Professional Documents

Culture Documents

Electronic Ballast Controller of A Fluorescent Lamp Using IR21571

Electronic Ballast Controller of A Fluorescent Lamp Using IR21571

Uploaded by

1cvbnmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronic Ballast Controller of A Fluorescent Lamp Using IR21571

Electronic Ballast Controller of A Fluorescent Lamp Using IR21571

Uploaded by

1cvbnmCopyright:

Available Formats

1 www.irf.

com

IR21571 Ballast Control IC Design Kit

Features

Drives: 1 x 32W T8 Lamp (IRPLLNR2U)

1 x 36W T8 Lamp (IRPLLNR2)

Input: 90-140VAC/60Hz (IRPLLNR2U)

185-265VAC/50Hz (IRPLLNR2)

High Power Factor/Low THD

High Frequency Operation (42kHz)

Lamp Filament Preheating

Lamp Fault Protection with Auto-Restart

Brownout Protection

IR21571 HVIC Ballast Controller

Description

The IRPLLNR2 is a high efficiency, high power factor, fixed output

electronic ballast designed for driving rapid start fluorescent lamp types. The design contains an EMI

filter, active power factor correction and a ballast control circuit using the IR21571. This demo board is

intended to ease the evaluation of the IR21571 Ballast Control IC, demonstrate PCB layout techniques

and serve as an aid in the development of production ballasts using the International Rectifier IR21571.

Ballast Block Diagram

EMI Filter Rectifier PFC Half-Bridge Output Stage

Line

Lamp

PFC Control IR21571

UVLO Lamp Fault

International Rectifier 233 Kansas Street, El Segundo, CA 90245 USA

IRPLLNR2

2 www.irf.com

Parameter Units Value (IRPLLNR2) Value (IRPLLNR2U)

Lamp Type 36W T8 32W T8

Input Power [W] 36 32

Input Current [Arms] 0.300 0.300

Preheat Mode Frequency [kHz] 44 44

Preheat Mode Lamp Voltage [Vrms] 220 220

Preheat Time [s] 0.9 0.6

Ignition Ramp Mode Frequency [kHz] 38 38

Run Mode Frequency [kHz] 42 42

Lamp Run Current [Arms] 0.34 0.34

Input AC Voltage Range [VACrms] 185..255/50..60Hz 90..140/50..60Hz

Input DC Voltage Range [VDC] 250..350 100..180

Power Factor 0.98 0.99

Total Harmonic Distortion [%] <15 <10

Maximum Output Voltage [Vpk] 600 600

Electrical Characteristics

Note: Measurements performed with input AC line voltage = 120Vrms (IRPLDIM1U)

230Vrms (IRPLDIM1)

Fault Ballast Restart Operation

Line voltage low Deactivates Increase line voltage

Upper filament broken Deactivates Lamp exchange

Lower filament broken Deactivates Lamp exchange

Failure to ignite Deactivates Lamp exchange

Open circuit (no lamp) Deactivates Lamp exchange

Fault Protection Characteristics

Functional Description

Overview

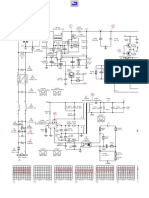

he IRPLDIM1 Demo Board consists of an EMI filter, an active power factor correction front end, a

ballast control section and a resonant lamp output stage. The active power factor correction section

is a boost converter operating in critical mode conduction, free-running frequency mode. The ballast

control section provides frequency modulation control of a traditional RCL lamp resonant output

circuit and is easily adaptable to a wide variety of lamp types. The ballast control section also pro-

vides the necessary circuitry to perform closed-loop dimming, lamp fault detection, shutdown and

auto-restart. All functional descriptions refer to the IRPLDIM1 schematic diagram.

3

w

w

w

.

i

r

f

.

c

o

m

L1

C2

BR1

C3

R1

R2

R3

R4

R5

R6

R7

C4

C5

L2

D1

C6

M1

R9

R10

D2

C8

CRAMP

CPH

C9

R11

CSTART

RSTART

RT

C13

CT

RRUN

RPH

RDT

C11

D4

C10

R14

R13

RCS

M3

R16

R15

C12

M2

D5

R17

C17

L3

D6

C15

C16

R18

R12

Note: Thick traces represent high-frequency, high-current paths. Lead

lengths should be minimized to avoid high-frequency noise problems

L

N

R8

RV1

GND

C1

ROC

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

I

R

2

1

5

7

1

VDC

CPH

RPH

RT

RUN

CT

DT

OC

LO

COM

VCC

VB

VS

HO

SD

CS

R19

COC

D3

8

7

6

5 4

3

2

1

MC34262

C7

C14

R20

R21

I

R

P

L

L

N

R

2

/

I

R

P

L

L

N

R

2

U

S

c

h

e

m

a

t

i

c

D

i

a

g

r

a

m

4 www.irf.com

IRPLLNR2U Bill Of Materials

Lamp type: T8/32W

Line Input Voltage: 90..140 VAC/50..60 Hz

Note: Different lamp types require different frequency programming components.

Item # Qt Manufacturer Part Number Description Reference

1 1 International Rectifier DF10S Bridge Rectifier, 1A 1000V BR1

2 1 Roederstein WY0222MCMBF0K Capacitor, 2.2nF 275 VAC Y Cap C1

3 1 Roederstein F1772433-2200 Capacitor, 0.33uF 275 VAC C2

4 1 Wima MKP10 Capacitor, 0.01uF 400 VDC C3

5 3 Panasonic ECU-V1H103KBM Capacitor, 0.01uF SMT 1206 C4, CRAMP, CSTART

6 3 Panasonic ECJ-3YB1E474K Capacitor, 0.47uF SMT 1206 C5, C6, C13

7 5 Panasonic ECU-V1H104KBM Capacitor, 0.1uF SMT 1206 C9,CPH, COC, C10, C11

8 1 Panasonic EEU-EB2V100 Capacitor, 10uF 350VDC 105C C8

9 1 Panasonic ECU-V1H471KBM Capacitor, 470pF SMT 1206 CT

10 1 Panasonic ECE-A1HGE010 Capacitor, 1uF 50VDC 105C C12

11 1 Vitramon 1812A152KXE Capacitor, 1.5nF 1KV SMT 1812 C14

12 1 Wima MKP10 Capacitor, 0.1uF 400VDC C15

13 1 Vitramon 1812A102KXE Capacitor, 1nF 1KV SMT 1812 C16

14 1 Panasonic ECW-H16103JV Capacitor, 0.01uF 1.6KV C17

15 1 Panasonic ECU-V1H101KBM Capacitor, 100pF SMT 1206 CCS

16 3 Diodes LL4148DICT-ND Diode, 1N4148 SMT DL35 D1, D5, D6

17 2 International Rectifier 10BF60 Diode, SMT SMB D2, D4

18 1 Diodes ZMM5250BCT Diode, Zener , 20V SMT DL35 D3

19 1 Motorola MC34262 IC, Power Factor Controller IC1

20 1 International Rectifier IR21571 IC, Ballast Driver IC2

21 1 Panasonic ELF-15N007A EMI Inductor, 1X10mH 0.7Apk L1

22 1 RG-Allen PFC Inductor, 2.0mH 2.0Apk L2

23 1 RG-Allen Inductor, 2.0mH 2.0Apk L3

24 3 International Rectifier IRF730 Transistor, MOSFET M1, M2, M3

25 5 Panasonic ERJ-8GEYJ680K Resistor, 680K ohm SMT 1206 R1, R2, R4, R5, R17

26 1 Panasonic ERJ-8GEYJ10K Resistor, 10K ohm SMT 1206 R3

27 1 Panasonic ERJ-8GEYJ12K Resistor, 12K ohm SMT 1206 R6

28 1 Panasonic ERJ-8GEYJ100K Resistor, 100K ohm SMT 1206 R7

29 3 Panasonic ERJ-8GEYJ22K Resistor, 22K ohm SMT 1206 R8, RSTART, RT

30 3 Panasonic ERJ-8GEYJ22 Resistor, 22 ohm SMT 1206 R9, R13, R15

31 1 Dale CW-1/2 Resistor, 0.5 ohm watt R10

32 1 Panasonic ERJ-8GEYJ130K Resistor, 130K ohm SMT 1206 R11

33 1 Yageo 2.2MQBK-ND Resistor, 2.2megohm watt R12

34 1 Dale CW-1/2 Resistor, 0.68 ohm watt RCS

35 1 Panasonic ERJ-8GEYJ5.6K Resistor, 5.6K ohm SMT 1206 RDT

36 1 Panasonic ERJ-8GEYJ30K Resistor, 30K ohm SMT 1206 ROC

37 1 Panasonic ERJ-8GEYJ91K Resistor, 91K ohm SMT 1206 RPH

38 1 Panasonic ERJ-8GEYJ150K Resistor, 150K ohm SMT 1206 RRUN

39 1 Yageo 390KQBK-ND Resistor, 390K ohm watt R14

40 1 Panasonic ERJ-8GEYJ1K Resistor, 1K ohm SMT 1206 R16

41 1 Panasonic ERJ-8GEYJ2.2M Resistor, 2.2megohm SMT 1206 R18

42 1 Yageo 100KQBK-ND Resistor, 100K ohm watt R19

43 1 Panasonic ERZ-V05D471 Transient Suppressor RV1

44 2 Panasonic ERJ-8GEYJ10 Resistor, 10 ohm SMT 1206 R20, R21

Total 67

5 www.irf.com

IRPLLNR2 Bill Of Materials

Lamp type: T8/36W

Line Input Voltage: 180..255 VAC/50..60 Hz

Note: Different lamp types require different frequency programming components.

Item # Qt Manufacturer Part Number Description Reference

1 1 International Rectifier DF10S Bridge Rectifier, 1A 1000V BR1

2 1 Roederstein WY0222MCMBF0K Capacitor, 2.2nF 275 VAC Y Cap C1

3 1 Roederstein F1772433-2200 Capacitor, 0.33uF 275 VAC C2

4 1 Wima MKP10 Capacitor, 0.01uF 400 VDC C3

5 3 Panasonic ECU-V1H103KBM Capacitor, 0.01uF SMT 1206 C4, CRAMP, CSTART

6 3 Panasonic ECJ-3YB1E474K Capacitor, 0.47uF SMT 1206 C5, C6, C13

7 5 Panasonic ECU-V1H104KBM Capacitor, 0.1uF SMT 1206 C9,CPH, COC, C10, C11

8 1 Panasonic EEU-EB2V100 Capacitor, 10uF 350VDC 105C C8

9 1 Panasonic ECU-V1H471KBM Capacitor, 470pF SMT 1206 CT

10 1 Panasonic ECE-A1HGE010 Capacitor, 1uF 50VDC 105C C12

11 1 Vitramon 1812A152KXE Capacitor, 1.5nF 1KV SMT 1812 C14

12 1 Wima MKP10 Capacitor, 0.1uF 400VDC C15

13 1 Vitramon 1812A102KXE Capacitor, 1nF 1KV SMT 1812 C16

14 1 Panasonic ECW-H16103JV Capacitor, 0.01uF 1.6KV C17

15 1 Panasonic ECU-V1H101KBM Capacitor, 100pF SMT 1206 CCS

16 3 Diodes LL4148DICT-ND Diode, 1N4148 SMT DL35 D1, D5, D6

17 2 International Rectifier 10BF60 Diode, SMT SMB D2, D4

18 1 Diodes ZMM5250BCT Diode, Zener 20V SMT DL35 D3

19 1 Motorola MC34262 IC, Power Factor Controller IC1

20 1 International Rectifier IR21571 IC, Ballast Driver IC2

21 1 Panasonic ELF-15N007A EMI Inductor, 1X10mH 0.7Apk L1

22 1 RG-Allen PFC Inductor, 2.0mH 2.0Apk L2

23 1 RG-Allen Inductor, 2.0mH 2.0Apk L3

24 3 International Rectifier IRF830 Transistor, MOSFET M1, M2, M3

25 5 Panasonic ERJ-8GEYJ680K Resistor, 680K ohm SMT 1206 R1, R2, R4, R5, R17

26 1 Panasonic ERJ-8GEYJ10K Resistor, 10K ohm SMT 1206 R3

27 1 Panasonic ERJ-8GEYJ8.2K Resistor, 8.2K ohm SMT 1206 R6

28 1 Panasonic ERJ-8GEYJ100K Resistor, 100K ohm SMT 1206 R7

29 3 Panasonic ERJ-8GEYJ22K Resistor, 22K ohm SMT 1206 R8, RSTART, RT

30 3 Panasonic ERJ-8GEYJ22 Resistor, 22 ohm SMT 1206 R9, R13, R15

31 1 Dale CW-1/2 Resistor, 1.0 ohm watt R10

32 1 Panasonic ERJ-8GEYJ56K Resistor, 56K ohm SMT 1206 R11

33 1 Yageo 2.2MQBK-ND Resistor, 2.2megohm watt R12

34 1 Dale CW-1/2 Resistor, 0.68 ohm watt RCS

35 1 Panasonic ERJ-8GEYJ5.6K Resistor, 5.6K ohm SMT 1206 RDT

36 1 Panasonic ERJ-8GEYJ30K Resistor, 30K ohm SMT 1206 ROC

37 1 Panasonic ERJ-8GEYJ75K Resistor, 75K ohm SMT 1206 RPH

38 1 Panasonic ERJ-8GEYJ150K Resistor, 150K ohm SMT 1206 RRUN

39 1 Yageo 390KQBK-ND Resistor, 390K ohm watt R14

40 1 Panasonic ERJ-8GEYJ1K Resistor, 1K ohm SMT 1206 R16

41 1 Panasonic ERJ-8GEYJ2.2M Resistor, 2.2megohm SMT 1206 R18

42 1 Yageo 100KQBK-ND Resistor, 100K ohm watt R19

43 1 Panasonic ERZ-V05D471 Transient Suppressor RV1

44 2 Panasonic ERJ-8GEYJ10 Resistor, 10 ohm SMT 1206 R20, R21

Total 65

6 www.irf.com

Power Factor Correction

The power factor correction section consists of the Motorola Semiconductor MC34262 Power Factor

Controller IC (IC1), MOSFET M1, inductor L2, diode D2, capacitor C8 and additional biasing, sens-

ing and compensation components (see schematic diagram). The IC was chosen for its minimal

component count, low start-up supply current and robust error amplifier. This is a boost topology

designed to step-up and regulate the output DC bus voltage while drawing sinusoidal current from

the line (low THD) which is in phase with the AC input line voltage (HPF). The design of the power

factor correction section was taken from the Motorola Semiconductor MC34262 data sheet and

information on the operation and design considerations for the MC34262 are contained therein.

Ballast Control

The ballast control section is built around the IR21571 Ballast Control IC, IC2 of the Demo board.

The IR21571 contains an oscillator, a high voltage half-bridge gate driver and lamp fault protection

circuitry. A block diagram of the IR21571 IC is shown in figure 1 and a state diagram of the IR21571

is shown in figure 2. Following is a breakdown of the operation of the ballast in all of the different

modes of operation.

OVER-

TEMP

DETECT

LEVEL

SHIFT

PULSE

FILTER &

LATCH

2

4.0V

5.1V

3

5

7.6V

3.0V

5.1V

1

1.0uA

4

2.0V

I

RT

6

I

CT

= I

RT

7

4.0V

2.0V

CPH

RPH

RT

RUN

CT

DT

VDC

Q S

R2 Q

R1

Q T

R Q

16

14

15 VS

HO

VB

13

11

12 COM

LO

VCC

15.6V

9 SD

10

0.2V

CS

Q S

R Q

Q D

R Q

CLK

Q S

R Q

UNDER-

VOLTAGE

DETECT

2.0V

8 OC

50uA

7.6V

7.6V

7.6V

Figure 1: IR21571 Block Diagram

7 www.irf.com

UVLO Mode

1

/

2

-Bridge Off

I

QCC

150A

CPH = 0V

Oscillator Off

PREHEAT Mode

1

/

2

-Bridge @ f

PH

CPH Charging @ I

PH

= 1A

RPH = 0V

RUN = Open Circuit

CS Disabled

IGNITION RAMP Mode

f

PH

ramps to f

MIN

CPH Charging @ I

PH

= 1A

RPH = Open Circuit

RUN = Open Circuit

CS+ Threshold Enabled

RUN Mode

f

MIN

Ramps to f

RUN

CPH Charges to 7.6V Clamp

RPH = Open Circuit

RUN = 0V

CS- Threshold Enabled

VCC > 11.4V (UV+)

and

VDC > 5.1V (Bus OK)

and

SD < 1.7V (Lamp OK)

and

T

J

< 140C (T

jmax

)

CPH > 4.0V

(End of PREHEAT Mode)

CPH > 5.1V

(End of IGNITION RAMP)

VCC < 9.5V

(VCC Fault or Power Down)

or

VDC < 3.0V

(dc Bus/ac Line Fault or Power Down)

or

SD > 2.0V

(Lamp Fault or Lamp Removal)

Power Turned On

FAULT Mode

Fault Latch Set

1

/

2

-Bridge Off

I

QCC

150A

CPH = 0V

VCC = 15.6V

Oscillator Off

T

J

> 140C

(Over-Temperature)

CS > CS+ Threshold

(Failure to Strike Lamp

or Hard Switching)

or

T

J

> 140C

(Over-Temperature)

CS > CS+ Threshold

(Over-Current or Hard Switching)

or

CS < 0.2V

(No-Load or Below Resonance)

or

T

J

> 140C

(Over-Temperature)

SD > 2.0V

(Lamp Removal)

or

VCC < 9.5V

(Power Turned Off)

Figure 2: IR21571 State Diagram

8 www.irf.com

Startup Mode

When power is initially applied to the ballast, the voltage on the VCC pin of IC2 (IR21571) begins to

charge up. The voltage for IC2 is derived from the current supplied from the rectified AC line through

startup resistor R14. During this initial startup when the VCC voltage of IC2 is below its rising under-

voltage lock-out threshold (11.4V), IC2 is in its UVLO and also its micro-power mode. The micro-

power mode of the IC2 allows the use of a large value,

low wattage startup resistor (R14). When the voltage

on IC2 reaches the rising under-voltage lockout thresh-

old, the oscillator is enabled (this assumes that there

are no fault conditions) and drives the half-bridge out-

put MOSFETs (M2 and M3). When the half-bridge is

oscillating, capacitor C16, diodes D5 and D6 form a

snubber /charge pump circuit which limits the rise and

fall time at the half-bridge output and also supplies the

current to charge capacitor C12 to the VCC clamp volt-

age (approx. 15.6V) of IC2. The voltage for IC1 is de-

rived from the current supplied from another snubber/

charge pump circuit formed by capacitor C14 and di-

odes D1 and D3. When the rising under-voltage lock-

out threshold of IC1 is reached, it starts to oscillate

and drive MOSFET M1 to boost and regulate the bus

voltage to 400 VDC. An oscillograph of the startup of

the VCC of IC1, VCC of IC2 and half-bridge output

voltage are shown in Figure 3. (For a complete de-

scription of the operation of IC1, refer to the Motorola Semiconductor MC34262 data sheet.)

Preheat Mode

When the ballast reaches the end of the UVLO mode, the Preheat mode is entered. At this point the

oscillator of IC2 has begun to operate and the half-bridge output is driving the resonant load (lamp)

circuit. The oscillator section of IC2 is similar to oscillators found in many popular PWM voltage

regulator ICs and consists of a timing capacitor and resistor connected to ground. Resistors RT and

RPH program a current which determines the ramp up time of capacitor CT and resistor RDT deter-

mines the ramp down time. The downward ramping time of CT is the deadtime between the switch-

ing off of the LO (HO) and the switching on of the HO (LO) pins on IC2. The Preheat mode frequency

of oscillation is selected such that the voltage appearing across the lamp is below the minimum lamp

ignition voltage while supplying enough current to preheat the lamp filaments to the correct emission

temperature within the Preheat mode period. The preheating of the lamp filaments is performed with

a constant current during the Preheat mode. The waveform in Figure 4 shows the lamp filament

current while Figure 5 shows lamp filament voltage during the normal Startup, Preheat, Ignition

Ramp and Run modes of the ballast.

Figure 3: Top trace: Half-bridge output voltage

Middle trace: VCC of IC2

Bottom trace: VCC of IC1

9 www.irf.com

Figure 4: Lamp filament current during Startup,

Preheat, Ignition Ramp and Run (500mA/div)

Figure 5: Lamp filament voltage during Startup,

Preheat, Ignition Ramp and Run

Figure 6 shows a plot of the half-bridge oscillation frequency as a function of time for all of the normal

modes of operation: Preheat mode, Ignition Ramp mode and Run mode. As shown in Figure 6 there

is an initial startup frequency that is much higher than the steady state Preheat mode frequency that

lasts for only a short duration. Components CSTART and RSTART are used to program this initial

startup frequency. This is done to insure that the initial voltage appearing across the lamp at the

startup of oscillation does not exceed the minimum lamp ignition voltage. If, at the initiation of oscil-

lation of the half-bridge, the voltage across the lamp is large enough, a visible flash of the lamp

occurs which should be avoided. This in effect is a cold strike of the lamp which could shorten the life

of the lamp. An oscillograph of the lamp voltage at startup is shown in Figures 7 and 8 (next page).

Figure 7 shows the lamp voltage without the high initial startup frequency while Figure 8 shows the

lamp voltage with the high initial frequency startup.

f

osc

t

preheat ignition run

f

Preheat

f

Run

f

Ignition

Figure 6: Oscillator frequency versus time, Normal operating conditions

10 www.irf.com

Figure 7: Typical lamp voltage at startup;

f

Startup

= f

P reheat

Figure 8: Improved lamp voltage at startup;

f

Startup

> f

P reheat

The duration of the Preheat mode as well as which mode of operation the ballast is operating in is

determined by the voltage on the CPH pin of IC2. At the completion of the UVLO mode, Preheat

mode is entered and an internal current source is activated at the CPH pin of IC2 which begins to

charge up capacitor CPH. The ballast remains in the Preheat mode until the voltage on the CPH

pin of IC2 exceeds the Ignition Ramp mode threshold (4V).

Ignition Ramp Mode

At the completion of the Preheat mode (4V < CPH

pin < 5.1V) the ballast switches to the Ignition Ramp

mode and the frequency ramps down to the ignition

frequency. The frequency ramping is accomplished

by turning off the internal open drain MOSFET on

the RPH pin of IC2 (see Figure 1, IR21571 block

diagram). Resistor RPH is no longer connected di-

rectly in parallel with resistor RT. The shift in frequency

does not occur in a step function but rather with an

exponential decay because of capacitor CRAMP in

series with resistor RPH to ground. The duration of

this frequency ramp is determined by the time con-

stant of the RC combination of capacitor CRAMP

and resistor RPH. The minimum frequency of oscil-

lation occurs at the end of this ramp and is deter-

mined by resistor RT and capacitor CT. During this

ramping downward of the frequency, the voltage

across the lamp increases in magnitude as the

frequency approaches the resonant frequency of

the LC load circuit until the lamp ignition voltage

Figure 9: Upper trace: voltage on capacitor

CRAMP during Ignition Ramp mode

Lower trace: Lamp voltage during Ignition

Ramp mode.

11 www.irf.com

is exceeded and the lamp ignites. Figure 9 shows the ramping of voltage appearing across the lamp

and also the voltage on capacitor CRAMP. Note that the sudden drop in lamp voltage indicates that

the lamp has ignited. Also note that the voltage on capacitor C12 is still increasing at the point when

the lamp has already ignited meaning the frequency is still ramping down to the final minimum

ignition frequency. This minimum frequency corresponds to the absolute maximum ignition voltage

required by the lamp under all conditions.

During the Ignition Ramp mode the voltage on the CPH pin of IC2 continues to ramp up until the

voltage at the CPH pin of IC2 exceeds the Run mode threshold (5.1V). Over-current sensing is also

enabled at the beginning of the Ignition Ramp mode. A full explanation of the functionality of the

over-current sensing is in the section on Fault Mode.

Run Mode

At the end of the Ignition Ramp mode (CPH pin

> 5.1V) the ballast switches to the Run mode at

which point the frequency is shifted to the run

frequency. The run frequency is determined by

the parallel combination of resistors RT and

RRUN and capacitor CT. Resistor RRUN is

connected in parallel by turning on the internal

open drain MOSFET connected to the RUN pin

of IC2 (see Figure 1, IR21571 block diagram).

The sensing of under-current conditions is also

enabled at the beginning of the Run mode. The

full explanation of the functionality of the under-

current sensing is in the section on Fault Mode.

Figure 10 shows the functionality of the CPH,

RPH and RUN pins of IC2 during Startup, Pre-

heat, Ignition Ramp and Run modes.

The Run mode frequency is that at which the lamp is driven to the lamp manufacturers recom-

mended lamp power rating. The running frequency of the lamp resonant output stage for selected

component values is defined as,

Figure 10: Top trace: CPH pin IC2

Middle trace: RPH pine IC2

Bottom trace: RUN pin IC2

2 2

2

2

2

2

2

2

2

1

4 2

1

2

1

2

1

C L

V

V

CV

P

LC CV

P

LC

f

Lamp

DCbus

Lamp

Lamp

Lamp

Lamp

run

,

_

1

1

]

1

,

_

,

_

(3)

12 www.irf.com

C = Lamp resonant circuit capacitor (C14) (F)

PLamp = Lamp running power (W)

VLamp = Lamp running voltage amplitude (V)

L = Lamp resonant circuit inductor (L3) (H)

where,

Figure 11 shows the voltage appearing across the lamp while Figure 12 shows the current flowing

through the lamp during Startup, Preheat, Ignition Ramp and Run modes.

Figure 11: Lamp voltage during Startup, Preheat,

Ignition Ramp and Run

Figure 12: Lamp current during Startup, Preheat,

Ignition Ramp and Run (100mA/div.)

Normal Powerdown

A Normal Powerdown occurs when the AC line voltage is disconnected from the ballast. When this

occurs the voltage on the VDC pin of IC2 drops below the line fault threshold (3V) and IC2 shuts

down in a controlled fashion. The oscillator is stopped, the half-bridge driver outputs (LO and HO)

are turned off and capacitors CPH, CRAMP, CSTART and CT are discharged. IC2 also goes into its

UVLO/micro-power mode and the bus voltage begins to collapse.

Fault Mode

Fault mode is when the ballast driver is shutdown due to the detection of a lamp fault. Note that when

the ballast is in this Fault mode the power factor correction section of the ballast is also shutdown

and the bus voltage will drop to the non-boosted/unregulated level. There are several lamp fault

conditions which can put the ballast into the Fault mode. The lamp fault conditions detected include:

near/below resonance (under-current) detection, hard-switching detection and over-current detec-

tion. Resistor RCS in the source lead of the low side MOSFET (M3) serves as the current sensing

point for the half-bridge which is used to detect these lamp fault conditions. In operation when the

half-bridge is oscillating, a voltage appears across RCS whenever the low side MOSFET, M3, is

13 www.irf.com

turned on or the high side MOSFET, M2, is turned off. The magnitude of this voltage directly relates

to the current in the lamp resonant circuit. Figure 13 shows the voltage which appears across resis-

tor RCS during normal Run mode conditions while Figure 14 shows the voltage appearing across the

lamp during the end of Preheat mode, Ignition Ramp mode and the beginning of Run mode. Also

shown in Figure 13 are the gate drive signals for the low side MOSFET (LO pin) and the high side

MOSFET (HO-VS pin).

Figure 13: Normal Run mode, Upper trace: voltage

across RCS, Middle trace: IC2 LO pin voltage,

Lower trace: IC2 HO-VS pin voltage

Figure 14: Normal lamp ignition: Lamp voltage during

the end of Preheat mode, Ignition Ramp mode

and the beginning of the Run mode

During the Preheat mode the voltage across resistor RCS is not measured. However, at the end of

Preheat mode (the beginning of the Ignition Ramp mode) the hard-switching and over-current detec-

tion are enabled. If at any time thereafter the voltage magnitude across resistor RCS rises above the

over-current (CS+) threshold of the CS pin of IC2, a lamp fault condition is signaled and the half-

bridge output MOSFETs, (M2 and M3) are turned off and the ballast goes into Fault mode. This can

happen if the lamp fails to ignite or if the upper filament is open. For failure to ignite the lamp, the

current in the half-bridge increases and thus the voltage across resistor RCS increases above the

over-current threshold signaling a fault. Figure 15 shows the voltage across resistor RCS and the

voltage appearing across the lamp when the ballast detects a failure to ignite the lamp and goes into

Fault mode. The CS+ threshold is determined by resistor ROC. An internal current source of 50uA is

connected to the OC pin of IC2 which when applied to resistor ROC sets a voltage at the OC pin.

This voltage is the CS+ threshold of IC2. Figure 16 shows the voltage appearing across the lamp

during the tail end of the Preheat mode and the Ignition Ramp mode for a failure of the lamp to ignite

condition. If the upper filament is open, the half-bridge output hard-switches and each time the low

side MOSFET (M3) is turned on a large current pulse occurs and thus a large voltage pulse occurs

across resistor RCS signaling a fault, Figure 17 shows this hard-switching condition. Figure 18 shows

the lamp voltage during the Preheat mode and beginning of Ignition Ramp mode for this hard-

switching condition when the lamp fault condition is detected. The ballast will remain in Fault mode

until either the line voltage is cycled or a lamp replacement is performed.

14 www.irf.com

Figure 15: Failure of lamp to ignite condition (lamp

filaments good): Upper trace: voltage across

RCS, Lower trace: lamp voltage

Figure 16: Failure of lamp to ignite condition (lamp

filaments good): Lamp voltage during the end

of Preheat and Ignition Ramp modes

Figure 17: Hard-switching condition (upper filament

open): Upper trace: voltage across RCS,

Middle trace: IC2 LO pin voltage,

Lower trace: IC2 HO-VS pin voltage

Figure 18: Hard-switching condition (upper filament open):

Lamp voltage during Preheat mode and beginning of

Ignition Ramp mode when lamp fault is detected

At the completion of the Ignition Ramp mode (beginning of the Run mode) the near/below resonance

(under-current) detection is also enabled. Near/below resonance detection is performed by synchro-

nously sensing the voltage across resistor RCS, which relates to the current flowing in the low side

MOSFET (M3), just prior to the turn off of M3. If this voltage is lower than the near/below resonance

threshold (CS- = 0.2V) of the CS pin of IC2, a lamp fault condition is signaled and the ballast goes

into Fault mode. This could occur if the frequency of oscillation becomes too close to the resonant

15 www.irf.com

frequency of the load circuit and the current in the load circuit commutates to close to zero. Figure 19

shows a near/below resonance condition where the voltage on resistor RCS falls below the 0.2V

threshold on the CS pin of IC2.

Figure 19: Near/Below Resonance conditions

Upper trace: voltage across RCS

Lower trace: half-bridge output voltage

Resistors R17, R18 and capacitor

C13 form a divider/filter network

which is used to detect an open lower

lamp filament and/or lamp replace-

ment. Under normal conditions, the

voltage across C8 is approximately

zero volts. However, if the lower fila-

ment becomes open or the lamp is

removed, the voltage across C13 in-

creases above the 2V threshold for

the SD pin of IC2 and signals a lamp

fault condition which in turn puts the

ballast into Fault mode. The ballast

remains in the Fault mode until the

line voltage is cycled or a lamp re-

placement is performed. If the lamp

is replaced with a lamp with a good

lower filament, the voltage on the SD

pin of IC2 is pulled back below the

2V threshold and the ballast will go

through a restart. Line voltage cycling

is also used to restart the ballast for all lamp fault conditions. The ballast will go through a full

Preheat, Ignition Ramp and Run modes any time a restart is performed. Note that the SD pin of IC2

is active during all modes of operation.

Another way that the ballast can go into Fault mode is if the AC line voltage falls below approximately

170Vrms. Resistors R11, R12 and capacitor C9 form a voltage divider/filter network which is con-

nected to the VDC pin of IC2 and is used to determine if the line voltage falls below permissible

levels. This happens when the line voltage is cycled or possibly a brownout condition occurs. The

VDC pin of IC2 senses a fault if the voltage at the pin falls below 3 volts and shutdown of the ballast

occurs. The ballast remains shutdown until the voltage at the VDC pin rises above 5.1 volts. At this

time if there are no other fault conditions the ballast will go through a full Preheat, Ignition Ramp and

Run mode. As in the case of the SD pin of IC2, the VDC pin of IC2 is active during all modes of

operation of the ballast.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245 Tel: (310) 252-7105

Data and specifications subject to change without notice. 10/28/2000

16 www.irf.com

Data Sheets

Lighting Ballast Control IC - Designers Manual

You might also like

- Coconut Midrib Removing Machine ThesisDocument91 pagesCoconut Midrib Removing Machine ThesisJohn Paul Del MundoNo ratings yet

- Iphone 6S Schematic - Vietmobile - VNDocument60 pagesIphone 6S Schematic - Vietmobile - VN1cvbnm60% (15)

- Iphone 6S Schematic - Vietmobile - VNDocument60 pagesIphone 6S Schematic - Vietmobile - VN1cvbnm60% (15)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- COMPASS TrainingDocument383 pagesCOMPASS TrainingNikhil Barshettiwar100% (3)

- Astm D635-2006Document7 pagesAstm D635-2006Boris AguilarNo ratings yet

- NXP Homebrew RF Design Challenge MRF300AN & MRF300BN 144Mhz Linear AmplifierDocument4 pagesNXP Homebrew RF Design Challenge MRF300AN & MRF300BN 144Mhz Linear AmplifierAnonymous cEIJYBqClG100% (4)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- M&E ReportDocument14 pagesM&E ReportMuhammad Zuhairi IINo ratings yet

- QuantEconlectures Python3Document1,362 pagesQuantEconlectures Python3Cristian F. SanabriaNo ratings yet

- Application Note 2034 LM3445 - 120VAC, 8W Isolated Flyback LED DriverDocument20 pagesApplication Note 2034 LM3445 - 120VAC, 8W Isolated Flyback LED DriverEduardoNo ratings yet

- f23Document3 pagesf23jaquel.kenithNo ratings yet

- Max 16841 Ev KitDocument16 pagesMax 16841 Ev KitjorojoroNo ratings yet

- Low-Cost Circuit Biases VCO For Cable and TV: Literature Number: SNOA836Document5 pagesLow-Cost Circuit Biases VCO For Cable and TV: Literature Number: SNOA836AtulNo ratings yet

- 300w PA Using A MRF300AN Transistor by Sergey EX8MLE The Four Metres Website - 1625828700391Document6 pages300w PA Using A MRF300AN Transistor by Sergey EX8MLE The Four Metres Website - 1625828700391Jeannot BopendaNo ratings yet

- Mikrotik 911 Repair - 222523Document7 pagesMikrotik 911 Repair - 222523antonio muñozNo ratings yet

- La 4278Document6 pagesLa 4278Carlos López Rivera0% (1)

- FAN7314 LCD Backlight Inverter Drive IC: Features DescriptionDocument3 pagesFAN7314 LCD Backlight Inverter Drive IC: Features DescriptionMaha DevanNo ratings yet

- Panasonic Inverter ManualDocument8 pagesPanasonic Inverter Manualsamernet2100% (1)

- LA4278Document7 pagesLA4278aalex28No ratings yet

- PC CMB Aux PCB v8 (Bill of Materials)Document1 pagePC CMB Aux PCB v8 (Bill of Materials)PRED4T0R85No ratings yet

- Trace Elliot Velocette 12r Schematic DiagramDocument9 pagesTrace Elliot Velocette 12r Schematic DiagramjonnycoolNo ratings yet

- TP M115 AiwaDocument12 pagesTP M115 AiwaBastierNo ratings yet

- TA8200ah Con DiagramaDocument12 pagesTA8200ah Con DiagramaHito de Merlo100% (1)

- Practical Electronics 1978 01 DrumsDocument6 pagesPractical Electronics 1978 01 DrumsDATrevinoNo ratings yet

- w1rtc Notes1 PDFDocument8 pagesw1rtc Notes1 PDFYogesh ThackreyNo ratings yet

- General Description Features: 300Khz, 2A/23V Step-Down DC-DC ConverterDocument23 pagesGeneral Description Features: 300Khz, 2A/23V Step-Down DC-DC ConverterJustin WilliamsNo ratings yet

- Ras Gkve2 Revisedfeb07 SVM 06036 2Document54 pagesRas Gkve2 Revisedfeb07 SVM 06036 2karunvandnaNo ratings yet

- LG Beko 28cz10rx Service ManualDocument32 pagesLG Beko 28cz10rx Service ManualAlan ScarfidiNo ratings yet

- Proiect CAD Ciorogariu Mihai Cristian, Grupa 2022: PWM GeneratorDocument25 pagesProiect CAD Ciorogariu Mihai Cristian, Grupa 2022: PWM GeneratorPlic TisitNo ratings yet

- MP3388Document12 pagesMP3388mirandowebsNo ratings yet

- QSC RMX1450 PDFDocument7 pagesQSC RMX1450 PDFJohnny Tenezaca DuarteNo ratings yet

- Elements v0.21: SMT PartsDocument3 pagesElements v0.21: SMT PartsrubixkubeNo ratings yet

- Intelligent CCFL Inverter Controller: FeaturesDocument12 pagesIntelligent CCFL Inverter Controller: FeaturesMirosław DżumakNo ratings yet

- BTX 250Document17 pagesBTX 250MUHAMMAD SISWANTORONo ratings yet

- LA4628Document9 pagesLA4628jgpbNo ratings yet

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocument9 pages20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66No ratings yet

- UC3842B/3843B: Unisonic Technologies Co., LTDDocument11 pagesUC3842B/3843B: Unisonic Technologies Co., LTDvannadioNo ratings yet

- Precision Waveform Generator/Voltage Controlled Oscillator FeaturesDocument12 pagesPrecision Waveform Generator/Voltage Controlled Oscillator FeaturesCharles Tineo0% (1)

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGiovanni Carrillo VillegasNo ratings yet

- An Analog Current Controller Design For Laser Diodes: Todd P. MeyrathDocument7 pagesAn Analog Current Controller Design For Laser Diodes: Todd P. MeyrathAfzal345No ratings yet

- Mikrotik RB433AHDocument8 pagesMikrotik RB433AHMochamad WahyudiNo ratings yet

- Analog Parts Kit - DigilentDocument6 pagesAnalog Parts Kit - DigilentMario AcostaNo ratings yet

- LYNX Audio Amplifier 275W 4 OhmiDocument11 pagesLYNX Audio Amplifier 275W 4 OhmiDanut777750% (2)

- G9 Bill of Materials: (The List May Contain Inaccuracies)Document4 pagesG9 Bill of Materials: (The List May Contain Inaccuracies)Marcos MesquitaNo ratings yet

- TinySwitch II PIDesign1Document7 pagesTinySwitch II PIDesign1Elias Moreira CamposNo ratings yet

- MK 2 PiDocument7 pagesMK 2 PiA Whick Bumbum TralalaNo ratings yet

- DIY 51 Super Rock Mite RM Kit CW Transceiver Shortwave TelegraphDocument11 pagesDIY 51 Super Rock Mite RM Kit CW Transceiver Shortwave TelegraphDavidNo ratings yet

- Mobile Photo Block DiagramDocument0 pagesMobile Photo Block DiagramAmeet Mehta100% (1)

- La 42205Document7 pagesLa 42205ban4444No ratings yet

- Ps 125 SMDocument7 pagesPs 125 SMGabNo ratings yet

- BOM - Rev-1 For SupreethDocument6 pagesBOM - Rev-1 For Supreethgautamkr15No ratings yet

- Amplificador LA42102Document8 pagesAmplificador LA42102SilvestrePalaciosLópezNo ratings yet

- Thiet Bi Bao Ve He Thong DienDocument215 pagesThiet Bi Bao Ve He Thong Dienngocvqpecc4No ratings yet

- Yaesu FT-101ZD Service ManualDocument193 pagesYaesu FT-101ZD Service ManualYayok S. AnggoroNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Fundamentals of Electronics 1: Electronic Components and Elementary FunctionsFrom EverandFundamentals of Electronics 1: Electronic Components and Elementary FunctionsNo ratings yet

- Beko Zz7.194r-5 Power Supply SCHDocument3 pagesBeko Zz7.194r-5 Power Supply SCH1cvbnmNo ratings yet

- Yamaha Rx-V559 Dsp-Ax559 Htr-5950 SMDocument116 pagesYamaha Rx-V559 Dsp-Ax559 Htr-5950 SM1cvbnmNo ratings yet

- Single Phase Tefc Cage MotorsDocument12 pagesSingle Phase Tefc Cage Motors1cvbnmNo ratings yet

- XTW100 Mini Programmer Schematic and Driver One TransistorDocument1 pageXTW100 Mini Programmer Schematic and Driver One Transistor1cvbnmNo ratings yet

- B140XTN02.0 40 Pin PDFDocument27 pagesB140XTN02.0 40 Pin PDF1cvbnmNo ratings yet

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 pagesIbm Lenovo Whistler Rev s1.3 SCH1cvbnmNo ratings yet

- Ibm r40 Laptop SchematicsDocument60 pagesIbm r40 Laptop Schematics1cvbnmNo ratings yet

- XTW100 Mini Programmer Schematic and Driver One TransistorDocument1 pageXTW100 Mini Programmer Schematic and Driver One Transistor1cvbnmNo ratings yet

- Acer Aspire 5542 5542G (Wistron JV50-TR8) Wistron JV50-TR 8VRAM JV50-TR8 Rev-1Document63 pagesAcer Aspire 5542 5542G (Wistron JV50-TR8) Wistron JV50-TR 8VRAM JV50-TR8 Rev-11cvbnmNo ratings yet

- Fujitsu Siemens Amilo l7310 Mitac 8650 Rev R0a SCHDocument34 pagesFujitsu Siemens Amilo l7310 Mitac 8650 Rev R0a SCH1cvbnmNo ratings yet

- Acer Aspire 5551G 5552G (Compal LA-5911P) Laptop SchematicsDocument55 pagesAcer Aspire 5551G 5552G (Compal LA-5911P) Laptop Schematics1cvbnmNo ratings yet

- R 30/35/40 HE Plus Combi: Installation and Servicing InstructionsDocument52 pagesR 30/35/40 HE Plus Combi: Installation and Servicing Instructions1cvbnmNo ratings yet

- GreenStar 25 CDi PDFDocument60 pagesGreenStar 25 CDi PDF1cvbnmNo ratings yet

- R 25 & 30 HE Combi: Installation and Servicing InstructionsDocument48 pagesR 25 & 30 HE Combi: Installation and Servicing Instructions1cvbnmNo ratings yet

- R 25 & 30 HE Combi: Installation and Servicing InstructionsDocument48 pagesR 25 & 30 HE Combi: Installation and Servicing Instructions1cvbnmNo ratings yet

- iPhone-3G Battery SVCM enDocument6 pagesiPhone-3G Battery SVCM en1cvbnmNo ratings yet

- Quadro ctv-55d10 ctv-55f12 ctv-55v20 ctv-55n11 ctv-55z10 ctv-55x10 ctv-37d10 ctv-37x10 TXT Mkii Chassis 5p60 PDFDocument40 pagesQuadro ctv-55d10 ctv-55f12 ctv-55v20 ctv-55n11 ctv-55z10 ctv-55x10 ctv-37d10 ctv-37x10 TXT Mkii Chassis 5p60 PDF1cvbnmNo ratings yet

- AN Self-Programming+Examples+for+78K0 Kx2+MicrocontrollersDocument78 pagesAN Self-Programming+Examples+for+78K0 Kx2+Microcontrollers1cvbnmNo ratings yet

- Mnit Admission LetterDocument1 pageMnit Admission LetterAjaj AlamNo ratings yet

- SOP-T-0005 - Standard Operating (Test) Procedure - CUBE TESTDocument18 pagesSOP-T-0005 - Standard Operating (Test) Procedure - CUBE TESTAvidip DeyNo ratings yet

- Property Options Pune - 5000 SF DSVDocument40 pagesProperty Options Pune - 5000 SF DSVjitesh vachhaniNo ratings yet

- Ultra Power Acb User ManualDocument138 pagesUltra Power Acb User ManualRaj KumarNo ratings yet

- TP Seating - 13 - Nov ANDocument5 pagesTP Seating - 13 - Nov ANNitish KumarNo ratings yet

- Tramfloc Polymer TechnologyDocument8 pagesTramfloc Polymer TechnologyVel MuruganNo ratings yet

- Coalbrookdale Darby Stove (Boiler Model) : Spare Parts ManualDocument7 pagesCoalbrookdale Darby Stove (Boiler Model) : Spare Parts ManualDavid Mark JonesNo ratings yet

- Eis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abDocument5 pagesEis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abhastmishNo ratings yet

- IP Code - Wikipedia, The Free EncyclopediaDocument6 pagesIP Code - Wikipedia, The Free Encyclopediarasheed313No ratings yet

- INNOVA 2.0E/2.0G (Auto) (Minor Change) : Model Code: TGN40Document4 pagesINNOVA 2.0E/2.0G (Auto) (Minor Change) : Model Code: TGN40Ismail IbrahimNo ratings yet

- Construction Material Lecture NoteDocument12 pagesConstruction Material Lecture NoteMohamedNo ratings yet

- Batch Short Circuit Users ManualDocument64 pagesBatch Short Circuit Users ManualAshleyNo ratings yet

- HDFC ERGO General Insurance Company Limited: Policy No. 2312 1005 0512 8700 000Document3 pagesHDFC ERGO General Insurance Company Limited: Policy No. 2312 1005 0512 8700 000rajkumargiritekarNo ratings yet

- 6016 ManualDocument9 pages6016 ManualDoceigenNo ratings yet

- Science:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonDocument3 pagesScience:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonJohnSmithNo ratings yet

- PBA Therm Clad BrochureDocument2 pagesPBA Therm Clad BrochureJames DickinsonNo ratings yet

- Ansul: Inergen 150 Bar SystemsDocument140 pagesAnsul: Inergen 150 Bar SystemsDaryl HeeralalNo ratings yet

- MAC Address and MAC FilteringDocument2 pagesMAC Address and MAC FilteringCleo RubinoNo ratings yet

- Development and Testing of Sugarcane Juice Extractor: Agidi GbaboDocument5 pagesDevelopment and Testing of Sugarcane Juice Extractor: Agidi Gbabomekanic24100% (1)

- CHAPTER 8: Checkboxes and Radio Buttons: ObjectivesDocument7 pagesCHAPTER 8: Checkboxes and Radio Buttons: Objectivesjerico gaspanNo ratings yet

- Optocoupler Input Drive CircuitsDocument7 pagesOptocoupler Input Drive CircuitsLuis Armando Reyes Cardoso100% (1)

- Salesforce Workflow CheatsheetDocument4 pagesSalesforce Workflow Cheatsheetgowtham 099091No ratings yet

- Design of Power Transmission SystemDocument67 pagesDesign of Power Transmission SystemVivek LevinNo ratings yet

- GL1200. .Service - ManualDocument415 pagesGL1200. .Service - ManualIpavec RokNo ratings yet

- Corrosion Magazine Issue117 LowresDocument36 pagesCorrosion Magazine Issue117 Lowressaminasritn100% (2)