Professional Documents

Culture Documents

Viper Error 00010033

Viper Error 00010033

Uploaded by

joecentroneOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viper Error 00010033

Viper Error 00010033

Uploaded by

joecentroneCopyright:

Available Formats

The error 10033 can be caused by this reason. .

When loading a platen into the Viper printer, the first layer will print fine, as it exits the printer at the back; the flip gear is affected by surrounding gears flipping it in the position to properly affect the reverse phase bar which is located at the back side of the printer under the blue cover.If the reverse phase bar cannot rotate when the printer calls for the platen to be reversed, it will normally kick off a 100033 service required error. Noise may also be heard from the head carriage making contact with this flip gear as it enters the capping station region. The Flip Gear is articulated via surrounding gears rotating at different times, and when ink is built up on the Flip gear and frame of the printer (See Image Below). The flip gear may sit in the up position causing it to be contacted by the carriage during the print cycle. We will need to clean the gears surrounding the flip gear, the flip gear itself and the frame so it becomes free moving again and can position itself against the surrounding gears to properly activate the reverse phase bar to bring the platen back properly.

DTG Viper Error : 00010033

Tools needed: 1) 2) 3) 4) #2 Phillips Screw Driver Hard bristled tooth brush 70% Isopropyl alcohol Paper towels or an old tee shirt

Step1: Removing the Spit Cup to Access the Flip Gear and surrounding gears. To access the flip gear and the surrounding gears to clean, we need to remove the Spit cup. Forward of the capping station is the black spit cup. On the left side just above the top left corner of the capping station is a Phillips screw. Remove that Phillip screw so we can slide the spit cup out of the way. (A magnetized Phillip screw driver is recommended so you do not loose the screw when loosened) Once the Phillip screw is extracted, Gently pull the spit cup back towards the capping station and that will unseat it from the end bracket, then move it towards the right side and tape it there so it will not get in our way when cleaning the flip gear. (Be careful on pulling up on the spit cup too much, there is a tube connected to the spit cup drain that we want to keep in tact.)

Revision Date / Version: 2/20/2014 - 2

DTG Viper Error : 00010033

Step 2: Cleaning the Flip Gear and surrounding gears from ink build up As we use our printer day in and day out, it is possible that ink will start to build up onto the gear assemblies located near our capping station assembly. As this happens, that ink build up till start to affect the movement of the flip gear. It is called the flip gear because of its movement, When the platen system is brought in to print a layer of ink, the flip gear is inactive, when the Viper commands to reverse

Revision Date / Version: 2/20/2014 - 2

the platen system back to the front to print the next layer, A gear assembly located to the top right of the spit cup are rotated and affect the flip gear which then triggers the reverse phase bar to rotate to allow our platen system to be brought back to the front. Over time, ink build up will disallow the flip gear to move up and down, when in the down position, it will trigger the reverse phase bar to allow the platen to bring back. Ink build up will disallow the Flip gear from rotating back down to affect the reverse action. We need to thoroughly clear the flip gear, the teeth of the surrounding gears, and the frame of the machine so the flip gear can move freely. 70% Isopropyl alcohol and a hard bristled tooth brush is the best way to thoroughly clean the flip gear and all surrounding components and to ensure free movement of it. With the Spit cup out of the way, Soak the toothbrush in 70% isopropyl alcohol, and begin to clean all the ink build up off the flip gear, the surrounding gears and off of the frame behind the flip gear. Then take a paper towel or an old tee shirt and wiper it clean. Test the movement of the flip gear to ensure that it can rotate up and down without being affected by any ink build up. It is Important to clean these components thoroughly so the flip gear can get to the right position to affect the reverse phase bar.

DTG Viper Error : 00010033

Step 3: Remounting the Spit Cup and testing the machine. Once you have the flip gear working properly, Re-affix your Spit cup by first seating the Tab at the top into the frame bracket, this will align up the screw hole for proper securing. Tighten the Phillip screw to secure the spit cup. Test by moving the Carriage assembly over the Capping station several times to ensure nothing is catching it. Power on the printer and print a two layer image onto a shirt to confirm that the flip gear is working again.

Revision Date / Version: 2/20/2014 - 2

You might also like

- Kenmore 158.1595 (Ultra Stitch 12)Document50 pagesKenmore 158.1595 (Ultra Stitch 12)Wilma Bernier72% (18)

- View Duplicate Invoice - Apple IphoneDocument1 pageView Duplicate Invoice - Apple IphoneGas67% (3)

- China Patcher Users Manual71719 PDFDocument13 pagesChina Patcher Users Manual71719 PDFeric pacha67% (6)

- Singer 1950s Sewing Machine Manual Class 99/99KDocument56 pagesSinger 1950s Sewing Machine Manual Class 99/99KSyllieC94% (48)

- Minnesota (Davis) Model C Sewing Machine Instruction ManualDocument20 pagesMinnesota (Davis) Model C Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- BM DF 3000 Complete ManualDocument21 pagesBM DF 3000 Complete ManualEduardo DelgadoNo ratings yet

- Error 204Document6 pagesError 204joecentrone100% (2)

- KGe Profiler ManualDocument5 pagesKGe Profiler ManualReinaldo PulidoNo ratings yet

- 1e 1r Series Cut 1023e 1025r 1026rDocument2 pages1e 1r Series Cut 1023e 1025r 1026rDaniel BealsNo ratings yet

- Switching DC Power Supply Maisen MP Series: JBM Instrumentos LtdaDocument3 pagesSwitching DC Power Supply Maisen MP Series: JBM Instrumentos LtdaRodrigo CardosoNo ratings yet

- 366-76-12 Extra Heavy Duty Long Arm Zigzag Sewingmachine For Manufacturing SailsDocument30 pages366-76-12 Extra Heavy Duty Long Arm Zigzag Sewingmachine For Manufacturing SailsBill JiangNo ratings yet

- 452 - 08799 Fluid System Clean Out Procedure For ZPrinter 310 PlusDocument2 pages452 - 08799 Fluid System Clean Out Procedure For ZPrinter 310 PlusvicvansNo ratings yet

- 502 - 09621 Z310 E Box Replacement ProcedureDocument15 pages502 - 09621 Z310 E Box Replacement ProcedurevicvansNo ratings yet

- Singer 2010A ManualDocument75 pagesSinger 2010A Manualswanstall88% (8)

- Setter Gun Nozzle Tip ReplacementDocument1 pageSetter Gun Nozzle Tip ReplacementjoecentroneNo ratings yet

- BS en Iso 1833-12-2010Document12 pagesBS en Iso 1833-12-2010EmkFataAliraqNo ratings yet

- Ecolab Social Media PolicyDocument4 pagesEcolab Social Media PolicyJavier GonzalezNo ratings yet

- NVDXT ParametersDocument5 pagesNVDXT ParametersStephen Blommestein50% (2)

- Graxa AliplexDocument1 pageGraxa AliplexMárcio EstevamNo ratings yet

- 1396 - 08798 ZPrinter 310 Flow Rate TestDocument3 pages1396 - 08798 ZPrinter 310 Flow Rate Testvicvans0% (1)

- Ac Nut Splitter ManualDocument12 pagesAc Nut Splitter ManualLoveNo ratings yet

- NOV Anson CatalogueDocument3 pagesNOV Anson Catalogueravmansion0% (1)

- Manual EZ4 AssemblyDocument36 pagesManual EZ4 Assemblyjavier_valdivia_42No ratings yet

- TopCon GTS600Document153 pagesTopCon GTS600adysnakeNo ratings yet

- Epson ET-M1120 Assembly ManualDocument25 pagesEpson ET-M1120 Assembly ManualnorbertscribdNo ratings yet

- 3DP Consumables Catalog PDFDocument18 pages3DP Consumables Catalog PDFDragana RajicNo ratings yet

- Keeway Superlight TuningDocument20 pagesKeeway Superlight TuningJohn SmithNo ratings yet

- Quanti Tray Sealer Plus ManualDocument52 pagesQuanti Tray Sealer Plus ManualHannah LeeNo ratings yet

- Assembly - InstallationDocument42 pagesAssembly - InstallationValentina AntohiNo ratings yet

- RTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWDocument1 pageRTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWMohamed MohamedNo ratings yet

- Details of Spare PartsDocument26 pagesDetails of Spare PartsMahla Raj KumarNo ratings yet

- Global Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFDocument800 pagesGlobal Detection - Electronic and Electromechanical Sensors Catalogue 2006.10 PDFSarah RichardNo ratings yet

- Hoover Lark Model 1334 Vacuum Cleaner, Instruction ManualDocument8 pagesHoover Lark Model 1334 Vacuum Cleaner, Instruction ManualnjwscribdNo ratings yet

- P640i TN5 Flip Station Rev 1Document4 pagesP640i TN5 Flip Station Rev 1khanileh0% (1)

- Cleaning, Service and Moving - Cleaning Your Air Assist Fan GlowforgeDocument20 pagesCleaning, Service and Moving - Cleaning Your Air Assist Fan GlowforgeTasheenaNo ratings yet

- K Ge Reeds Profiling Machine ManualDocument6 pagesK Ge Reeds Profiling Machine ManualNeuromante3223No ratings yet

- Crippen: L e G e N D 1 2 8 8Document23 pagesCrippen: L e G e N D 1 2 8 8Faeyza shopNo ratings yet

- KX Free Piston ModDocument2 pagesKX Free Piston ModKidKawie100% (1)

- OperatorsManual A1334 A2968 Rotary Brush 130Document17 pagesOperatorsManual A1334 A2968 Rotary Brush 130Павел ХромовNo ratings yet

- Pfaff 90 ManualDocument49 pagesPfaff 90 ManualGeorge GreeneNo ratings yet

- Statim Service Manual 1Document3 pagesStatim Service Manual 1rhymenNo ratings yet

- Consew Chandler CM-101 Parts BookDocument27 pagesConsew Chandler CM-101 Parts BookIndumentariaCosturaNo ratings yet

- Cartridge-Ink Model: Mimaki Engineering Co., LTDDocument36 pagesCartridge-Ink Model: Mimaki Engineering Co., LTDjohnNo ratings yet

- Lexmark Optra S 1855 Maintenance Kit InstructionsDocument2 pagesLexmark Optra S 1855 Maintenance Kit Instructionshmartin80No ratings yet

- EN Pilot-XPDocument6 pagesEN Pilot-XProssandcoNo ratings yet

- Review This Manual Before Operating ApplianceDocument22 pagesReview This Manual Before Operating ApplianceKhaled MoussaNo ratings yet

- Treadmill Operating ManualDocument2 pagesTreadmill Operating ManualjtbushbergNo ratings yet

- SINGER 14U64A Instruction Manuals and User Guides ENDocument28 pagesSINGER 14U64A Instruction Manuals and User Guides ENGustavs KrievkalnsNo ratings yet

- Deep Clean Passap DuomaticDocument19 pagesDeep Clean Passap DuomaticLiesjevg99100% (1)

- LEXMARK OPTRA T Maintenance Kit InstructionsDocument2 pagesLEXMARK OPTRA T Maintenance Kit InstructionskswongNo ratings yet

- EXT ERA Basic Service ManualDocument11 pagesEXT ERA Basic Service ManualMarco CaggeseNo ratings yet

- Spurgo Freni ShimanoDocument9 pagesSpurgo Freni ShimanoJackson WallNo ratings yet

- User Manual For Printing Machine - Only EnglishDocument58 pagesUser Manual For Printing Machine - Only EnglishprevencionistaNo ratings yet

- Manual For Stingray X2 Tattoo Machine en Rev1Document23 pagesManual For Stingray X2 Tattoo Machine en Rev1Felipe G. J Olivos De QuintoNo ratings yet

- Fabrication of A Centrifugal Pump: ENGR 120Document44 pagesFabrication of A Centrifugal Pump: ENGR 120Jaishree ChauhanNo ratings yet

- Dyson UP32 User ManualDocument12 pagesDyson UP32 User ManualCaroline DunfordNo ratings yet

- 1997 2005 Subaru Forester Short Shifter InstallDocument8 pages1997 2005 Subaru Forester Short Shifter InstallmadvadinNo ratings yet

- CUIDADOS DIÁRIOS CJV30 - BS Ver1.00Document8 pagesCUIDADOS DIÁRIOS CJV30 - BS Ver1.00Renato CarneiroNo ratings yet

- Preventive Maintenance of Electroglas Eg2001Document8 pagesPreventive Maintenance of Electroglas Eg2001Tan Chiang Li100% (1)

- Remanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesDocument8 pagesRemanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesservicerNo ratings yet

- jv330 Series 2Document44 pagesjv330 Series 2隔壁老王No ratings yet

- Redback Operations ManualDocument11 pagesRedback Operations ManualDon BraithwaiteNo ratings yet

- Tapmatic 50X Safety and Operation ManualDocument12 pagesTapmatic 50X Safety and Operation ManualrvpilotNo ratings yet

- Exp 6Document1 pageExp 6Nod salNo ratings yet

- E39 540i - M62TU Timing Chain Plastic Guide DisintegrationDocument37 pagesE39 540i - M62TU Timing Chain Plastic Guide DisintegrationEngine Tuning UpNo ratings yet

- Cleaning and Adjusting Your Sewing Machine: Instruction BookDocument8 pagesCleaning and Adjusting Your Sewing Machine: Instruction BookCia ednaAbacahan100% (1)

- Installation Directions For The Presser Foot (Compact)Document6 pagesInstallation Directions For The Presser Foot (Compact)joecentroneNo ratings yet

- Presser Foot Stopper Roller-C SeriesDocument8 pagesPresser Foot Stopper Roller-C SeriesjoecentroneNo ratings yet

- Installation Directions For The Presser Foot (Compact)Document5 pagesInstallation Directions For The Presser Foot (Compact)joecentroneNo ratings yet

- Buckle SetDocument1 pageBuckle SetjoecentroneNo ratings yet

- Take Up Lever Gray.Document6 pagesTake Up Lever Gray.joecentroneNo ratings yet

- Picker and Picker BaseDocument4 pagesPicker and Picker BasejoecentroneNo ratings yet

- Reciprocator Compact Single and MultiheadDocument14 pagesReciprocator Compact Single and MultiheadjoecentroneNo ratings yet

- Installation Directions For The Rotary HookDocument5 pagesInstallation Directions For The Rotary HookjoecentroneNo ratings yet

- Installation Directions For The Presser Foot (Compact)Document6 pagesInstallation Directions For The Presser Foot (Compact)joecentroneNo ratings yet

- Upper Thread Catcher-WiperDocument3 pagesUpper Thread Catcher-WiperjoecentroneNo ratings yet

- Part Direction - Thread Take Up SpringDocument4 pagesPart Direction - Thread Take Up SpringjoecentroneNo ratings yet

- CAMS Training AssuranceDocument1 pageCAMS Training Assurancejoecentrone100% (1)

- Part Direction - Tension Adjusting Bolt.Document2 pagesPart Direction - Tension Adjusting Bolt.joecentroneNo ratings yet

- ProSpangle Customer Training Assurance FormDocument1 pageProSpangle Customer Training Assurance FormjoecentroneNo ratings yet

- Replacing The X Belt 1V6P MachineDocument6 pagesReplacing The X Belt 1V6P MachinejoecentroneNo ratings yet

- Solenoid Replacement 1V6P (CAMC2E001-A)Document2 pagesSolenoid Replacement 1V6P (CAMC2E001-A)joecentroneNo ratings yet

- DTG Training AssuranceDocument1 pageDTG Training AssurancejoecentroneNo ratings yet

- Part Direction - Tension Adjusting Bolt.Document2 pagesPart Direction - Tension Adjusting Bolt.joecentroneNo ratings yet

- Part Direction - Thread Take Up SpringDocument4 pagesPart Direction - Thread Take Up SpringjoecentroneNo ratings yet

- Replacing The Double Acting Solenoid 1V2P and 1V6P MachinesDocument2 pagesReplacing The Double Acting Solenoid 1V2P and 1V6P MachinesjoecentroneNo ratings yet

- Replacing The Y Belt 1V6P MachineDocument3 pagesReplacing The Y Belt 1V6P MachinejoecentroneNo ratings yet

- Error 300Document2 pagesError 300joecentroneNo ratings yet

- Error 206Document8 pagesError 206joecentroneNo ratings yet

- Error 400Document11 pagesError 400joecentrone100% (1)

- Gun Up Down Sensors 1V6PDocument5 pagesGun Up Down Sensors 1V6PjoecentroneNo ratings yet

- Error Code 104 - 105Document8 pagesError Code 104 - 105joecentroneNo ratings yet

- Gun Nozzle Tip Maintenance and ReplacementDocument2 pagesGun Nozzle Tip Maintenance and ReplacementjoecentroneNo ratings yet

- Error 102 - 103Document18 pagesError 102 - 103joecentroneNo ratings yet

- Sap Service Description For Managed Services Ams English v04 2016Document16 pagesSap Service Description For Managed Services Ams English v04 2016Karthick MNo ratings yet

- Manual RugosimetroDocument6 pagesManual RugosimetroFabian Kmilo de GomezNo ratings yet

- 1AA17AT051 - Bus Terminal Cum Commercial Complex by Sanjay SS PDFDocument63 pages1AA17AT051 - Bus Terminal Cum Commercial Complex by Sanjay SS PDFBriza Marie BeltranNo ratings yet

- DHC Order - Section 59 Claim AmendmentsDocument35 pagesDHC Order - Section 59 Claim AmendmentsM VridhiNo ratings yet

- Triton Cargo Worthy Standards - May2017 RevisionDocument57 pagesTriton Cargo Worthy Standards - May2017 RevisionHoan VuNo ratings yet

- Ac Auxiliary Power Supply Scheme 125aDocument13 pagesAc Auxiliary Power Supply Scheme 125aAbhishek RajputNo ratings yet

- 1 Crypt Mausoleum Foundation Plan Rev - New - SanitizedDocument1 page1 Crypt Mausoleum Foundation Plan Rev - New - SanitizedWinmentolMalisa100% (1)

- Artificial Intelligence:: Implications For Business StrategyDocument12 pagesArtificial Intelligence:: Implications For Business StrategyWilliam PolhmannNo ratings yet

- Dwnload Full Anatomy and Physiology 6th Edition Gunstream Test Bank PDFDocument35 pagesDwnload Full Anatomy and Physiology 6th Edition Gunstream Test Bank PDFamess.trias.xpuax100% (23)

- Fixed Term Employment Agreement - MLJDRDocument11 pagesFixed Term Employment Agreement - MLJDRrizalyn perezNo ratings yet

- Sannna Ruhi AffidavitDocument2 pagesSannna Ruhi AffidavitAhsan Ali JavedNo ratings yet

- Strategic Foresight For Innovation Management: A Review and Research AgendaDocument34 pagesStrategic Foresight For Innovation Management: A Review and Research AgendaTABAH RIZKINo ratings yet

- Surface Treatments and CoatingsDocument4 pagesSurface Treatments and Coatingsmightym85No ratings yet

- 2013 Get Organized Challenge WorkbookDocument22 pages2013 Get Organized Challenge WorkbookJennifer Collins100% (4)

- Communal T1 El-ELDocument1 pageCommunal T1 El-ELteddyNo ratings yet

- Replacement Parts List: Indoor Air Handler (B5, GB5) SeriesDocument12 pagesReplacement Parts List: Indoor Air Handler (B5, GB5) SeriesAlvaro GarciaNo ratings yet

- TP-20 For Protective RelaysDocument20 pagesTP-20 For Protective RelayssathiyaseelanNo ratings yet

- Retail Fin IntegrationDocument4 pagesRetail Fin IntegrationNabeel RashidNo ratings yet

- Leica Rugby 320 410 420 BROCHUREDocument6 pagesLeica Rugby 320 410 420 BROCHUREbbutros_317684077No ratings yet

- Ashghal Issue11 EngDocument32 pagesAshghal Issue11 Engmanojj65No ratings yet

- Bafna Pharmaceuticals: Regulated GrowthDocument8 pagesBafna Pharmaceuticals: Regulated GrowthpradeepchoudharyNo ratings yet

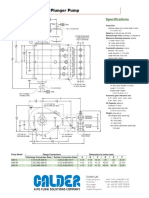

- 300Q-5 Quintuplex Plunger PumpDocument2 pages300Q-5 Quintuplex Plunger PumpJuanNo ratings yet

- Week 1 Shs Organic AgriDocument2 pagesWeek 1 Shs Organic Agrijessica coronel100% (2)

- 2021 1 Eau p2 Estereotomía Programa de CursoDocument6 pages2021 1 Eau p2 Estereotomía Programa de CursoDixom Javier Monastoque RomeroNo ratings yet