated with the extraction and processing of virgin resources.

Maintain at least 40% or 60% by area of the existing non-shell, nonstructural components (e.g., walls, flooring, and ceiling systems). Fasara glass finishes are designed to be applied to existing windows. When a fresh new look is needed, save the cost of scrapping and replacing windows by removing the existing film and applying a new innovative design. Use salvaged, refurbished or reused materials, the sum of which constitutes at least 5% or 10%, based on cost, of the total value of materials on the project. The minimum percentage materials reused for each point threshold is as follows 5% - 1 point 10% - 2 points Fasara glass finishes are designed to be applied to new or existing windows. When a fresh new look is needed, save the cost of scrapping and replacing windows by removing the existing film and applying a new innovative design.

CI 40% = 1 60% = 2

CI 1-2

You might also like

- Wastewater Engineering: Treatment and Resource Recovery: (5th Edition)Document7 pagesWastewater Engineering: Treatment and Resource Recovery: (5th Edition)Hmid AljbreNo ratings yet

- Sustainable Development Lesson PlanDocument11 pagesSustainable Development Lesson PlanRomano LuisNo ratings yet

- Design and Development of A Three Storey Dormitory BuildingDocument109 pagesDesign and Development of A Three Storey Dormitory BuildingAnonymous FxmcZ1KxEX100% (3)

- Green Initiatives of Sri LankaDocument21 pagesGreen Initiatives of Sri LankashenaNo ratings yet

- A Business Plan For Sustainable Modular HomesDocument13 pagesA Business Plan For Sustainable Modular Homesshaf0% (1)

- Report On Visit of Tema Oil Refinery On October 21Document4 pagesReport On Visit of Tema Oil Refinery On October 21Bernard AmooNo ratings yet

- Final EthicsDocument29 pagesFinal EthicsDivya Dinesh0% (2)

- GREEN Building FinalDocument35 pagesGREEN Building FinalShaimaa SakrNo ratings yet

- Report - MSA - 03082021Document15 pagesReport - MSA - 03082021Jennifer NesterNo ratings yet

- 3M Virtual Tour (Draft)Document9 pages3M Virtual Tour (Draft)Dipak PatilNo ratings yet

- Green Rating Systems at Building Level: Building Research Establishment Environmental Assessment Method (Breeam)Document12 pagesGreen Rating Systems at Building Level: Building Research Establishment Environmental Assessment Method (Breeam)NikiNo ratings yet

- Business and Project ManagementDocument12 pagesBusiness and Project Managementapi-19543618No ratings yet

- Management Report 13sep23Document12 pagesManagement Report 13sep23LING YU SHU ASHLEYNo ratings yet

- Bimtech Case Analysis Competition 2021-22, NdimDocument7 pagesBimtech Case Analysis Competition 2021-22, Ndimshreyansh chaudharyNo ratings yet

- 20c-d. Design For EnvironmentDocument79 pages20c-d. Design For EnvironmentPrashantNo ratings yet

- Green DesignDocument3 pagesGreen DesignShaira Patrice CalesaNo ratings yet

- Leed Information: Flat Glass EuropeDocument6 pagesLeed Information: Flat Glass Europepranav mohanNo ratings yet

- Green Building MaterialsDocument23 pagesGreen Building MaterialsFirman IrmansyahNo ratings yet

- Final DmadvDocument39 pagesFinal DmadvMehrad Sarabandi100% (1)

- Green Building Index For Malaysia PDFDocument6 pagesGreen Building Index For Malaysia PDFtehtehtehNo ratings yet

- Green Building PMPDocument47 pagesGreen Building PMPShaimaa SakrNo ratings yet

- Case Study GrundfosDocument13 pagesCase Study GrundfosPrasanna Padmanabhan50% (2)

- Greenbuilding BrandonryanestibenjordyDocument4 pagesGreenbuilding Brandonryanestibenjordyapi-349743085No ratings yet

- Construction of A Pasig Riverside Green Building Condominium in Downtown ManilaDocument38 pagesConstruction of A Pasig Riverside Green Building Condominium in Downtown ManilaMehrad SarabandiNo ratings yet

- Claver Recovery Facility Manuscript r.2Document11 pagesClaver Recovery Facility Manuscript r.2chuck entocNo ratings yet

- Green Construction A Growing Global TrendDocument10 pagesGreen Construction A Growing Global TrendAnıcan Vurgun ÖztabakNo ratings yet

- Interfaceflor: A Sustainable Green Business VentureDocument7 pagesInterfaceflor: A Sustainable Green Business VentureMandeep SinghNo ratings yet

- Chapter 8 (DC) Construction TechnologiesDocument79 pagesChapter 8 (DC) Construction TechnologiesAbang Mohd NawawiNo ratings yet

- Green Mark BCADocument9 pagesGreen Mark BCAmanuremongerNo ratings yet

- Preyesh - Design For Environmental and Substainable DesignDocument18 pagesPreyesh - Design For Environmental and Substainable DesignSHYAM SUNDARNo ratings yet

- CAPSTONEDocument3 pagesCAPSTONEChinee LontocNo ratings yet

- SCM Case StudyDocument9 pagesSCM Case StudyHue Wen HaoNo ratings yet

- New DOC DocumentDocument32 pagesNew DOC DocumentbahreabdellaNo ratings yet

- Sustainable Architecture 2010Document24 pagesSustainable Architecture 2010Rodrick TracyNo ratings yet

- Pi ECO Vietnam Project Abstract & Summary 7 March 2019Document11 pagesPi ECO Vietnam Project Abstract & Summary 7 March 2019ICT Bảo HànhNo ratings yet

- Chapter Six Wastage: Cost Efficient ConstructionDocument8 pagesChapter Six Wastage: Cost Efficient ConstructionTole DelúxëNo ratings yet

- Santiago - Green Construction MethodsDocument8 pagesSantiago - Green Construction MethodsJoshua SantiagoNo ratings yet

- ENGG684 CaseStudy Project3Document2 pagesENGG684 CaseStudy Project3rahibrahmbhatt04No ratings yet

- Unit 4: Basic Building ResourcesDocument2 pagesUnit 4: Basic Building ResourcesHasini KadaruNo ratings yet

- Construction WasteDocument23 pagesConstruction WasteNithin BasheerNo ratings yet

- ARCH 311 DES5 Sustainable Development Sustainable ArchitectureDocument49 pagesARCH 311 DES5 Sustainable Development Sustainable ArchitectureNovie ViernesNo ratings yet

- Activity 2.3.2 Green Building and Sustainable DesignDocument4 pagesActivity 2.3.2 Green Building and Sustainable DesignJames JerzNo ratings yet

- Relationship Between Project Management and Green BuildingsDocument8 pagesRelationship Between Project Management and Green BuildingsPeter E. AkpokodjeNo ratings yet

- The Business Case For Sustainability ReportDocument17 pagesThe Business Case For Sustainability ReportAdedotun OlanrewajuNo ratings yet

- EeeDocument3 pagesEee21076 Danovan AnindyaNo ratings yet

- Mini ProjectDocument15 pagesMini ProjectRevanth Local MokkapatiNo ratings yet

- Victorio, S - BsEconomics4-5 - Activity 1Document3 pagesVictorio, S - BsEconomics4-5 - Activity 1sebastian victorioNo ratings yet

- Research Paper Green ArchitectureDocument5 pagesResearch Paper Green Architectureihprzlbkf100% (1)

- Organizational Configuration For Optimal Application of Environmentally Sustainable Building DesignDocument40 pagesOrganizational Configuration For Optimal Application of Environmentally Sustainable Building DesignGahl Sorkin SpanierNo ratings yet

- Single Motored Plastic Shredder With Integrated Extruder - Docx Joshua Thesisi Gogogog 1Document20 pagesSingle Motored Plastic Shredder With Integrated Extruder - Docx Joshua Thesisi Gogogog 1JoshuaPeralta100% (1)

- 04 Hufcor and LEEDDocument4 pages04 Hufcor and LEEDArqmantrueNo ratings yet

- GYIIF Natanael Christanto Brawijaya UniversityDocument11 pagesGYIIF Natanael Christanto Brawijaya UniversityPutu Wisnu Ari WigamaNo ratings yet

- Thesis EiaDocument7 pagesThesis Eiaafcnugzpd100% (1)

- Een BuidingDocument3 pagesEen BuidingmariyaNo ratings yet

- Green Buildings ProjectDocument53 pagesGreen Buildings Projectpradeepkumar1826No ratings yet

- Site Waste Management - ReferenceDocument48 pagesSite Waste Management - ReferenceAbir DeyNo ratings yet

- An Overview of The Green Building ConceptDocument3 pagesAn Overview of The Green Building ConceptjaffnaNo ratings yet

- The 3DayCar Programme - Green Approaches To The Integrated Supply ChainDocument24 pagesThe 3DayCar Programme - Green Approaches To The Integrated Supply ChainYan1203No ratings yet

- Sustainable ArchitectureDocument16 pagesSustainable Architecturemohammed fahadNo ratings yet

- Environmental Management Systems in Construction Projects in Kenya: Barriers, Drivers, Adoption LevelsDocument14 pagesEnvironmental Management Systems in Construction Projects in Kenya: Barriers, Drivers, Adoption LevelsCristian Delgado FloresNo ratings yet

- Leed India: Leadership in Energy and Environmental Design-IndiaDocument67 pagesLeed India: Leadership in Energy and Environmental Design-IndiaHepil VekariyaNo ratings yet

- Building a Strong Foundation: Pioneering Advances in Architecture and Civil Engineering for the Future (Foundations for the Future: Advances in architecture and civil engineering 2)From EverandBuilding a Strong Foundation: Pioneering Advances in Architecture and Civil Engineering for the Future (Foundations for the Future: Advances in architecture and civil engineering 2)No ratings yet

- FasaraGlassFinishes DS BulletinDocument4 pagesFasaraGlassFinishes DS Bulletinreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Yamato (Sh2Ptya) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Yamato (Sh2Ptya) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Vista (SH2FGVI) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Vista (SH2FGVI) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Safu (Sh2Ptsf) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Safu (Sh2Ptsf) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Shutie Black (SH2BKST) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Shutie Black (SH2BKST) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Vega (SH2FGVG) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Vega (SH2FGVG) : Product Detailreflections1272No ratings yet

- 3M Dusted & Frosted MSDSDocument5 pages3M Dusted & Frosted MSDSreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Tsurugi (SH2FGTG) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Tsurugi (SH2FGTG) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Slat (SH2FGSL) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Slat (SH2FGSL) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Seattle Fine (SH2DGST-F) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Seattle Fine (SH2DGST-F) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Slat-G (SH2FGSL-G) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Slat-G (SH2FGSL-G) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Robe (SH2FGRB) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Robe (SH2FGRB) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Shutie (SH2FGST) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Shutie (SH2FGST) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Seattle (SH2DGST) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Seattle (SH2DGST) : Product Detailreflections1272No ratings yet

- San Marino (Milky Milky)Document1 pageSan Marino (Milky Milky)reflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Shizuku (Sh2Fgsk) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Shizuku (Sh2Fgsk) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Prism Silver (SH2CSPS) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Prism Silver (SH2CSPS) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Radius (SH2CSRD) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Radius (SH2CSRD) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Sagano (Sh2Ptsa2) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Sagano (Sh2Ptsa2) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Pixela (SH2FGPX) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Pixela (SH2FGPX) : Product Detailreflections1272No ratings yet

- Mat Crystal 2Document1 pageMat Crystal 2reflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Prism Noir (SH2CSPN) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Prism Noir (SH2CSPN) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Nokto (SH2CSNK) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Nokto (SH2CSNK) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Oslo-P (Sh2Emos-P) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Oslo-P (Sh2Emos-P) : Product Detailreflections1272No ratings yet

- Milky CrystalDocument1 pageMilky Crystalreflections1272No ratings yet

- Milano (Milky White)Document1 pageMilano (Milky White)reflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Luna 9 (SH2PCL9) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Luna 9 (SH2PCL9) : Product Detailreflections1272No ratings yet

- Mat Crystal IDocument1 pageMat Crystal Ireflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Luna 6 (SH2PCL6) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Luna 6 (SH2PCL6) : Product Detailreflections1272No ratings yet

- 3M™ Fasara™ Glass Finishes Luce (SH2FGLU) : Product DetailDocument1 page3M™ Fasara™ Glass Finishes Luce (SH2FGLU) : Product Detailreflections1272No ratings yet

- Toxic Gas Exposure Limits and Alarm Levels, Portable Gas DetectionDocument1 pageToxic Gas Exposure Limits and Alarm Levels, Portable Gas DetectionwisnukerNo ratings yet

- Tilmicosin Phosphate (Cas 137330-13-3) MSDSDocument7 pagesTilmicosin Phosphate (Cas 137330-13-3) MSDSMiMi JoyNo ratings yet

- Secondary Treatment System: Trickling FilterDocument5 pagesSecondary Treatment System: Trickling FilterMaryrose GalapNo ratings yet

- CE 312 - Sewage Disposal in Unsewered Areas PDFDocument9 pagesCE 312 - Sewage Disposal in Unsewered Areas PDFkennysawegNo ratings yet

- 25 Compelling Reasons Why Plastic Bottles Should Be Banned Immediately - Conserve Energy FutureDocument8 pages25 Compelling Reasons Why Plastic Bottles Should Be Banned Immediately - Conserve Energy FutureakshayNo ratings yet

- P11X21EN New Global Engine Range - 280851Document16 pagesP11X21EN New Global Engine Range - 280851Jan HendriksNo ratings yet

- TP CFB 12 03Document16 pagesTP CFB 12 03Harish MechNo ratings yet

- IGBC AP: Comparision of Credits Between Reference GuidesDocument6 pagesIGBC AP: Comparision of Credits Between Reference GuidesRupin Sidharth100% (3)

- Evs SeminarDocument17 pagesEvs SeminarAthul RameshNo ratings yet

- Handbook On RechargeDocument49 pagesHandbook On RechargeN.J. PatelNo ratings yet

- Aspect Impact Register Hfd.Document3 pagesAspect Impact Register Hfd.julio_salas_59100% (1)

- Environmental Studies - I (Credit - 4) : Full Marks: 50Document2 pagesEnvironmental Studies - I (Credit - 4) : Full Marks: 50DINNNo ratings yet

- Basement VentilationDocument31 pagesBasement VentilationgauNo ratings yet

- Thesis StatementDocument2 pagesThesis StatementDan Larson0% (1)

- Example Method Statement For Excavation WorkDocument8 pagesExample Method Statement For Excavation WorkMustafa SütcüoğluNo ratings yet

- CPCB - Hazardous WasteDocument57 pagesCPCB - Hazardous WasteAlan TuringNo ratings yet

- Externalities and Public PolicyDocument36 pagesExternalities and Public PolicyAmalina JuraimiNo ratings yet

- Provisional Consent Order (CCA) : Consent No. AWH-39922 Valid Upto: 31/03/2020Document1 pageProvisional Consent Order (CCA) : Consent No. AWH-39922 Valid Upto: 31/03/2020Ks SainiNo ratings yet

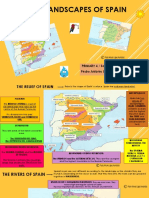

- Unit 3. The Landscapes of SpainDocument7 pagesUnit 3. The Landscapes of SpainAnonymous pxoQu65t6xNo ratings yet

- E023586592 PDFDocument7 pagesE023586592 PDFs_murugan02No ratings yet

- Membrane Technology LectureDocument25 pagesMembrane Technology LectureZaiEbido100% (1)

- Introduction To Environmental Engineering Worksheet: Vocabulary DefinitionsDocument3 pagesIntroduction To Environmental Engineering Worksheet: Vocabulary DefinitionssaritasahuNo ratings yet

- Fact Sheet Gorgon Co2 Injection ProjectDocument2 pagesFact Sheet Gorgon Co2 Injection ProjectCorreo OpcionalNo ratings yet

- A Review On Sustainability of Rainwater Harvesting With Especial Reference To NepalDocument11 pagesA Review On Sustainability of Rainwater Harvesting With Especial Reference To NepalmozimNo ratings yet

- BAKAJUAN Project - Project Building 5 PresentationDocument8 pagesBAKAJUAN Project - Project Building 5 PresentationCharlene Ypil Licay-licayNo ratings yet

- Environmental HealthDocument6 pagesEnvironmental HealthdivyaNo ratings yet