Professional Documents

Culture Documents

Installation and Service Instructions Lateral - Expansion Joint

Installation and Service Instructions Lateral - Expansion Joint

Uploaded by

A. Venugopal0 ratings0% found this document useful (0 votes)

38 views2 pagesCatalogue

Original Title

MA LateralExpansionJoint

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCatalogue

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

38 views2 pagesInstallation and Service Instructions Lateral - Expansion Joint

Installation and Service Instructions Lateral - Expansion Joint

Uploaded by

A. VenugopalCatalogue

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

A- 2135 Kottingneusiedl 112, Tel: (02522)7381 Fax: 7381-10

e-mail: innoflex@innoflex.at Internet: http://www.innoflex.at

Installation and Service instructions

Lateral - Expansion Joint

The following points must be observed during installation:

1. Make sure the expansion joint is the correct size for the installation (where necessary, allow for pre-tensioning).

2. If the expansion joint has an arrow on it, this must point in the direction of flow.

3. During installation and subsequent operation, the expansion joint must under no circumstances be subjected to torsion (twisting).

4. The bellows of the expansion joint must be protected with ceramic fibre material (e.g. against sweat, plaster or mortar splashes) and

against high mechanical stresses (throwing, heavy blows).

5. If present, the yellow marked installation fixing must be removed before putting into service.

6. Do not apply any test pressure until the line has been made immovable at the fixed points and guides.

7. During servicing, check for freedom of movement in the guide bearings. Inspect the bellows for damage, corrosion and cracks and check

that the stroke is within limits. Test the fixed points for rigidity.

8. Testing after changes in operation conditions (e.g. pressure, temperature, medium, flow direction, vibrations, frequency of load

fluctuations) and when the existing equipment is extended. In such cases consultation with us should take place, regarding testing the

existing expansion joints for their suitability under the altered conditions.

9. The valid working pressure has to be limited with a suitable safety-feature.

laying of pipe:

Installation of the pipes must be done as to ensure a straight run. The fixed points must be arranged in such a way that only those expansion

occur wich correspond to the chosen type of expansion joint.

Only one lateral expansion joint may be mounted between two fixed points.

guide bearings:

As guide bearings, which protect the pipeline from bending in all directions, plain or roller bearings are preferable. A free-swinging suspension

has to be avoided. For pipelines in the open, protection against wind and snow should be provided.

fixed points:

The section of pipe in which the expansion joint is installed must be bounded by fixed points. These must take up both the displacement

forces of the expansion jointed the frictional resistance of the guides must be laid out so that the expansion joint does not bear the weight of

the pipe.

Important: Make sure that the fixed points are really rigid. It must not be possible for the pipeline to move several milimeters

before the system actually becomes rigid.

pre-tensioning:

Lateral expansion joints are designed as standard for taking up movements in both plus and minus directions. With the appropriate installation,

half the movement can be taken up in each direction - e.g. +/- 20 = 40 mm. By pre-tensioning the bellows, the full working range of the

expansion joint can be exploited.

The following parameters are relevant for calculation of the pre-tensioning:

1. Installation dimensions at installation temperature 4. highest actual operating temperature

2. neutral length of the expansion joint without pre-tensioning 5. lowest actual operating temperature

3. total movement of the expansion joint 6. installation temperature

caution: If there are temperatures above 100 C make use of the decreasing factors concerning "pressure" and "movement".

decreasing factors

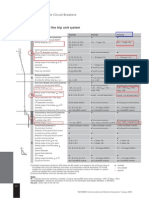

temperature C 50 100 150 200 250 300 350 400

pressure 0,93 0,86 0,84 0,78 0,75 0,68 0,59 0,54

movement 0,98 0,95 0,93 0,91 0,89 0,87 0,86 0,85

2004 Montageanleitung\3 Kompensatoren\31 Metallkompensatoren\31-27engl Lateral Expansion Joint

A- 2135 Kottingneusiedl 112, Tel: (02522)7381 Fax: 7381-10

e-mail: innoflex@innoflex.at Internet: http://www.innoflex.at

Installation and Service Instructions

Lateral - Expansion Joint

Examples of pre-tensioning:

E = H/2 - H x t /t

u d

where t = t - t and t = t - t

u e m d max min

example 1 example 2

t maximum possible temperature of the pipeline + 130C +50C

max

t minimum possible temperature of the pipeline - 10C - 10C

min

t installation temperature +20C +20C

e

H calculated total expansion of the pipeline 216 mm 216 mm

Installation length according to above formula 61 mm 0 mm

pre-tensioning in the direction:

1. Fix the pipeline at both ends

2. Mount the lateral expansion joint in the initial position.

3. Cut out a lenth of pipe corresponding to the required pre-tensioning E, or mount the pipe line such that the seperation of the pipes from

one another corresponds to the required pre-tensioning E.

4. Move the lateral expansion joint into the pre-tensioned positon E. Finally weld the pipes or combine them using a flange.

Only one lateral expansion joint may be mounted between two fixed points. If there are more than one lateral expansion joints please use

intermediate fixed points.

2004 Montageanleitung\3 Kompensatoren\31 Metallkompensatoren\31-28engl Lateral Expansion Joint

You might also like

- BlueSky BlueLock ProcedureDocument2 pagesBlueSky BlueLock ProcedurealtexsteveNo ratings yet

- Dunlop Hoses and Fittings CatalogDocument242 pagesDunlop Hoses and Fittings CatalogBrandon Troc50% (4)

- EMT 140 With ADocument30 pagesEMT 140 With AJoe KaplowitzNo ratings yet

- What Caused The Steam System Accident That Killed Jack SmithDocument12 pagesWhat Caused The Steam System Accident That Killed Jack SmithSven T. Johansson100% (1)

- A750-A761E VacTestLocationsDocument5 pagesA750-A761E VacTestLocationsPedroMecanico100% (5)

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- Type A: Installation, Operation & Maintenance ManualDocument10 pagesType A: Installation, Operation & Maintenance ManualAntonio Luque CruzNo ratings yet

- Introduction - Metallic Expansion Joint PDFDocument16 pagesIntroduction - Metallic Expansion Joint PDFsdmel100% (2)

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Method Statement of Utracon Post TensioningDocument7 pagesMethod Statement of Utracon Post TensioningIrshad Khan0% (1)

- Piping FabricationDocument3 pagesPiping FabricationNa100% (2)

- Control Rods of Rubber Flexible JointDocument2 pagesControl Rods of Rubber Flexible Jointdedikartiwa_dkNo ratings yet

- Post Tensioning SystemDocument13 pagesPost Tensioning SystemAbhijit JadhavNo ratings yet

- 0004 V PDFDocument181 pages0004 V PDFDarling Encina JustinianoNo ratings yet

- Notice Installation Maintenance GE215000aDocument40 pagesNotice Installation Maintenance GE215000amuhammad nazirNo ratings yet

- With Bonnet: ModelDocument10 pagesWith Bonnet: Modeltoto-gmbhNo ratings yet

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNo ratings yet

- Evo Operation & Maintenance v3Document38 pagesEvo Operation & Maintenance v3denzil_1000No ratings yet

- 1 - Operation Instruction SSC15Document6 pages1 - Operation Instruction SSC15sumanta_2008dredifmaNo ratings yet

- Installation Operation Maintenance: HFO Fan CoilsDocument12 pagesInstallation Operation Maintenance: HFO Fan CoilsRd GzNo ratings yet

- BA 2020-06 enDocument9 pagesBA 2020-06 enMahmoudNo ratings yet

- 03 PullersDocument18 pages03 Pullersspsl5No ratings yet

- PTFE Expansion Joint Instructions 1Document1 pagePTFE Expansion Joint Instructions 1DDNo ratings yet

- Rubber Expansion Joints Installation GuideDocument3 pagesRubber Expansion Joints Installation GuideLudi D. LunarNo ratings yet

- 60 000 354 Lateral Expansion Joints - LowRes 02Document20 pages60 000 354 Lateral Expansion Joints - LowRes 02Ishu VohraNo ratings yet

- Manual de Montacarga CatDocument20 pagesManual de Montacarga CatJulio Elias Mayta Ramos71% (7)

- Hot-Tap Saddle: Installation InstructionsDocument2 pagesHot-Tap Saddle: Installation InstructionsSusan Sue Berrospi MerinoNo ratings yet

- Heat Exchanger Tube Bundle PullingDocument4 pagesHeat Exchanger Tube Bundle PullingahamedthousifNo ratings yet

- NorsokDocument4 pagesNorsokNaNo ratings yet

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDocument4 pagesChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyNo ratings yet

- Pre-Setting Manual Balancing Valves CIM 788: Technical InformationDocument7 pagesPre-Setting Manual Balancing Valves CIM 788: Technical InformationblindjaxxNo ratings yet

- Co2 Weld Machine TroubleshootingDocument12 pagesCo2 Weld Machine TroubleshootingHemantNo ratings yet

- Hattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBDocument4 pagesHattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBFareethAbdullahNo ratings yet

- System Design: Compensating For Expansion and ContractionDocument3 pagesSystem Design: Compensating For Expansion and ContractionSaeed RehmanNo ratings yet

- Expansion Loop 1Document3 pagesExpansion Loop 1ArindomNo ratings yet

- Gate Elka PDFDocument36 pagesGate Elka PDFครูแร๊พโย่วNo ratings yet

- NOTICE DE MONTAGE ST (Anglais)Document41 pagesNOTICE DE MONTAGE ST (Anglais)tsogniNo ratings yet

- Inst Manual CeilingFloorDocument16 pagesInst Manual CeilingFloorANDERSON HERRERANo ratings yet

- Air Conditional: Service ManualDocument26 pagesAir Conditional: Service Manualdanielradu27No ratings yet

- PT 355 ManualDocument32 pagesPT 355 ManualhegallarNo ratings yet

- Acson AHU O&M ManualDocument13 pagesAcson AHU O&M ManualKamran AhmedNo ratings yet

- M50 enDocument338 pagesM50 entomwilkinsNo ratings yet

- Clch-svx01b-En 0801 Energy Wheels For T-Series IomDocument28 pagesClch-svx01b-En 0801 Energy Wheels For T-Series Iomh2odavidNo ratings yet

- Methodology For PSC GirdersDocument5 pagesMethodology For PSC GirdersvnilNo ratings yet

- With Bonnet: ModelDocument11 pagesWith Bonnet: ModelSamet BabaNo ratings yet

- Elaflex Rubber Bellows: Safety Notes InstallationDocument2 pagesElaflex Rubber Bellows: Safety Notes Installationdima65No ratings yet

- Elmo 2bh1 Gas Ring Vacuum PumpsDocument11 pagesElmo 2bh1 Gas Ring Vacuum PumpsAlberto Costilla GarciaNo ratings yet

- Tozen Flex - RubberDocument4 pagesTozen Flex - Rubberkingathur26681No ratings yet

- Manual de Detail Drawing PTX Ecosmart Model 1800Document7 pagesManual de Detail Drawing PTX Ecosmart Model 1800francisco velascoNo ratings yet

- Large Grilles Multiple SectionsDocument46 pagesLarge Grilles Multiple SectionsFaquruddin AliNo ratings yet

- Manual GISDocument36 pagesManual GISDanil Pangestu ChandraNo ratings yet

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, IncAbdul RaheemNo ratings yet

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARNo ratings yet

- Methodology For Stressing of PSC Girders (C)Document2 pagesMethodology For Stressing of PSC Girders (C)VB665No ratings yet

- Methodology For Stressing of PSC Girders (C)Document2 pagesMethodology For Stressing of PSC Girders (C)HegdeVenugopalNo ratings yet

- Installation and Commissining of TransformerDocument27 pagesInstallation and Commissining of TransformereliahudNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Thermal BowingDocument8 pagesThermal BowingA. VenugopalNo ratings yet

- Two Stage CausticizingDocument6 pagesTwo Stage CausticizingA. VenugopalNo ratings yet

- End Effects of Elbows Subjected To Moment LoadingsDocument75 pagesEnd Effects of Elbows Subjected To Moment LoadingsA. VenugopalNo ratings yet

- Effect of Dead Load ChemicalsDocument8 pagesEffect of Dead Load ChemicalsA. VenugopalNo ratings yet

- Dynamic Susceptibility Method For Piping VibrationDocument13 pagesDynamic Susceptibility Method For Piping VibrationA. Venugopal100% (1)

- Thermal Efficiency Fired HeaterDocument5 pagesThermal Efficiency Fired Heatermuhammad_asim_10No ratings yet

- Alembic Pharmaceuticals Ltd. (APL) (CMP: Rs.142.20) : Stock Update October 04, 2013Document4 pagesAlembic Pharmaceuticals Ltd. (APL) (CMP: Rs.142.20) : Stock Update October 04, 2013A. VenugopalNo ratings yet

- Radiant Vs Convective Super HeatersDocument2 pagesRadiant Vs Convective Super HeatersA. VenugopalNo ratings yet

- Radiant Vs Convective Super HeatersDocument2 pagesRadiant Vs Convective Super HeatersA. VenugopalNo ratings yet

- PadyamDocument3 pagesPadyamA. VenugopalNo ratings yet

- Staad 4Document37 pagesStaad 4saisssms9116100% (2)

- N R P Book - DR V PatkarDocument250 pagesN R P Book - DR V PatkarAl Fatima Trust100% (1)

- Hypothesis Testing LectureDocument28 pagesHypothesis Testing LectureyogibhNo ratings yet

- E3 BernoulliDocument16 pagesE3 BernoullikishoreNo ratings yet

- Bandpass Microstrip FiltersDocument24 pagesBandpass Microstrip FilterssohelhqNo ratings yet

- Irb 360 Rob0082en - e PDFDocument2 pagesIrb 360 Rob0082en - e PDFImagyred MxNo ratings yet

- Uncertainities in Nuclear Doctrines of India and PakistanDocument10 pagesUncertainities in Nuclear Doctrines of India and Pakistanhammad HassanNo ratings yet

- Number of Groups - IEEE-SBM WIE Codathon Question - Contests - HackerRankDocument2 pagesNumber of Groups - IEEE-SBM WIE Codathon Question - Contests - HackerRankSayali SachinNo ratings yet

- CVF07 Lec07-08Document22 pagesCVF07 Lec07-08api-3709263No ratings yet

- RGB Fan Connection TranslatedDocument30 pagesRGB Fan Connection Translatedjonel.javierNo ratings yet

- 65-Muffle Furnace Calibration CartificateDocument1 page65-Muffle Furnace Calibration CartificateCustomer SupportNo ratings yet

- 16outline CADDocument1 page16outline CADGanesh KumarNo ratings yet

- Freeman AV - Theft ProtectionDocument2 pagesFreeman AV - Theft ProtectionJohn BarnettNo ratings yet

- Pasteurization IIDocument19 pagesPasteurization IIMohammad Ashraf Paul100% (1)

- Application LayerDocument4 pagesApplication LayeredwardoNo ratings yet

- 36 Stragegic ManagementDocument345 pages36 Stragegic ManagementMuhammad Adnan Latif100% (1)

- Tubing Convey PerforationDocument50 pagesTubing Convey PerforationRaed fouadNo ratings yet

- Microsoft Word - Deployment Diagram - An - An IntroductionDocument6 pagesMicrosoft Word - Deployment Diagram - An - An IntroductionChandra MohanNo ratings yet

- TenderDocument RR - Bidr.18 19Document76 pagesTenderDocument RR - Bidr.18 19kmrsg7No ratings yet

- ETU 776 TripDocument1 pageETU 776 TripbhaskarinvuNo ratings yet

- RealSens Pipetech WorkshopDocument45 pagesRealSens Pipetech Workshopalioo44No ratings yet

- Enercat 1Document8 pagesEnercat 1avinavgautam100% (1)

- Chapter 2 Arrayed Waveguide Gratings, Application and DesignDocument18 pagesChapter 2 Arrayed Waveguide Gratings, Application and DesignTrường Trắng TrợnNo ratings yet

- KarthikeyanRatheesh MRDocument1 pageKarthikeyanRatheesh MRRatheeshKRNo ratings yet

- AU Datacentre Structural Ceiling Grid 60CM DatasheetDocument9 pagesAU Datacentre Structural Ceiling Grid 60CM Datasheetguillote_666No ratings yet

- Manual IDS v1.0Document47 pagesManual IDS v1.0André SantanaNo ratings yet

- Energy Storage Systems For Advanced Power Applications: Calvin CollegeDocument41 pagesEnergy Storage Systems For Advanced Power Applications: Calvin College98_kingsukNo ratings yet

- Practical Boat Building For Amateurs ConDocument145 pagesPractical Boat Building For Amateurs ConMiguel OrbeNo ratings yet

- Caleffi Central HeatingDocument1 pageCaleffi Central HeatingSite OfficeNo ratings yet

- Audi A5 2016 CameraDocument8 pagesAudi A5 2016 CameraTung NguyenNo ratings yet