Professional Documents

Culture Documents

Gabion Wall

Gabion Wall

Uploaded by

Bijay Krishna DasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gabion Wall

Gabion Wall

Uploaded by

Bijay Krishna DasCopyright:

Available Formats

Alexandria Engineering Journal (2013) 52, 705710

Alexandria University

Alexandria Engineering Journal

www.elsevier.com/locate/aej www.sciencedirect.com

ORIGINAL ARTICLE

The stability of gabion walls for earth retaining structures

Mahyuddin Ramli a, T.J.r. Karasu a, Eethar Thanon Dawood

a b

b,*

School of Housing Building and Planning, Universiti Sains Malaysia, Penang, Malaysia Building and Construction Technology Engineering, Technical college of Mosul, Mosul-Iraq

Received 25 May 2011; accepted 22 July 2013 Available online 31 August 2013

KEYWORDS Gabion walls; Retaining structures; Erosion control; Slop stability

Abstract The stability of earth retaining structures in ood prone areas has become a serious problem in many countries. The two most basic causes of failure arising from ooding are scouring and erosion of the foundation of the superstructure. Hence, a number of structures like bridges employ scour-arresting devices, e.g., gabions to acting on the piers and abutments during ooding. Research was therefore undertaken to improve gabion resistance against lateral movement by means of an interlocking conguration instead of the conventional stack-and-pair system. This involved simulating lateral thrusts against two dimensionally identical retaining wall systems congured according to the rectangular and hexagonal gabion type. The evolution of deformation observed suggested that the interlocking design exhibits better structural integrity than the conventional box gabion-based wall in resisting lateral movement and therefore warrants consideration for use as an appropriate scour-arresting device for earth retaining structures.

2013 Production and hosting by Elsevier B.V. on behalf of Faculty of Engineering, Alexandria University.

1. Introduction According to the US Federal Highway Administration, up to 60% of bridge failures were caused by natural phenomena, especially from ooding [1]. It is apparent that since the past two decades, this ratio has not appreciably changed in many countries.

* Corresponding author. E-mail address: eethar2005@yahoo.com (E.T. Dawood). Peer review under responsibility of Faculty of Engineering, Alexandria University.

Production and hosting by Elsevier

The two leading causes of failures from ooding are scouring (which can also occur without ooding) and debris impact against bridge superstructure. This debris can also reroute ows, resulting in aggravated scouring and/or increased horizontal pressures acting on bridge piers and abutments. As known, scouring is the result of the erosive action of running water, which excavates and transports material away from the banks of streams and waterways. Different types of material scour at different rates and conditions, i.e., loose granular soils would scour more rapidly compared to cohesive soils. In addition, shifting of the stream may aggravate scour by eroding the approach roadway or changing the waterways ow angle. Lateral movement of a waterway is affected by stream geomorphology, diversions, and characteristics of its bed and bank materials. For this purpose, gabions have long been used as scour-arresting devices on bridge abutments and piers. Apart from fortication against ooding, gabion walls are also suited to the following cases:

1110-0168 2013 Production and hosting by Elsevier B.V. on behalf of Faculty of Engineering, Alexandria University. http://dx.doi.org/10.1016/j.aej.2013.07.005

706 1. Poor orientation of bridge piers with respect to water ows. 2. Large restrictions in ow imposed by the bridge superstructure. 3. Fine-grained materials, susceptible to move with a small increase in ow velocity. 4. Unpredictable increases in the water ow, e.g., during monsoons.

M. Ramli et al. 1. A hexagonal-shaped gabion displays better strength capabilities as opposed to the conventional rectangular-shaped gabion. 2. A retaining wall composed of an interlocking system of individual gabion units display better overall structural integrity compared to a system of conventional stackedand-paired gabions units. These questions effectively reect the principle that form inuences function. To this end, the results of individual and cumulative experimentation investigating the hexagonal ` -vis the traditional degabions responses to external load vis-a sign would be examined. The ndings intend to promote a new and useful contribution to the eld of design and construction of such structures by disseminating the research results to the attention of engineers and offering alternate design solutions. 1.3. Technical and functional characteristics Gabion walls are cellular structures, i.e., rectangular cages made of zinc-coated steel wire mesh and lled with stone of appropriate size and necessary mechanical characteristics. Individual units are stacked, paired, and tied to each other with zinc-coated wire (or fasteners) to form the continuum. The choice of the materials to be used is fundamental for obtaining a functionally effective structure. In particular, the mesh must satisfy the requirements of high mechanical and corrosive resistance, good deformability and lack of susceptibility to unravel. The conventional gabion possesses some peculiar technical and functional advantages as follows: 1. They are reinforced structures, capable of resisting most types of stress, particularly tension and shear. The mesh not only acts to contain the stone ll but also provides a comprehensive reinforcement throughout to structure. 2. They are deformable structures, which (contrary to popular opinion) does not diminish the structure but increases it by drawing into action all resisting elements as a complex reinforced structure, facilitating load redistribution. They are permeable structures, capable of collecting and transporting groundwater and therefore, able to attenuate a principal cause of soil instability. The drainage function is further augmented by evaporation generated by the natural circulation on air through the voids in the ll. They are permanent (and therefore durable) structures, with a virtually maintenance-free regime from effects no more severe than the natural aging of any other structure (with the exception of highly corrosive environments). Furthermore, their characteristics over time tend to gravitate toward establishing a natural state of equilibrium. They are easily installed, i.e. that deployment is possible without the aid of special equipment of highly trained personnel. This aspect is notably important in river and marine reclamation, where rapid intervention to retain soil is often necessary and/or when post-deployment modications are necessary. 2. Theory Although retaining walls imply resistance to movement, some forms of horizontal and vertical wall yield are still anticipated.

1.1. Gabion wall failures in hostile environments Despite many apparent advantages of gabion walls in protecting bridges against aggravated scour, failures can occur if the walls are subjected to high magnitudes of lateral forces. The sudden increase in lateral thrusts tends to cause side-shifting of adjacent gabion units congured in a conventional stackand-pair arrangement. The end result is usually large-scale lateral movement of the affected abutment or pier. Conventional bridge designs often initially incorporate drainage mechanisms behind the backwalls and wingwalls of their abutments. The mechanism is usually achieved by depositing free-draining backll material behind the wall, collecting the seeped-through water and discharging it into an inlet connected to a storm water system. However, clogging of the drainage system can result in accumulated hydrostatic pressure behind the wall over time, subjecting the pier and/or abutment to overstressing, consequently leading to unacceptable lateral movement. (The damage is usually more severe is cold countries, owing to repeated freezing and thawing of the accumulated water.) When gabions are used to fortify bridge abutments and piers, the integrity of structural xity remains the core factor in preserving bridge stability in such hostile environments. In a conventional stack-and-pair conguration of gabion units, resistance to the lateral shifting on individual units rests almost exclusively to the tie wires connecting adjacent units. There is virtually no contribution of the remaining structural components constituting the gabion unit in resisting these aggravated lateral forces, e.g., the frame, mesh, or stone ll. Since gabions are essentially gravity structures, which rely on their weight to achieve stability against lateral forces, any increase in gravity function would entail increasing their individual masses. This solution may not only be inefcient from a material perspective, but also pose settlement problems. To resolve this problem, a research was undertaken to examine the feasibility of using an interlocking conguration of gabion units, instead of the traditional stacked-and-paired system. The system employs a continuum of hexagonal gabions to interlock with one another by virtue of shape and conguration. The new gabion design is functionally similar to the conventional box gabion, but modied conceptually in accordance with the York method used in concrete wall facings [2]. 1.2. The interlocking gabion design A simple observation of naturally occurring structures (e.g. bees nets or crystalline arrangement for metals) suggests that in any structural continuum, interlocking properties and individual unit shape determine overall structural performance. An extrapolation of this hypothetical principal in cellularbased retaining structures, e.g., gabion walls suggest the following two possibilities:

The stability of gabion walls for Earth retaining structures This horizontal (i.e. sliding) and vertical movement (i.e. settlement) is essentially a manifestation of the resultant pressures acting behind the wall surface [3,4]. The resultant pressure, P, is always thought to act upon an inclined plane at a third of the walls height from its toe [5,6]. Although its computed angle of inclination and height is specic computed gures, it is clear that determination is based on a series of assumptions, depending on which classical theory was subscribed to during analysis (i.e., Rankine vs. Coulomb). The fact that the total resultant pressure, P, acts along an inclined plane suggests that P may be derived into its horizontal and vertical components. Therefore, different walls would invariably withstand different magnitudes of each force component. This argument sets the premise that the shape and orientation of distinct gabion designs (i.e., rectangular vs. hexagonal) will likewise result in distinct capabilities to absorb one (or both) of the force components constituting the resultant lateral pressure, P. As a basis for comparison, both types of gabions must conform to similar dimensions, so that shape and orientation remain the determining variables in evaluating various structural properties associated with each gabion type. The research therefore compares the rectangular gabion (also referred to as the box gabion) with the hexagonal gabion to investigate the mechanical responses of either type of structure to external load, both individually and in a cumulative setting. 3. Formulation of test specimens As tests on full-scale mock-up units are impractical, samples were scaled down to approximately 40% of commercial gabions. A total of 129 gabion samples were prepared for constructing the twin simulation walls, comprising 50 hexagonal units. All samples were formulated by hand, utilizing two types of bars for the frame. The rst stage of sample formulation involves forming the requisite frames dening each gabion shape. These were fabricated from typical plain round, 6 mm mild steel bars, with a characteristic strength of 250 N m m2. The second stage involves covering the frame with BRC wire mesh, which was cut to size with a slight overlap for tension reinforcement. To minimize lateral movement, the mesh is tied to the R6 frame with zinc-coated steel wire of 1.60 mm thickness. The third stage involved the lling process, whereby selected crusher-run stones between 25 and 50 mm are lled by hand up to each gabions full height. Once the gabions are lled, all samples are sealed and hosed to expel impurities and to expedite ll readjustment. A typical design of each type of gabion unit is shown in Fig. 1. A schematic representation of the each type of gabion unit is shown in Fig. 2, while technical dimensions of 10% of the test specimens are presented in Table 1 for types A (hexagonal), B (rectangular), and C (semi-hexagonal). X, Y, and Z denote standard Cartesian planes, whereas void ratio is simply expressed as percentage disparity between aggregate rock density (2500 kg m3) and apparent gabion density. 4. Construction of twin walls Two sets of retaining walls composed of each gabion type were constructed for evaluating the mechanical responses of the conventional gabion wall versus the hexagonal wall to external load. The walls were of 1.80 m height and 1.75 m width and

707 spaced 1.80 m from each other as shown in Fig. 3. The height-to-base ratio of each wall was purposely designed to be excessive in order to permit large deections, although overturning moments were not tolerated in the interest of safety. Each wall was built with a stepped front-face and smooth back-face that reduces the wall thickness by 50% at three-fths of the wall height from its base to the top. The space between both walls was closed-off with plywood restraining panels to create a boxed area for the subsequent loading stage. The entire box was covered with plastic sheeting as an impervious membrane, purposely oversized to accommodate large moments expected of both structures. A maximum soil-hydrostatic head of 1.80 m and average per unit gabion density of 2000 kg/m3 will be assumed. The twin wall system employs reduced safety factor, i.e., 1.30 against overturning and 1.10 against sliding using a predetermined soil angle of internal friction, maximum bearing pressure and stone average shear stress. 5. Research issues Several pertinent issues arise from evaluating the behavior of both walls under extreme loading: 1. The gabions abilities to collectively deform under aggravated loads when combined soil-hydrostatic pressures are involved. Reversibility (or irreversibility) of deformation at low stress values was a point of contention. 2. The rate in which deformation occurs from changes in displacement under progressive loads. These conditions represent the successive increments in soil lateral thrust occurring at the back of a retaining wall from uctuations in the backlls water content. 3. The nature of the process of deformation in terms of localized mechanical responses when loaded over an indenite period. Assuming that localized response is prevalent, it would be necessary to evaluate what factors resulted in the unstable equilibrium. 4. Evaluation of the structural characteristics of both walls at the point of terminal failure, i.e., when the structures have been loaded to maximum capacity. Of particular interest would be if the nal load leads to abrupt collapse (or susceptibility to collapse)

6. Evaluation of deformation The basis for comparing both walls is visual deformation, i.e., changes in horizontal and vertical displacements of an arbi` -vis its original position trary point (on the walls surfaces) vis-a (Fig. 1). The assumed plane of deformation is represented along the two-dimensional exterior cross-section of either wall. A standard cartesian system was adopted to measure the extent of displacement occurring on both walls under the same stress magnitudes. The cartesian reference grid covers the cross-section of both walls with a matrix of 220 points, based on a specied number of horizontal and vertical gridlines superimposed on each wall. Shifting observed of each point was compared with a permanent vertical line to establish deformation under load. Each point was tagged and measured for horizontal distance from the xed benchmark to establish relative initial position. For

708

M. Ramli et al.

Figure 1

(a) Hexagonal, (b) rectangular, and (c) semi rectangular shape of gabions.

The walls were loaded to 0.075H, corresponding to a load of approximately 1250 kg for the purpose of establishing initial wall inertia and mobilize active thrust. Following that, the walls were loaded to 0.375H (6250 kg), 0.5625H (9375 kg), and 0.75H (12,500 kg). Finally, hydrostatic pressure was applied gradually up to full wall height, i.e., 0.75H soil + 0.25H hydrostatic head.

Figure 2 Hexagonal (left), semi-hexagonal (center) and rectangular gabion (right).

6.1. Test results Tacheometric measurements of all moving targets under progressively increasing load enabled conversion into horizontal and vertical displacement with respect to the xed vertical line. From the data generated, it is possible to determine the average values for deformation at various wall heights for each loading stage. On plotting these results, the evolution of the average deection along the wall as a function of the soilhydrostatic load is illustrated. The evolution of deformation observed on both test structures necessitates empirical assessment. For this purpose, a series of prole-graphs depict the shift in horizontal positions for each moving target on the reference grid for load conditions 0.075H, 0.1875H, 0.375H, 0.5625H, 0.75H, and the nal 0.75H + 0.25H hydrostatic head stage. The evolution of vertical displacements was purposely omitted as they were found to be both erratic and insignicant (i.e., with average relative displacements of only 0.001%). This was observed for all vertical gridlines 1, 2, 3, 7, and 9 for the rectangular wall and 4, 5, 6, 8, and 10 for the hexagonal wall. The observations present several interesting ndings. The actual linear shifts established along the cartesian X plane and the percentage change in each corresponding shift relative to its preceding position describe the stability of both walls. For practical purposes, six stages of wall deformation were deemed sufcient for interpretation. Since load conditions were identical, the limits were simply indicated in terms of the height of the soil mass as a function of the total wall height. Movement was designated in terms of X0, X1, X2, X3, X4, and X5, each corresponding to a soil height of 0.075H, 0.1875H, 0.375H, 0.5625H, 0.75H, and 0.75H + 0.25H hydrostatic head. Issues pertaining to the structural integrity of each test wall system will be assessed upon evaluating the visual deformation of each principal grid line, i.e., lines 1, 2, and 3 (for the rectangular wall conguration) and 4, 5, and 6 for its hexagonal

Table 1

Unit A01 A02 A03 A04 A05 B01 B02 B03 B04 B05 C01 C02 C03

a

Principal dimensions of gabion test samples.

H (cm)a 19.9 20.0 19.5 20.5 20.2 19.8 20.6 20.5 20.4 21.6 20.6 20.5 21.0 Mass (kg) 40.3 39.6 37.6 41.2 40.9 40.9 42.4 40.9 41.5 42.8 20.1 20.2 20.6 Volume (cm3) 21,590 21,326 20,979 21,982 22,151 24,186 26,619 27,141 26,145 27,904 10,721 10,828 10,511 Density (kg/m3) 1866.6 1856.9 1792.3 1874.2 1846.4 1691.0 1592.8 1506.9 1587.2 1533.8 1919.3 1949.5 1884.2 V. ratio (%) 25.34 25.72 28.31 25.03 26.14 32.36 36.29 39.72 36.51 38.65 23.23 22.02 24.63

H refers to average specimen height.

easy identication, standard Roman alphabets were used to represent the horizontal grids and Arabic numerals for the vertical grids. A digital theodolite was used to determine the horizontal displacements of all principal points as a function of their viewed angular shift. The instrument was used to ascertain all readings from two measuring stations, each placed directly opposite each wall type. The soil load was applied by manually lling the walls expandable tank in successive increments. For obvious reasons, unsuitable material was selected to impose higher lateral thrusts against both walls. The imposition of incremental soil load permits progressive assessments pertaining to the mechanical responses of each structure at that particular load level.

The stability of gabion walls for Earth retaining structures

709 state) correspond to a reduced gradient. Trend lines established for each curve suggest a polynomial expression for lateral displacement versus load, and that the rate of displacement change for the last three load stages is signicantly higher than the initial three. A possible explanation is that during the initial loading stages, the resultant earth pressure is used to increase structural inertia. Initial sliding on the hexagonal wall experienced is much lower, i.e., only 7.6% for the rst three load stages (compared to its maximum deection) and 10.8% for the last three loading stages. The maximum deection observed on both walls clearly indicates that the hexagonal-congured wall deforms less and under more controlled outcomes than the rectangular wall. In terms of the vertical lines shifts for the last three load stages, the grid points on the rectangular wall deect some 1000%, 350%, and 73%, compared to the same moving targets positioned on the hexagonal wall, which deect about 180%, 17%, and 35%, respectively. This observed erratic behavior of the rectangular-congured gabion wall has tremendous implications in its inherent resistance to deformation, which consequently reects upon its stability when responding to increasing lateral thrust. This is evident from its prole itself at the region between 0.35H and 0.55H, where the zigzagging pattern clearly indicates shear failure. Despite the polynomial relationship of wall movement versus load from initial to full load, a more linear relationship is evident if movements are strictly assessed above the walls critical 0.33H height, where the resultant earth pressures are believed to act. In the case of both walls, the average gradient values obtained for the rst three load stages were 0.135, 0.113, and 0.114 for lines 1, 2, and 3, respectively. The last three load stages, however, produced a marked shift in gradient, i.e., 0.052, 0.050, and 0.051 for the same gridlines. This radical change in gradient sign convention demonstrates the high shear stresses imposed on the rectangular wall at the shear zone of 0.35H 0.55H. The hexagonal wall, on the other hand, registers milder curve gradients of 0.198, 0.248, and 0.263 for lines 4, 5, and 6 (for the rst three load stages) and subsequently 0.051 for all Lines for the last three load stages. A consistent sign convention indicates lower shear levels and hence lower susceptibility to shear failure at the same zone.

Figure 3 model.

Different types of wall gabions constructed for the test

counterpart. Figs. 3 and 4 show lateral displacements versus wall height for all loading stages. Upon plotting the results, the scatter was found to be relatively minor, and after discarding anomalies, the average values obtained for deection were deemed dependable. This therefore permits a largely accurate illustration of the evolution of observed deection as a function of load, presented as follows in Figs. 3 and 4. 7. Discussion of results The results indicate that the hexagonal gabion exhibits better overall structural integrity than the conventional gabion in terms of deformation resistance and susceptibility to collapse. The shear behavior exhibited by each wall illustrates the principal link between unit conguration and overall stability when cellular units are built into a continuum. These assertions undoubtedly present major implications when considering practical application in bridge design, where such mechanical advantages, when magnied, may mean the difference between success or failure in the performance of piers and/or abutments fortied with cellular-based retaining structures against scour. The lines depicting the evolution of each principal vertical grid on the external cross-sectional faces of the test walls depict actual wall proles for each loading stage. Foremost, it is possible to assert that the two sets of principal vertical gridlines are largely consistent in terms of their average deections at the various loading stages. All line movements for the rst three loading stages (i.e. 0.075H, 0.1875H, and 0.375H) essentially register common gradients, whereas line movements for the last three stages (i.e. 0.5625H, 0.75H, and the terminal

8. Conclusions The technical focus of this research invariably arises from a social perspective, namely is addressing the alarming trend of scour-induced bridge failures through innovation and improvisation of a common abutment/pier protection device-the gabion wall. By examining the century old pair-and-stack ` -vis an intermethod of using rock cages to retain earth vis-a locking alternative comprising a hexagonal design with interlocking properties, the link between shape and structural function has been addressed. The study outcome and subsequent interpretation of ndings suggest several pertinent conclusions as follows: 1. Comparison of average deections between both walls suggests that the hexagonal-congured wall deforms under more controlled outcomes compared to its rectangular counterpart. This invariably suggests that lateral deformation exhibited by an interlocked gabion system is more

Figure 4 failure.

Load application on the gabion units and their mode of

710 stable than a conventional stacked-and-paired system. This observation undoubtedly presents major implications in the continued utility of conventional gabions with respect to deformation resistance under gradually increasing lateral thrust. 2. An examination of wall proles at the region between 0.35H and 0.55H clearly reveals severe shear-induced deformation of the rectangular wall compared to the hexagonal wall. This observation suggests that the hexagonal walls inherent interlocking mechanisms operating at aggravated loads compensates for the observed excessive strains occurring at the shear zone. 3. The deformation induced by the various loading stages is irreversible for both wall systems, which suggests that gabions, regardless of shape or conguration, do not behave as elastic structures. References

M. Ramli et al.

[1] K.R. White, J. Minor, K.N. Derucher, Bridge Maintenance Inspection and Evaluation, Marcel Dekker, New York, 1992. [2] C.J.F.P. Jones, The york method of reinforced earth construction, in: ASCE Symposium on Earth Reinforcement, ASCE, Pittsburgh, 1978. [3] B.M. Das, Principles of Soil Dynamics, PWS Kent Publishing Company, Boston, 1993. [4] B.M. Das, Fundamentals of Geotechnical Engineering, Brooks/ Cole Thomson, Pacic Grove, 2000. [5] P.K. Banerjee, Principles of analysis and design of reinforced earth retaining walls, International Journal of Rock Mechanics and Mining Science 12 (1975) 100109. [6] J.C. Mitchell, Fundamentals of Soil Behavior, John Wiley & Sons, New York, 1976.

You might also like

- Monolithic GlassDocument12 pagesMonolithic Glassxkunk9813No ratings yet

- X2 Service ManualDocument107 pagesX2 Service ManualkatjhoNo ratings yet

- The Stability of Gabion Walls For Earth Retaining StructuresDocument6 pagesThe Stability of Gabion Walls For Earth Retaining StructuresNazawee ZakiNo ratings yet

- The Stability of Gabion Walls For Earth Retaining StructuresDocument7 pagesThe Stability of Gabion Walls For Earth Retaining StructuresGouthami NaraNo ratings yet

- Bahasa IndoDocument5 pagesBahasa Indoipulsaepulloh688No ratings yet

- 02-Gabion Structure AnalysesDocument15 pages02-Gabion Structure AnalysesBIJAY KRISHNA DASNo ratings yet

- Repairing and Strengthening Techniques For Historic Masonry Arch BridgesDocument5 pagesRepairing and Strengthening Techniques For Historic Masonry Arch BridgesComet AstroNo ratings yet

- Stability of Gabion WallDocument6 pagesStability of Gabion WallSohaibNo ratings yet

- Chapter 1Document33 pagesChapter 1Divya V SNo ratings yet

- A Survey On Masonry Lateral Force Resisting Systems: Codes vs. Research PerspectiveDocument8 pagesA Survey On Masonry Lateral Force Resisting Systems: Codes vs. Research PerspectivefilipeNo ratings yet

- 4 Joints in BuildingsDocument18 pages4 Joints in BuildingsDipeshNo ratings yet

- Study On Sliding Stability of Porous-Concrete Retaining WallDocument9 pagesStudy On Sliding Stability of Porous-Concrete Retaining Wallraul.chiriacNo ratings yet

- Study On Vertical Dowel Connections in Precast WallsDocument14 pagesStudy On Vertical Dowel Connections in Precast WallsroshidNo ratings yet

- Earthquake Shear Load in Load-Bearing Masonry Buildings P Sing-SangDocument19 pagesEarthquake Shear Load in Load-Bearing Masonry Buildings P Sing-SangSohan GeorgeNo ratings yet

- Time-Dependent Behavior of Continuous Composite Integral Abutment BridgesDocument10 pagesTime-Dependent Behavior of Continuous Composite Integral Abutment BridgesMuhammad AbdullahNo ratings yet

- DocumentDocument3 pagesDocumentAbuu HassanNo ratings yet

- Seismic Analysis and Design of Rigid Bridge Abutments Considering Rotation and Sliding Incorporating Non-Linear Soil BehaviorDocument31 pagesSeismic Analysis and Design of Rigid Bridge Abutments Considering Rotation and Sliding Incorporating Non-Linear Soil BehaviorAndres LopezNo ratings yet

- Review On Non Linear Dynamic Analysis of Precast Retaining WallDocument7 pagesReview On Non Linear Dynamic Analysis of Precast Retaining WallVishvajit KohakadeNo ratings yet

- Enhancing The Seismic Performance of Batter Piles in Pile-Supported Wharves Using Fluid Viscous Dampers - P - 2018Document15 pagesEnhancing The Seismic Performance of Batter Piles in Pile-Supported Wharves Using Fluid Viscous Dampers - P - 2018Halil Can EryasarNo ratings yet

- Study of The Rock Foundation Stability of The Aizhai Suspension BridgeDocument14 pagesStudy of The Rock Foundation Stability of The Aizhai Suspension BridgeY.I. JangNo ratings yet

- El Uso de GavionesDocument4 pagesEl Uso de Gavionescati_bmNo ratings yet

- Drainage For DamsDocument10 pagesDrainage For Damschutton681No ratings yet

- Numerical Stress Deformation Analysis of Cut Off Wall I 2016 Water Science ADocument8 pagesNumerical Stress Deformation Analysis of Cut Off Wall I 2016 Water Science AKoko HermawanNo ratings yet

- Tsinker1997 Chapter PiledWaterfrontStructuresDocument184 pagesTsinker1997 Chapter PiledWaterfrontStructuresvuxuandung84No ratings yet

- 2018 - Pelekis Et AlDocument20 pages2018 - Pelekis Et AlDeviprasad B SNo ratings yet

- S 151 ContentDocument17 pagesS 151 ContentcurlyjockeyNo ratings yet

- King - Load Bearing Straw Blalle ConstructionDocument26 pagesKing - Load Bearing Straw Blalle ConstructionJaba de SojaNo ratings yet

- Static and Dynamic Analysis of Shear Wall Subjected To Lateral LoadsDocument7 pagesStatic and Dynamic Analysis of Shear Wall Subjected To Lateral LoadsVivek PatvaNo ratings yet

- Intze Type Water TankDocument62 pagesIntze Type Water TankNitya Patel75% (4)

- Confinement Effect of Different Arrangements of Transverse Reinforcement On Axially Loaded Concrete Columns: An Experimental StudyDocument7 pagesConfinement Effect of Different Arrangements of Transverse Reinforcement On Axially Loaded Concrete Columns: An Experimental StudyEmre GuneyNo ratings yet

- 17WCEE WallAxialCollapse Final-V3Document13 pages17WCEE WallAxialCollapse Final-V3rondana1No ratings yet

- Dynamic Analysis of Flanged Shear Wall Using Staad Pro: T. Subramani, B. Saravanan, J. JayalakshmiDocument6 pagesDynamic Analysis of Flanged Shear Wall Using Staad Pro: T. Subramani, B. Saravanan, J. JayalakshmiPandal RajNo ratings yet

- Experimental and Numerical Study of An InnovativeDocument23 pagesExperimental and Numerical Study of An InnovativeSang NguyenNo ratings yet

- Strengthening MethodDocument30 pagesStrengthening MethodaokankNo ratings yet

- Journal Inter 3 (Selesai 18)Document16 pagesJournal Inter 3 (Selesai 18)Putu DidiNo ratings yet

- 2014 Geotechnique 64 11 895 909 Cocjin Et Al PDFDocument49 pages2014 Geotechnique 64 11 895 909 Cocjin Et Al PDFPaypal BusinessNo ratings yet

- Influence of Masonry Infill Wall Position and OpenDocument23 pagesInfluence of Masonry Infill Wall Position and OpenLê Nguyễn VănNo ratings yet

- Design of Monolithic Concrete Ground FloorsDocument13 pagesDesign of Monolithic Concrete Ground FloorsЕгор ШигинNo ratings yet

- Cebel 2020 86Document7 pagesCebel 2020 86ismal sirajNo ratings yet

- Erosion Control of Steep Open Channels Using Articulated ConcreteDocument105 pagesErosion Control of Steep Open Channels Using Articulated ConcretesamratjgecNo ratings yet

- Water 14 01442Document23 pagesWater 14 01442SteveNo ratings yet

- 2020 Bridge Structures RockingDocument20 pages2020 Bridge Structures RockingFerit GashiNo ratings yet

- Critical Gradients For Tailings Dam DesignDocument10 pagesCritical Gradients For Tailings Dam DesignMargarita CaceresNo ratings yet

- Dynamic Testing of Combined Rock Bolt and Mesh Schemes: Conference PaperDocument11 pagesDynamic Testing of Combined Rock Bolt and Mesh Schemes: Conference PaperAriberto SaccoNo ratings yet

- Study On The Stability of The Geogrids-Reinforced EarthDocument11 pagesStudy On The Stability of The Geogrids-Reinforced EarthrullyirwandiNo ratings yet

- Research Paper 13 - Elseier - Sir YasirDocument10 pagesResearch Paper 13 - Elseier - Sir YasirAbdullah aminNo ratings yet

- Gabbion Wall PresentationDocument32 pagesGabbion Wall PresentationUsman Ilyas100% (1)

- Case StudyDocument11 pagesCase StudyshehanNo ratings yet

- 48J 2023 Rachit and Senthil European J of Civil and Environ EnggDocument31 pages48J 2023 Rachit and Senthil European J of Civil and Environ EnggsenthilkasilingamNo ratings yet

- Design of Flexible Barriers Against Sizeable Landslides in Hong KongDocument14 pagesDesign of Flexible Barriers Against Sizeable Landslides in Hong Kongceice2013No ratings yet

- Coefficient of Friction RubberDocument13 pagesCoefficient of Friction RubberanilpradeepNo ratings yet

- Unit-Iii Coffer Dams and Caissons-1Document29 pagesUnit-Iii Coffer Dams and Caissons-1Abuye HD100% (1)

- Applsci 11 11506 v3Document18 pagesApplsci 11 11506 v3Shivam PratapNo ratings yet

- Shear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingDocument14 pagesShear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingJalal KeNo ratings yet

- Coastal Structures - Lecture Note - New - REV - BH - SWDocument6 pagesCoastal Structures - Lecture Note - New - REV - BH - SWTharindu Nuwan JayakodyNo ratings yet

- Steel Sheet PileDocument16 pagesSteel Sheet PilesetiapanggabeanNo ratings yet

- Effect of Differential Settlement On Frame Forces - A Parametric StudyDocument12 pagesEffect of Differential Settlement On Frame Forces - A Parametric Studyyaj leumas seyerNo ratings yet

- 20.study of Seismic Behaviour of Building With Viscous Damping WallDocument4 pages20.study of Seismic Behaviour of Building With Viscous Damping WallSiddhesh NanawareNo ratings yet

- Wang White RandolphDocument16 pagesWang White RandolphSouha BaliNo ratings yet

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- The Behaviour of Concrete by Partial Replacement of Fine Aggregate With Copper Slag and Cement With GGBS - An Experimental StudyDocument6 pagesThe Behaviour of Concrete by Partial Replacement of Fine Aggregate With Copper Slag and Cement With GGBS - An Experimental StudyBijay Krishna DasNo ratings yet

- Mittsure Table Book5-6Document2 pagesMittsure Table Book5-6Bijay Krishna DasNo ratings yet

- Makripani Bridge L - SECTION of NallahDocument1 pageMakripani Bridge L - SECTION of NallahBijay Krishna DasNo ratings yet

- Bentley Civil Guide: V8I Selectseries 3Document110 pagesBentley Civil Guide: V8I Selectseries 3Bijay Krishna DasNo ratings yet

- Overlay Stripping and Widening Practice WorkbookDocument62 pagesOverlay Stripping and Widening Practice WorkbookBijay Krishna DasNo ratings yet

- Aimil Asphalt TestingDocument31 pagesAimil Asphalt TestingBijay Krishna DasNo ratings yet

- Vocabulary Building: Date Word Meaning Example of Usage Synonym AntonymDocument9 pagesVocabulary Building: Date Word Meaning Example of Usage Synonym AntonymBijay Krishna DasNo ratings yet

- Second Floor Plan 3760.88 - 2101.1 1659.78 SQM: D3 D3 D3 D3 D3 D3 D3Document1 pageSecond Floor Plan 3760.88 - 2101.1 1659.78 SQM: D3 D3 D3 D3 D3 D3 D3Bijay Krishna DasNo ratings yet

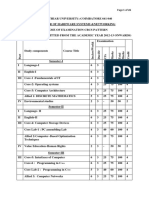

- MI Room R1 21 MayDocument1 pageMI Room R1 21 MayBijay Krishna DasNo ratings yet

- Cold Mix For Road ConstructionDocument43 pagesCold Mix For Road ConstructionBijay Krishna DasNo ratings yet

- FL-2 - Book B - Online - PDocument28 pagesFL-2 - Book B - Online - PBijay Krishna DasNo ratings yet

- Brief On Construction of Deopani BridgeDocument9 pagesBrief On Construction of Deopani BridgeBijay Krishna DasNo ratings yet

- What Is The Difference Between Codes IRC 37-2001 & 2012Document5 pagesWhat Is The Difference Between Codes IRC 37-2001 & 2012Bijay Krishna Das100% (1)

- What Is The Difference Between Codes IRC 37-2001 & 2012Document5 pagesWhat Is The Difference Between Codes IRC 37-2001 & 2012Bijay Krishna Das100% (1)

- Concept of Class 9 EqvtDocument2 pagesConcept of Class 9 EqvtBijay Krishna DasNo ratings yet

- Excel To C I For Positive in PutDocument23 pagesExcel To C I For Positive in PuthimanshuNo ratings yet

- Rajan Mis 22.06.2019Document14 pagesRajan Mis 22.06.2019Bhavin SagarNo ratings yet

- Hilti HCC-B For Concrete Overlays: Fastening Technology ManualDocument39 pagesHilti HCC-B For Concrete Overlays: Fastening Technology ManualPablo Martinez FesserNo ratings yet

- Mobile TechnologiesDocument23 pagesMobile Technologiesgobra senNo ratings yet

- How To Start & Run A Community Computer CenterDocument38 pagesHow To Start & Run A Community Computer Centerarvinds_40No ratings yet

- Colorcalibrationtutorial 2008 v4 enDocument21 pagesColorcalibrationtutorial 2008 v4 enpicolorjNo ratings yet

- Jurnal NAT OverloadingDocument7 pagesJurnal NAT OverloadingMohammad NowafNo ratings yet

- Wiringdiagram DcaDocument209 pagesWiringdiagram DcallapusescuNo ratings yet

- Cubenew July 11Document81 pagesCubenew July 11ganeshNo ratings yet

- Example1 1-StraightsupportedDocument7 pagesExample1 1-StraightsupportedOmar BayouNo ratings yet

- Useful Function Keys and ShortcutsDocument2 pagesUseful Function Keys and ShortcutsLucianNo ratings yet

- JCSR 2004 Integral Stub Dicleli AlbhaisiDocument22 pagesJCSR 2004 Integral Stub Dicleli AlbhaisipostensadosNo ratings yet

- TIB SpotWebPlay 4.0.2 InstallationManualDocument101 pagesTIB SpotWebPlay 4.0.2 InstallationManualsrgaurNo ratings yet

- Chapter 1 & 2Document15 pagesChapter 1 & 2Sy LolzeNo ratings yet

- University: Cebu Institute of TechnologyDocument3 pagesUniversity: Cebu Institute of TechnologyNiña Jean MarquezNo ratings yet

- Wonderland Botanical Illustration GuideDocument15 pagesWonderland Botanical Illustration Guidekmd78100% (3)

- Design Guidelines For Campus Planing - 1Document9 pagesDesign Guidelines For Campus Planing - 1Inara SbNo ratings yet

- Key Plan Typical Floor Plan Lift M/C. Room LVL.: Dimensional DetailsDocument1 pageKey Plan Typical Floor Plan Lift M/C. Room LVL.: Dimensional DetailsVinay KatariyaNo ratings yet

- OTA105210 Opti NG-SDH Alarm and Performance Event: ISSUE 1.02Document79 pagesOTA105210 Opti NG-SDH Alarm and Performance Event: ISSUE 1.02farhanwaliNo ratings yet

- Attachment 7 - ExecutionDocument210 pagesAttachment 7 - Executionyadvikram7No ratings yet

- Manual - Carrier (Reparado)Document156 pagesManual - Carrier (Reparado)Juan Carlos Chapoñan SilvaNo ratings yet

- American Craftsman Windows BrochureDocument32 pagesAmerican Craftsman Windows BrochureAllan Morgan100% (1)

- The Product Keys For Autodesk 2018 Products Are As FollowsDocument4 pagesThe Product Keys For Autodesk 2018 Products Are As FollowsSofiene GuedriNo ratings yet

- Designmed Europe: Special Focus Motors & Drives Mobile Dram AnalysisDocument54 pagesDesignmed Europe: Special Focus Motors & Drives Mobile Dram AnalysisGiuseppe BarbagalloNo ratings yet

- Users Manual RTN360Document88 pagesUsers Manual RTN360peperimeNo ratings yet

- SyllabusDocument26 pagesSyllabustfacultyNo ratings yet

- Thesis Project: "Orphanage Cum Old Age Home "Document67 pagesThesis Project: "Orphanage Cum Old Age Home "moon100% (1)

- Adventure - The Gnomes of Levnec PDFDocument20 pagesAdventure - The Gnomes of Levnec PDFLucas Luna100% (2)