Professional Documents

Culture Documents

Pipeline Mechanical Design

Pipeline Mechanical Design

Uploaded by

Arun RamuCopyright:

Available Formats

You might also like

- B - Minimum Required Thickness Permanent Blank ASME 304.5.3Document2 pagesB - Minimum Required Thickness Permanent Blank ASME 304.5.3edisjdavNo ratings yet

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 pageData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanNo ratings yet

- HDPE Flange AdaptorDocument1 pageHDPE Flange Adaptorcld72No ratings yet

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument62 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressArunkumar RackanNo ratings yet

- Trun CalcDocument215 pagesTrun CalcmohamedeliasNo ratings yet

- Blind Flange CalculationsDocument4 pagesBlind Flange CalculationsSergio SmithNo ratings yet

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocument2 pagesMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- Fire Jockey Pump. Rev B1Document3 pagesFire Jockey Pump. Rev B1Pump SpesialistNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Calculation Cover SheetDocument8 pagesCalculation Cover SheetYogesh PangareNo ratings yet

- 00257650-BO11432 - Rev PB - Waste Heat Recovery EquipmentDocument13 pages00257650-BO11432 - Rev PB - Waste Heat Recovery EquipmentSubrata Das0% (1)

- Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument76 pagesMaximum Span Between Pipe Supports For A Given Maximum Bending Stresserodrguez100% (1)

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (2)

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabs100% (1)

- Duct Weight 28Document16 pagesDuct Weight 28STANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- Design of Pressure ComponentsDocument34 pagesDesign of Pressure ComponentsYFFernando100% (1)

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Piping MaterialsDocument3 pagesPiping MaterialsMurtadda MohammedNo ratings yet

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziNo ratings yet

- Quick Reference CardDocument3 pagesQuick Reference Cardaslam.ambNo ratings yet

- AISC Steel Book2Document452 pagesAISC Steel Book2obaniceNo ratings yet

- Ip Pressure Transmitter Data SheetDocument2 pagesIp Pressure Transmitter Data Sheetneurolepsia3790No ratings yet

- Hdpe Anchor Load CalcualtionDocument14 pagesHdpe Anchor Load CalcualtionPipeline EngineerNo ratings yet

- Pressure Drop AdjustmentsDocument2 pagesPressure Drop AdjustmentsFaheem MushtaqNo ratings yet

- DS For FW TankDocument9 pagesDS For FW TankAbhay Kumar0% (1)

- Service Water TankDocument58 pagesService Water TankRanu Januar100% (1)

- Dimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mDocument77 pagesDimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mPablo Cesar PanessoNo ratings yet

- Welded Shoe CalculationDocument4 pagesWelded Shoe CalculationMichael RobinsonNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (2)

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Compressor Air Piping Calculation PDFDocument1 pageCompressor Air Piping Calculation PDFThai VoNo ratings yet

- Strainer DatasheetDocument1 pageStrainer DatasheetdgmprabhakarNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document614 pagesAISC 13ed - LRFD Bolted Moment Connections Post r4kfischer13No ratings yet

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocument2 pagesMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002No ratings yet

- WPS - 017Document12 pagesWPS - 017MAT-LIONNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- CN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018Document1 pageCN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018EmamokeNo ratings yet

- Hydrotest Calculation FormulaDocument1 pageHydrotest Calculation FormulaSandipPatelNo ratings yet

- Calc Hoop StressDocument11 pagesCalc Hoop StressApril Trevino100% (1)

- Conversion ASME Unit ConversionDocument3 pagesConversion ASME Unit ConversionMohdBadruddinKarimNo ratings yet

- ANZ-DS-E-5016 HV Surge DiverterDocument17 pagesANZ-DS-E-5016 HV Surge Divertermika cabelloNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Asme Tubesheet (Heater 10m2)Document23 pagesAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Heater 10m2 (ASME Tubesheet)Document17 pagesHeater 10m2 (ASME Tubesheet)Omil RastogiNo ratings yet

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Basics of Pipe Stress Analysis-PartDocument5 pagesBasics of Pipe Stress Analysis-Part7761430No ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Rectangular Tank SizingDocument66 pagesRectangular Tank SizinglavascudoNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

Pipeline Mechanical Design

Pipeline Mechanical Design

Uploaded by

Arun RamuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipeline Mechanical Design

Pipeline Mechanical Design

Uploaded by

Arun RamuCopyright:

Available Formats

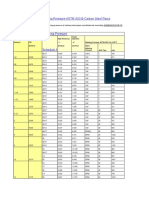

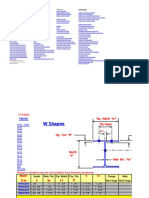

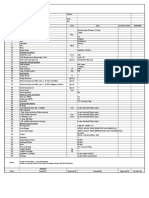

INPUT Pipeline Design Parameters Pipeline outer Diameter Pipeline Design Internal Pressure Pipeline Hydrotest Pressure Maximum

Design Temperature (aboveground) Maximum Design Temperature (underground) Minimum Design Temperature (aboveground) Minimum Design Temperature (underground) Hydrotest Temperature Installation Temperature Temperature derating factor Selected wall thickness Corrosion Allowance Type of pipe (SMLS/SAW/ERW/HFW) Lonjitudinal Joint factor Uplift coiefficient for up heavel buckling check Deapth of soil cover imperfection height

Design Factors of the Pipeline as per ASME B31.8: Location Class 2 (hoop stress) Restrained - Max. Longitudinal Stress Restrained - Max. Combined Stress Unrestrained - Max. Longitudinal Stress Design Factors of the Pipeline as per DGS-9550-003: Restrained - Max. Comb. Stress (Hydrotest) External Axial Force Soil Density Content Density Elastic Bend Radii Coefficient of friction - Pipe/Soil Line Pipe Material Properties Pipeline product specification level Pipeline Material SMYS of linepipe material Steel Density Poisson ratio of linepipe material Elastic modulus of linepipe material Expansion co-efficient of linepipe material

CALCULATION A. Combined Stress at Fully Restrained Section (Design Condition)

Maximum Allowable Hoop Stress Maximum Allowable Longitudinal Stress Maximum Allowable Combined Stress Maximum Allowable Combined Stress (Hydrotest) a. Non-Corroded Condition

Hoop Stress Calculation Hoop Stress Ratio

Longitudinal Stress (ASME B31.8: 833.2 & 833.3) Due to Internal Pressure

Due to Bending Load Outer Radius Inner Radius Due to Thermal Exp.

Due to External Forces

Total Longitudinal Stress Outer Radius Inner Radius

Max Longitudinal Stress Ratio

Combined Stress (ASME B31.8: 833.4) Tresca Combined Stress

Von Mises Combined Stress

Max Combined Stress Ratio

INPUT Pipeline Design Parameters D p ph Ta1 Tu1 Ta2 Tu2 Th Ti T t CA HFW Ej Uc H hi 0.508 6.35 130 85 65 0 13 38 13 1 0.0088 1.5 1 0.1 1 0.3 m mpa bar C C C C C C m mm

m m

FH FL1 FC1 FL2

0.6 0.9 0.9 0.75

FC.hyd Fax soil content R

0.95 0 1500 0.753 750 0.3

KN kg m 3 kg m 3 m

PSL API 5L X60 SMYS steel E

PSL2 415 7850 0.3 207000 0.0000117 MPa kgf m 3 MPa

SH=SMYSFHEjT SL = SMYSFL1T SC = SMYSFC1T SC.hyd = SMYSFC.hyd

249 373.5 373.5 394.25

mpa mpa mpa mpa

Sh= pD/ 2 t rhoop

183.2840909 0.736080686

Sp=(cv ) S Sb=ED/ (2R) sb1 sb2 ST=E(Ti Tu1) SX=Fax/A

54.98522727

mpa

70.104 -70.104 -125.9388 mpa

SL1 := Sp + Sb1 + ST + SX SL2 := Sp + Sb2 + ST + SX rlong=max( /SL1/ ,/ SL2/ )/ SL

-0.849572727 -141.0575727

0.377664184 SAFE

SCt.1=/Sh SL1/ SCt.2=/Sh SL2/

184.1336636 324.3416636

mpa mpa

SCv.1=(Sh^2-Sh*SL1+SL1^2)^0.5

183.7103506

mpa

SCv.2=(Sh^2-Sh*SL2+SL2^2)^0.5 rcom=max(SCt.1, SCt.2, SCv.1, SCv.2)/SC

281.680503 0.868384642 SAFE

mpa

You might also like

- B - Minimum Required Thickness Permanent Blank ASME 304.5.3Document2 pagesB - Minimum Required Thickness Permanent Blank ASME 304.5.3edisjdavNo ratings yet

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 pageData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanNo ratings yet

- HDPE Flange AdaptorDocument1 pageHDPE Flange Adaptorcld72No ratings yet

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument62 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressArunkumar RackanNo ratings yet

- Trun CalcDocument215 pagesTrun CalcmohamedeliasNo ratings yet

- Blind Flange CalculationsDocument4 pagesBlind Flange CalculationsSergio SmithNo ratings yet

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocument2 pagesMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- Fire Jockey Pump. Rev B1Document3 pagesFire Jockey Pump. Rev B1Pump SpesialistNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Calculation Cover SheetDocument8 pagesCalculation Cover SheetYogesh PangareNo ratings yet

- 00257650-BO11432 - Rev PB - Waste Heat Recovery EquipmentDocument13 pages00257650-BO11432 - Rev PB - Waste Heat Recovery EquipmentSubrata Das0% (1)

- Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument76 pagesMaximum Span Between Pipe Supports For A Given Maximum Bending Stresserodrguez100% (1)

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (2)

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabs100% (1)

- Duct Weight 28Document16 pagesDuct Weight 28STANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- Design of Pressure ComponentsDocument34 pagesDesign of Pressure ComponentsYFFernando100% (1)

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Piping MaterialsDocument3 pagesPiping MaterialsMurtadda MohammedNo ratings yet

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziNo ratings yet

- Quick Reference CardDocument3 pagesQuick Reference Cardaslam.ambNo ratings yet

- AISC Steel Book2Document452 pagesAISC Steel Book2obaniceNo ratings yet

- Ip Pressure Transmitter Data SheetDocument2 pagesIp Pressure Transmitter Data Sheetneurolepsia3790No ratings yet

- Hdpe Anchor Load CalcualtionDocument14 pagesHdpe Anchor Load CalcualtionPipeline EngineerNo ratings yet

- Pressure Drop AdjustmentsDocument2 pagesPressure Drop AdjustmentsFaheem MushtaqNo ratings yet

- DS For FW TankDocument9 pagesDS For FW TankAbhay Kumar0% (1)

- Service Water TankDocument58 pagesService Water TankRanu Januar100% (1)

- Dimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mDocument77 pagesDimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mPablo Cesar PanessoNo ratings yet

- Welded Shoe CalculationDocument4 pagesWelded Shoe CalculationMichael RobinsonNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (2)

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Compressor Air Piping Calculation PDFDocument1 pageCompressor Air Piping Calculation PDFThai VoNo ratings yet

- Strainer DatasheetDocument1 pageStrainer DatasheetdgmprabhakarNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document614 pagesAISC 13ed - LRFD Bolted Moment Connections Post r4kfischer13No ratings yet

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocument2 pagesMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002No ratings yet

- WPS - 017Document12 pagesWPS - 017MAT-LIONNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- CN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018Document1 pageCN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018EmamokeNo ratings yet

- Hydrotest Calculation FormulaDocument1 pageHydrotest Calculation FormulaSandipPatelNo ratings yet

- Calc Hoop StressDocument11 pagesCalc Hoop StressApril Trevino100% (1)

- Conversion ASME Unit ConversionDocument3 pagesConversion ASME Unit ConversionMohdBadruddinKarimNo ratings yet

- ANZ-DS-E-5016 HV Surge DiverterDocument17 pagesANZ-DS-E-5016 HV Surge Divertermika cabelloNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Asme Tubesheet (Heater 10m2)Document23 pagesAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Heater 10m2 (ASME Tubesheet)Document17 pagesHeater 10m2 (ASME Tubesheet)Omil RastogiNo ratings yet

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Basics of Pipe Stress Analysis-PartDocument5 pagesBasics of Pipe Stress Analysis-Part7761430No ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Rectangular Tank SizingDocument66 pagesRectangular Tank SizinglavascudoNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet