Professional Documents

Culture Documents

Seat Track Fittings

Seat Track Fittings

Uploaded by

AmolPagdalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seat Track Fittings

Seat Track Fittings

Uploaded by

AmolPagdalCopyright:

Available Formats

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.

,

=n&e&~11c~ =n&e&~11c~ =n&e&~11c~ =n&e&~11c~

c~ c~ c~ c~

e&1 1nc r11~ce e&1 1nc r11~ce e&1 1nc r11~ce e&1 1nc r11~ce

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

=LL&1 eeve =LL&1 eeve =LL&1 eeve =LL&1 eeve

EOS

QANTAS

KINGFISHER

EMIRATES

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

ASSY, SCREEN TRACK

ELECTRICAL, COVER PLATE

PADS

ASSY, SUITE PALLET

FITTING FLANGES

&Mn1&e =LL&1 eev

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Aft (+X)

RHS (+Y)

Up (+Z)

1 2 3

4

5

6

7

8 9

11

12

13

17

Suite 1F Pallet

Suite 2F Pallet

Aft Bulkhead

10

SEAT TRACKS AND LOCATIONS FOR FITTINGS

EMIRATES

SEAT TRACk LOCATIONS FOR FLANSE FITTINS

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

e&1 1nc r11~c eev e&1 1nc r11~c eev e&1 1nc r11~c eev e&1 1nc r11~c eev

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

ec=+ +n=c r11~c eev ec=+ +n=c r11~c eev ec=+ +n=c r11~c eev ec=+ +n=c r11~c eev

SELF LOCKING NUT

WASHER

BUSHING ECCENTRIC

SMALL

BUSHING ECCENTRIC

LARGE

FITTING FLANE

WASHER LARGE OD

SHEAR RETAINER

STUD

3PAG0001001

3PAG0003001

3PAG0002001

61311-22-14

61315-03

NAS970-6

NAS1149F0632P

MS21042

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Seat track

and

Seat track Fitting Assy

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

5EAT TRACK FITTING5 IN DIFFERENT PROGRAM5

EOS

QANTAS

KINGFISHER

EMIRATES

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

CONCEPT OF 5EAT TRACK FITTING5 ADJE5TMENT5 IN DIFFERENT PROGRAM5

X DIRECTION

X and Y DIRECTIONS

X ,Y and Z - DIRECTIONS

EOS

QANTAS and EMIRATES

KINGFISHER

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Introduction of Z adjustment to seat track fittings

in

Emirates

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

&min=+ce eLi+ce &min=+ce eLi+ce &min=+ce eLi+ce &min=+ce eLi+ce

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

&min=+ce eLi+c &min=+ce eLi+c &min=+ce eLi+c &min=+ce eLi+c

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Air craft floor

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

No adjustment of the sliding screens was designed in, providing adjustment

only provides the opportunity to get it wrong.

The philosophy was that the pallet at 1.04 thick aluminum skinned honeycomb

panel and the track extrusion would maintain straightness.

Keeping the screen gap parallel

The large gusset and the vanity shelf would keep the aft and forward stationary

panel perpendicular to the wardrobes maintaining alignment

Keeping the screens aligned

Neither Boeing nor Airbus have requirements for Z adjustment

Introduction of Z adjustment will allow some adjustment of the screen alignment

Vanity Table not square

It has been recognized that the Vanity Table end is not truly square.

The engineering tolerance and manufacturing methods (composite part) do

mean that a angle tolerance of +/- .5 degree have been noted.

This generally results in a wardrobe to fwd stationary panel angle greater

than 90 degrees.

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Results Terminology

There are effectively 3 results that have been identified with

regard to the Sliding Screen alignment and gap.

1. Screen Alignment where the top area of the Sliding

Screens are offset to each other, where this has been

considered a problem it is generally the forward screen

that is more outward of the suite than the aft sliding

screen, in line with the vanity edge being greater than 90

degrees.

2. Screen Gap Not Parallel Where the Sliding Screens

may be touching at either the bottom or the top and there

is a gap at the other end, where this has been

considered a problem it is generally the bottom that is

touching and the top has a gap, up to .20 inches.

3. Screen Non Consistent Gap Where a non consistent

gap over length of the sliding sliding where maybe the

Sliding Screens touch top and bottom but not in the

middle. This is not a problem that is addressed here as it

relates to the Sliding Screen detail assemblies and not

the installation alignment.

1. Screen Alignment

problems would

show here

2. Screen Gap

Not Parallel

problems would

show here

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

To address the Installation Alignment and Parallel

Gap issues B/E has considered a Z adjustment Seat

Track Fitting

Simple Z adjustment washers where considered

but to assist with Installation adjustment from above

the suite pallets was considered necessary

A Z adjustment fitting was therefore developed, An

early prototype was reviewed and further

adjustments made.

Note all fittings within the B777 and A380 mini suites

can not be reached to access adjustment.

Introduction of

threaded collar to

provide Z

adjustment

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Sliding Screen Adjustment Status

The Theory

Related to Fwd Sliding Screen

Rotating fitting A + E clockwise will provide

X+ve

Rotating fitting A clockwise will provide V+ve

Rotating fitting E clockwise will provide V-ve

The same can be said for the Aft Sliding Screen however

as the B777 generally does not have fitting D & H, it is

hoped that through trials only forward fitting adjustment

will be required and the aft sliding screen with the large

machined gusset can act as the target.

Expectations

Non Linear movements of the Sliding Screens will result

from adjustment of the new fittings due to other parts of

the suite creating complex adjustment characteristics.

Concerns

Negative knock on effects could result including

Misalignment of Wardrobe door

Sliding Screen mechanism become less smooth

Reduced clearance with seat

E F G H

A B C D

Plan View on Typical Pallet

FWD

Not applicable

to B777 Aircraft

Not applicable

to B777 Aircraft

Side View on Sliding Screen

V+ve W+ve

X+ve Y+ve

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Aft Screen

Aft Stationary

Panel

supported at

90 degrees by

large

machined

gusset located

behind close

out

B777 Static Test Unit module parts have

been collated and reassembled for

adjustment review

2A suite utilized as shown

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

FWD

Looking at aisle side of Suite

This

Position

fully

locked

down

Looking at outboard side of Suite

This Position

fully locked

down

FWD

Note Marks

made at

effective Zero

position

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

In setting up to begin experiment

measurement positions considered

3 positioned of measurement taken

Top Providing data on

inboard/outboard adjustment of the

forward sliding screen

Middle towards the top of the

sliding screen, providing data on gap

between sliding screens at top

Bottom towards the bottom of the

sliding screens, providing data on the

gap between sliding screens at the

bottom

Using Middle and Bottom results

parallelism of screens can be considered,

key in keeping screens aligned

Sliding Screen Adjustment Status

Top

Middle

Bottom

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

In process views taken

Maintaining aft screen as target and via Z

adjustment fwd screen movement shown towards

aisle and towards suite

Max towards aisle from zero = 0.279

Max towards suite from zero = 0.437

Each movement viewed to ensure

no binding

- When testing initiated on position B screens

caught up on each other after 1.5 turns of B

Movement of

forward screen

towards suite

binding up on aft

screen edge cap

Test restarted

FWD

FWD

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Results Legend and Results

Suite raised at position A only

Good movement on screen alignment

Towards Aisle

Little movement on screen parallelism

D C B

A E

2A Tested Suite

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

Conclusions

The use of adjustable Z fittings will allow adjustment of both screen alignment

and parallelism

The results show consistency and are thought to be predictable across

individual suites

Although multiple suites may skew results and installation adjustment

directions will need to consider multiple in line suites

The results have produced a wide enough adjustment range to conclude that

further methods of adjustment should not be considered

Next steps

Introduction of Z adjustment fittings will require Static testing and substantiation

to allow fitment to already certified product types (B777 and A380)

Earliest opportunity via static testing for Boeing MC on B777 program

Introduce Z adjustment fittings into A345 program, commercial implications to be

considered

Sliding Screen Adjustment Status

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

CONCEPT OF FITTING5 IN EMIRATE5 PROGRAM5

X and Y DIRECTIONS

X ,Y and Z DIRECTIONS QANTAS KINGFISHER

FROM THIS TWO DESISNS THE NEW DESISN SENERATED FOR

EMIRATES

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

FITTING5 IN EMIRATE5

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

e11c 1&e1 nn~cM&~1 e11c 1&e1 nn~cM&~1 e11c 1&e1 nn~cM&~1 e11c 1&e1 nn~cM&~1

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

e11c 1&e1 nn~cM&~1 e11c 1&e1 nn~cM&~1 e11c 1&e1 nn~cM&~1 e11c 1&e1 nn~cM&~1

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

TOOL USED FOR ROTATE

THE INNER BUSHING.

TO LIFT IN Z-DIRECTION

e11c 1&e1 e11c 1&e1 e11c 1&e1 e11c 1&e1

e-mug Technologies Pvt. Ltd, Aerospace Division - DEDC for B/E Aerospace Inc.,

You might also like

- Apu 131-9BDocument1 pageApu 131-9BArjun BhatnagarNo ratings yet

- The God Code by Gregg BradenDocument1 pageThe God Code by Gregg BradenAmolPagdal50% (8)

- Youcaitec Price List 20221019Document1 pageYoucaitec Price List 20221019Phillip FriedmanNo ratings yet

- (Aviation) Aircraft Quickie Construction PlansDocument120 pages(Aviation) Aircraft Quickie Construction PlansJcastrosilva89% (19)

- AquacycleUserGuide PDFDocument82 pagesAquacycleUserGuide PDFMariana_AlbertoNo ratings yet

- IndustryPrint Process Modeler User GuideDocument168 pagesIndustryPrint Process Modeler User GuideCatán PatánNo ratings yet

- An Integrated Outsourcing Framework: Analyzing Boeing 'S Outsourcing Program For Dreamliner (B787)Document16 pagesAn Integrated Outsourcing Framework: Analyzing Boeing 'S Outsourcing Program For Dreamliner (B787)FalahNo ratings yet

- B1level Only-6d - Aircraft Materials - Wood and Fabric - SRDocument54 pagesB1level Only-6d - Aircraft Materials - Wood and Fabric - SRAnnd100% (1)

- Study of Seat AssemblyDocument53 pagesStudy of Seat AssemblyAmolPagdalNo ratings yet

- Aircraft Seat MaterialDocument23 pagesAircraft Seat MaterialSanjay Matthews100% (2)

- ATA 2200 SpecificationDocument17 pagesATA 2200 SpecificationhjhjhhNo ratings yet

- Interface control document The Ultimate Step-By-Step GuideFrom EverandInterface control document The Ultimate Step-By-Step GuideNo ratings yet

- Creating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFDocument7,750 pagesCreating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFAmolPagdal10% (10)

- BASF Snap Fit Design GuideDocument24 pagesBASF Snap Fit Design GuidewantamanualNo ratings yet

- Study of Seat AssemblyDocument53 pagesStudy of Seat AssemblyAmolPagdalNo ratings yet

- Sintering. Mechanisims of Convention Nanodensification and Fiels Assisted Processes. Castro BenthemDocument245 pagesSintering. Mechanisims of Convention Nanodensification and Fiels Assisted Processes. Castro Benthemceliamr42100% (1)

- Arts Council EnglandDocument6 pagesArts Council EnglandShankeyNo ratings yet

- CKD MBD - Dr. AidaDocument41 pagesCKD MBD - Dr. AidaFITRINo ratings yet

- Aircraft Seat RegulationDocument2 pagesAircraft Seat RegulationaerendiliNo ratings yet

- CFM 56 Compressor Surge PresentationDocument14 pagesCFM 56 Compressor Surge PresentationKamal Mh100% (1)

- August 16, 2021 Hardware Specifications Highlighted Updated Specification Rev. TitleDocument8 pagesAugust 16, 2021 Hardware Specifications Highlighted Updated Specification Rev. TitleTony C.No ratings yet

- Aircraft ApprovalDocument8 pagesAircraft ApprovalrajrajeswariNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument199 pages@airbus: Component Maintenance Manual With Illustrated Part ListVero GAtelesisNo ratings yet

- Risk of Injury in Side Facing Aircraft Seats 200713 CAMI SFSDocument32 pagesRisk of Injury in Side Facing Aircraft Seats 200713 CAMI SFStjgNo ratings yet

- PTB Magazine BookletDocument24 pagesPTB Magazine BooklettcalithNo ratings yet

- Kickstart Guide To Traceability and CertDocument17 pagesKickstart Guide To Traceability and CertJessie O.BechaydaNo ratings yet

- Concurrent Engineering Development and Practices For Aircraft Design at AirbusDocument9 pagesConcurrent Engineering Development and Practices For Aircraft Design at Airbusanon_658728459No ratings yet

- APU and EngineDocument15 pagesAPU and Enginemikenquez80867% (3)

- FACC TakeOff Ausgabe1-12 en 1009 FDocument11 pagesFACC TakeOff Ausgabe1-12 en 1009 Fbooks1111No ratings yet

- 016Document9 pages016zoomviewerNo ratings yet

- Catalog GROMMETDocument235 pagesCatalog GROMMETAlief PambudhiNo ratings yet

- The 21st Century Jet: The Boeing 777 Multimedia Case StudyDocument26 pagesThe 21st Century Jet: The Boeing 777 Multimedia Case StudyRahul Jayanti JoshiNo ratings yet

- 10.7 Applicable National and International RequirementsDocument76 pages10.7 Applicable National and International Requirementsmohan reddyNo ratings yet

- A320IPC使用讲解Document41 pagesA320IPC使用讲解a1304795230No ratings yet

- EASA V2500 Type CertificateDocument13 pagesEASA V2500 Type CertificateGioVanni LorizioNo ratings yet

- CF34 10eDocument9 pagesCF34 10eJulia GarciaNo ratings yet

- Certificado Tipo B-737 PDFDocument99 pagesCertificado Tipo B-737 PDFCardenitasForfyTathyNo ratings yet

- 10.5 Certification of Aircraft, Parts and AppliancesDocument56 pages10.5 Certification of Aircraft, Parts and Appliancesmohan reddyNo ratings yet

- AC 21-99 Aircraft Wiring and BondingDocument10 pagesAC 21-99 Aircraft Wiring and BondingmritsoudisNo ratings yet

- CADCDocument60 pagesCADCCamelia MunteanuNo ratings yet

- Dornier 328Jet-Landing GearDocument27 pagesDornier 328Jet-Landing GearАндрей СокурNo ratings yet

- Airworthiness Documentation Tracking DescriptionDocument9 pagesAirworthiness Documentation Tracking DescriptionrmdecaNo ratings yet

- The Flight Shop Catalog Rev 7Document77 pagesThe Flight Shop Catalog Rev 7Tan Chinwei100% (1)

- Aircraft MaintenanceDocument33 pagesAircraft MaintenanceFahad NaeemNo ratings yet

- SSADDocument192 pagesSSADathul_udayNo ratings yet

- Certification Docs Certification Memorandum EASA CM SWCEH 002 Issue 01 Rev 01 Software Aspects of CertificationDocument111 pagesCertification Docs Certification Memorandum EASA CM SWCEH 002 Issue 01 Rev 01 Software Aspects of CertificationsarikapravinNo ratings yet

- Anm 03 115 31 PDFDocument7 pagesAnm 03 115 31 PDFHeechang LeeNo ratings yet

- SAE ARP 5429-2001 (R2006) Landing Gear Fatigue Tests With Equivalent Damage SpectraDocument15 pagesSAE ARP 5429-2001 (R2006) Landing Gear Fatigue Tests With Equivalent Damage Spectraabo029100% (1)

- Va One Installation and Licensing GuideDocument68 pagesVa One Installation and Licensing GuideHonorato Maria B. AnaNo ratings yet

- Tcds Easa r009 Ahd Ec135 Issue 13Document102 pagesTcds Easa r009 Ahd Ec135 Issue 13forumid2697No ratings yet

- 93M VVC 10570 Aircraft Inspection ReportDocument140 pages93M VVC 10570 Aircraft Inspection ReportMaria Fernanda Peñates VargasNo ratings yet

- Arp 5632Document11 pagesArp 5632batmanbittuNo ratings yet

- Human Factors Case Study Aircraft Seats: Michelle Hirlam April 2002Document19 pagesHuman Factors Case Study Aircraft Seats: Michelle Hirlam April 2002pvssrhNo ratings yet

- Aerospace Seat TracksDocument7 pagesAerospace Seat TracksSergey FedorinovNo ratings yet

- ATA OverviewDocument17 pagesATA OverviewRavindra BhatnagarNo ratings yet

- Landing Gear: AIRBUS A350-900Document1 pageLanding Gear: AIRBUS A350-900kiran2381No ratings yet

- Aircraft Electric Power Characteristics 飞机电源特性 MIL-std-704fDocument40 pagesAircraft Electric Power Characteristics 飞机电源特性 MIL-std-704fqingtaoNo ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Ms20002an970 (MS63040)Document1 pageMs20002an970 (MS63040)robinyNo ratings yet

- Gif2008 Workshop Composites HellardDocument26 pagesGif2008 Workshop Composites HellardAlejandroPoloLlanaNo ratings yet

- Master Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationDocument203 pagesMaster Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationHetskuniNo ratings yet

- Boeing Phantom Works ObogsDocument13 pagesBoeing Phantom Works ObogsYJanitorNo ratings yet

- brDoc, BREX, and Co.: S1000D Business Rules Made EasierFrom EverandbrDoc, BREX, and Co.: S1000D Business Rules Made EasierNo ratings yet

- 0085-Design For AssemblyDocument41 pages0085-Design For AssemblyAmolPagdalNo ratings yet

- MAB Vessel ViewDocument12 pagesMAB Vessel Viewengmohsen.ramadanhotmail.comNo ratings yet

- Automotive Sample ApplicationDocument9 pagesAutomotive Sample ApplicationSimion FloryNo ratings yet

- Atcx CFD Altair LaDocument24 pagesAtcx CFD Altair LaSantiago MolinaNo ratings yet

- BIW Design PDFDocument17 pagesBIW Design PDFAmolPagdalNo ratings yet

- Catia SymbolsDocument9 pagesCatia SymbolsAmolPagdalNo ratings yet

- Automotive Interior Solutions Optimised Performance and Surface AestheticsDocument16 pagesAutomotive Interior Solutions Optimised Performance and Surface AestheticsAmolPagdal100% (1)

- Volvo ApqpDocument30 pagesVolvo ApqpAmolPagdalNo ratings yet

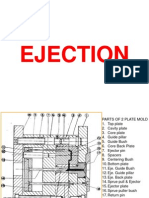

- K EjectionDocument21 pagesK EjectionAmolPagdalNo ratings yet

- Eaton ApqpDocument142 pagesEaton ApqpAmolPagdalNo ratings yet

- Green Planet Store ManagementDocument2 pagesGreen Planet Store ManagementAmolPagdalNo ratings yet

- Basic Hole System or Hole Basi1Document2 pagesBasic Hole System or Hole Basi1AmolPagdalNo ratings yet

- Natural Brilliance, Move From Feeling Stuck To Achieving Success (1997) 0925480517Document106 pagesNatural Brilliance, Move From Feeling Stuck To Achieving Success (1997) 0925480517AmolPagdalNo ratings yet

- Concept Generation & Concept Selection PDFDocument20 pagesConcept Generation & Concept Selection PDFcadcam01No ratings yet

- PlasticProductdesign 2 PDFDocument115 pagesPlasticProductdesign 2 PDFAmolPagdalNo ratings yet

- Electrical Presentation & General TopicsDocument77 pagesElectrical Presentation & General TopicsAmolPagdalNo ratings yet

- Total Quality Management (TQM) 1Document21 pagesTotal Quality Management (TQM) 1AmolPagdalNo ratings yet

- PlasticProductdesign 3 PDFDocument116 pagesPlasticProductdesign 3 PDFAmolPagdalNo ratings yet

- C006a JDocument44 pagesC006a JVignesh WaranNo ratings yet

- Dwatering Oct 2012Document92 pagesDwatering Oct 2012sukiraj100% (1)

- 16 e Chapter 10Document29 pages16 e Chapter 10Yuki MiharuNo ratings yet

- Time Series DatabaseDocument4 pagesTime Series DatabaseCHINGZU212No ratings yet

- Service Manual: Controller Sigma Control 2Document33 pagesService Manual: Controller Sigma Control 2Mukhlis YasinNo ratings yet

- Quality MGT Practices and Impact On PerformanceDocument28 pagesQuality MGT Practices and Impact On PerformanceMizaa Jamali0% (1)

- Dilip Datta (Auth.) - LaTeX in 24 Hours - A Practical Guide For Scientific Writing-Springer International Publishing (2017)Document309 pagesDilip Datta (Auth.) - LaTeX in 24 Hours - A Practical Guide For Scientific Writing-Springer International Publishing (2017)Leandro de Queiroz100% (3)

- Creating A Raspberry Pi Cluster - A Tutorial For StudentsDocument7 pagesCreating A Raspberry Pi Cluster - A Tutorial For StudentsAlan SagarNo ratings yet

- Homelite Chain Saw Parts Manual For 20 Chain Saw UT 10782 ADocument14 pagesHomelite Chain Saw Parts Manual For 20 Chain Saw UT 10782 AJoe EisentragerNo ratings yet

- I On16 EngineerDocument68 pagesI On16 EngineerjamesmathiesonNo ratings yet

- ARELLANO - SEISMIC VULNERABILITY ASSESSMENT OF BUILDINGS AMONG BPSU CAMPUSES IN BATAAN USING RVS METHOD 1 AutosavedDocument18 pagesARELLANO - SEISMIC VULNERABILITY ASSESSMENT OF BUILDINGS AMONG BPSU CAMPUSES IN BATAAN USING RVS METHOD 1 AutosavedRhea BasilioNo ratings yet

- Tools For Marketing: David Goldstein President, Mekko GraphicsDocument10 pagesTools For Marketing: David Goldstein President, Mekko GraphicsTracy Tam NguyenNo ratings yet

- IRS Module5-IDocument15 pagesIRS Module5-IPravin ShindeNo ratings yet

- Ict1 July2014 ColorDocument289 pagesIct1 July2014 ColorLawrence ManaliliNo ratings yet

- Influence Lines For Indeterminate StructureDocument9 pagesInfluence Lines For Indeterminate StructureveerusiteNo ratings yet

- Lesson 5. Risk Management - Attempt Review - KMADistEduDocument5 pagesLesson 5. Risk Management - Attempt Review - KMADistEduyu4obrawlstarsNo ratings yet

- Magneto Optical Current TransformerDocument23 pagesMagneto Optical Current Transformersushilkumarbhoi2897No ratings yet

- Oro Verde Limited (ASX: OVL) ("The Company or OVL") Is Pleased To AnnounceDocument5 pagesOro Verde Limited (ASX: OVL) ("The Company or OVL") Is Pleased To Announceanouari2014No ratings yet

- 3 MI Tanks PPT (Neeru Chettu)Document39 pages3 MI Tanks PPT (Neeru Chettu)vishnuNo ratings yet

- EMail Collaboration in Release 9.1 Rev1Document12 pagesEMail Collaboration in Release 9.1 Rev1PradeepNo ratings yet

- Mat 060 Ve01 Syllabus Fa12Document6 pagesMat 060 Ve01 Syllabus Fa12educareNo ratings yet

- Guidance Settlement Application SET (O)Document13 pagesGuidance Settlement Application SET (O)Amir FarooquiNo ratings yet

- PALE No. 1Document14 pagesPALE No. 1Anonymous lXytcd5NWNo ratings yet

- Information Technology Fundamentals: CCIT4085Document43 pagesInformation Technology Fundamentals: CCIT4085singyuetchan05No ratings yet

- Week 06Document70 pagesWeek 06HawJingZhiNo ratings yet