Professional Documents

Culture Documents

The Demolition Contractor Is A

The Demolition Contractor Is A

Uploaded by

jayadushCopyright:

Available Formats

You might also like

- EXAM Section A Closed Book 2007Document9 pagesEXAM Section A Closed Book 2007Krispin Fong94% (16)

- Demolition of Structure Using Implosion TechnologyDocument17 pagesDemolition of Structure Using Implosion TechnologySreerag Dileep100% (1)

- Demolition of BuildingsDocument18 pagesDemolition of BuildingsJamilaBeevi94% (16)

- Cable Tray InstallationDocument10 pagesCable Tray Installationalrwin_b2yNo ratings yet

- Four Elevator COntrollerDocument26 pagesFour Elevator COntrollerMehul Garg100% (1)

- CASE STUDY of HIGH-RISE BUILDINGDocument23 pagesCASE STUDY of HIGH-RISE BUILDINGJamie Anne Mendi75% (4)

- Jet A1 Fueling SystemDocument54 pagesJet A1 Fueling SystemMaaz Junaidi67% (3)

- Demolition of StructuresDocument28 pagesDemolition of StructuresSharath WankdothNo ratings yet

- Demolition of BuildingDocument13 pagesDemolition of BuildingAmeer pashaNo ratings yet

- Controlled Demolition: Under The Guidance of Associate Prof. Dr. K. KumarDocument24 pagesControlled Demolition: Under The Guidance of Associate Prof. Dr. K. KumarSyed YunussNo ratings yet

- Demolition of A BuildingDocument9 pagesDemolition of A BuildingMark James CalumpangNo ratings yet

- Orbital Light-Rail: Threats To From TheDocument9 pagesOrbital Light-Rail: Threats To From TheLaura MeyerNo ratings yet

- QTN 23b - Demolition of Affected StructuresDocument7 pagesQTN 23b - Demolition of Affected StructuresPrabhat Kumar SinghNo ratings yet

- Demolition FullDocument18 pagesDemolition FullnanamallowNo ratings yet

- Detonation of Buildings (Explosive Demolition of Building) : Prepared By: Sagar Shah Faculty Guide: Sonal ThakkarDocument26 pagesDetonation of Buildings (Explosive Demolition of Building) : Prepared By: Sagar Shah Faculty Guide: Sonal ThakkarSagar D ShahNo ratings yet

- Controlled Demolition of BuildingsDocument27 pagesControlled Demolition of BuildingsNigam MeherNo ratings yet

- Icbp PDFDocument22 pagesIcbp PDFVarunNo ratings yet

- Demolition Techniques and Case StudiesDocument24 pagesDemolition Techniques and Case StudiesVenkat NitheshNo ratings yet

- Demolition of Building PresentationDocument24 pagesDemolition of Building Presentationವಿಶ್ವನಾಥ್ ಸಿ ಎಸ್No ratings yet

- Demolition by Controlled BlastingDocument7 pagesDemolition by Controlled BlastingEr Manak Chand SainiNo ratings yet

- Demolition of StructuresDocument20 pagesDemolition of Structureshimanshu100% (1)

- Proceedings PDFDocument139 pagesProceedings PDFR RathiNo ratings yet

- History of WasteDocument6 pagesHistory of Wastejans_13No ratings yet

- Chapter 4 Demolition WorksDocument25 pagesChapter 4 Demolition WorksAmir AlistyNo ratings yet

- Demolition of BuildingDocument22 pagesDemolition of Buildingpooja patil100% (1)

- Stuctural Design of Interlocking Concrete PavementsDocument18 pagesStuctural Design of Interlocking Concrete Pavementsantonio_poma_3No ratings yet

- Fremen - Explosive Demolitions HandbookDocument30 pagesFremen - Explosive Demolitions HandbookJoaquin RiccitelliNo ratings yet

- Week 11 - Demolition PDFDocument34 pagesWeek 11 - Demolition PDFMark TruongNo ratings yet

- Method Statement For Demolition WorksDocument1 pageMethod Statement For Demolition WorksYoven NadaNo ratings yet

- Precast Construction SeminarDocument30 pagesPrecast Construction SeminarNzar HamaNo ratings yet

- Presentation 1 Demolition Work (Edited)Document17 pagesPresentation 1 Demolition Work (Edited)imah4152100% (2)

- Demolition of BuildingsDocument20 pagesDemolition of Buildingssvivek75% (4)

- 19VE1A0114 Seminar Demolition of BuildingsDocument21 pages19VE1A0114 Seminar Demolition of BuildingsbhavaniNo ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- Lo 2 - DemolitionDocument29 pagesLo 2 - DemolitionEng Stephen ArendeNo ratings yet

- Demolition Works: L/O/G/ODocument29 pagesDemolition Works: L/O/G/OZahin SamsudinNo ratings yet

- Demolition of BuildingDocument30 pagesDemolition of BuildingSahil Gandhi100% (1)

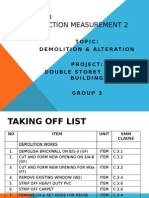

- SBEC 2823 Construction Measurement 2: Topic: Demolition & Alteration Project: Double Storey Office Building Group 3Document38 pagesSBEC 2823 Construction Measurement 2: Topic: Demolition & Alteration Project: Double Storey Office Building Group 3Amalina YaniNo ratings yet

- Gabon / Libreville Aman Resorts Ngombe ProjectDocument11 pagesGabon / Libreville Aman Resorts Ngombe ProjectBogdan BungardiNo ratings yet

- Implosion NewDocument44 pagesImplosion NewRamesh KannanNo ratings yet

- Demolition of Building 2Document30 pagesDemolition of Building 2pramod Kumar sahaniNo ratings yet

- Checklist - DemolitionDocument2 pagesChecklist - DemolitionRommel Carlo Largado100% (1)

- 1demolition of Building PDFDocument9 pages1demolition of Building PDFAbhishek100% (1)

- Demolition Safety: Sample Written Program For Your Company ForDocument8 pagesDemolition Safety: Sample Written Program For Your Company ForVivek REDDY G YNo ratings yet

- Kerbs, Footways and Paved AreasDocument4 pagesKerbs, Footways and Paved AreasNoorul Mufas MnNo ratings yet

- Georgina Chikwati - Demolition of Construction Works Assignment - Bqs3Document9 pagesGeorgina Chikwati - Demolition of Construction Works Assignment - Bqs3Georgina ChikwatiNo ratings yet

- Technical Advisory For DemolitionDocument16 pagesTechnical Advisory For DemolitionLiew Yen ChingNo ratings yet

- Day 3 - Demolition SafetyDocument41 pagesDay 3 - Demolition Safetychum onaNo ratings yet

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- Building Construction EditDocument26 pagesBuilding Construction EditSami Zama100% (1)

- Work Method StatementDocument2 pagesWork Method StatementSetyawanNo ratings yet

- Demolition of Construction WorksDocument8 pagesDemolition of Construction WorksGeorgina ChikwatiNo ratings yet

- Building A Sustainable Future: Circular Economy and Waste Management in ConstructionDocument13 pagesBuilding A Sustainable Future: Circular Economy and Waste Management in ConstructionMakanjuola SinaNo ratings yet

- Architecturally Exposed Structural Steel PDFDocument8 pagesArchitecturally Exposed Structural Steel PDFJagatheesh RadhakrishnanNo ratings yet

- Structural Steel Reuse in ConstructionDocument12 pagesStructural Steel Reuse in ConstructionMuhammad MurtazaNo ratings yet

- Gvccv-Mathod Statement of Brick Wall WorkDocument17 pagesGvccv-Mathod Statement of Brick Wall WorkMengthuyNo ratings yet

- History of RecycledDocument64 pagesHistory of RecycledKimNo ratings yet

- Demolition 0407Document115 pagesDemolition 0407MelhinoNo ratings yet

- Construction Practice 1 For TechnicianDocument24 pagesConstruction Practice 1 For TechnicianMichael_Mensah_2238No ratings yet

- DemolitionDocument38 pagesDemolitionjayadush100% (1)

- ProfileDocument24 pagesProfilebj velNo ratings yet

- Seminar Report On Demolition 2015-2016Document31 pagesSeminar Report On Demolition 2015-2016Archana Mol100% (1)

- Interlocking Concrete Paver SpecsDocument6 pagesInterlocking Concrete Paver Specscarolinetrippin100% (1)

- Stage 1 Demolition Method StatementDocument27 pagesStage 1 Demolition Method StatementPaul OchiengNo ratings yet

- 6538 PDFDocument5 pages6538 PDFRam Dela CruzNo ratings yet

- A Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperDocument2 pagesA Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperMohammed Abdul RazzakNo ratings yet

- Code of Professional Ethics For EeDocument12 pagesCode of Professional Ethics For EeatoyskeeNo ratings yet

- The Project TeamDocument3 pagesThe Project Teamjemisha charlesNo ratings yet

- Daa Lab Manual 2018Document58 pagesDaa Lab Manual 2018Srinjoy dasNo ratings yet

- Presentation - IKEA Nov 2013 - Engineering After DiplomaDocument23 pagesPresentation - IKEA Nov 2013 - Engineering After DiplomaLila Poonawalla FoundationNo ratings yet

- IRC 112 - Oct 2013 Amendments PDFDocument3 pagesIRC 112 - Oct 2013 Amendments PDFSiva Prasad MamillapalliNo ratings yet

- Chapter-1 Introduction To PLC: Types of PLC Avialable in MarketDocument50 pagesChapter-1 Introduction To PLC: Types of PLC Avialable in MarketSarikaNo ratings yet

- Basics of Limit State Method LSM 1 RCCDocument12 pagesBasics of Limit State Method LSM 1 RCCDrGanesh KameNo ratings yet

- Silt Gravel Removal GateDocument16 pagesSilt Gravel Removal GateRaja SinghNo ratings yet

- Polaris ResumeDocument1 pagePolaris Resumeapi-302628110No ratings yet

- Internship Report 1 PDFDocument32 pagesInternship Report 1 PDFJaydev BhadeliyaNo ratings yet

- JR - MEP Engineer - CVDocument1 pageJR - MEP Engineer - CVsayed ananNo ratings yet

- Steel Angles D 1322Document2 pagesSteel Angles D 1322Shanmuga SundaramNo ratings yet

- 13 IvecoDocument103 pages13 Ivecovladimir_p80No ratings yet

- Global SchoolDocument15 pagesGlobal SchoolMaria C.No ratings yet

- Ansi Asabe Ad4254-11-2010 (R2012)Document20 pagesAnsi Asabe Ad4254-11-2010 (R2012)StephanNo ratings yet

- NFC Institute of Engineering & Technology: WWW - Nfciet.edu - PK Nfciet@nfcet - Edu.pkDocument1 pageNFC Institute of Engineering & Technology: WWW - Nfciet.edu - PK Nfciet@nfcet - Edu.pkhammad ghaffarNo ratings yet

- Documentation Report: Project: STG & Boiler Batubara Project Date: Location: Item InspectionDocument34 pagesDocumentation Report: Project: STG & Boiler Batubara Project Date: Location: Item InspectionBayu RahmanNo ratings yet

- Aerospace Engineer Sample ResumeDocument1 pageAerospace Engineer Sample ResumeKiran Kumar100% (1)

- Graduate BulletinDocument470 pagesGraduate BulletinaccesskamranNo ratings yet

- Fatigue Analysis On Crank ShaftDocument1 pageFatigue Analysis On Crank ShaftPramit Kumar SenapatiNo ratings yet

- AFT Arrow 9 Quickstart MetricDocument126 pagesAFT Arrow 9 Quickstart MetricUdaya kumar SubramaniNo ratings yet

- 7-Equipment Damage Curves CapacitorsDocument2 pages7-Equipment Damage Curves CapacitorsMoulay m'hammed LOUKILINo ratings yet

- Awais Ahmad: Research Assistant Position, Energy and Environment Lab, City University of Hong KongDocument4 pagesAwais Ahmad: Research Assistant Position, Energy and Environment Lab, City University of Hong KongMuhammadAsimNo ratings yet

- Mil STD 100e Notice 2Document58 pagesMil STD 100e Notice 2logonwheelerNo ratings yet

The Demolition Contractor Is A

The Demolition Contractor Is A

Uploaded by

jayadushOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Demolition Contractor Is A

The Demolition Contractor Is A

Uploaded by

jayadushCopyright:

Available Formats

The demolition contractor is a specialist in wrecking or destroying buildings safely.

With careful planning, he can make the job look easy, and by selecting the right demolition method he also makes the job profitable. Most contractors, even though not demolition specialists, will have to demolish portions of stru c t u re s as part of their repair and remodeling business. Knowing which method or combination of methods to use for demolition of reinforced or prestressed concrete stru c t u re s is essential for a safe and profitable job. Because of the difficulty of estimating the costs of demolition of c o n c re t e, the general contractor is usually well advised to engage the services of a competent demolition contractor when his job re!uires a significant amount of demolition. "election of the best method or methods depends partly on time and money available and on the surrounding environment. The following discussion of methods used is based primarily on my own e#perience, but $ have also relied upon the e#perience of others and data provided by manufacturers of demolition e!uipment. Ball and crane

This is one of the oldest and most commonly used methods for building demolition. % crane uses a wrecking ball, weighing up to &',()) pounds, which is either dropped onto or swung into the element to be demolished *+igure &,. -oncrete members can be broken into small pieces, but secondary cutting of reinforcing may be necessary. The ball and crane method of demolition has certain disadvantages. / it demands a great deal of skill from the crane operator / the height of a building that can be demolished is limited by crane si0e and working room1 howe ve r, buildings as high as 2) stories have been demolished / the breakup process can cause considerable dust, vibration and noise which may be objectionable. The 3ational %ssociation of 4emolition -ontractors provides guidance for the safe operation of a crane using a wrecking ball. The ball weight should not e#ceed () percent of the safe load of the boom at ma#imum length or angle of operation, or 2( percent of the nominal breaking strength of the supporting line, whichever is less. The demolition ball should be attached to the load line with a swivel type connection to prevent twisting of the load

line. Taglines may help control the ball during the swinging operation. "moothness in controlling the swing of the ball is important1 missing the target may tip or overload the crane and a wild swing back may cause the ball to hit the boom. The safety ha0ards of cranes operating near electrical wires are well known. The absolute limit of approach for a crane boom near a power line is &) feet. % signalman must be assigned to warn the operator when he is nearing the limit of approach. 4ismantling "elective or complete demolition of concrete structures is possible by cutting elements and then removing them with a crane. The cutting process may be by sawing, water jetting or thermic lance. Because the surface of the cut concrete is smooth and relatively regular, these methods have particular application when the objective is partial demolition, for instance in the creation of openings in walls and slabs. $n the case of the lance, howe ve r, e#cessive heat causes some deterioration of the concrete adjacent to the 4emolition of concrete structures Bringing it downsafely B5 6%7 T. 6849$3"

:;<"$4<3T 6849$3" = ->M:%35, $3-. 4<M>7$T$>3 ":<-$%7$"T" %T7%3T%, 9<>;9$% +igure &. Wrecking balls weighing as much as &',()) pounds can be used to demolish structures as high as 2) stories. -ontrolling the swing of the ball is important1 missing the target may tip or overload the crane and a mild swing back may cause the ball to hit the crane boom. cut. Whatever the method used, the cutting process isolates a particular element so that it may be lowered to the ground for further breakup or transportation to the dump site. Most objectives of controlled demolition can be achieved using standard concrete sawing techni!ues and e!uipment, including diamond tipped blades to cut reinforcement. "peciali0ed saws may be developed to handle unusual projects *+igure 2,. %lthough sawing produces negligible vibration and dust, it may be noisy and re!uire e!uipment to supply and clean up the large !uantity of water used to cool the saw. -oncrete up to ' feet thick may be cut with an abrasive water jet. The heart of the abrasive water jet cutting system is a small no00le in which water is pre s s u ri 0ed up to

?),))) psi and combined with solid a b ra s i ves to create a high velocity cutting jet. -utting with a water jet minimi0es dust and eliminates vibration and fire ha0ards. %n abrasive and water catching system is re!uired to clean up during the jetting process. The water jet can be used not only for cutting straight lines but also contours, a useful feature for cutting access manholes. "traight line cut rates on the order of & inch penetration per minute are possible for reinforced concrete slabs. % thermic lance is created by packing a seamless mild steel tube with low carbon rods and passing o#ygen through the tube. >nce the lance is ignited, fusion will take place creating a temperature between @))) and A))) degrees + which is capable of burning through concrete up to &2 feet thick. % 2 inch diameter hori0ontal hole can be bored in concrete at a typical rate of 2 to ' inches per minute. The presence of reinforcing steel is an advantage for thermic demolition, since this provides e#tra steel that can be o#idi0ed to melt the conc re t e. Work may also be facilitated by following the path of re i n f o rc ement. While this method eliminates vibration and dust problems, it creates

other ha0ards associated with smoke and fire danger. Whether sawing, jetting or lancing is used to dismantle the structure or its components, each element must be safely lowered to the ground. 7ifting hooks or special rigging should be ade!uately secured to dismantled members. $f e#isting lifting hooks or loops are found to be in good condition then they should be used. :neumatic and hydraulic breakers % common piece of e!uipment used for demolishing bridge decks, foundations and pavements is a hydraulically or pneumatically operated, boom mounted breaker. %lthough small hand operated breakers are still used, in many cases they have been replaced by machine mounted breakers capable of d e l i ve ring &)) to 2),))) footpounds of energy at a fre!uency of ')) to B)) blows per minute *+igure ',. The advantages of a machinemounted breaker may include a telescoping boom for easy reach and maneuve ra b i l i t y, remote control operation and underwater demolition capabilities. "ome of the smaller remote controlled machines can be lifted through window openings and used inside a building

to demolish floors and walls. :roductivity can vary greatly depending on hammer si0e, type of concrete, amount of reinforcing and working conditions. +or unreinforced concrete, breakout rates may be as low as &) cubic yards to as high as &))) cubic yards per B hour day. Breakout rates for reinforced concrete *larger hammer re!uired for reinforced versus unreinforced concrete, vary from &' to A() cubic yards per B hour day. The 4odge :ublic Works and -ost 9uide indicates a productivity of &2 cubic yards per B hour day using handheld breakers *jackhammers,. Machine mounted breakers are usually noisy, generate dust and vibration and may be restricted in areas of limited work space. To keep vibrations at a safe level, one -orps of <ngineers office places a &() footpound limit on the hammer energy +igure 2. % special A2 inch diameter saw was manufactured to dismantle the '' inch thick beams of this cantilevered skywalk. <ach dismantled segment weighs A tons. +igure '. % boom mounted remotecontrolled hydraulic breaker reduces the slab section prior to lifting with a crane. The slab section has been sawn free on two sides while it rested

on shoring. allowed for concrete removal on its locks and dams. :ressure bursting This method of demolition can be classified into two categories, mechanical and chemical bursting. :ressure bursting with mechanical tools is fairly ine#pensive, !uiet, and doesnCt cause vibration1 but the drilling of holes for the insertion of the splitter does produce noise and vibration. This can be overcome by coring the holes with a diamondtipped coring machine, but at far greater cost. Mechanical bursting is done with a hand held splitting machine that operates on hydraulic pressure provided by a small motor. The splitting end of the device is a steel wedge or plug positioned between two hard metal shims called feathers. 6oles ranging from & to 2 inches in diameter are drilled into the concrete. The wedge is inserted into the hole and the subse!uent hydraulic pressure forces the wedge against the two feathers. +orces as high as @&) tons can be e#erted against the feathers, which e#pand and force the concrete to split. -ontrolling the crack direction and the movement of the demolished mass may be difficult using

mechanical bursting tools. %dditionally, when reinforced concrete is being split, it is almost always necessary to utili0e a hydraulic or pneumatic breaker, either hand held or machine mounted to e#pose the reinforcing bars for cutting. +igure @ shows how to use a splitter to break a reinforced concrete wall. %lthough they are more costly, chemicals may be preferred for p re s s u re bursting. %n e#pansive agent when correctly mi#ed will undergo a large increase in volume over a period of time. By placing the e#pansive slurry into boreholes that are located in a predetermined pattern, concrete can be split in a controlled manner for removal *+igure (,. Within &) to 2) hours, cracks are generated by an e#pansive pressure that can e#ceed @')) psi. The chemical agent is formulated to be used at a certain temperature1 any deviation from this temperature will reduce the e#pected e#pansive p re s s u re. +ree0ing the chemical agent will greatly reduce its effectiveness. <#plosives Blasting methods employ rapidly e#panding gases confined within a series of boreholes to produce controlled fractures which provide for easy concrete removal. $n general, blasting methods are efficient

means of removing large volumes of distressed or deteriorated concrete. But, due to dangers inherent in handling and usage, blasting is considered most dangerous and re ! u i re s more stringent controls than any other methods of demolition. +or the demolition of concrete structures it is usual to drill holes at a predetermined angle into the concrete to be removed. The holes are then charged with an e#plosive which is electrically detonated. <mpirical judgment based on the skill and e#perience of the operator is the basis for blasting design. ;ecent advances in blasting design include the utili0ation of recogni0ed formulas and calculations which determine the position, angle and depth of the borehole, as well as the si0e of the charge. % simpler but far less effective method of blasting is to lay the e#plosive charge on the element to be demolished and cover it with sandbags. %nother method, particularly useful for containers, is to fill the s t ru c t u re with water and detonate an e#plosive charge which has been suspended at the center. The water transmits shock waves to the surrounding walls. "haped charges for the directional cutting of elements are also available.

<#plosives are versatile and have great fle#ibility in terms of work output. 6owe ve r, e#cessive ground vibration may damage adjacent structures and air blast may cause superficial damage such as window breakage elsewhere. The 3ational %ssociation of 4emolition -ontractors states that the use of e#plosives to demolish entire buildings or portions thereof shall not be permitted unless there is sufficient clear space in all directions e!ual to A( percent of the height of the building being +igure @. The demolition of reinforced concrete re!uires that both the concrete and bond between the concrete and steel be broken. The splitter can be used on reinforced concrete walls to break pieces at a @( degree angle, providing access to cut the reinforcing steel. +igure (. This bridge pier was cracked by none#plosive demolition material, an e#pansive powder added to water and poured into predrilled holes. demolished. :recautions should be taken to stop flying debris and in all circumstances strict site control must be maintained to ensure the safety of workers and the general public. "afety checklist Whatever the demolition method chosen, or the si0e of the job, safety

is of prime importance. +o l l ow i n g are some key factors to consider. Services. 9as, water, electricity and other services to the structure must be properly capped where necessary. <lectricity or other lines needed to aid demolition must be of approved heavy duty construction and must be kept ade!uately protected along a known path. Access. %ll movements of people within the structure should be along designated routes, that is, through agreed doorways and stairways, or along specially constructed walkways with fi#ed ladders. ;emoval of debris should also follow an agreed route. %ll other openings, hori0ontal and vertical, should be blocked off completely to avoid danger from falling material. <ven openings needed for debris removal should be blocked when not in use. Loadings. 4emolition may seriously change loadings from those for which the structure was originally designed. %ny wall or floor that will be re!uired to carry the e#cess weight of stored material, or which will be subject to undue pressure from waste, must be ade!uately shored to withstand the e#tra loading. %t no time should debris be allowed to accumulate to a weight greater than a floor can carry. 6igh

impact loads from falling debris can be another source of unsafe loading. $n general, no area of wall or slab greater than &) s!uare feet should be allowed to fall on any floor at one time. The lower walls of a building within which waste is allowed to pile up are particularly susceptible to the effects of a destructive loading for which they were not designed. Wind loadings must also be considered. 8nder no circumstances should walls be left standing overnight if they are not plumb and strong enough to resist toppling by wind pressure. $f wall stability is !uestionable, demolition should continue down to the nearest structural cross member, or temporary shoring should be erected. $n general, no section of wall more than one story high should be left standing unsupported at any time unless it was specifically designed to stand higher. Structural members. When demolishing a structure from the top down, no supports at a lower level should be cut or removed until demolition at the upper level is complete. :articular care should be e#ercised in removing load bearing beams and columns which tie into party walls. When beams and columns are cut they should always

be well secured with wire rope or chains. $f a large amount of debris is e#pected it may be desirable to increase the volume of ground floor space into which waste can be dumped. Worker protection. Workers must always stand on a firm base while carrying out demolition. +ree ends of cut members may be needed as work platforms and must therefore be shored. Other ha ards. %ll glass and combustible material should be removed from a structure before demolition begins. ;emoval of asbestos and polyc h l o ri n a t e d biphenyls *:-Bs, must be done in accordance with regulations set by the >ccupational "afety and 6ealth %ct *>"6%, and the <nvironmental :rotection %gency *<:%,. <ach of these materials can be e#tremely dangerous to workers. 4emolition of :restressed -oncrete 4emolishing prestressed concrete structures can be more difficult than demolishing reinforced concrete because of the energy stored in the prestressing tendons. :restressing tendons are like stretched rubber bands, with energy stored in the stretching process. The release of the stored energy in

a rubber band causes it to sail through the air. 7ikewise, the release of stored energy in a prestressing tendon may cause it to sail through the airDas a dangerous missileDthreatening the lives of workers. While a rubber band carries only small forces, a prestressing tendon commonly transmits forces in e#cess of &2(,))) pounds. Methods of prestressing Two basic methods of prestressing are in use. / :re tensioning, in which the steel is tensioned before the concrete is cast, transfers the prestressing force to the concrete by bond. / :ost tensioning, in which the tendons are tensioned after the concrete has been cast and allowed to harden, transfers the prestressing force by means of end anchors. :re tensioning is used primarily for factory made units. These may be subse!uently post tensioned on site with additional tendons. 9enerally post tensioning is applied to cast in place concrete in which ducts are formed within the members. The tendons are inserted in these ducts and then stressed and permanently anchored.

:ost tensioned tendons can be bonded or unbonded. %fter the tendon is inserted into the duct, the space between the tendon and duct may be grouted for the full length of the member. This grouting bonds the tendon to the duct :8B7$-%T$>3 E-BA))2@ -opyright F &GBG, The %berdeen 9roup %ll rights reserved and the surrounding concrete, hence the name bonded. Tendons for which the duct is filled with grease *to prevent corrosion, rather than grout are considered unbonded. 4emolition of prestressed pretensioned structures The total demolition of a prestressed pre tensioned structure is no more difficult than the demolition of a cast in place re i n f o rc e d concrete structure. :re s t re s s e d pre tensioned members are usually designed to resist applied loading in only one direction. Because of this, the members will fail rather easily if a force can be applied in an opposite or lateral direction. The partial demolition of a prestressed pre tensioned structure re!uires more care than a similar operation on a cast in place structure. More attention must be given to proper placement of ade!uate

shoring, careful rigging and lifting, and the avoidance of impact loads to the structure below. :re tensioned slabs and beams, or smaller dismantled portions, may be lifted and lowered to the ground as complete units *:hoto %,. 9ene ra l l y, any necessary shoring and subse!uent lifting should be from points near the ends of the units. 4emolition of prestressed post tensioned structures The total demolition of a prestressed post tensioned structure presents a very different problem, particularly if the tendons are unbonded. %s this is a relatively new type of construction, few post tensioned buildings have been demolished. "afe, uneventful demolition of relatively low stru c t u re s using a crane and a ball has been accomplished where there is ade!uate surrounding work space. 6owe ve r, the majority of e#perienced contractors and engineers familiar with the problems and potential dangers of post tensioned structures suggest that they be dismantled a floor at a time. This is true whether the structure is of cast in place concrete with subse!uent post tensioning, or of precast, prestressed members which were also post tensioned.

4isassembly or from the topdown demolition re!uires a large amount of shoring which must be installed along the entire length of the members, unless intermediate tendon anchors were installed during construction. >nce shored, the slab and beams can be detensionedD in reverse order in which they were tensioned. Then the slabs and beams can be demolished using those methods previously described, with the e#ception of the ball and crane method. :artial demolition of post tensioned structures The partial demolition of an unbonded post tensioned structure can be very complicated and ha0a rd o u s. $f Has builtI drawings are not available, this operation can be even more comple#. The original s t ru c t u re drawings are used as a guide for the proper placement of shoring under each member. %fter the shoring is in place, the tendon and reinforcing bars are located using magnetic detection devices. >nce this is done, careful drilling, chipping or sawing may be used to e#pose the prestressing tendons *:hoto B,. Then a hydraulic tensioning device is used to detension the tendon, releasing its force and allowing the

concrete member to rest on the shoring. The concrete can then be broken with either hand held or machinemounted breakers, or once completely severed, reduced to a si0e which may be lifted and lowe re d . Because the concrete may contain no reinforcing steel, or only top reinforcing, the section must be rigged such that it can be lifted and lowered without causing the concrete section to rupture from its own dead weight. -areful planning by competent persons e#perienced in post tensioning is essential before attempting partial demolition of post tensioned structures. The demolition of prestressed structures re!uires a thorough understanding of the fundamentals of prestressing. The underside of this slab illustrates the prestressing force released by cutting the tendons. "horing is in place as a safety precaution. :hoto %. "ections of this precast, prestressed double tee unit were shored, sawed and lifted out. :hoto B. 4etensioning the tendon releases its force and allows safe removal of post tensioned concrete sections. 6ere a laborer is chipping

grout out of an anchorage pocket to allow access for a hydraulic

You might also like

- EXAM Section A Closed Book 2007Document9 pagesEXAM Section A Closed Book 2007Krispin Fong94% (16)

- Demolition of Structure Using Implosion TechnologyDocument17 pagesDemolition of Structure Using Implosion TechnologySreerag Dileep100% (1)

- Demolition of BuildingsDocument18 pagesDemolition of BuildingsJamilaBeevi94% (16)

- Cable Tray InstallationDocument10 pagesCable Tray Installationalrwin_b2yNo ratings yet

- Four Elevator COntrollerDocument26 pagesFour Elevator COntrollerMehul Garg100% (1)

- CASE STUDY of HIGH-RISE BUILDINGDocument23 pagesCASE STUDY of HIGH-RISE BUILDINGJamie Anne Mendi75% (4)

- Jet A1 Fueling SystemDocument54 pagesJet A1 Fueling SystemMaaz Junaidi67% (3)

- Demolition of StructuresDocument28 pagesDemolition of StructuresSharath WankdothNo ratings yet

- Demolition of BuildingDocument13 pagesDemolition of BuildingAmeer pashaNo ratings yet

- Controlled Demolition: Under The Guidance of Associate Prof. Dr. K. KumarDocument24 pagesControlled Demolition: Under The Guidance of Associate Prof. Dr. K. KumarSyed YunussNo ratings yet

- Demolition of A BuildingDocument9 pagesDemolition of A BuildingMark James CalumpangNo ratings yet

- Orbital Light-Rail: Threats To From TheDocument9 pagesOrbital Light-Rail: Threats To From TheLaura MeyerNo ratings yet

- QTN 23b - Demolition of Affected StructuresDocument7 pagesQTN 23b - Demolition of Affected StructuresPrabhat Kumar SinghNo ratings yet

- Demolition FullDocument18 pagesDemolition FullnanamallowNo ratings yet

- Detonation of Buildings (Explosive Demolition of Building) : Prepared By: Sagar Shah Faculty Guide: Sonal ThakkarDocument26 pagesDetonation of Buildings (Explosive Demolition of Building) : Prepared By: Sagar Shah Faculty Guide: Sonal ThakkarSagar D ShahNo ratings yet

- Controlled Demolition of BuildingsDocument27 pagesControlled Demolition of BuildingsNigam MeherNo ratings yet

- Icbp PDFDocument22 pagesIcbp PDFVarunNo ratings yet

- Demolition Techniques and Case StudiesDocument24 pagesDemolition Techniques and Case StudiesVenkat NitheshNo ratings yet

- Demolition of Building PresentationDocument24 pagesDemolition of Building Presentationವಿಶ್ವನಾಥ್ ಸಿ ಎಸ್No ratings yet

- Demolition by Controlled BlastingDocument7 pagesDemolition by Controlled BlastingEr Manak Chand SainiNo ratings yet

- Demolition of StructuresDocument20 pagesDemolition of Structureshimanshu100% (1)

- Proceedings PDFDocument139 pagesProceedings PDFR RathiNo ratings yet

- History of WasteDocument6 pagesHistory of Wastejans_13No ratings yet

- Chapter 4 Demolition WorksDocument25 pagesChapter 4 Demolition WorksAmir AlistyNo ratings yet

- Demolition of BuildingDocument22 pagesDemolition of Buildingpooja patil100% (1)

- Stuctural Design of Interlocking Concrete PavementsDocument18 pagesStuctural Design of Interlocking Concrete Pavementsantonio_poma_3No ratings yet

- Fremen - Explosive Demolitions HandbookDocument30 pagesFremen - Explosive Demolitions HandbookJoaquin RiccitelliNo ratings yet

- Week 11 - Demolition PDFDocument34 pagesWeek 11 - Demolition PDFMark TruongNo ratings yet

- Method Statement For Demolition WorksDocument1 pageMethod Statement For Demolition WorksYoven NadaNo ratings yet

- Precast Construction SeminarDocument30 pagesPrecast Construction SeminarNzar HamaNo ratings yet

- Presentation 1 Demolition Work (Edited)Document17 pagesPresentation 1 Demolition Work (Edited)imah4152100% (2)

- Demolition of BuildingsDocument20 pagesDemolition of Buildingssvivek75% (4)

- 19VE1A0114 Seminar Demolition of BuildingsDocument21 pages19VE1A0114 Seminar Demolition of BuildingsbhavaniNo ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- Lo 2 - DemolitionDocument29 pagesLo 2 - DemolitionEng Stephen ArendeNo ratings yet

- Demolition Works: L/O/G/ODocument29 pagesDemolition Works: L/O/G/OZahin SamsudinNo ratings yet

- Demolition of BuildingDocument30 pagesDemolition of BuildingSahil Gandhi100% (1)

- SBEC 2823 Construction Measurement 2: Topic: Demolition & Alteration Project: Double Storey Office Building Group 3Document38 pagesSBEC 2823 Construction Measurement 2: Topic: Demolition & Alteration Project: Double Storey Office Building Group 3Amalina YaniNo ratings yet

- Gabon / Libreville Aman Resorts Ngombe ProjectDocument11 pagesGabon / Libreville Aman Resorts Ngombe ProjectBogdan BungardiNo ratings yet

- Implosion NewDocument44 pagesImplosion NewRamesh KannanNo ratings yet

- Demolition of Building 2Document30 pagesDemolition of Building 2pramod Kumar sahaniNo ratings yet

- Checklist - DemolitionDocument2 pagesChecklist - DemolitionRommel Carlo Largado100% (1)

- 1demolition of Building PDFDocument9 pages1demolition of Building PDFAbhishek100% (1)

- Demolition Safety: Sample Written Program For Your Company ForDocument8 pagesDemolition Safety: Sample Written Program For Your Company ForVivek REDDY G YNo ratings yet

- Kerbs, Footways and Paved AreasDocument4 pagesKerbs, Footways and Paved AreasNoorul Mufas MnNo ratings yet

- Georgina Chikwati - Demolition of Construction Works Assignment - Bqs3Document9 pagesGeorgina Chikwati - Demolition of Construction Works Assignment - Bqs3Georgina ChikwatiNo ratings yet

- Technical Advisory For DemolitionDocument16 pagesTechnical Advisory For DemolitionLiew Yen ChingNo ratings yet

- Day 3 - Demolition SafetyDocument41 pagesDay 3 - Demolition Safetychum onaNo ratings yet

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- Building Construction EditDocument26 pagesBuilding Construction EditSami Zama100% (1)

- Work Method StatementDocument2 pagesWork Method StatementSetyawanNo ratings yet

- Demolition of Construction WorksDocument8 pagesDemolition of Construction WorksGeorgina ChikwatiNo ratings yet

- Building A Sustainable Future: Circular Economy and Waste Management in ConstructionDocument13 pagesBuilding A Sustainable Future: Circular Economy and Waste Management in ConstructionMakanjuola SinaNo ratings yet

- Architecturally Exposed Structural Steel PDFDocument8 pagesArchitecturally Exposed Structural Steel PDFJagatheesh RadhakrishnanNo ratings yet

- Structural Steel Reuse in ConstructionDocument12 pagesStructural Steel Reuse in ConstructionMuhammad MurtazaNo ratings yet

- Gvccv-Mathod Statement of Brick Wall WorkDocument17 pagesGvccv-Mathod Statement of Brick Wall WorkMengthuyNo ratings yet

- History of RecycledDocument64 pagesHistory of RecycledKimNo ratings yet

- Demolition 0407Document115 pagesDemolition 0407MelhinoNo ratings yet

- Construction Practice 1 For TechnicianDocument24 pagesConstruction Practice 1 For TechnicianMichael_Mensah_2238No ratings yet

- DemolitionDocument38 pagesDemolitionjayadush100% (1)

- ProfileDocument24 pagesProfilebj velNo ratings yet

- Seminar Report On Demolition 2015-2016Document31 pagesSeminar Report On Demolition 2015-2016Archana Mol100% (1)

- Interlocking Concrete Paver SpecsDocument6 pagesInterlocking Concrete Paver Specscarolinetrippin100% (1)

- Stage 1 Demolition Method StatementDocument27 pagesStage 1 Demolition Method StatementPaul OchiengNo ratings yet

- 6538 PDFDocument5 pages6538 PDFRam Dela CruzNo ratings yet

- A Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperDocument2 pagesA Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperMohammed Abdul RazzakNo ratings yet

- Code of Professional Ethics For EeDocument12 pagesCode of Professional Ethics For EeatoyskeeNo ratings yet

- The Project TeamDocument3 pagesThe Project Teamjemisha charlesNo ratings yet

- Daa Lab Manual 2018Document58 pagesDaa Lab Manual 2018Srinjoy dasNo ratings yet

- Presentation - IKEA Nov 2013 - Engineering After DiplomaDocument23 pagesPresentation - IKEA Nov 2013 - Engineering After DiplomaLila Poonawalla FoundationNo ratings yet

- IRC 112 - Oct 2013 Amendments PDFDocument3 pagesIRC 112 - Oct 2013 Amendments PDFSiva Prasad MamillapalliNo ratings yet

- Chapter-1 Introduction To PLC: Types of PLC Avialable in MarketDocument50 pagesChapter-1 Introduction To PLC: Types of PLC Avialable in MarketSarikaNo ratings yet

- Basics of Limit State Method LSM 1 RCCDocument12 pagesBasics of Limit State Method LSM 1 RCCDrGanesh KameNo ratings yet

- Silt Gravel Removal GateDocument16 pagesSilt Gravel Removal GateRaja SinghNo ratings yet

- Polaris ResumeDocument1 pagePolaris Resumeapi-302628110No ratings yet

- Internship Report 1 PDFDocument32 pagesInternship Report 1 PDFJaydev BhadeliyaNo ratings yet

- JR - MEP Engineer - CVDocument1 pageJR - MEP Engineer - CVsayed ananNo ratings yet

- Steel Angles D 1322Document2 pagesSteel Angles D 1322Shanmuga SundaramNo ratings yet

- 13 IvecoDocument103 pages13 Ivecovladimir_p80No ratings yet

- Global SchoolDocument15 pagesGlobal SchoolMaria C.No ratings yet

- Ansi Asabe Ad4254-11-2010 (R2012)Document20 pagesAnsi Asabe Ad4254-11-2010 (R2012)StephanNo ratings yet

- NFC Institute of Engineering & Technology: WWW - Nfciet.edu - PK Nfciet@nfcet - Edu.pkDocument1 pageNFC Institute of Engineering & Technology: WWW - Nfciet.edu - PK Nfciet@nfcet - Edu.pkhammad ghaffarNo ratings yet

- Documentation Report: Project: STG & Boiler Batubara Project Date: Location: Item InspectionDocument34 pagesDocumentation Report: Project: STG & Boiler Batubara Project Date: Location: Item InspectionBayu RahmanNo ratings yet

- Aerospace Engineer Sample ResumeDocument1 pageAerospace Engineer Sample ResumeKiran Kumar100% (1)

- Graduate BulletinDocument470 pagesGraduate BulletinaccesskamranNo ratings yet

- Fatigue Analysis On Crank ShaftDocument1 pageFatigue Analysis On Crank ShaftPramit Kumar SenapatiNo ratings yet

- AFT Arrow 9 Quickstart MetricDocument126 pagesAFT Arrow 9 Quickstart MetricUdaya kumar SubramaniNo ratings yet

- 7-Equipment Damage Curves CapacitorsDocument2 pages7-Equipment Damage Curves CapacitorsMoulay m'hammed LOUKILINo ratings yet

- Awais Ahmad: Research Assistant Position, Energy and Environment Lab, City University of Hong KongDocument4 pagesAwais Ahmad: Research Assistant Position, Energy and Environment Lab, City University of Hong KongMuhammadAsimNo ratings yet

- Mil STD 100e Notice 2Document58 pagesMil STD 100e Notice 2logonwheelerNo ratings yet