Professional Documents

Culture Documents

A Flat Type Touch Probe Sensor Using PZT Thin Film Vibrator: T. Kanda, T. Morita, M.K. Kurosawa, T. Higuchi

A Flat Type Touch Probe Sensor Using PZT Thin Film Vibrator: T. Kanda, T. Morita, M.K. Kurosawa, T. Higuchi

Uploaded by

Grigore ValentinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Flat Type Touch Probe Sensor Using PZT Thin Film Vibrator: T. Kanda, T. Morita, M.K. Kurosawa, T. Higuchi

A Flat Type Touch Probe Sensor Using PZT Thin Film Vibrator: T. Kanda, T. Morita, M.K. Kurosawa, T. Higuchi

Uploaded by

Grigore ValentinCopyright:

Available Formats

Sensors and Actuators 83 2000. 6775 www.elsevier.

nlrlocatersna

A flat type touch probe sensor using PZT thin film vibrator

T. Kanda ) , T. Morita 1, M.K. Kurosawa 2 , T. Higuchi

Department of Precision Machinery Engineering, Graduate School of Engineering, Uniersity of Tokyo, 7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan Received 9 June 1999; received in revised form 7 December 1999; accepted 9 December 1999

Abstract We fabricated a touch probe sensor, having a flat configuration and using a PZT thin film vibrator. This sensor is intended for use in high-precision surface shape measuring tools at low contact force, for example, scanning probe microscopes SPMs.. The sensor consists of an oscillator vibrating in the longitudinal direction. According to our calculations higher sensitivity can be obtained by using longitudinal vibration than by using bending vibration. The vibration was excited and detected by a hydrothermally deposited PZT thin film device. The length of the vibrator was 9.8 mm, and its resonance frequency was 304.35 kHz. When the driving voltage was 3 Vp p at the resonance frequency, the vibration amplitude at the tip of the sensor was 126 nm o p . We used the flat configuration and miniaturized the oscillator to increase the quantity ratio of piezo film in comparison to the base material, thus improving the sensitivity. The sensitivity and the resolution were evaluated experimentally, with the vertical resolution estimated to be 2.4 nm. This sensor device will be effective for use in high-speed and high-resolution surface shape measuring tools without damage to nano scale construction. q 2000 Elsevier Science S.A. All rights reserved.

Keywords: Touch probe sensor; PZT thin film; Hydrothermal method

1. Introduction Touch probe sensors have been used as probes in surface shape measuring tools. For example, vibrating cantilevers are employed as touch probes in scanning probe microscopes SPM. as well as in atomic force microscopes AFM. w1x. Most of these microscopes use bending vibrating cantilevers. However, a longitudinally vibrating probe has also been proposed for use in such measuring tools w2,3x. Since a longitudinal vibrator has a much higher Q value, and is not as influenced by the damping of air viscosity compared to a bending vibrator. When measurements are taken in fluid, longitudinal vibrators in particular will have much higher sensitivity than bending vibrators. In addition, a longitudinal vibrator has a much higher resonance frequency than cantilevers, thus enabling quick scanning of the probe. However, a much

Corresponding author. Tel.: q 81-3-5841-6466; fax: q 81-3-58006968; http:rrwww.intellect.pe.u-tokyo.ac.jp. E-mail address: kanda@intellect.pe.u-tokyo.ac.jp T. Kanda.. 1 Present address: The Institute of Physical and Chemical Research RIKEN., Hirosawa 2-1, Wako-shi, Saitama 351-0198, Japan. 2 Present address: Interdisciplinary Graduate School of Science and Engineering, Tokyo Institute of Technology, 4259 Nagatsuta-cho, Midoriku, Yokohama 226-8502, Japan.

)

more important matter is that the longitudinal vibrator has much higher sensitivity than bending vibrators. This sensitivity can be defined as the transfer ratio from the vibration amplitude to the pickup voltage. We fabricated a touch probe sensor using a longitudinal vibrator. The vibration was generated by hydrothermally deposited PZT thin film w4x. This previous sensor consisted of a rod vibrating in the axial direction. Its length was 27.8 mm and its resonance frequency was 116 kHz. Its vertical resolution was higher than 67 nm w3x. However, the pickup voltage contained the same frequency signal that was considered to be caused by induced interference from the driving current to the pickup wire and electrode. Thus the reduction of this interference signal will improve the sensitivity. In this paper, in order to obtain much higher sensitivity, we examine a much smaller and flat-type sensor.

2. Principle and structure 2.1. Principle The schematic view of the touch probe sensor in the process of measurement is shown in Fig. 1. The sensor

0924-4247r00r$ - see front matter q 2000 Elsevier Science S.A. All rights reserved. PII: S 0 9 2 4 - 4 2 4 7 0 0 . 0 0 2 9 8 - 3

68

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

Fig. 1. Schematic view of surface shape measurement by a touch probe sensor.

consists of a half wavelength, longitudinally vibrating oscillator. An exponential horn enlarges the amplitude of vibration. When the tip end of the horn touches the surface of the workpiece, the resonance frequency of the vibrator shifts. By continuously detecting the tips contact to the workpiece surface, the surface profile of the workpiece can be obtained. If we can use tapping mode, namely, a cyclic contact mode, we can minimize the damage to the surface. By using the tapping mode, the contact force will be smaller than existing tools for measuring surface roughness. 2.2. Structure The structure of the touch probe sensor is shown in Fig. 2. The vibrator length is 9.8 mm. The step-up ratio of the exponential horn is 3.2. The base material of the vibrator is titanium Ti. substrate. The thickness of this substrate was 100 m m. On the surface of the Ti substrate, we deposited PZT thin film using the hydrothermal method w5,6x. The thickness of the PZT film was about 10 m m on each side. The electrodes deposited on the surface of the PZT film were used to drive and pickup. Those electrodes were made of gold, and were deposited by vapor deposition. In order to reduce the induced interference, we used a differential amplifier. This is because the interferences value would be mainly due to the leakage between the power supply and the pickup wires. In addition, the differential amplifier circuit decreased the influence of the high impedance of PZT film. As shown in Fig. 3, the pickup voltage was defined as the differential potential between the voltage of the pickup electrode and that of the reference electrode. The differential amplifier circuit gain was set to 10. 2.3. Comparison of the sensitiity Longitudinal vibrating sensors can effectively realize much higher sensitivities and much higher scanning speeds than can bending vibrating sensors.

Fig. 2. Structure of the touch probe sensor: a. photo, b. schematic view.

To compare the sensitivity of the sensor consisting of the longitudinal vibrator and the bending vibrator, we estimated the sensitivity of a bending vibrator sensor as shown in Fig. 4. Electrodes are positioned on each side, one is for driving, and the other is for pickup. The length, width, and thickness of the Ti substrate and that of PZT film are l, b, t 1 , and t 2 , respectively. There are PZT thin film layers on both surfaces of the Ti substrate.

Fig. 3. Touch probe sensor with the deferential amplifier circuit.

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

69

Fig. 4. Vibrator for evaluating sensitivity.

To evaluate the pickup voltage of the sensor, an equivalent circuit of the vibrator is effective. Fig. 5 shows the equivalent circuit of the oscillator in Fig. 4 w4x. Lump element circuit components of L, 1rC, R , A1 and A 2 are equivalent mass, equivalent elasticity modules, equivalent viscosity coefficient, and force factors in the driving piezo element and that in the pickup piezo element. Cd1 and Cd2 indicate the capacitance in the driving element and that in the pickup element due to the PZT films ferroelectricity. By using these parameters, the pickup voltage can be described as w4x A1 A 2

Fig. 6. Relationship between d d and dV .

dV r d d as shown in Fig. 6. From the appendix, sensitivity P can be described as

A1 A 2 y

2 2 d2

A1 A 2

(A q v R C

4 2 2 r

Ps

A1

< Vout < s

2 A2 2 y v LCd 2 q

Cd 2 C

< Vin < .

2 q v 2 R 2 Cd 2

vr R

( (

2 A2 2 y v r LCd 2 q

Cd 2 C

X

/

X2

2 q vr2 R Cd 2

X2

A1 1 C

X 2

y vr2 L q vr2 R

2. 1.

In Eq. 2., vr is the angular resonance frequency at the freely vibrating condition. RX and CX mean, RX s R q R 1 1 C

X

In Eq. 1., v is the angular frequency. Vin is the driving voltage, and Vout is the pickup voltage. When the tip of the sensor is brought close to the workpiece, the pickup voltage of the sensor changes as shown in Fig. 6. In the region of the cyclic contact, we can measure the derivation of the gap between the sensor tip and the workpiece. In this region, in simplified model, the vibration amplitude is limited by the gap. Hence the vibration amplitude decreases linearly when the sensor is brought close to the workpiece. The declination of the vibration amplitude corresponds to the change of the pickup voltage. Sensitivity can be defined as the tangent of the slope in Fig. 6. Namely, sensitivity P is defined by

3.

1 C1 .

1 s C q

4.

Fig. 5. Equivalent circuit of the vibrator shown in Fig. 4.

R 1 and 1rC1 indicate the equivalent elasticity modules and the equivalent viscosity coefficient at the surface of the workpiece. We calculated the sensitivity of each vibrator at the ratio between l, b, and t 1 as 40:10:1. The thickness of the PZT film, t 2 , was constant at 10 m m. When the PZT thin film was deposited using the hydrothermal method, the thickness of the film was constant at about 10 m m. Fig. 7 shows the results of the calculation. The sensitivity of the bending vibrator does not change against the change of length l. However, the sensitivity of the longitudinal vibrator increases as the sensor miniaturized. This is because the strain becomes larger when the vibrator is miniaturized with the same vibration displacement is unchanged. This result means the miniaturization of the vibrator can effectively to obtain higher sensitivity, especially in the longitudinal vibrator. From the comparison of the sensitivity of both vibrators, the sensitivity of the longitudinal vibrator is higher than that of the bending vibrator in an order of 10 4 .

70

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

Fig. 8. Admittance of the vibrator. Fig. 7. Relationship between the width of the vibrator and its sensitivity using the calculation.

The calculation did not include the contribution of air viscosity and other factors. Air viscosity has a larger influence on the bending vibrator than on the longitudinal vibrator. Then, if we take into account the air damping effect, the difference will be much larger. The factors between the tip of both vibrators and the sample surface equally effect the sensitivity of each vibrator sensor. In this case, the sensitivity of the longitudinal vibrator is much higher than that of the bending vibrator. However, the longitudinal vibrator has much higher rigidity than the bending vibrator. Hence the contact force between the tip of the vibrator and the workpiece will be much larger in the longitudinal vibrator. However, the contact force also depends on the vibration amplitude. Therefore, by using the smaller vibration amplitude, the vibrator can operate using a smaller contact force. The longitudinal vibrator has smaller vibration amplitude than a bending vibrator when the driving or pickup voltage is the same value. Then as the step-up ratio of the horn becomes larger, a smaller contact force can be obtained. In addition to the comparison of the vibrators sensitivity, the resonance frequencies can also be compared. When the length l s 4 mm, the resonance frequency of the longitudinal vibrator and the bending vibrator were 290 kHz and 4.2 kHz, respectively. The scanning frequency cannot exceed the resonance frequency. Thus, from the comparison of the resonance frequency of both vibrators, the longitudinal vibrating sensor has the possibility of realizing high-speed scanning.

The measurement showed that the admittance increased as the frequency increased. The phase of the admittance also changed. This means that the value tan d dielectric loss tangent. increased as the driving frequency increased, namely, the loss in the vibrator increased. In such a vibrator, the loss has to be considered in the equivalent circuit. The equivalent circuit in Fig. 5 must be converted to the circuit in Fig. 9. In this circuit, the resistance, R d1 and R d2 , describes the dielectric loss in the piezoelectric material. 3.2. Vibration amplitude and pick-up To evaluate the relationship between the vibration amplitude and the pickup voltage, the velocity of the vibrator tip and the output voltage of the amplifier were measured as the function of driving frequency. A laser Doppler vibrometer and vector voltage meter were used for the measurement. The driving voltage was maintained at a constant value of 3 Vp p . The results are shown in Fig. 10. The plots of the pickup voltage indicate the measurement value results divided by amplifier gain. The vibration amplitude and the pick-up voltage peaked at the resonance frequency of 304.35 kHz. At that frequency, the vibration amplitude and pickup voltage were 126 nm o p and 3.36 mVrms . The mechanical Q value was 705. As can be seen from the plots of the pickup voltage, the induced interference voltage was small enough. Hence, the resonance frequency can be detected from the peak of the pick-up voltage. 3.3. Ealuation by equialent circuit

3. Experiments 3.1. Admittance of the ibrator We measured the admittance change of the vibrator under a non-contact condition using an impedance analyzer. The results are shown in Fig. 8. The deviation of the admittance curve was detected around 304.5 kHz. This shift would be caused by the resonance of the vibrator. The resonance frequency was 10 kHz lower than the result of the analysis by the finite element method, which was 315 kHz.

From the measurement of the vibration amplitude and mechanical Q value, we can obtain the value of each

Fig. 9. Equivalent circuit of the touch probe sensor.

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

71

Fig. 11. Results regarding the relationship between the driving frequency and the pick-up voltage arrived at using the equivalent circuit. Fig. 10. Relationship between the amplitude of the vibration and the pick-up voltage of the sensor by measurement: the vibration amplitude was measured by laser Doppler vibrometer. The pick-up voltage was measured using the vector voltage meter.

mated. When the shape of the oscillator is as shown in Fig. 4, the force factor can be described by using e31 w10x; A s 2 be31 .

5.

parameter in the equivalent circuit. Parameters are shown in Table 1. Resistance R d1 and R d2 were calculated from the relationship between the admittance and the frequency shown in Fig. 8. By using this equivalent circuit in the way shown in Fig. 9, the pick-up voltage can be estimated. Fig. 11 shows the calculated results of the pickup voltage. At the resonance frequency of 304.35 kHz, the calculated pickup value was 1.24 mVrms . This value is smaller than the result of the measurement, although the frequency of the resonance is the same as the measurement. The source of error will be the exponential horn. The equivalent mass, L, is especially influenced by the step-up ratio of the exponential horn. The step-up ratio used in the calculation is that derived from the width of both ends of the horn. However, the ratio was actually diminished by the supporting part. With this, there was a restriction in the machining process to make the form of the element, especially in regard to the accuracy of the wired discharge cutting. So the horn did not consist of the exponential curve but of straight lines. Therefore the step-up ratio was different from that of the design. If the step-up ratio in the calculation were larger than the actual ratio, the equivalent mass and force factors would be smaller than actual values. Then the pickup voltage would then be smaller than the measurement result. As shown in Eq. 2., especially under the condition that the term including the viscoelasticity of the sensor is large against the term including the force factor, the sensitivity of this sensor depends on the force factor. From the force factor in the equivalent circuit, the piezoelectric constant of the PZT film, e 31 , can be estiTable 1 Parameters of the equivalent circuit based on measurement L R C A1 Equivalent mass wkgx Equivalent viscoelastic loss wNsrmx Equivalent compliance wmrNx Force factor wNrVx 2.0=10y6 5.4=10y3 1.4=10y7 8.7=10y5

From Eq. 5. and the step-up ratio of the exponential horn, the piezoelectric constant e 31 of the PZT film was y0.13 Crm2 . The constant of bulk PZT is y3.1 Crm2 calculated from the constants on Ref. w7x.. The pick-up voltage as well as sensitivity depends on the force factor. The force factor is proportional to e31 , as shown in Eq. 5.. So it is important to improve the piezoelectric constant in order to obtain high sensitivity. These results indicate that the sensitivity will be made much higher by improving e 31 of the PZT thin film. 3.4. Vibration in the bending direction This sensor has a flat configuration, and the electrode for driving is on one side. It is likely then that the thin structure causes bending vibration. If the bending amplitude is large, the resolution of the sensor is diminished not only laterally but also vertically. To evaluate the vibration amplitude in the bending direction, we measured longitudinal and bending vibration amplitude using laser Doppler vibrometers. Fig. 12 shows the relationship between the amplitude in the longitudinal direction and that in the bending direction.

Fig. 12. Relationship between longitudinal vibration amplitude and bending vibration amplitude.

72

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

At the longitudinal resonance frequency, 307.6 kHz, the bending vibration velocity was 72 m mrs, which was measured with the laser Doppler vibrometer Polytec OFV-3001, OFV-501.. The bending vibration amplitude was only 36 pm although the longitudinal amplitude was 138 nm. The bending direction amplitude was only 0.03% of the longitudinal vibration. The bending amplitude was thus small enough and it was not so serious for the resolution of the sensor. 3.5. Sensitiity and resolution To evaluate the sensitivity and the resolution of this sensor, we measured the relationship between pickup voltage and tipworkpiece distance. Fig. 13 shows the experimental set up. The workpiece is an aluminum plate. The plate was driven by a layered type piezo element. The sensor output signal was amplified by the differential amplifier. The output voltage from the amplifier was measured using a vector voltage meter HP8508A.. The results are shown in Fig. 14. The pickup voltage was measured when the workpiece was brought close to the vibrator tip. The plots of the pickup voltage are not divided by the differential amplifier gain. The plots describe the force curve w8x. From the left side of the graph, each area corresponds to A. the freely vibration, B. the tapping vibration, and C. the contact regions. The variation of the pickup voltage is similar to that seen in Fig. 6. In the area B. of Fig. 6, the change is linear. However, it is non-linear in Fig. 14. This will be because the vibrator body in the experiment has elasticity although it was defined as a rigid body in the theoretical model. From the change of the pickup voltage in region B., the sensitivity of this sensor is obtained. From this sensitivity the vertical resolution of this sensor can be estimated. The sensitivity can be defined as the tangent of the tapping mode in region B. of Fig. 14. The slope will change for

Fig. 14. Relationship between the pick-up voltage of the sensor and the displacement of the workpiece by the measurement: each area A., B., and C. corresponds to the free vibration, the tapping vibration, and the contact regions.

the workpiece, which in this estimation was aluminum. From the slope of the curve in Fig. 14, the sensitivity was 2.0 = 10y2 mVrnm. From the calculation by Eq. 2., the sensitivity was estimated to be 7.3 = 10y2 mVrnm. This difference would be mainly mechanical loss such as the loss by supporting. The resolution of the sensor corresponds to the minimum detectable voltage divided by the sensitivity. The minimum detectable voltage is defined as the equivalent background noise level at the input terminal of the amplifier. This means the signal-to-noise ratio is 0 dB when the minimum detectable voltage equals the equivalent background noise level. The equivalent background noise included the sensor noise, the amplifier noise, and others. The resolution can be defined as the minimum detectable scale corresponding to the minimum detectable voltage. When Vmin , m , G, P , and Pr indicate the minimum detectable voltage, the noise level measured by the vector voltage meter in Fig. 13, the gain of the differential amplifier, the sensitivity of the sensor, and the resolution. The resolution can be estimated by the following equations, nm Vmin s 6. G Vmin Pr s . 7. P From the measurement of the noise level 0.4 mVrms at the output of the differential amplifier measured using the vector voltage meter, and the sensitivity as mentioned above, the resolution was 2.4 nm. This value was smaller than that of our previous probe sensor w4x, thus improving the resolution. In this experiment, the operational amplifier devices LF356. in differential amplifier were not the low-noisetype, and the bandwidth 420 kHz. was wide. However, the noise level was measured using a vector voltage meter that detected only the referred frequency. Hence the wide bandwidth is not significant. That noise would be caused by the thermal noise of the PZT film, and by the mechanical vibration of the oscillator. The noise caused by the

Fig. 13. Experimental setup for estimation of the relationship between the tip sample distance and the pickup voltage.

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

73

capacitance of the film would be especially serious because the impedance of the PZT film of the oscillator is very high.

those in the freely vibrating condition are. Hence, Eq. 2. can be transferred as A1 A 2 Ps

(A q v R C

4 2 2 r 2

2 d2

4. Discussion Based on the measurements, the piezoelectric constant e 31 of the hydrothermally deposited PZT film was only 4.3% of the bulk PZT. On the other hand, from the measurement, the piezoelectric constant d 31 was y34.2 CrN w9x. This value corresponds to 37% of the bulk PZT material d 31 , y93.6 CrN w7x. Yet the piezoelectric constant e 31 is an important factor in regard to sensitivity. The piezoelectric constant e 31 is derived from the product of d constants and modulus of elasticity. Then, by comparing the measured constants d 31 and e 31 , it can be said that the modulus of elasticity of the PZT film is too small. The reason of the low elasticity of the PZT film seems to be the materials structure. Fig. 15 shows the surface of the PZT thin film of the touch probe sensor. As this photograph shows, there is a lot of void space between PZT crystals. It can be considered that the density of the film, including void space, will be small, and the binding force between crystals will be weaker. These matters correspond to the fact that the modulus of elasticity is also small. To increase the modulus of elasticity, the amount of void must be reduced. If the crystal can be grown much larger, the amount of void will be reduced, and the binding force can be improved. The modulus of elasticity will then be much larger. The piezoelectric constant, e 31 , has an important relationship to the sensitivity and the resolution of the sensor. From the measurements, the pickup voltage and the amplitude under the damped condition are much smaller than

A1

8.

vr R

Then, under the condition that A1 equals A 2 , the sensitivity can be described as Ps Cd 2 A1 . A2 1

2

9.

1q

vr RCd 2

From the results of the measurement shown in Table 1, the relationship

A2 1

vr RCd 2

- 10y 6

is obtained. Hence the sensitivity can be said to be in proportion to the force factor. From Eq. 5., the sensitivity can be said to be in proportion to the piezoelectric constant e 31 , and the resolution is in inverse proportion to sensitivity. So, the piezoelectric constant e 31 of the PZT film should be improved. If the constant, e 31 , of the PZT film is about 23 times as large as the present film constant, which is the same as that of the bulk PZT material, the resolution will be up to 0.1 nm.

5. Conclusion We estimated and compared the sensitivity of the longitudinal and the bending vibrating sensor. The results demonstrated that the longitudinal vibrating sensor has much higher sensitivity than the bending vibrating sensor as the vibrator was miniaturized. As well, the resonance frequency of the longitudinal sensor is higher than that of the bending sensor. Hence, the longitudinal vibrating sensor device will be effective for use in high-speed and high-resolution surface shape measuring tools. We fabricated a touch probe sensor using hydrothermal deposited PZT thin film, and evaluated its sensitivity and resolution. The resonance frequency and the tipamplitude at that frequency were 304.35 kHz and 126 nm o p , respectively. The sensitivity of the sensor was 2.0 = 10y2 mVrnm. At this sensitivity, the vertical resolution of this sensor was estimated to be 2.4 nm. We could achieve higher sensitivity and resolution than those described in our previous paper w4x by miniaturizing the vibrator and using a flat configuration. In order to increase the sensitivity and the resolution of this touch probe sensor, the force factor must be increase.

Fig. 15. Photo of the surface of the PZT thin film deposited using the hydrothermal method.

74

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775

Measurements indicated that the piezoelectric constant e 31 was only 4.3% of the bulk PZT material, while d 31 was 37%. These results show that the piezoelectric constant, especially constant e 31 , must be improved. The discussion indicates as well that the modulus of elasticity has to be increased. By improving the piezoelectric constant of the PZT film, we will obtain higher sensitivity and higher resolution.

The vibration amplitude can then be described as < u R . < s < u F . < s A1 < Vin < 1 A1 < Vin < . qv R

2 2

vR

A.5 . A.6 .

1 C

yv L

Appendix A Sensitivity is described as

Then, when the tip of the sensor is brought close to the workpiece with the frequency maintained at the resonance frequency of the freely vibration, from Eqs. 1., A.1., A.2., A.5. and A.6., sensitivity P can be described as

A1 A 2 y A1 A 2

Ps

Vout R . y Vout F . u R . y u F .

A.1 .

Ps

2 2 2 A4 2 q v r R Cd 2

A1

The parameter u R . indicates the vibration amplitude at the tip and Vout R . means the pickup voltage when the oscillator vibrates freely at its resonance frequency. The amplitude u R . equals the distance between the surface of the workpiece and the tip of the sensor in the start point of the cyclic contact mode. The parameters u F . and Vout F . are the vibration amplitude and the pickup voltage under the continuous contact condition. The continuous contact condition indicates the condition in which the tip maintains constant contact with the workpiece. This condition also indicates the condition at the end of the cyclic contact mode. In this contact condition, the factors such as the equivalent elasticity modules and the equivalent viscosity coefficient at the surface of the workpiece influence the pickup voltage and the vibration amplitude. In Eq. 1., the relationship between the driving voltage and the pickup voltage is described. Especially in the resonance frequency, the output voltage can be described as < Vout < s A1 A 2 < Vin < .

vr R

( (

2 A2 2 y v r LCd 2 q

Cd 2 C

X

/

X2

2 q vr2 R Cd 2

X2

A1 1 C

2 2 2 X y vr L q vr R

A.7 .

In Eq. A.7., RX and CX indicates, RX s R q R 1 1 C

X

A.8 .

1 C1 .

1 s C q

A.9 .

R 1 and 1rC1 signify the equivalent elasticity modules and the equivalent viscosity coefficient at the surface of the workpiece, respectively. When the contact takes place, the values of R 1 and 1rC1 change from R 1 s 1rC1 s 0 to not equal 0, and the condition shifts from the resonance. So sensitivity P can be described by Eq. 2..

2 vr2 R 2 Cd2 q A4 2

A.2 .

References

w1x G. Binnig, C.F. Quate, Ch. Gerber, Atomic force microscope, Phys. Rev. Lett. 56 1986. 930933. w2x S.M. Harb, M. Vidic, Resonator-based touch-sensitive probe, Sens. Actuators A 50 1995. 2329. w3x M. Nishimura, K. Hidaka, M. Teraguti, Dependence on directions of the sensitivity of the vibrational touch sensor, Proc. Ann. Spring Meeting JSPE, 1994 1994. 795796 in Japanese.. w4x T. Kanda, T. Morita, K. Kurosawa, T. Higuchi, A rod-shaped vibro touch sensor using PZT thin film, IEEE Trans. UFFC 46 4. 1999. 875882. w5x K. Shimomura, T. Tsurumi, Y. Ohba, M. Daimon, Preparation of lead zirconate titanate thin film by hydrothermal method, Jpn. J. Appl. Phys. 30 9B. 1991. 21742177. w6x T. Morita, T. Kanda, M. Kurosawa, T. Higuchi, Single process to deposit lead zirconate titanate PZT. thin film by a hydrothermal method, Jpn. J. Appl. Phys. 36 5B. 1997. 29982999. w7x B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics, Academic Press, London, 1971. w8x C. Lee, T. Itoh, T. Suga, Self-excited piezoelectric PZT microcan-

In Eq. A.2., v r is the angular resonance frequency. From the electro-acoustic transfer equation, the vibration amplitude at the tip of the oscillator is described as w11x us A1Vin .

vZ

A.3 .

In Eq. A.3., u and Z signify the amplitude and the mechanical impedance, respectively. When the oscillator vibrates freely, the mechanical impedance equals R. When the oscillator is in the contact condition, the mechanical impedance is described as ZsRqj vLy

vC

A.4 .

T. Kanda et al. r Sensors and Actuators 83 (2000) 6775 tilevers for dynamic SFM-with inherent sensing and actuating capabilities, Sens. Actuators A 72 1999. 179188. w9x T. Morita, M.K. Kurosawa, T. Higuchi, A cylindrical micro ultrasonic motor using PZT thin film deposited by single process hydrothermal method 2.4 mm, L s 10 mm stator transducer., IEEE Trans. UFFC 45 5. 1998. 11781187. w10x T. Ikeda, Fundamentals of Piezoelectricity, Oxford University Press, Oxford, 1990, p. 86. w11x T. Ikeda, Fundamentals of Piezoelectricity, Oxford University Press, Oxford, 1990, p. 98.

75

Biographies

Takefumi Kanda was born in Fukuoka, Japan, on June 18, 1972. He received the B. Eng. and the M. Eng. in precision machinery engineering from The University of Tokyo, Japan in 1997 and 1999. He is currently a doctoral course student of the Graduate School of Engineering. His research interests are micro sensor and PZT thin film. He is a member of the Japan Society for Precision Engineering. Takeshi Morita was born in Tokyo, Japan, on August 4, 1970. He received the B. Eng., the M. Eng. and Dr. Eng. in precision machinery engineering from The University of Tokyo, Japan in 1994, 1996 and 1999. He is currently a special postdoctoral researcher in The Institute of Physical and Chemical Research RIKEN.. His research interests are micro ultrasonic motor and PZT thin film. He is a member of the Institute of Electrical Engineers of Japan, the Ceramic Society of Japan, and the Japan Society for Precision Engineering.

Minoru Kuribayashi Kurosawa formerly Kuribayashi. was born in Nagano, Japan, on April 24, 1959. He received the B. Eng. in electrical and electronic engineering, and the M. Eng. and Dr. Eng. from Tokyo Institute of Technology, Tokyo, in 1982, 1984, and 1990, respectively. He was a Research Associate at the Precision and Intelligence Laboratory, Tokyo Institute of Technology, Yokohama, Japan, since 1984, and an Associate Professor at the Graduate School of Engineering, The University of Tokyo, Tokyo, Japan, since 1992. Since 1999, he has been an Associate Professor at the Interdisciplinary Graduate School of Science and Engineering, The Tokyo Institute of Technology, Yokohama, Japan. His current research interests include ultrasonic motor, micro actuator, PZT thin film, SAW sensor and actuator, and single bit digital signal processing and its application to control systems. Dr. Kurosawa is a member of the Institute of Electronics Information and Communication Engineers, the Acoustical Society of Japan, IEEE, the Institute of Electrical Engineers of Japan and the Japan Society for Precision Engineering.

Toshiro Higuchi was born in Ehime, Japan on February 26, 1950. He received the B. Eng., MS, and PhD in precision engineering from The University of Tokyo, Japan, in 1972, 1974, and 1977, respectively. He was a Lecturer at the Institute of Industrial Science, The University of Tokyo in 1977 and an Associate Professor in the same institute from 1978. Since 1991, he has been a Professor at the Graduate School of Engineering, The University of Tokyo. His present interests include mechatronics, magnetic bearing, stepping motors, electrostatic actuator, robotics and manufacturing. Dr. Higuchi is a member of the Japan Society for Precision Engineering, the Japan Society of Mechanical Engineers, and the Society of Instrument and Control Engineers.

You might also like

- eDOF - PI Architecture Blue Print v1 1Document38 pageseDOF - PI Architecture Blue Print v1 1tetio100% (1)

- Java Programming AssignmentDocument2 pagesJava Programming Assignmentvikas_saini_4uNo ratings yet

- Capacitive Type Surface-Micromachined Silicon Accelerometer With Stiffness Tuning CapabilityDocument8 pagesCapacitive Type Surface-Micromachined Silicon Accelerometer With Stiffness Tuning CapabilityminhibtNo ratings yet

- Sensors 15 23205 PDFDocument13 pagesSensors 15 23205 PDFVinoth ProtoSemNo ratings yet

- Sensors 15 23205 PDFDocument13 pagesSensors 15 23205 PDFVinoth ProtoSemNo ratings yet

- Session 2004: 21, Rue D'artois, F-75008 Paris © CigréDocument8 pagesSession 2004: 21, Rue D'artois, F-75008 Paris © CigréCesar ZamudioNo ratings yet

- CF RT - : Monitoring of Rock Movements Using Probe Inclinometer - GuidelinesDocument10 pagesCF RT - : Monitoring of Rock Movements Using Probe Inclinometer - GuidelinesRoshanRSVNo ratings yet

- Ultrasonic Wire-Bond Quality Monitoring Using Piezoelectric SensorDocument7 pagesUltrasonic Wire-Bond Quality Monitoring Using Piezoelectric SensorNguyen Hai Dang Tam100% (1)

- ICSS YCChuangDocument3 pagesICSS YCChuangyi-chun.chuangNo ratings yet

- SI 4 UnitDocument292 pagesSI 4 UnitRaagul SNo ratings yet

- Development Land Application Mass Sensors Based On Flexural Resonances in Alumina BeamsDocument8 pagesDevelopment Land Application Mass Sensors Based On Flexural Resonances in Alumina BeamspandyyanNo ratings yet

- A Position Sensor For A Micro-ActuatorDocument2 pagesA Position Sensor For A Micro-Actuatorkong_neoNo ratings yet

- FEM Acoustic Analysis - NDT Angle Beam ExampleDocument28 pagesFEM Acoustic Analysis - NDT Angle Beam ExampleN DNo ratings yet

- ICSS YCChuangDocument3 pagesICSS YCChuangyi-chun.chuangNo ratings yet

- LOC Biopsy Tool 1-07Document7 pagesLOC Biopsy Tool 1-07vlsipranatiNo ratings yet

- Bio Accoustic 131203Document10 pagesBio Accoustic 131203Choirun Nisa Nur AiniNo ratings yet

- Characteristics of Probe SensitivityDocument10 pagesCharacteristics of Probe SensitivityBhadresh Patel100% (1)

- Frequency Measurement ExperimentDocument4 pagesFrequency Measurement ExperimentKEDARISETTY SAISREENo ratings yet

- Transduction PrinciplesDocument14 pagesTransduction PrinciplesNavin KaranthNo ratings yet

- Ultrasonic Sensor For Level MeasurementDocument34 pagesUltrasonic Sensor For Level MeasurementAshish RawatNo ratings yet

- Biomedical Sensors PDFDocument14 pagesBiomedical Sensors PDFBMT0% (1)

- Sensors 07 03192Document17 pagesSensors 07 03192Nilesh GuptaNo ratings yet

- MWE Exp 4Document6 pagesMWE Exp 4krNo ratings yet

- A Scintillator Based Halo-Detector For Beam Position MonitoringDocument3 pagesA Scintillator Based Halo-Detector For Beam Position MonitoringSean Captain HonestlagoNo ratings yet

- NOE0415380416 ch084 PDFDocument7 pagesNOE0415380416 ch084 PDFUmed Abd-alsatarNo ratings yet

- Prosig Hardware ReportDocument21 pagesProsig Hardware ReportMustika Rizki FitriyantiNo ratings yet

- هاجر رعد PDFDocument7 pagesهاجر رعد PDFHajar RaadNo ratings yet

- Wu 2017Document4 pagesWu 2017Moish KumarNo ratings yet

- Structural Design For Microaccelerometer: SciencedirectDocument12 pagesStructural Design For Microaccelerometer: SciencedirectsachinNo ratings yet

- Microwave MeasurementsDocument9 pagesMicrowave Measurementsugahaga9213No ratings yet

- Advances in Fluxgate Sensors: Pavel RipkaDocument7 pagesAdvances in Fluxgate Sensors: Pavel RipkaJose AlaezNo ratings yet

- 2008.09898v1Document17 pages2008.09898v1Gheymisson BrennoNo ratings yet

- SENSORSDocument10 pagesSENSORSFaustin MailuNo ratings yet

- Reliability, Long-Term Stability and Gage Performance of Vibrating Wire Sensors With Reference To Case HistoriesDocument8 pagesReliability, Long-Term Stability and Gage Performance of Vibrating Wire Sensors With Reference To Case HistoriesSafwat El RoubyNo ratings yet

- Piezoresistive Cantilever Beam For Force Sensing in Two DimensionsDocument9 pagesPiezoresistive Cantilever Beam For Force Sensing in Two DimensionsnguyenphucthuanNo ratings yet

- Normal Incidence Shear Wave TransducersDocument3 pagesNormal Incidence Shear Wave Transducerscal2_uniNo ratings yet

- Sensors 19 03989Document13 pagesSensors 19 03989Ahlam BOUANINo ratings yet

- Second - Harmonic Jack M JanickeDocument5 pagesSecond - Harmonic Jack M JanickeCamilla Steffensen100% (1)

- LDT With Crimps Vibration Sensor/SwitchDocument4 pagesLDT With Crimps Vibration Sensor/SwitchMohanedelshawyNo ratings yet

- Linear Variable Differential Transformer (LVDT)Document10 pagesLinear Variable Differential Transformer (LVDT)Sam WaikarNo ratings yet

- Experiment 1Document12 pagesExperiment 1Ashish Meena100% (1)

- 1 130322152456 PDFDocument60 pages1 130322152456 PDFAnonymous 7fP7O8ZNo ratings yet

- Sensor Technologies: Syed Khawar Hussain ShahDocument26 pagesSensor Technologies: Syed Khawar Hussain ShahM. RazaNo ratings yet

- Feasibility Study On Crack Detection of Pipelines Using Piezoceramic TransducersDocument8 pagesFeasibility Study On Crack Detection of Pipelines Using Piezoceramic TransducersAnonymous lV8E5mEONo ratings yet

- Basics: Ultrasonic Testing MethodDocument7 pagesBasics: Ultrasonic Testing Methodponnivalavans_994423No ratings yet

- Unit 4 - Characterization of Thin Film PropertiesDocument20 pagesUnit 4 - Characterization of Thin Film PropertiesSumukh MudalagiriNo ratings yet

- Complementary Split Ring Resonator Based Sensor For Crack DetectionDocument6 pagesComplementary Split Ring Resonator Based Sensor For Crack DetectionShrey GroverNo ratings yet

- Cuerda Vibrantes Articulo FMGMDocument0 pagesCuerda Vibrantes Articulo FMGMealvarez_27683No ratings yet

- Compact Large-Range Cryogenic Scanraer: Department Physics, The University Michigan, Ann Arbol Michigan 48109Document4 pagesCompact Large-Range Cryogenic Scanraer: Department Physics, The University Michigan, Ann Arbol Michigan 48109Muraleetharan BoopathiNo ratings yet

- PZT and PVDF Bimorph ActuatorsDocument5 pagesPZT and PVDF Bimorph ActuatorsRavi TulsianNo ratings yet

- AFM Lab ReportDocument14 pagesAFM Lab Reportsmoothieboy0% (1)

- Rosell 2001Document11 pagesRosell 2001ionhandshakerNo ratings yet

- Lesson 3instrumentationsystemelementsDocument21 pagesLesson 3instrumentationsystemelementsRhandel ZamoraNo ratings yet

- Pierced Sensor For A Nano-Microscope (NMSC) : R. Sklyar Verchratskogo St. 15-1, Lviv 79010 UkraineDocument4 pagesPierced Sensor For A Nano-Microscope (NMSC) : R. Sklyar Verchratskogo St. 15-1, Lviv 79010 UkraineFrontiers0% (1)

- A Fiber Optical Sensor For Non-Contact Vibration MeasurementsDocument2 pagesA Fiber Optical Sensor For Non-Contact Vibration MeasurementsEd TrawtmamNo ratings yet

- A Microprocessor Based Clutter Canceller For Life Locator SystemDocument6 pagesA Microprocessor Based Clutter Canceller For Life Locator SystemPln DivyaNo ratings yet

- Eddycurrentsensor PCB SENSOR 2010Document8 pagesEddycurrentsensor PCB SENSOR 2010Siphesihle NkosiNo ratings yet

- Fluxgate Sensor With A Special Permalloy Core - Construction and InvestigationDocument4 pagesFluxgate Sensor With A Special Permalloy Core - Construction and Investigationegurr12No ratings yet

- Design and Characterization of A Passive Wireless Strain SensorDocument9 pagesDesign and Characterization of A Passive Wireless Strain SensorPhong Đào Văn HoàngNo ratings yet

- The Magnetic Center Finding Using Vibrating Wire TechniqueDocument6 pagesThe Magnetic Center Finding Using Vibrating Wire TechniqueHatem AbdelrahmanNo ratings yet

- Lettering League Cursive Handwriting Practice SheetsDocument11 pagesLettering League Cursive Handwriting Practice SheetsJohana MonteroNo ratings yet

- B.inggris ImamDocument70 pagesB.inggris ImamMohammed Al-bhabasyi ImamNo ratings yet

- Hybrid Energy - Presentation - February 2016Document16 pagesHybrid Energy - Presentation - February 2016Eyosyas NathanNo ratings yet

- End Pore CatalogueDocument80 pagesEnd Pore CataloguedhdgdgdNo ratings yet

- Are Transformers Effective For Time Series Forecasting?Document8 pagesAre Transformers Effective For Time Series Forecasting?山木No ratings yet

- The Rafiki MapDocument72 pagesThe Rafiki MapAnonymous Y2qwEuANo ratings yet

- The Rhetorical Works of George of Trebizond and Their Debt To CiceroDocument11 pagesThe Rhetorical Works of George of Trebizond and Their Debt To CicerobrysonruNo ratings yet

- Determination of Chloride Ions in A Given Water SampleDocument5 pagesDetermination of Chloride Ions in A Given Water SampleMg H100% (2)

- Unit - 2 Short Questions (2 & 3 Marks)Document6 pagesUnit - 2 Short Questions (2 & 3 Marks)Sujit KumarNo ratings yet

- Vivek Colloquium MTMDocument81 pagesVivek Colloquium MTMc2vivek_p1481No ratings yet

- Assignment 1Document1 pageAssignment 1Mc AxNo ratings yet

- Market Risk: You Manage What You MeasureDocument14 pagesMarket Risk: You Manage What You MeasureLuis EcheNo ratings yet

- Oracle O2C Cycle TrainingDocument8 pagesOracle O2C Cycle Trainingarungupta870% (1)

- Thermal Stress Analysis With SOLIDWORKS SimulationDocument6 pagesThermal Stress Analysis With SOLIDWORKS SimulationManicks VelanNo ratings yet

- Specific Heat CapacityDocument5 pagesSpecific Heat CapacityDeepak KumarNo ratings yet

- Transparent, Translucent and Opaque Materials: NameDocument4 pagesTransparent, Translucent and Opaque Materials: NameJake D La MadridNo ratings yet

- August 2022 (Test Paper)Document17 pagesAugust 2022 (Test Paper)Jhuanna Marie CabalteraNo ratings yet

- What Is Fsharp Microsoft DocumentDocument582 pagesWhat Is Fsharp Microsoft DocumentMaamar DliouahNo ratings yet

- Electrical Fudamental Quiz 3Document18 pagesElectrical Fudamental Quiz 3Ahyad Arif Abdul Rahman100% (2)

- ME Week 9 WaveguidesDocument33 pagesME Week 9 WaveguidesSaad NadeemNo ratings yet

- Appendix I - AirDocument155 pagesAppendix I - AirTown of Colonie LandfillNo ratings yet

- 55 60 Manual Tilt SystemDocument38 pages55 60 Manual Tilt SystemRyan ActonNo ratings yet

- Y5 - Syllabus - Science Unit, CDDDocument11 pagesY5 - Syllabus - Science Unit, CDDluckmasterNo ratings yet

- Floating Point MultiplierDocument35 pagesFloating Point Multiplierbindu_ankuNo ratings yet

- Specification of Injection Moulding MachineDocument4 pagesSpecification of Injection Moulding MachineNIKHIL PATHADENo ratings yet

- BR Cat 300ind Nem Eng r00 0Document608 pagesBR Cat 300ind Nem Eng r00 0Putut Suprihartono100% (1)

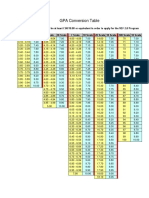

- VEF GPA Conversion TableDocument2 pagesVEF GPA Conversion TableMinh Khôi AnNo ratings yet

- Handbook On The Physics and Chemistry of Rare Earths, Volume 18Document643 pagesHandbook On The Physics and Chemistry of Rare Earths, Volume 18Eliezer Alves MartinsNo ratings yet