Professional Documents

Culture Documents

Athen 534 E Neu

Athen 534 E Neu

Uploaded by

Dewi Rianti MandasariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Athen 534 E Neu

Athen 534 E Neu

Uploaded by

Dewi Rianti MandasariCopyright:

Available Formats

Vossloh Kiepe GmbH

Kiepe Traction Equipment for the Low-floor Trolleybusses

and Articulated Low-floor Trolleybusses for

Athens, Greece

Traction Equipment for the Low-floor Trolleybusses

As the Olympic Games are to take place in Athens in 004, the Athens transport

authority ILPAP decided to purchase new, reliable trolleybuses with Kiepe traction

equipment, which are to provide environment-friendly public transport.

91 low-foor solo trolleybuses and 51 articu-

lated low-foor trolleybuses of the type series

N616 and N61 meet all the requirements

for passenger and operator friendliness.

The new low-foor vehicles are based

on a Neoplan design, and the inte-

rior is from the Greek frm of ELBO.

Besides stronger air conditioning and

heating the new vehicle generation has

got kneeling and a boarding ramp for

passengers restricted in their mobility.

The technical appearance is completed by

a VDV drivers workplace with information

display, fully automatic current collec-

tors and a state-of-the-art, 100 kW strong

diesel generator with an Euro III engine

so that the trolleybus can also be oper-

ated out of the current collector zone.

Electronic data messages on a CANo-

pen basis are to reduce the cabling

and thus to eliminate interference

sources and save weight for the trac-

tion equipment and the subsystems.

Moreover, a comfortable and eff-

cient diagnostic system is available,

which can be operated via PC.

The compact Kiepe drive container has been

ftted on the roof of the trolleybus. This con-

tainer is easily accessible for maintenance

and safely protected in case of traffc acci-

dents. It is made of aluminium and includes

the most important electronic units for the

traction and the on-board power supply. The

modern technology also offers ABS and TCS

as well as automatic hill holding and allows

powerful driving up to a maximum speed of

65 km/h, at which it is limited electronically.

Project characteristics

- Regenerative brake to the

standstill of the vehicle

- Automatic rise and fall of the

current collector possible

- Powerful auxiliary power unit

(APU) with 100 kW electrical

power

- Extensive diagnosis program

on Windows-basis

Arrangement of equipment

System outline

1

Braking resistor

2

Roof equipment container

Direct pulse inverter

Static converter for auxiliary devices

Converter for air conditioning

Line filter, EMC filter

Main contactors and main fuses

3

Current collector

4

A/C for passenger compartment

5

Auxiliary power unit

6

Compressor for compressed air

supply

7

Traction motor

8

Heating of drivers cab

5

7 8 6

1 3 4 2

5

k|epe CAhepen car-bus

Aux|||ary pewer un|t 8SM 334

Ma|n centacters, heat|ng,

fan, aux|||ary pewer un|t

Current ce||ecter

8hu 440

Stat|c cenverter

fer aux|||ary dev|ces

ZLC 316 SCu 200

Master centre||er 1ract|en e|ectren|c uSM 300 W8u 101

J1939

C

A

h

8SM 401

C

A

h

C

A

h

C

A

h

C

A

h

CAh CAh

Speed senser, temperature M0M 100 CAh

CAh-LWL LWL

k

S

2

3

2

J

1

9

3

9

veh|c|e-CAh J1939

J

1

9

3

9

J

1

9

3

9

A8S/ASk

v0 Zk-2

r|ver's werkp|ace

kCu 101

Cenverter

fer a|r cend|t|en|ng

k

|

e

p

e

C

A

h

t

r

a

c

t

|

e

n

-

b

u

s

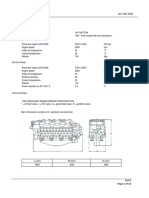

Technical data

Design -axle low-floor trolleybus

Manufacturer of the chassis and vehicle body Neoplan

Manufacturer of the interior ELBO

Manufacturer of the traction electronic Vossloh Kiepe

Maximum speed 65 km/h

Line voltage DC 600 V (+ 5 %, - 0 %)

Vehicle length 1.0 m

Vehicle width .5 m

Gear ratio 11.0 : 1

Tyres 75 /70 R-.5

Tare mass of the vehicle / 33 full approx. 1.7 t / approx. 19.5 t

Vehicle capacity 7 + 1 seating, 56 standing

Traction inverter IGBT direct pulse inverter

Input voltage DC 600 V (+ 0 %, - 0 %)

Output permanent /max. 160 kW / 70 kW for t 60 s

Cooling Forced air cooling

Mass (Weight) approx. 90 kg

Characteristics - Action of the regenerative brake to the standstill of the vehicle

- Contactless power/brake/direction changeover

Control system Control and adjustment of traction by microprocessor technology.

Signal transmission between car-bus and traction-bus via optical waveguide

CANopen protocol

Wheel slip/slide protection, gradient slope slide protection, line current limitation, regenerative brake

Diagnosis program on Windows-basis: failure analysis, event / fault storage

Traction motor Force-ventilated three-phase asynchronous motor

Rated output 10 kW

Number of poles 4

Dimensions 98 x 510 x 40 mm (length x width x height)

Mass (weight) 585 kg

Current collector Kiepe OSA 07

Characteristics With pneumatic quick-lowering, triggered by the maximum height (static)

and monitoring of the rope drum (dynamic). Automatic rise and fall possible.

On-board power supply Static on-board converter Kiepe BNU 440

Outputs /N AC 400/0 V, 50 Hz, 14 kVA

DC 4 V, 50 A, battery charge 5 A up to 100 A adjustable

Mass (Weight) approx. 75 kg

Converter for air conditioning Kiepe KGU 101

Output 5 kVA, AC, 400 V,

Auxiliary power unit (APU) Water-cooled 4-cylinder turbo-diesel engine

Type BF 4M 101 FC / EURO III, with permanent excited brushless three-phase synchronous motor

Output diesel engine 15 kW at 400 rpm

Output of generator 100 kW at 00 rpm

Automatic speed control according to power requirement of consumers (infinitely variable)

Heating operator's stand Electric heating for the operators stand Kiepe HKL 10

Output 8 kW, AC, 400 V, 50 Hz, infinitely variable

Heating passenger compartment El. heating for the passenger compartment, x Kiepe HKL 41 plus heating capacity of the roof air condition

Output each kW, AC, 400 V, 50 Hz

Compressed air supply Screw compressor ES-6-5.5HH Sullair

Output 4.1 kW, 10 Bar, 490 l/min

Subject to change without notice

4

5

Arrangement of equipment

System outline

1

Braking resistor

2

Roof equipment container

Direct pulse inverter

Static converter for auxiliary devices

Converter for air conditioning

Line filter, EMC filter

3

Roof equipment container,

rear bank

Main contactors and main fuses

4

Current collector

5

A/C for passenger compartment

6

Auxiliary power unit

7

Compressor for compressed air

supply

8

Traction motor

9

Heating of drivers cab

5 4 2 5 1 3

6

7 8 9

k|epe CAhepen car-bus

Aux|||ary pewer un|t 8SM 333

Ma|n centacters, heat|ng,

fan, aux|||ary pewer un|t

Current ce||ecter

ZLC 316

k

|

e

p

e

C

A

h

t

r

a

c

t

|

e

n

-

b

u

s

SCu 200 1ract|en e|ectren|c uSM 300 W8u 101

J1939

C

A

h

8SM 401

C

A

h

C

A

h

CAh CAh

Speed senser, temperature

CAh

CAh-LWL LWL

k

S

2

3

2

J

1

9

3

9

veh|c|e-CAh J1939

J

1

9

3

9

J

1

9

3

9

A8S/ASk

v0 Zk-2

r|vers werkp|ace

M0M 100

Current ce||ecter

8SM 332

C

A

h

C

A

h

Stat|c cenverter

aux|||ary dev|ces

8hu 440

C

A

h

Cenverter

a|r cend|t|en|ng

kCu 101-2

C

A

h

Cenverter

a|r cend|t|en|ng

kCu 101-1

Master centre||er

Vossloh Kiepe GmbH

Kiepe-Platz 1 D-40599 Dsseldorf

Telefon: +49(0)11/7497-0

Telefax: +49(0)11/7497-00

www.vossloh-kiepe.com

info

@

vkd.vossloh.com

5

4

/

1

0

9

/

0

6

Technical data

Design -axle low-floor trolleybus N 61

Manufacturer of the chassis and vehicle body Neoplan

Manufacturer of the interior ELBO

Manufacturer of the traction electronic Vossloh Kiepe

Maximum speed 65 km/h

Line voltage DC 600 V (+ 5 %, - 0 %)

Vehicle length 18.0 m

Vehicle width .5 m

Gear ratio 11.47 : 1

Tyres 75/70 R-.5

Tare mass of the vehicle / 33 full approx. 19.4 t / approx. 8.5 t

Vehicle capacity 40 + 1 seating, 94 standing

Traction inverter IGBT direct pulse inverter Kiepe DPU 551

Input voltage DC 600 V (+ 0 %, - 0 %)

Output permanent /max. 50 kW / 600 kW for t 0 s

Cooling Forced air cooling

Mass (Weight) approx. 100 kg

Characteristics - Action of the regenerative brake to the standstill of the vehicle

- Contactless power/brake/direction changeover

Control system Control and adjustment of traction by microprocessor technology.

Signal transmission between car-bus and traction-bus via optical waveguide

CANopen protocol

Wheel slip/slide protection, Gradient slope slide protection, Line current limitation, Regenerative brake

Diagnosis program on Windows-basis: failure analysis, event / fault storage

Traction motor Force-ventilated three-phase asynchronous motor

Type 14 ML 550 K /4 (with gear 1,85 : 1)

Rated output 40 kW

Number of poles 4

Dimensions 1167 x 54 x 40 mm (length x width x height)

Mass (weight) 70 kg

Current collector Kiepe OSA 07

Characteristics With pneumatic quick-lowering, triggered by the maximum height (static)

and monitoring of the rope drum (dynamic). Automatic rise and fall possible.

On-board power supply Static on-board converter Kiepe BNU 440

Outputs /N AC 400/0 V, 50 Hz, 14 kVA

DC 4 V, 50 A, battery charge 5 A up to 100 A, adjustable

Mass (Weight) approx. 75 kg

Converter for air conditioning x Kiepe KGU 101

Output 5 kVA, AC, 400 V

Auxiliary power unit (APU) Water-cooled 4-cylinder turbo-diesel engine

Type BF 4M 101 FC / EURO III, with permanent excited brushless three-phase synchronous motor

Output diesel engine 15 kW at 400 rpm

Output of generator 100 kW at 00 rpm

Automatic speed control according to power requirement of consumers (infinitely variable)

Heating operator's stand Electric heating for the operators stand Kiepe HKL 10

Output 8 kW, AC, 400 V, 50 Hz, infinitely variable

Heating passenger compartment El.heating for the passenger compartment, 4 x Kiepe HKL 41 plus heating capacity of the roof air condition

Output each kW, AC, 400 V, 50 Hz

Compressed air supply Screw compressor ES-6-5.5HH Sullair

Output 4.1 kW, 10 Bar, 490 l/min

Subject to change without notice

You might also like

- Ford Transit VM 2006-2013 Workshop ManualDocument2,347 pagesFord Transit VM 2006-2013 Workshop ManualVygintas Balcius89% (44)

- F-16C Flight Crew ChecklistDocument111 pagesF-16C Flight Crew ChecklistBranislav LackovicNo ratings yet

- Coelmo 60 kVA PDT114TG3 PDFDocument2 pagesCoelmo 60 kVA PDT114TG3 PDFEmily BullockNo ratings yet

- Amp MBW 800amp@2006 SmallDocument4 pagesAmp MBW 800amp@2006 Smalljanuar92021068100% (1)

- JAGUAR 2010XFRWorkshop PDFDocument3,039 pagesJAGUAR 2010XFRWorkshop PDFworkshop car manuals100% (2)

- Manual Oficina PDFDocument20 pagesManual Oficina PDFFelipe Douglas da Silva100% (1)

- Galeo Wa430-6 PDFDocument1,612 pagesGaleo Wa430-6 PDFWalter100% (1)

- Fundamentals of Control r1 0Document33 pagesFundamentals of Control r1 0Felipe Dias40% (5)

- Drilling Machine ReportDocument38 pagesDrilling Machine ReportPraveen Mathias80% (15)

- 988H Hydraulic System PDFDocument2 pages988H Hydraulic System PDFtom souza100% (1)

- Manual Caterpillar 992g Wheel Loader Steering Brakes Components Layout Operation Testing Adjusting PDFDocument28 pagesManual Caterpillar 992g Wheel Loader Steering Brakes Components Layout Operation Testing Adjusting PDFBruno Cecatto60% (5)

- Uromac T-Rail MV - BrochureDocument2 pagesUromac T-Rail MV - BrochureCristiano RonaldoNo ratings yet

- Low Floor Tram 08Document8 pagesLow Floor Tram 08skidamdnevnoNo ratings yet

- 3412C 900 kVA Standby LowBsfc EU 50HzDocument6 pages3412C 900 kVA Standby LowBsfc EU 50HzddzoningcomNo ratings yet

- Coelmo 20 KVA PDT44DaDocument2 pagesCoelmo 20 KVA PDT44DaEmily BullockNo ratings yet

- Cursor 013 Te1 315kwm eDocument6 pagesCursor 013 Te1 315kwm ellovar100% (1)

- ENERCON Productoverview enDocument8 pagesENERCON Productoverview enAnaApcarianNo ratings yet

- EJC 110 112 Data SheetDocument4 pagesEJC 110 112 Data SheetM.casaNo ratings yet

- CukurovapowerDocument6 pagesCukurovapowerAhmed GadNo ratings yet

- Rental: XQ2000 Sound Attenuated Power ModuleDocument8 pagesRental: XQ2000 Sound Attenuated Power ModuleAngel Javier NuñezNo ratings yet

- 3412C 725 kVA Prime LowBsfc EU 50HzDocument6 pages3412C 725 kVA Prime LowBsfc EU 50Hzrbmr1No ratings yet

- TBD 616Document6 pagesTBD 616sdiamanNo ratings yet

- APD100A-6: 100 kVA / 80 KWDocument4 pagesAPD100A-6: 100 kVA / 80 KWRonald H SantosNo ratings yet

- Tandard Drives: Saving Energy With Innovative Electric DrivesDocument20 pagesTandard Drives: Saving Energy With Innovative Electric DrivesSangeet BhandariNo ratings yet

- TechnicalData EMD-350 Inso PDFDocument2 pagesTechnicalData EMD-350 Inso PDFajrojas1359No ratings yet

- Unimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfDocument2 pagesUnimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfIvana Ilic67% (3)

- 1015Document5 pages1015sdiamanNo ratings yet

- Volvo D16Document2 pagesVolvo D16yojan2015063% (8)

- EC210B Forestry Spec SheetDocument2 pagesEC210B Forestry Spec Sheetdalibor_bogdanNo ratings yet

- ACS Analogue Control Systems eDocument12 pagesACS Analogue Control Systems eKhaled KamelNo ratings yet

- Uromac T-Rail SV - Brochure PDFDocument2 pagesUromac T-Rail SV - Brochure PDFCristiano RonaldoNo ratings yet

- Datenblatt ELP Eurodual EN V2-1Document2 pagesDatenblatt ELP Eurodual EN V2-1Kaki0No ratings yet

- Deutz 616Document6 pagesDeutz 616sdiamanNo ratings yet

- AC250 Data SheetDocument5 pagesAC250 Data SheetAshutosh SinghNo ratings yet

- Coelmo 45 kVA PDT113T1-ne PDFDocument2 pagesCoelmo 45 kVA PDT113T1-ne PDFEmily BullockNo ratings yet

- enDocument2 pagesenSören Christopher LaxNo ratings yet

- Ac Loco ManualDocument103 pagesAc Loco ManualDeepak Gehlot100% (1)

- English 3-Phase Loco BookDocument103 pagesEnglish 3-Phase Loco BookSankati Srinivas100% (5)

- APD50PDocument4 pagesAPD50PMarino MatevskiNo ratings yet

- Coelmo 250 Kva Fdtc87-25Document2 pagesCoelmo 250 Kva Fdtc87-25Emily Bullock100% (1)

- Eh1700 3Document8 pagesEh1700 3Robert KnightNo ratings yet

- MTUDocument16 pagesMTUWira Karya Diesel50% (6)

- C175 16 2725KVA CAT Rebuild WYB00115Document6 pagesC175 16 2725KVA CAT Rebuild WYB00115ardhanteknik53No ratings yet

- Ex3600 6Document16 pagesEx3600 6MasterAmorNo ratings yet

- 7 55T GT550e TadanoDocument12 pages7 55T GT550e Tadanoa1435No ratings yet

- XQ1000 Lehx0532Document6 pagesXQ1000 Lehx0532Anonymous uZJfsg819LNo ratings yet

- 1015Document4 pages1015Martin KratkyNo ratings yet

- TAD1642GE: Volvo Penta Genset EngineDocument2 pagesTAD1642GE: Volvo Penta Genset EngineroozbehxoxNo ratings yet

- Unimog Techdata U300 Euro5 1209 en PDFDocument2 pagesUnimog Techdata U300 Euro5 1209 en PDFRahmi Elsa DianaNo ratings yet

- Uromac T-Rail RV - BrochureDocument2 pagesUromac T-Rail RV - BrochureCristiano RonaldoNo ratings yet

- 1000 Kva 400v c32 Low BSFC PrimeDocument6 pages1000 Kva 400v c32 Low BSFC PrimeelipholebNo ratings yet

- Olympus HP SpecificationDocument8 pagesOlympus HP SpecificationaminvelayatNo ratings yet

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 pagesSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- 3516B LocoDocument4 pages3516B LocomarcosNo ratings yet

- DFHD - Model Specification SheetDocument4 pagesDFHD - Model Specification SheetAlejandro Lagares100% (1)

- Komatsu Excavadora PC850 - 850se-8 - PDFDocument8 pagesKomatsu Excavadora PC850 - 850se-8 - PDFCrecencio Sanches100% (1)

- Atlas Copco Explorac 220RC - Reverse Circulation Drilling RigsDocument4 pagesAtlas Copco Explorac 220RC - Reverse Circulation Drilling Rigsவிமல் அந்தோணி100% (1)

- 1607-gtg 2046ev Cat3616 HfoDocument7 pages1607-gtg 2046ev Cat3616 HfobastechNo ratings yet

- Uromac T-Rail 18 SV - BrochureDocument2 pagesUromac T-Rail 18 SV - BrochureCristiano RonaldoNo ratings yet

- 3406 400kva STANDBY PDFDocument6 pages3406 400kva STANDBY PDFPablo Gaspar D'Agostini AmengualNo ratings yet

- Daily 65c18 VanDocument4 pagesDaily 65c18 VanAlexeIonutNo ratings yet

- APD50ADocument4 pagesAPD50AMarino MatevskiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Electric Tech Form 2023Document4 pagesElectric Tech Form 2023nathaniel benelishaNo ratings yet

- 988 GDocument64 pages988 Gtransteven93100% (1)

- 2nd Formula Green - 2017 PDFDocument49 pages2nd Formula Green - 2017 PDFApurva ChakrabortyNo ratings yet

- Track Data: Broad Gauge Metro Car (25 KV Ac)Document2 pagesTrack Data: Broad Gauge Metro Car (25 KV Ac)vipin kumarNo ratings yet

- Motion Control D31 1 Complete English 2021 10 - Update - 2022 10Document388 pagesMotion Control D31 1 Complete English 2021 10 - Update - 2022 10Teddy NickolayevskyNo ratings yet

- Trouble Shooting Brake Drum Wear by MeritorDocument10 pagesTrouble Shooting Brake Drum Wear by MeritorEdo RonaldoNo ratings yet

- Baja Brake DesignDocument3 pagesBaja Brake DesignpravinkumarkrNo ratings yet

- Cessna 172 ChecklistDocument7 pagesCessna 172 Checklistpeter9869No ratings yet

- Lecture No. 10 - Case StudyDocument17 pagesLecture No. 10 - Case Studyضياء بن احمد الكباريNo ratings yet

- CC995ADocument67 pagesCC995AMauricio HdezNo ratings yet

- A316 CF6-80C2 GRD OpsDocument54 pagesA316 CF6-80C2 GRD OpsLuiz FerrazNo ratings yet

- F1 Reglements Techniques 2003 ADocument17 pagesF1 Reglements Techniques 2003 ABlaze123xNo ratings yet

- Wagon Airbrake System, Indian Railways.Document75 pagesWagon Airbrake System, Indian Railways.Srinivas Avutapalli82% (11)

- Electromagnetic Braking SystemDocument15 pagesElectromagnetic Braking SystemVivace SystmNo ratings yet

- Clutch SystemDocument18 pagesClutch SystemalecslopezNo ratings yet

- ABS (Anti-Lock Brake System)Document34 pagesABS (Anti-Lock Brake System)LiviaChirtopNo ratings yet

- 007 Operation&Safety CabinDocument33 pages007 Operation&Safety CabinJose Carmona100% (1)

- Spare Parts List: From Series 09/2013Document101 pagesSpare Parts List: From Series 09/2013ИсмаилNo ratings yet

- Check List Technam p2008jfDocument2 pagesCheck List Technam p2008jfGourav DasNo ratings yet

- TOMCAR 2013 BrochureDocument16 pagesTOMCAR 2013 BrochureTony LimNo ratings yet

- GES Drive Manual: Installation Operation & MaintenanceDocument11 pagesGES Drive Manual: Installation Operation & MaintenanceKovács EndreNo ratings yet