Professional Documents

Culture Documents

July 8, 1930. I - C. GRANT ' 1,770,234

July 8, 1930. I - C. GRANT ' 1,770,234

Uploaded by

Hermano PeixotoCopyright:

Available Formats

You might also like

- Composeal Mobilea Ii Service ManualDocument50 pagesComposeal Mobilea Ii Service ManualL Eru Roraito100% (1)

- Eec 236Document64 pagesEec 236Luise ShadrachNo ratings yet

- Manual de CambiadoresDocument11 pagesManual de CambiadoresMiguel Angel Medina CastellanosNo ratings yet

- User Manual XRF 9900Document221 pagesUser Manual XRF 9900Edgar Adrian100% (9)

- US2059487Document3 pagesUS2059487Jean DelaronciereNo ratings yet

- US2442773Document3 pagesUS2442773Jean DelaronciereNo ratings yet

- United States Patent (191: Taddeo Patent Number: Date of PatentDocument4 pagesUnited States Patent (191: Taddeo Patent Number: Date of PatentseansotoNo ratings yet

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Document3 pagesDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891No ratings yet

- Hot WhizDocument7 pagesHot WhizCristian LópezNo ratings yet

- Noise in Ventilation DuctsDocument9 pagesNoise in Ventilation DuctslkakeanNo ratings yet

- Bergeron On Flute-MakingDocument11 pagesBergeron On Flute-MakingAnton StylesNo ratings yet

- United States Patent (191: (54) Vibrostimulative DeviceDocument5 pagesUnited States Patent (191: (54) Vibrostimulative Devicejalepa_esNo ratings yet

- TEPZZ - 98957B - T: European Patent SpecificationDocument10 pagesTEPZZ - 98957B - T: European Patent Specificationzweisteine777No ratings yet

- US Patent 709,871 by J. A. Clukies - TrapDocument3 pagesUS Patent 709,871 by J. A. Clukies - TrapthoushaltnotNo ratings yet

- C147-Rindel BNAM2021 Flute AcousticsDocument17 pagesC147-Rindel BNAM2021 Flute AcousticsGöksu DirilNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- Spring Reverb PatentDocument4 pagesSpring Reverb PatentklepkojNo ratings yet

- U.S. Patent 4,993,301, Jagged Edge Pick, Issued 1991.Document5 pagesU.S. Patent 4,993,301, Jagged Edge Pick, Issued 1991.Anonymous a7S1qyXNo ratings yet

- Trompa (Horn) : Chasse, Huchet, Trompe de Chasse (Hunting Horn) - Ger. Horn Ventilhorn (Valve Horn) NaturhornDocument18 pagesTrompa (Horn) : Chasse, Huchet, Trompe de Chasse (Hunting Horn) - Ger. Horn Ventilhorn (Valve Horn) NaturhornKin Tat Alfred LeeNo ratings yet

- Noise in Ventilation Ducts Sound in DuctsDocument8 pagesNoise in Ventilation Ducts Sound in DuctsRohitash NitharwalNo ratings yet

- Workshop: Pan Pipes: PurposeDocument5 pagesWorkshop: Pan Pipes: Purposedavo3030No ratings yet

- T9 Loudspeakers: Chapter - 3Document29 pagesT9 Loudspeakers: Chapter - 3lvsaru100% (1)

- US898276Document5 pagesUS898276Jacob LukaNo ratings yet

- Improving The Bass Response of SchroederDocument11 pagesImproving The Bass Response of Schroeder从依云No ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- A Low Frequency Horn of Small DimensionsDocument9 pagesA Low Frequency Horn of Small DimensionsBob BeduneauNo ratings yet

- Frenophone 1923Document1 pageFrenophone 1923raineymj100% (1)

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- European Patent Application: Non-Conventional Use of Cups in CymbalsDocument31 pagesEuropean Patent Application: Non-Conventional Use of Cups in CymbalsJosé Ricardo SilvaNo ratings yet

- Ported Box Enclosures Speaker SystemDocument13 pagesPorted Box Enclosures Speaker SystemSubaru_10150% (2)

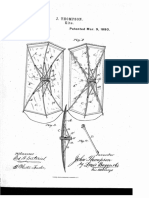

- No. 225,306. Patented Mar. 9, 1880.: J. ThompsonDocument2 pagesNo. 225,306. Patented Mar. 9, 1880.: J. ThompsonEmmanuel Avalos HuarteNo ratings yet

- Fundamntos Del Violonchelo-81-100Document20 pagesFundamntos Del Violonchelo-81-100Alejandro MoraNo ratings yet

- To Silence Centrifugal Blowers: The Use of ResonatorsDocument11 pagesTo Silence Centrifugal Blowers: The Use of ResonatorsmaryaoannaNo ratings yet

- Design and Performance of High Pressure Blowoff SilencersDocument8 pagesDesign and Performance of High Pressure Blowoff SilencersBrent100% (1)

- Exhaust Muffler Design PrinciplesDocument9 pagesExhaust Muffler Design Principlespaulomareze67% (3)

- Sonic Logs: Figure 6 - 1Document4 pagesSonic Logs: Figure 6 - 1Zaher Kammoun NaturalisteNo ratings yet

- Calculation of An Acoustic Phase InverterDocument7 pagesCalculation of An Acoustic Phase InverterAnonymous DjWqKpZ1No ratings yet

- LoudspeakersDocument104 pagesLoudspeakersicko lazoskiNo ratings yet

- Acoustic Properties of Miter Bends: John W. ColtmanDocument4 pagesAcoustic Properties of Miter Bends: John W. ColtmansandbadbahriNo ratings yet

- June 26, 1956 J, - NK ETAL 2,752,594: M # AttorneyjDocument3 pagesJune 26, 1956 J, - NK ETAL 2,752,594: M # Attorneyjdavid19775891No ratings yet

- April 26, 1966 A. Bartolini 3,248,735: Filed Jan. 17, 1962 2 Sheets-Sheet LDocument6 pagesApril 26, 1966 A. Bartolini 3,248,735: Filed Jan. 17, 1962 2 Sheets-Sheet Ldavid19775891No ratings yet

- Turbulent K Model of Ute-Like Musical Instrument Sound ProductionDocument2 pagesTurbulent K Model of Ute-Like Musical Instrument Sound ProductionMohammad Talha AamirNo ratings yet

- Freeman v. AsmusDocument11 pagesFreeman v. AsmusScribd Government DocsNo ratings yet

- Acoustic ImpedanceDocument18 pagesAcoustic ImpedanceMartín AuzaNo ratings yet

- Patente No. 201,488Document3 pagesPatente No. 201,488Maricela De MorenoNo ratings yet

- EP0229675B1Document10 pagesEP0229675B112348No ratings yet

- Head Joint Embouchure Hole and Filtering PDFDocument4 pagesHead Joint Embouchure Hole and Filtering PDFericdanoNo ratings yet

- United States Patent (19) : 73 Assignee: Stokes, Dewey Moore, & George L. Stevens, JRDocument5 pagesUnited States Patent (19) : 73 Assignee: Stokes, Dewey Moore, & George L. Stevens, JRLopez Shian ErvinNo ratings yet

- Ryan v. Hard, 145 U.S. 241 (1892)Document5 pagesRyan v. Hard, 145 U.S. 241 (1892)Scribd Government DocsNo ratings yet

- Geometrical Stiffness of Loudspeaker Cones A FINECone FEM StudyDocument8 pagesGeometrical Stiffness of Loudspeaker Cones A FINECone FEM StudylaserzenNo ratings yet

- Chum/W: April 8, 194?. H. C. HebardDocument3 pagesChum/W: April 8, 194?. H. C. HebarderwerNo ratings yet

- Flute LabDocument8 pagesFlute Lablexard1No ratings yet

- Acoustic Impedance of A BB TrumpetDocument44 pagesAcoustic Impedance of A BB TrumpetEduardo MoguillanskyNo ratings yet

- Infrasonic Helmholtz ResonatorDocument5 pagesInfrasonic Helmholtz ResonatorFranzJNo ratings yet

- NDT of Composite Materials Bond of Wind Turbine Blade Using UT - NDT JournalDocument6 pagesNDT of Composite Materials Bond of Wind Turbine Blade Using UT - NDT Journalpokeboy19No ratings yet

- Snow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Document8 pagesSnow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Scribd Government DocsNo ratings yet

- Changing Register - (Position Levres)Document7 pagesChanging Register - (Position Levres)lilyNo ratings yet

- Hose Hanger 1895Document3 pagesHose Hanger 1895Michael DavisNo ratings yet

- Sound Recording for Films - The History and Development of Sound RecordingFrom EverandSound Recording for Films - The History and Development of Sound RecordingNo ratings yet

- High Energy PMT TPMO0007EDocument76 pagesHigh Energy PMT TPMO0007Eshail2405No ratings yet

- Service Manual MIR-554: Cooled IncubatorDocument104 pagesService Manual MIR-554: Cooled IncubatorАНДРЕЙNo ratings yet

- D June 2014 (R)Document23 pagesD June 2014 (R)Vraj PatelNo ratings yet

- Venus Global Training Manual: WD8122CVD WD8122CVC WD8122CVB WD8122CVWDocument80 pagesVenus Global Training Manual: WD8122CVD WD8122CVC WD8122CVB WD8122CVWCesar Calderon GrNo ratings yet

- Pedesphere Elevated Storage TankDocument2 pagesPedesphere Elevated Storage TankReza KhajeNo ratings yet

- Peh A2-A6 Process Controller Serv Man 0740801006 PDFDocument70 pagesPeh A2-A6 Process Controller Serv Man 0740801006 PDFIgor GrujićNo ratings yet

- MT8Document2 pagesMT8fahsaiiNo ratings yet

- I Crrftsmrn°I: Operator's ManualDocument36 pagesI Crrftsmrn°I: Operator's Manualpaul_swiftNo ratings yet

- 108 Manual 1Document41 pages108 Manual 1Joel BrasilBorgesNo ratings yet

- Performance of Water-in-Glass Evacuated Tube Solar Water HeatersDocument10 pagesPerformance of Water-in-Glass Evacuated Tube Solar Water HeatersJavier Ojeda MuñozNo ratings yet

- BC-2800 - Service Manual V1.1 PDFDocument109 pagesBC-2800 - Service Manual V1.1 PDFMarcelo Ferreira CorgosinhoNo ratings yet

- Code Picture Description Unit Price: Left / Right Hand Operate Dental UnitDocument10 pagesCode Picture Description Unit Price: Left / Right Hand Operate Dental UnitalissNo ratings yet

- VF Display FundamentalsDocument5 pagesVF Display FundamentalsdanyNo ratings yet

- Broncolor - CatalogDocument68 pagesBroncolor - CatalogMie DtsNo ratings yet

- EU - Complete Catalogue Sizes 60-84 GB 201004Document203 pagesEU - Complete Catalogue Sizes 60-84 GB 201004Alexandros RouvasNo ratings yet

- 930 Argon Laser Photocoagultaor Service Manual: DangerDocument56 pages930 Argon Laser Photocoagultaor Service Manual: DangerJohn NanceNo ratings yet

- Travelling Wave Tube WJ 10m28Document8 pagesTravelling Wave Tube WJ 10m289999igiNo ratings yet

- Patente Del Señor Edwin H. Colpitts 1918 US1624537Document5 pagesPatente Del Señor Edwin H. Colpitts 1918 US1624537Adrian GarciaNo ratings yet

- Kennedy 4th EditionDocument14 pagesKennedy 4th EditionJesmar PosadasNo ratings yet

- The Electronic Experimenter's Manual FindlayDocument176 pagesThe Electronic Experimenter's Manual FindlayTEDY-RNo ratings yet

- Granville PhilipsDocument70 pagesGranville PhilipsthegreatbatNo ratings yet

- Gun Tube Rifling Electrochemical Machining Cathode Design and Experiment StudyDocument4 pagesGun Tube Rifling Electrochemical Machining Cathode Design and Experiment Studyy3llowcak3No ratings yet

- Atwood Water Heater Service ManualDocument40 pagesAtwood Water Heater Service ManualJohn LarsonNo ratings yet

- Emerson Battery Selection GuidanceDocument30 pagesEmerson Battery Selection GuidancejluisleonpNo ratings yet

- Streamline: 4 Knob Panel Anodized 491229Document14 pagesStreamline: 4 Knob Panel Anodized 491229AlexNo ratings yet

- RHM30-160 Installation GuideDocument30 pagesRHM30-160 Installation GuideJoseph FranciscoNo ratings yet

July 8, 1930. I - C. GRANT ' 1,770,234

July 8, 1930. I - C. GRANT ' 1,770,234

Uploaded by

Hermano PeixotoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

July 8, 1930. I - C. GRANT ' 1,770,234

July 8, 1930. I - C. GRANT ' 1,770,234

Uploaded by

Hermano PeixotoCopyright:

Available Formats

July 8, 1930.

|_. c. GRANT

APPARATUS FOR REPRODUCING SOUND

'

1,770,234

Filed July 6, 1928

Patented July 8, 1930

1,770,234

UNITED STATES PATENT OFFICE

LEWIS COLIN GRANT, OF HEATON, NEWCASTLE-UPON-TYNE, ENGLAND

APPARATUS FOR REPRODUCING SOUND

Application ?led July 6, 1828, Serial No. 290,783, and in Great Britain July 20, 1927.

This invention relates to apparatus for re

producing sound, for example gramophones,

loud speaking telephones and the like.

large area being required to produce lower

frequency tones satisfactorily. "

In some cases the area of the air column

It is well known that such apparatus as usu within the horn orresonator tube may be re 5 ally made does not give a true reproduction of stricted either by making the horn itself or 55.

the original sound but distorts it by amplify portions thereof of comparatively small di

ing vibrations at certain frequencies more mensions in cross-section or my forming or than those at other frequencies. Generally placing in the horn an internal restriction or

10 lost or but slightly ampli?ed.

it is the low-er frequency vibrations which are orifice. The object of this is to enable the Such lower low frequency energy to set up an increased 60 tones can be reproduced by the employment air pressure within the horn or tube to act

of a horn of great length and large outlet on the ?exible portions and? enhance their ' area but apart from the disadvantagev of effect. 'The desired object of equalizing the am size, such horns suffer from the defect of be 15 ing but slightly responsive to Vibrations of pli?cation of the various frequencies 65 higher frequency. ' throughout the range may be further assured The object of the present invention is the by making use of the well known properties construction ofa horn or resonator tube which of certain materials for re?ecting or absorb is free from such disadvantages, and whilst ing vibrations of various frequencies. Thus _

20 of a size suitable for ordinary commercial use, felt and like substances tend to re?ect low 70

ampli?es much more equally vibrations whose frequency vibrations and absorb those at

frequencies extend over a wide range.

higher frequencies whilst hard polished sur

faceshave the opposite tendency. In a horn

This is accomplished according to the pres

ent invention by so constructing the horn or or resonator tube according to this invention 25 resonator tube that it has a natural peridicity there may be parts made of or lined with 75 different from that of the air column con-y substances having these properties. The member which transmits the vibra ' tained in it. This natural peridicity of the

horn itself is. preferably, though not neces sarily, lower than that of the air column in order to amplify the lower tones which, owing to the natural period of vibration of the comparatively short air column in a horn of normal size, are not reproduced at all.

tions which are ampli?ed bythe improved

horn or resonator tube may be a diaphragm, a reed, or a piston but with the details of 60

construction of this member itself andthe means for setting it in motion, the present

application is not concerned. . In one construction of horn according to One or more of the walls or sides of the horn or resonator tube or a portion thereof. this invention the smallest portion of the a.

may be made responsive to vibrations which neckcadj acent to the diaphragm or like mem are lost or only slightly ampli?ed in the ber .is made of polished metal. Following sound due to the normal vibration of the air this is aportion preferably square in cross section all four made sides ofor a wooden two opposite framing sides with, of either thin 90 40 The resonant portion is preferably made material stretched over the framing by forming it of ?exible or thin material, such ?exible and secured to it. A third portion is of for instance as paper, treated fabric or thin metal lined wholly or partially with baize, wood, its dimensions being such as to give it felt or similar material and this portion _, the desired natural frequency. There may leads to a ?ared mouth which may be of as. u be more than one such portion and they may metal or wood and may, if desired, form part

column. s r '

be arranged to respond to different frequen

cies or hands of frequencies. The horn as awhole increases in cross-sec These ?exible portions provide a large area tional area from the neck onwards in ac

. ii

of an enclosing cabinet. ~

of coupling to the air outside the walls-,such cordance with known practice and its axis 190

1,770,234

may be straight, but it is preferred to shape stood that all the dimensions given are mere the various sections so that the axis is curved ly by way of example.

to enable the horn to occupy less space and to

\Vhat I claim as my invention and desire

be contained easily in a gramophone or loud to secure by Letters Patent is :-

speaking telephone cabinet.

In the accompanying drawings,

resonator tube comprising an inlet, a ?ared 70

1. In apparatus for reproducing sound, a

Figure 1 is an elevation partly in section mouth, a portion made of ?exible material of one construction of horn according to this between said inlet and said ?ared mouth, and a constriction between said portion made of invention, flexible material and said mouth. Figure 2 is a cross-section on the line 2-2 10 2. In apparatus for reproducing sound, a of Figure 1, a

15

mouth, a portion made of ?exible material between said inlet and said ?ared mouth, a vention, and Figure 4: is a cross-section on the line 44 constriction between said portion made of ?exible material and said mouth, and another of Figure 3. With reference first to Figures 1 and 2, A portion lined with material to absorb some

struction of horn also according to this in

is the small or inlet end of the horn which of the higher frequency vibrations.

Figure 3 is an elevation of another con

resonator tube comprising an inlet, a ?ared

80

20

or like member. It is made of polished metal name to this speci?cation.

receives the vibrations from the diaphragm

In testimony whereof I have signed my

and leads into the adjoining section two sides

B of which are made of wood and the other two sides B1 of fabric, paper or other ?ex

ible material to furnish a large area of cou

25

LEIVIS COLIN GRANT.

pling to the air outside.

From this ?ex

90

ible walled section a curved metal section C leads to a ?ared mouth D which may be of

wood and is preferably rectangular in cross section. The ori?ce of this mouth section 80 may constitute the open front of the contain ing cabinet and its dimensions may be, for

instance, 84 inches high and 27 inches wide. The horn is of gradually increasing cross

sectional area from the inlet to the mouth

35 and the rate of increase is preferably such as

100

to follow the well known logarithmic or ex

ponential law.

As indicated in Figure 1 the curved sec

tion C may be lined as at C1 with baize or like material which tends to absorb some of

the higher frequency vibrations.

The horn illustrated in Figures 3 and 4: comprises a metal inlet sect-ion A1, an interme diate section B2 with all four walls B3 of

105

?exible material (Figure 4) and a ?ared mouth section D1. The dotted lines at E in

Figure 3 indicate a constriction in the por

110

tion of the mouth section where it joins the intermediate section B2. Such a constriction

50 may be provided to increase the air pressure .

115

acting on the ?exible walls B3 and thus en

hance the effect of the low frequency vibra~ tions. This Gi'fQC't may also be produced by

55 relatively to the rest of the horn as, for in slance, is indicated in dotted lines in Figure

qt. The curved portion of the inlet section

it in Figure is shown as lined as at C2 with

' baize or like material to absorb some of the

enlarging the area of the ?exible walls B3

120

higher frequency vibrations.

The orifice of the mouth section I)1 of the horn shown in Figure 3 may be say 15 to 18 inches square and the other dimen sions in proportion, but it is to be under

130

You might also like

- Composeal Mobilea Ii Service ManualDocument50 pagesComposeal Mobilea Ii Service ManualL Eru Roraito100% (1)

- Eec 236Document64 pagesEec 236Luise ShadrachNo ratings yet

- Manual de CambiadoresDocument11 pagesManual de CambiadoresMiguel Angel Medina CastellanosNo ratings yet

- User Manual XRF 9900Document221 pagesUser Manual XRF 9900Edgar Adrian100% (9)

- US2059487Document3 pagesUS2059487Jean DelaronciereNo ratings yet

- US2442773Document3 pagesUS2442773Jean DelaronciereNo ratings yet

- United States Patent (191: Taddeo Patent Number: Date of PatentDocument4 pagesUnited States Patent (191: Taddeo Patent Number: Date of PatentseansotoNo ratings yet

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Document3 pagesDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891No ratings yet

- Hot WhizDocument7 pagesHot WhizCristian LópezNo ratings yet

- Noise in Ventilation DuctsDocument9 pagesNoise in Ventilation DuctslkakeanNo ratings yet

- Bergeron On Flute-MakingDocument11 pagesBergeron On Flute-MakingAnton StylesNo ratings yet

- United States Patent (191: (54) Vibrostimulative DeviceDocument5 pagesUnited States Patent (191: (54) Vibrostimulative Devicejalepa_esNo ratings yet

- TEPZZ - 98957B - T: European Patent SpecificationDocument10 pagesTEPZZ - 98957B - T: European Patent Specificationzweisteine777No ratings yet

- US Patent 709,871 by J. A. Clukies - TrapDocument3 pagesUS Patent 709,871 by J. A. Clukies - TrapthoushaltnotNo ratings yet

- C147-Rindel BNAM2021 Flute AcousticsDocument17 pagesC147-Rindel BNAM2021 Flute AcousticsGöksu DirilNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- Spring Reverb PatentDocument4 pagesSpring Reverb PatentklepkojNo ratings yet

- U.S. Patent 4,993,301, Jagged Edge Pick, Issued 1991.Document5 pagesU.S. Patent 4,993,301, Jagged Edge Pick, Issued 1991.Anonymous a7S1qyXNo ratings yet

- Trompa (Horn) : Chasse, Huchet, Trompe de Chasse (Hunting Horn) - Ger. Horn Ventilhorn (Valve Horn) NaturhornDocument18 pagesTrompa (Horn) : Chasse, Huchet, Trompe de Chasse (Hunting Horn) - Ger. Horn Ventilhorn (Valve Horn) NaturhornKin Tat Alfred LeeNo ratings yet

- Noise in Ventilation Ducts Sound in DuctsDocument8 pagesNoise in Ventilation Ducts Sound in DuctsRohitash NitharwalNo ratings yet

- Workshop: Pan Pipes: PurposeDocument5 pagesWorkshop: Pan Pipes: Purposedavo3030No ratings yet

- T9 Loudspeakers: Chapter - 3Document29 pagesT9 Loudspeakers: Chapter - 3lvsaru100% (1)

- US898276Document5 pagesUS898276Jacob LukaNo ratings yet

- Improving The Bass Response of SchroederDocument11 pagesImproving The Bass Response of Schroeder从依云No ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- A Low Frequency Horn of Small DimensionsDocument9 pagesA Low Frequency Horn of Small DimensionsBob BeduneauNo ratings yet

- Frenophone 1923Document1 pageFrenophone 1923raineymj100% (1)

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- European Patent Application: Non-Conventional Use of Cups in CymbalsDocument31 pagesEuropean Patent Application: Non-Conventional Use of Cups in CymbalsJosé Ricardo SilvaNo ratings yet

- Ported Box Enclosures Speaker SystemDocument13 pagesPorted Box Enclosures Speaker SystemSubaru_10150% (2)

- No. 225,306. Patented Mar. 9, 1880.: J. ThompsonDocument2 pagesNo. 225,306. Patented Mar. 9, 1880.: J. ThompsonEmmanuel Avalos HuarteNo ratings yet

- Fundamntos Del Violonchelo-81-100Document20 pagesFundamntos Del Violonchelo-81-100Alejandro MoraNo ratings yet

- To Silence Centrifugal Blowers: The Use of ResonatorsDocument11 pagesTo Silence Centrifugal Blowers: The Use of ResonatorsmaryaoannaNo ratings yet

- Design and Performance of High Pressure Blowoff SilencersDocument8 pagesDesign and Performance of High Pressure Blowoff SilencersBrent100% (1)

- Exhaust Muffler Design PrinciplesDocument9 pagesExhaust Muffler Design Principlespaulomareze67% (3)

- Sonic Logs: Figure 6 - 1Document4 pagesSonic Logs: Figure 6 - 1Zaher Kammoun NaturalisteNo ratings yet

- Calculation of An Acoustic Phase InverterDocument7 pagesCalculation of An Acoustic Phase InverterAnonymous DjWqKpZ1No ratings yet

- LoudspeakersDocument104 pagesLoudspeakersicko lazoskiNo ratings yet

- Acoustic Properties of Miter Bends: John W. ColtmanDocument4 pagesAcoustic Properties of Miter Bends: John W. ColtmansandbadbahriNo ratings yet

- June 26, 1956 J, - NK ETAL 2,752,594: M # AttorneyjDocument3 pagesJune 26, 1956 J, - NK ETAL 2,752,594: M # Attorneyjdavid19775891No ratings yet

- April 26, 1966 A. Bartolini 3,248,735: Filed Jan. 17, 1962 2 Sheets-Sheet LDocument6 pagesApril 26, 1966 A. Bartolini 3,248,735: Filed Jan. 17, 1962 2 Sheets-Sheet Ldavid19775891No ratings yet

- Turbulent K Model of Ute-Like Musical Instrument Sound ProductionDocument2 pagesTurbulent K Model of Ute-Like Musical Instrument Sound ProductionMohammad Talha AamirNo ratings yet

- Freeman v. AsmusDocument11 pagesFreeman v. AsmusScribd Government DocsNo ratings yet

- Acoustic ImpedanceDocument18 pagesAcoustic ImpedanceMartín AuzaNo ratings yet

- Patente No. 201,488Document3 pagesPatente No. 201,488Maricela De MorenoNo ratings yet

- EP0229675B1Document10 pagesEP0229675B112348No ratings yet

- Head Joint Embouchure Hole and Filtering PDFDocument4 pagesHead Joint Embouchure Hole and Filtering PDFericdanoNo ratings yet

- United States Patent (19) : 73 Assignee: Stokes, Dewey Moore, & George L. Stevens, JRDocument5 pagesUnited States Patent (19) : 73 Assignee: Stokes, Dewey Moore, & George L. Stevens, JRLopez Shian ErvinNo ratings yet

- Ryan v. Hard, 145 U.S. 241 (1892)Document5 pagesRyan v. Hard, 145 U.S. 241 (1892)Scribd Government DocsNo ratings yet

- Geometrical Stiffness of Loudspeaker Cones A FINECone FEM StudyDocument8 pagesGeometrical Stiffness of Loudspeaker Cones A FINECone FEM StudylaserzenNo ratings yet

- Chum/W: April 8, 194?. H. C. HebardDocument3 pagesChum/W: April 8, 194?. H. C. HebarderwerNo ratings yet

- Flute LabDocument8 pagesFlute Lablexard1No ratings yet

- Acoustic Impedance of A BB TrumpetDocument44 pagesAcoustic Impedance of A BB TrumpetEduardo MoguillanskyNo ratings yet

- Infrasonic Helmholtz ResonatorDocument5 pagesInfrasonic Helmholtz ResonatorFranzJNo ratings yet

- NDT of Composite Materials Bond of Wind Turbine Blade Using UT - NDT JournalDocument6 pagesNDT of Composite Materials Bond of Wind Turbine Blade Using UT - NDT Journalpokeboy19No ratings yet

- Snow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Document8 pagesSnow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Scribd Government DocsNo ratings yet

- Changing Register - (Position Levres)Document7 pagesChanging Register - (Position Levres)lilyNo ratings yet

- Hose Hanger 1895Document3 pagesHose Hanger 1895Michael DavisNo ratings yet

- Sound Recording for Films - The History and Development of Sound RecordingFrom EverandSound Recording for Films - The History and Development of Sound RecordingNo ratings yet

- High Energy PMT TPMO0007EDocument76 pagesHigh Energy PMT TPMO0007Eshail2405No ratings yet

- Service Manual MIR-554: Cooled IncubatorDocument104 pagesService Manual MIR-554: Cooled IncubatorАНДРЕЙNo ratings yet

- D June 2014 (R)Document23 pagesD June 2014 (R)Vraj PatelNo ratings yet

- Venus Global Training Manual: WD8122CVD WD8122CVC WD8122CVB WD8122CVWDocument80 pagesVenus Global Training Manual: WD8122CVD WD8122CVC WD8122CVB WD8122CVWCesar Calderon GrNo ratings yet

- Pedesphere Elevated Storage TankDocument2 pagesPedesphere Elevated Storage TankReza KhajeNo ratings yet

- Peh A2-A6 Process Controller Serv Man 0740801006 PDFDocument70 pagesPeh A2-A6 Process Controller Serv Man 0740801006 PDFIgor GrujićNo ratings yet

- MT8Document2 pagesMT8fahsaiiNo ratings yet

- I Crrftsmrn°I: Operator's ManualDocument36 pagesI Crrftsmrn°I: Operator's Manualpaul_swiftNo ratings yet

- 108 Manual 1Document41 pages108 Manual 1Joel BrasilBorgesNo ratings yet

- Performance of Water-in-Glass Evacuated Tube Solar Water HeatersDocument10 pagesPerformance of Water-in-Glass Evacuated Tube Solar Water HeatersJavier Ojeda MuñozNo ratings yet

- BC-2800 - Service Manual V1.1 PDFDocument109 pagesBC-2800 - Service Manual V1.1 PDFMarcelo Ferreira CorgosinhoNo ratings yet

- Code Picture Description Unit Price: Left / Right Hand Operate Dental UnitDocument10 pagesCode Picture Description Unit Price: Left / Right Hand Operate Dental UnitalissNo ratings yet

- VF Display FundamentalsDocument5 pagesVF Display FundamentalsdanyNo ratings yet

- Broncolor - CatalogDocument68 pagesBroncolor - CatalogMie DtsNo ratings yet

- EU - Complete Catalogue Sizes 60-84 GB 201004Document203 pagesEU - Complete Catalogue Sizes 60-84 GB 201004Alexandros RouvasNo ratings yet

- 930 Argon Laser Photocoagultaor Service Manual: DangerDocument56 pages930 Argon Laser Photocoagultaor Service Manual: DangerJohn NanceNo ratings yet

- Travelling Wave Tube WJ 10m28Document8 pagesTravelling Wave Tube WJ 10m289999igiNo ratings yet

- Patente Del Señor Edwin H. Colpitts 1918 US1624537Document5 pagesPatente Del Señor Edwin H. Colpitts 1918 US1624537Adrian GarciaNo ratings yet

- Kennedy 4th EditionDocument14 pagesKennedy 4th EditionJesmar PosadasNo ratings yet

- The Electronic Experimenter's Manual FindlayDocument176 pagesThe Electronic Experimenter's Manual FindlayTEDY-RNo ratings yet

- Granville PhilipsDocument70 pagesGranville PhilipsthegreatbatNo ratings yet

- Gun Tube Rifling Electrochemical Machining Cathode Design and Experiment StudyDocument4 pagesGun Tube Rifling Electrochemical Machining Cathode Design and Experiment Studyy3llowcak3No ratings yet

- Atwood Water Heater Service ManualDocument40 pagesAtwood Water Heater Service ManualJohn LarsonNo ratings yet

- Emerson Battery Selection GuidanceDocument30 pagesEmerson Battery Selection GuidancejluisleonpNo ratings yet

- Streamline: 4 Knob Panel Anodized 491229Document14 pagesStreamline: 4 Knob Panel Anodized 491229AlexNo ratings yet

- RHM30-160 Installation GuideDocument30 pagesRHM30-160 Installation GuideJoseph FranciscoNo ratings yet