Professional Documents

Culture Documents

Re 95023

Re 95023

Uploaded by

Rafael Torres SabalzaCopyright:

Available Formats

You might also like

- Ats46c41n Square D Altistart 46 Telemecanique ManualDocument236 pagesAts46c41n Square D Altistart 46 Telemecanique ManualTheSufferoneNo ratings yet

- Error Code EMR 2Document5 pagesError Code EMR 2Nafrizal SuhendrikNo ratings yet

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- KomatsuDocument2 pagesKomatsumuhammad aliNo ratings yet

- Esm 7-22Document8 pagesEsm 7-22Endre FarkasNo ratings yet

- Proportional Amplifier PVRDocument8 pagesProportional Amplifier PVRgaliardi100% (1)

- What Is RAID Control PDFDocument6 pagesWhat Is RAID Control PDFAhmedNo ratings yet

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Isuzu MNF CodesDocument15 pagesIsuzu MNF Codesjames gichuhiNo ratings yet

- Proportional Indicating Controller: DescriptionDocument5 pagesProportional Indicating Controller: DescriptionFastcross Honda100% (1)

- BODAS-service: RE 95086/2021-04-19 Replaces: 2020-03-02Document10 pagesBODAS-service: RE 95086/2021-04-19 Replaces: 2020-03-02Vinod HegdeNo ratings yet

- Caterpillar Industrial C9 SpecificationsDocument5 pagesCaterpillar Industrial C9 SpecificationsIrfan SaeedNo ratings yet

- Brochure 2200CR enDocument28 pagesBrochure 2200CR enCoras LucianNo ratings yet

- TCD2015 PDFDocument67 pagesTCD2015 PDFRosa ChNo ratings yet

- ReleaseNotes BODAS-service 3.6.2Document3 pagesReleaseNotes BODAS-service 3.6.2OHW SERNo ratings yet

- Kato KR 22HDocument17 pagesKato KR 22Hanwar salimNo ratings yet

- Gulliver RGDF - TS0063UK00 PDFDocument16 pagesGulliver RGDF - TS0063UK00 PDFCarlos Castillo UrrunagaNo ratings yet

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocument109 pagesThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsRolandas PetkusNo ratings yet

- Diode Ir1fDocument6 pagesDiode Ir1fedgarlibanioNo ratings yet

- EMR4 - CAN - BUS - Specification - Ver02 - 34Document73 pagesEMR4 - CAN - BUS - Specification - Ver02 - 34morusNo ratings yet

- FTA2000 Medium Voltage Electric Fire Pump ControllersDocument8 pagesFTA2000 Medium Voltage Electric Fire Pump ControllersOhaneje Uzoma50% (2)

- Features: TAIK Electric Co., LTDDocument3 pagesFeatures: TAIK Electric Co., LTDWaseem WasiNo ratings yet

- GPM 22Document2 pagesGPM 22Khalid SaddikNo ratings yet

- Implement Valve Chassis Wiring: 980K Wheel Loader and Electrical System 980K OEM Wheel LoaderDocument4 pagesImplement Valve Chassis Wiring: 980K Wheel Loader and Electrical System 980K OEM Wheel LoaderJose Cruz RiosNo ratings yet

- HKD-100D PA ManualDocument5 pagesHKD-100D PA ManualLucas BarriosNo ratings yet

- Status Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Document9 pagesStatus Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Jean DiscretNo ratings yet

- Copex Brochure REFLEX FR-GB 2016Document2 pagesCopex Brochure REFLEX FR-GB 2016Nicolas BourbeyNo ratings yet

- EDC-1 Tutorial 6Document1 pageEDC-1 Tutorial 6samarthNo ratings yet

- GCM02 GB App R03Document37 pagesGCM02 GB App R03Karim AssoumaniNo ratings yet

- Hitachi EX550-5, EX600H-5 Workshop ManualDocument20 pagesHitachi EX550-5, EX600H-5 Workshop ManualLidetu DemissieNo ratings yet

- VF500 VF600 VR600Document24 pagesVF500 VF600 VR600Mehdi FarrokhiNo ratings yet

- Xas 400 CD t3 Row Xc2003 Supplement 2015Document23 pagesXas 400 CD t3 Row Xc2003 Supplement 2015Luc DumontNo ratings yet

- KP-C500P (KTA19-G3A) Generating Set Technical Data SheetDocument5 pagesKP-C500P (KTA19-G3A) Generating Set Technical Data SheetMario CastroNo ratings yet

- Páginas Extraídas de Manual - MX2Document8 pagesPáginas Extraídas de Manual - MX2Anonymous 97JlpvN4No ratings yet

- BODAS Controller RC4-5 Series 30: RE 95205/06.2018, Bosch Rexroth AGDocument22 pagesBODAS Controller RC4-5 Series 30: RE 95205/06.2018, Bosch Rexroth AGVinod HegdeNo ratings yet

- Brochure Abg7820b Abg8820b t3 en 21 20000048 CDocument12 pagesBrochure Abg7820b Abg8820b t3 en 21 20000048 CKurniawan100% (1)

- T-Scale Bws PDFDocument24 pagesT-Scale Bws PDFIvan Agreda SalvadorNo ratings yet

- DENAIR Oil-Free Air Compressor PDFDocument8 pagesDENAIR Oil-Free Air Compressor PDFagasmekatron100% (1)

- Concrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBDocument2 pagesConcrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBBourenaneNo ratings yet

- Ficha Tecnica Lishide Escavadora Lishide SC220-8 - 1081Document3 pagesFicha Tecnica Lishide Escavadora Lishide SC220-8 - 1081PABLO HERNAN PRADA MONCADANo ratings yet

- Sauer-Danfoss Mcx103b Position TransducerDocument4 pagesSauer-Danfoss Mcx103b Position TransducerJosé Fidencio Carrillo MorenoNo ratings yet

- Ug-26 Skad-Kad 04Document1 pageUg-26 Skad-Kad 04Nisar AhmedNo ratings yet

- Piovan Chillers CH50 CH900Document8 pagesPiovan Chillers CH50 CH900Karel VajdakNo ratings yet

- TYPE ATS-050: Switching Control UnitDocument8 pagesTYPE ATS-050: Switching Control UnitAhmed El-AdawyNo ratings yet

- EN Imapla TroubleshootingDocument15 pagesEN Imapla TroubleshootingAndrei 26No ratings yet

- Tad722ge PDFDocument2 pagesTad722ge PDFWasif Irfan100% (1)

- 1526 BG15H Doku ENDocument68 pages1526 BG15H Doku ENBoss kevinNo ratings yet

- Proportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGDocument16 pagesProportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGRonald Rayme VenturaNo ratings yet

- Furnace ITV Color Camera: Series FK-CF-3712Document2 pagesFurnace ITV Color Camera: Series FK-CF-3712Italo Rodrigues100% (1)

- Philips (Funai) PL10.4 40PFL5705Document59 pagesPhilips (Funai) PL10.4 40PFL5705Israel B ChavezNo ratings yet

- Tesmec Catalogue TmeDocument208 pagesTesmec Catalogue TmeDidier solanoNo ratings yet

- 3 Waukesha Gas Engine Maintenance ManualDocument75 pages3 Waukesha Gas Engine Maintenance ManualMamunNo ratings yet

- Deep Sea Controller 4410 Drawing PDFDocument3 pagesDeep Sea Controller 4410 Drawing PDFjorge andres yanez quezada100% (2)

- Status Report Fruytier 972K Pem00444 DPF A Plus de 140% Soot - PSRPT - 2021-07-28 - 09.36.43Document13 pagesStatus Report Fruytier 972K Pem00444 DPF A Plus de 140% Soot - PSRPT - 2021-07-28 - 09.36.43Jean DiscretNo ratings yet

- DSE 710-720 Data SheetDocument2 pagesDSE 710-720 Data SheetAnas BasarahNo ratings yet

- 962H Electrical DiagramDocument4 pages962H Electrical DiagramMarielis ContrerasNo ratings yet

- 140k Elec PDFDocument20 pages140k Elec PDFhitler morales gavidiaNo ratings yet

- Especificações TecnicasDocument20 pagesEspecificações TecnicasDanubio Rocha de LimaNo ratings yet

- Proportional Amplifier PV: For The Control of A Proportional SolenoidDocument8 pagesProportional Amplifier PV: For The Control of A Proportional SolenoidIvan BeljinNo ratings yet

- LM2907Document21 pagesLM2907leorio88No ratings yet

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocument13 pagesFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadNo ratings yet

- lm2917 NDocument24 pageslm2917 NAlejandro RojoNo ratings yet

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- Masterglenium Ace: Solutions For The Pre-Cast IndustryDocument7 pagesMasterglenium Ace: Solutions For The Pre-Cast IndustryAlanNo ratings yet

- TPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™Document57 pagesTPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™sbrhomeNo ratings yet

- Water Content in SoilDocument4 pagesWater Content in SoilJohn Paul CristobalNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- A. Title of Experiment B. Date and Time of Experiment: Wednesday, 10Document15 pagesA. Title of Experiment B. Date and Time of Experiment: Wednesday, 10LichaNo ratings yet

- Basic Presentation SkillsDocument20 pagesBasic Presentation Skills11Rula SabithaTB100% (1)

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Comparison of Three Phase PV System in PSCAD and PowerFactoryDocument8 pagesComparison of Three Phase PV System in PSCAD and PowerFactorymlkz_01No ratings yet

- Open-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsDocument24 pagesOpen-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsSHAIK MUSTHAFANo ratings yet

- Process Flow Chart - Manufacturing TS: Rejected, Sent Back To SupplierDocument1 pageProcess Flow Chart - Manufacturing TS: Rejected, Sent Back To Suppliersukumar bhowmickNo ratings yet

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Lecture 7 - Synchronous Generators 7 PDFDocument28 pagesLecture 7 - Synchronous Generators 7 PDFDorwinNeroNo ratings yet

- 1 s2.0 S0264127522004105 MainDocument11 pages1 s2.0 S0264127522004105 MainAsimov RiyazNo ratings yet

- Filipino BasicDocument21 pagesFilipino BasicReiko Nakayama100% (1)

- Uccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversDocument38 pagesUccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversTeles SilvaNo ratings yet

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Understanding Your Electricity Bill in PakistanDocument13 pagesUnderstanding Your Electricity Bill in PakistanGhayas Ud-din DarNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- WATERGUARD 45 (Acrylic Waterproofing Coating)Document3 pagesWATERGUARD 45 (Acrylic Waterproofing Coating)Santosh Kumar PatnaikNo ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- HP Deskjet D1600 Printer SeriesDocument13 pagesHP Deskjet D1600 Printer SeriesRizki JuliadiNo ratings yet

- Hillfoot Data Sheets V5 1Document4 pagesHillfoot Data Sheets V5 1Kristijan IlicNo ratings yet

- 10 Science TP 11 1Document5 pages10 Science TP 11 1Ananaya BansalNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

Re 95023

Re 95023

Uploaded by

Rafael Torres SabalzaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Re 95023

Re 95023

Uploaded by

Rafael Torres SabalzaCopyright:

Available Formats

RE 95 023/04.

00

RE 95 023/04.00

Replaces: 07.98

Proportional Amplifier PV

for the control of a proportional solenoid Series 2

PV24FE/20

Features

The proportional amplifier PV is used for control of a variable displacement pump, a variable displacement motor or a valve with one proportional solenoid. As input signal the amplifier PV is processing the control voltage adjustable by means of a potentiometer. As output signal the amplifier is providing a closed loop electric current, e.g. for control a variable displacement pump A7VO (RE 92202) or a variable displacement motor A6VM (RE 91604). Main components Voltage stabilisation PWM output stage (pulse width modulation) Time ramp function for demand value Multiple trimmer potentiometer for precise settings of the solenoid currents and time ramp LED display for functions Switching output fault display Circuit board poured in synthetic Special characteristics Optionally version E with recognition of cable breaks and short circuits in the potentiometer cables Optional external control with a voltage signal, e.g. from a SPC (stored program control) Solenoid current pulse width modulated (PWM) for minimum hysteresis Solenoid current closed loop controlled, i.e. voltage and temperature independent, measurement resistance on the board located in the +line to the solenoids Solenoid output short circuit protected Pole and overvoltage protection

Ordering Code

PV

Type Proportional amplifier Voltage supply U= 12V U= 24 V Connections Flat pin vehicle plug Model Standard Extended with fault recognition and fault display Series PV

/ 2 0

12 24 F

2 Index 0

PV

1/8

RE 95 023/04.00

Technical Data

Type Nominal voltage Voltage supply Residual ripple (DIN 40839/1) Reverse voltage protection (supply) Current consumption, without load Current consumption, maximum Fuse on the circuit board Resistance of the external potentiometer Control voltage (input) Ramp time, from Imin to Imax Output current, max. (load depend. potentiometer 4,7 k) Start current, adjustable Pulse frequency (PWM output stage) Fault-switching output max. current Electro-magnetic compatibility (EMC) Short circuit protection Permissible short circuit current for internally connected connections, briefly (< 1 min) Ambient operating temperature Ambient storage temperature Installation position Weight 1500 mA 0900 mA < 1,6 A 1,6 AT 500 ...2 k 0...7,8 V PV12F/20 12 V 10...17 V DC PV24F/20 PV12FE/20 PV24FE/20 24 18...33 V DC

24 V 12 V 18...33 V DC 10...17 V DC max. 2 V response of the fuse approx. 30 mA

< 2,5 A 2,5 AT 2 k...5 k 20% potentiometer 2 k: approx. 0...5,3 V potentiometer 5 k: approx. 0...6,7 V 0,2 s ... 30 s, adjustable 750 mA 0...750 mA 100 Hz

+20 0

1500 mA 0...900 mA 1000 mA

750 mA 0...750 mA 1000 mA

Immunity to interference: 50 V/m Impulse to DIN 40839, parts 1 and 3 all in-/outputs 10 A 25 C ...+70 C 40C ...+80 C optional approx. 130 g

Description

Function (PV...F/20 and PV...FE/20) With the amplifier PV a proportional solenoid is charged with current depending on the input signal. If there is any modification of the control voltage at the input side, leading off from 0V (position of the potentiometer on "0"), the solenoid current is increasing linear from min. value lmin to the max. current lmax. Start current lmin and max. current lmax are adjustable independent of each other. At fast modification of the input signal the output current is retarded by means of a time ramp function. The time for the course from lmin untill lmax is adjustable between 0,2 s and 30 s. The output stage is working almost free of losses by pulse width modulation (PWM) with a pulse repetition rate of 100 Hz. The current closed loop control is effected by modification of the duration of connection resp. disconnection. Temperature related resistance modifications in the proportional solenoid circuit and variations of the operating voltage are settled. With over-loads at the proportional solenoid output the switched-on time of the output stage is reduced to 0,5 ms, so that it is not possible to damage the amplifier.

Characteristics

0

potentiometer

max

Isolenoid

Imax

Imin

0V

+ 7,8 V control voltage (for PV...FE/20 see technical data)

Brueninghaus Hydromatik

2/8

PV

RE 95 023/04.00

Block Circuit Diagram/Connection Diagrams (Potentiometer Control)

PV...F/20

emergency off +12V/+24V battery 0V/ground

1 2

fuse

1,6 AT

voltage supply

LED voltage supply H3

+7,8V

max.

control potentiometer

6 5 3

time ramp

output stage PWM current control

proportional solenoid

1)

4 not allocated

R1 ramp time

LED H1 R2 R3 control Imax Imin signal

1)

A connection to connection 7, the chassis or to the battery ground is possible

With the version PV...F/20 faults at the potentiometer or in the potentiometer connection cables can lead to unforeseen output currents. For safety relevant projects a check should be carried out to see whether the application of the PV...FE/20 version offers advantages. PV...FE/20

emergency off 1 +12V/+24V battery 0V/ground 2

fuse

2,5 AT

voltage supply

LED voltage H3 supply

switch output stage

9 10

fault display potentiometer

1)

max.

6 +5,3...+7,5V 5 3

control potentiometer

0

fault recognition potentiometer

time ramp

output stage

8

proportional solenoid

PWM current control

1)

fault recognition potentiometer

4

2)

H2 fault

R1 ramp time

LED H1 R2 R3 control Imax Imin signal

1) 2)

A connection to connections 7, 10, the chassis or to the battery ground is possible If connection 4 is not allocated then the fault recognition is activated, if connection 4 is connected with a ground then the fault recognition is not acitve.

PV

3/8

Brueninghaus Hydromatik

RE 95 023/04.00

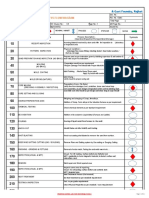

Fault status PV...FE/20

Connection number 3 Meaning potentiometer: ground Effect with connection open output current Imin (via a time ramp), fault display LED H2 lights up, external fault display is active output current Imin (via a time ramp) Effect of a short circuit to the supply voltage internal short circuit without damage, no output current Effect of a short circuit to a ground no effect

potentiometer: wiper

output current Imin (via a time ramp), fault display LED H2 lights up, external fault display is active output current Imin (via a time ramp), fault display LED H2 lights up, external fault display is active maximum solenoid current (DC voltage condition)

output current Imin (via a time ramp)

potentiometer: supply

output current Imin (via a time ramp), fault display LED H2 lights up, external fault display is active no output current

output current Imin (via a time ramp), fault display LED H2 lights up, external fault display is active no output current, LED H1 does not light up

solenoid output

Fault recognition and fault display PV...FE/20

The PV...FE/20 version has a circuit which reduces the solenoid output to a minimum current value if there is a cable break or short circuit in the potentiometer cables. It is also possible, in the case of a fault, to control a lamp via an additional switched output for a fault display. When projecting amplifier controlled hydraulic systems it has to be ensured that with a minimum output current a safe condition can be achieved, (e.g. the vehicle stops)! If a control voltage is used as an input signal instead of a potentiometer, the fault monitoring must be deactivated by a special input circuit at connection 4.

Brueninghaus Hydromatik

4/8

PV

RE 95 023/04.00

Connection Diagrams (alternative)

PV...F/20 Two point control

Voltage control

Current control

8 7 6 5 4 3 2 1

proportional solenoid 1)

8 7 6 RX

proportional solenoid 1)

8 7 6 5

proportional solenoid 1)

RX IS

max 0

5 4 3 US

4 3

- battery (ground) 2 + battery (+UB)

1

- battery (ground) + battery (+UB)

2 1

- battery (ground) + battery (+UB)

RI = 12,7 k input resistance RX = 3,3 k for US = 10 V PV...FE/20 Two point control

RX = 390 for IS max = 20 mA (current source)

Voltage control

Current control

10 9 8 7 6

fault display

10 9

fault display proportional solenoid 1)

RX

10 9 8 7 6 5

fault display

proportional solenoid 1)

8 7 6

proportional solenoid 1)

RX IS

max 5 4 3 2 1

5 4 3

fault recognition potentiometer off

fault recognition potentiometer off

US

4 3

fault recognition potentiometer off

- battery (ground) + battery (+UB)

2 1

- battery (ground) + battery (+UB)

2 1

- battery (ground) + battery (+UB)

RI = 110 k input resistance RX = 27 k for US = 10 V

RX = 390 for IS max = 20 mA (current source)

1)

A connection to connections 7, 10, the chassis or to the battery ground is possible

PV

5/8

Brueninghaus Hydromatik

RE 95 023/04.00

Unit Dimensions

PV...F/20 View drawn without fuse connection strip PV...FE/20 View drawn without fuse connection strip

21

12

12

4,3

sealing compound fixing point

4,3

sealing compound fixing point

H2 LED fault

potentiometer

1 2 3 4 5 6 7 8

LED output signal

LED output signal

103 1

69

69

R2 Imax R1 time ramp

LED

R2 Imax R1 time ramp

LED

voltage

voltage

H3 supply

H3 supply

fuse

11 1

11 1

fuse

1,6 AT

2,5 AT

9 1

58 75 1

9 1

58 75 1

fixing point

fixing point

The counterplug connectors consist of individual pin connectors AMP-Faston size 6,3 are not included. Use only connectors with insulation (avoidance of short circuits)!

Brueninghaus Hydromatik

6/8

103 1

H1 R3 Imin

H1 R3 Imin

1 2 3 4 5 6 7 8 9 10

21

PV

RE 95 023/04.00

Presetting for Delivery

(for variable displacement pumps and motors) Amplifier Nominal voltage Solenoid current PV12.../20 12 V Imin = 400 mA Imax = 1200 mA approx. 5 s PV24.../20 24 V Imin = 200 mA Imax = 600 mA approx. 5 s

Setting Instruction PV.../20

(change of presetting) 1. Set control potentiometer to "0" (control voltage 0V at port 3). Adjust start current Imin with R3. (current increase by rotating in clockwise direction) 2. Set control potentiometer to maximum. Adjust maximum current Imax with R2. (current increase by rotating in clockwise direction) 3. Adjust duration of time ramp with R1. (ramp time increase by rotating in clockwise direction)

Ramp time

The presetting relate to a control potentiometer with a resistance of 4,7 k. For the PV...FE/20 version with fault recognition, other resistance values may result in changes to the current settings.

Compatibility to PV.../10

With regard to the dimensions and the connections 1 to 8 the PV...F/20 and PV...FE/20 amplifiers are compatible with the earlier PV.../10 version. With regard to the functions the PV...F/20 version is directly interchangeable with the earlier PV.../10 version. The version PV...FE/20 with fault recognition, other current values may result at the output which are in relation to the resistance value of the control potentiometer. For the PV.../20 version the measuring resistance for the current control of the solenoid output is switched in the +line of the solenoids; in the PV.../10 version the measurement resistance is in the -line against ground.

Please note:

Brueninghaus Hydromatik cannot accept any responsibility for technical problems occurring within the system arising from using a circuit diagram based on the recommendation. The Safety Regulations for Hydrostatic Transmissions with Electronic Controls (RDE 90301-01) are to be observed. An emergency switch must be fitted to cut off the power supply to the electronics in the event of an emergency. This switch must be easily accessible to the operator. Safe and effective braking must be guaranteed on operating the emergency switch. Lines to the electronics may not be laid in the vicinity of other power lines in the equipment. There must be sufficient distance between any radio equipment. During welding operations all electrical connectors to the electronics must be unplugged. Only test the electronics when proportional solenoids are connected. The proportional solenoid may not be fitted with free wheeling diodes. Switching solenoids at outputs of the electronics and other inductive actuators within the system must be fitted with free wheeling diodes. External switching contacts in the solenoid lines are not permitted.

PV

7/8

Brueninghaus Hydromatik

RE 95 023/04.00

Brueninghaus Hydromatik GmbH Elchingen Plant Glockeraustrae 2 D89275 Elchingen Phone +49 (0) 73 08 82-0 Telefax +49 (0) 73 08 72 74 Internet: www.rexroth.com/brueninghaushydromatik / E-Mail: info@bru-hyd.com The specified data is for product description purposes only and may not be deemed to be guaranteed unless expressly confirmed in the contract.

All rights reserved Subject to revision

8/8

PV

You might also like

- Ats46c41n Square D Altistart 46 Telemecanique ManualDocument236 pagesAts46c41n Square D Altistart 46 Telemecanique ManualTheSufferoneNo ratings yet

- Error Code EMR 2Document5 pagesError Code EMR 2Nafrizal SuhendrikNo ratings yet

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- KomatsuDocument2 pagesKomatsumuhammad aliNo ratings yet

- Esm 7-22Document8 pagesEsm 7-22Endre FarkasNo ratings yet

- Proportional Amplifier PVRDocument8 pagesProportional Amplifier PVRgaliardi100% (1)

- What Is RAID Control PDFDocument6 pagesWhat Is RAID Control PDFAhmedNo ratings yet

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Isuzu MNF CodesDocument15 pagesIsuzu MNF Codesjames gichuhiNo ratings yet

- Proportional Indicating Controller: DescriptionDocument5 pagesProportional Indicating Controller: DescriptionFastcross Honda100% (1)

- BODAS-service: RE 95086/2021-04-19 Replaces: 2020-03-02Document10 pagesBODAS-service: RE 95086/2021-04-19 Replaces: 2020-03-02Vinod HegdeNo ratings yet

- Caterpillar Industrial C9 SpecificationsDocument5 pagesCaterpillar Industrial C9 SpecificationsIrfan SaeedNo ratings yet

- Brochure 2200CR enDocument28 pagesBrochure 2200CR enCoras LucianNo ratings yet

- TCD2015 PDFDocument67 pagesTCD2015 PDFRosa ChNo ratings yet

- ReleaseNotes BODAS-service 3.6.2Document3 pagesReleaseNotes BODAS-service 3.6.2OHW SERNo ratings yet

- Kato KR 22HDocument17 pagesKato KR 22Hanwar salimNo ratings yet

- Gulliver RGDF - TS0063UK00 PDFDocument16 pagesGulliver RGDF - TS0063UK00 PDFCarlos Castillo UrrunagaNo ratings yet

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocument109 pagesThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsRolandas PetkusNo ratings yet

- Diode Ir1fDocument6 pagesDiode Ir1fedgarlibanioNo ratings yet

- EMR4 - CAN - BUS - Specification - Ver02 - 34Document73 pagesEMR4 - CAN - BUS - Specification - Ver02 - 34morusNo ratings yet

- FTA2000 Medium Voltage Electric Fire Pump ControllersDocument8 pagesFTA2000 Medium Voltage Electric Fire Pump ControllersOhaneje Uzoma50% (2)

- Features: TAIK Electric Co., LTDDocument3 pagesFeatures: TAIK Electric Co., LTDWaseem WasiNo ratings yet

- GPM 22Document2 pagesGPM 22Khalid SaddikNo ratings yet

- Implement Valve Chassis Wiring: 980K Wheel Loader and Electrical System 980K OEM Wheel LoaderDocument4 pagesImplement Valve Chassis Wiring: 980K Wheel Loader and Electrical System 980K OEM Wheel LoaderJose Cruz RiosNo ratings yet

- HKD-100D PA ManualDocument5 pagesHKD-100D PA ManualLucas BarriosNo ratings yet

- Status Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Document9 pagesStatus Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Jean DiscretNo ratings yet

- Copex Brochure REFLEX FR-GB 2016Document2 pagesCopex Brochure REFLEX FR-GB 2016Nicolas BourbeyNo ratings yet

- EDC-1 Tutorial 6Document1 pageEDC-1 Tutorial 6samarthNo ratings yet

- GCM02 GB App R03Document37 pagesGCM02 GB App R03Karim AssoumaniNo ratings yet

- Hitachi EX550-5, EX600H-5 Workshop ManualDocument20 pagesHitachi EX550-5, EX600H-5 Workshop ManualLidetu DemissieNo ratings yet

- VF500 VF600 VR600Document24 pagesVF500 VF600 VR600Mehdi FarrokhiNo ratings yet

- Xas 400 CD t3 Row Xc2003 Supplement 2015Document23 pagesXas 400 CD t3 Row Xc2003 Supplement 2015Luc DumontNo ratings yet

- KP-C500P (KTA19-G3A) Generating Set Technical Data SheetDocument5 pagesKP-C500P (KTA19-G3A) Generating Set Technical Data SheetMario CastroNo ratings yet

- Páginas Extraídas de Manual - MX2Document8 pagesPáginas Extraídas de Manual - MX2Anonymous 97JlpvN4No ratings yet

- BODAS Controller RC4-5 Series 30: RE 95205/06.2018, Bosch Rexroth AGDocument22 pagesBODAS Controller RC4-5 Series 30: RE 95205/06.2018, Bosch Rexroth AGVinod HegdeNo ratings yet

- Brochure Abg7820b Abg8820b t3 en 21 20000048 CDocument12 pagesBrochure Abg7820b Abg8820b t3 en 21 20000048 CKurniawan100% (1)

- T-Scale Bws PDFDocument24 pagesT-Scale Bws PDFIvan Agreda SalvadorNo ratings yet

- DENAIR Oil-Free Air Compressor PDFDocument8 pagesDENAIR Oil-Free Air Compressor PDFagasmekatron100% (1)

- Concrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBDocument2 pagesConcrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBBourenaneNo ratings yet

- Ficha Tecnica Lishide Escavadora Lishide SC220-8 - 1081Document3 pagesFicha Tecnica Lishide Escavadora Lishide SC220-8 - 1081PABLO HERNAN PRADA MONCADANo ratings yet

- Sauer-Danfoss Mcx103b Position TransducerDocument4 pagesSauer-Danfoss Mcx103b Position TransducerJosé Fidencio Carrillo MorenoNo ratings yet

- Ug-26 Skad-Kad 04Document1 pageUg-26 Skad-Kad 04Nisar AhmedNo ratings yet

- Piovan Chillers CH50 CH900Document8 pagesPiovan Chillers CH50 CH900Karel VajdakNo ratings yet

- TYPE ATS-050: Switching Control UnitDocument8 pagesTYPE ATS-050: Switching Control UnitAhmed El-AdawyNo ratings yet

- EN Imapla TroubleshootingDocument15 pagesEN Imapla TroubleshootingAndrei 26No ratings yet

- Tad722ge PDFDocument2 pagesTad722ge PDFWasif Irfan100% (1)

- 1526 BG15H Doku ENDocument68 pages1526 BG15H Doku ENBoss kevinNo ratings yet

- Proportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGDocument16 pagesProportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGRonald Rayme VenturaNo ratings yet

- Furnace ITV Color Camera: Series FK-CF-3712Document2 pagesFurnace ITV Color Camera: Series FK-CF-3712Italo Rodrigues100% (1)

- Philips (Funai) PL10.4 40PFL5705Document59 pagesPhilips (Funai) PL10.4 40PFL5705Israel B ChavezNo ratings yet

- Tesmec Catalogue TmeDocument208 pagesTesmec Catalogue TmeDidier solanoNo ratings yet

- 3 Waukesha Gas Engine Maintenance ManualDocument75 pages3 Waukesha Gas Engine Maintenance ManualMamunNo ratings yet

- Deep Sea Controller 4410 Drawing PDFDocument3 pagesDeep Sea Controller 4410 Drawing PDFjorge andres yanez quezada100% (2)

- Status Report Fruytier 972K Pem00444 DPF A Plus de 140% Soot - PSRPT - 2021-07-28 - 09.36.43Document13 pagesStatus Report Fruytier 972K Pem00444 DPF A Plus de 140% Soot - PSRPT - 2021-07-28 - 09.36.43Jean DiscretNo ratings yet

- DSE 710-720 Data SheetDocument2 pagesDSE 710-720 Data SheetAnas BasarahNo ratings yet

- 962H Electrical DiagramDocument4 pages962H Electrical DiagramMarielis ContrerasNo ratings yet

- 140k Elec PDFDocument20 pages140k Elec PDFhitler morales gavidiaNo ratings yet

- Especificações TecnicasDocument20 pagesEspecificações TecnicasDanubio Rocha de LimaNo ratings yet

- Proportional Amplifier PV: For The Control of A Proportional SolenoidDocument8 pagesProportional Amplifier PV: For The Control of A Proportional SolenoidIvan BeljinNo ratings yet

- LM2907Document21 pagesLM2907leorio88No ratings yet

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocument13 pagesFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadNo ratings yet

- lm2917 NDocument24 pageslm2917 NAlejandro RojoNo ratings yet

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- Masterglenium Ace: Solutions For The Pre-Cast IndustryDocument7 pagesMasterglenium Ace: Solutions For The Pre-Cast IndustryAlanNo ratings yet

- TPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™Document57 pagesTPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™sbrhomeNo ratings yet

- Water Content in SoilDocument4 pagesWater Content in SoilJohn Paul CristobalNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- A. Title of Experiment B. Date and Time of Experiment: Wednesday, 10Document15 pagesA. Title of Experiment B. Date and Time of Experiment: Wednesday, 10LichaNo ratings yet

- Basic Presentation SkillsDocument20 pagesBasic Presentation Skills11Rula SabithaTB100% (1)

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Comparison of Three Phase PV System in PSCAD and PowerFactoryDocument8 pagesComparison of Three Phase PV System in PSCAD and PowerFactorymlkz_01No ratings yet

- Open-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsDocument24 pagesOpen-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsSHAIK MUSTHAFANo ratings yet

- Process Flow Chart - Manufacturing TS: Rejected, Sent Back To SupplierDocument1 pageProcess Flow Chart - Manufacturing TS: Rejected, Sent Back To Suppliersukumar bhowmickNo ratings yet

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Lecture 7 - Synchronous Generators 7 PDFDocument28 pagesLecture 7 - Synchronous Generators 7 PDFDorwinNeroNo ratings yet

- 1 s2.0 S0264127522004105 MainDocument11 pages1 s2.0 S0264127522004105 MainAsimov RiyazNo ratings yet

- Filipino BasicDocument21 pagesFilipino BasicReiko Nakayama100% (1)

- Uccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversDocument38 pagesUccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversTeles SilvaNo ratings yet

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Understanding Your Electricity Bill in PakistanDocument13 pagesUnderstanding Your Electricity Bill in PakistanGhayas Ud-din DarNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- WATERGUARD 45 (Acrylic Waterproofing Coating)Document3 pagesWATERGUARD 45 (Acrylic Waterproofing Coating)Santosh Kumar PatnaikNo ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- HP Deskjet D1600 Printer SeriesDocument13 pagesHP Deskjet D1600 Printer SeriesRizki JuliadiNo ratings yet

- Hillfoot Data Sheets V5 1Document4 pagesHillfoot Data Sheets V5 1Kristijan IlicNo ratings yet

- 10 Science TP 11 1Document5 pages10 Science TP 11 1Ananaya BansalNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet