Professional Documents

Culture Documents

Acee 2010-2 Ce W - Wuwer R - Walentynski

Acee 2010-2 Ce W - Wuwer R - Walentynski

Uploaded by

Pasc Oana JianinaCopyright:

Available Formats

You might also like

- Stories For Good MannersDocument55 pagesStories For Good Mannersሃይማኖት ኬሜቶNo ratings yet

- On Bending Stiffness of Composite TubesDocument7 pagesOn Bending Stiffness of Composite TubesJeremy WilliamsNo ratings yet

- Committed StiffnessDocument15 pagesCommitted StiffnessMarco Gaetani d'AragonaNo ratings yet

- Notes On The Linear Analysis of Thin-Walled BeamsDocument76 pagesNotes On The Linear Analysis of Thin-Walled BeamsPasc Oana JianinaNo ratings yet

- Library Hub and School Library Action Plan: Areas Objectives Activities Persons Involved Time Line Expected OutcomeDocument4 pagesLibrary Hub and School Library Action Plan: Areas Objectives Activities Persons Involved Time Line Expected OutcomeKaren dale Doble100% (4)

- EpidemiologyDocument58 pagesEpidemiologyrebecca100% (4)

- Crowd Psychology - WikipediaDocument8 pagesCrowd Psychology - WikipediaD BNo ratings yet

- Finite Element Modeling of Concrete Beams Prestressed With External TendonsDocument8 pagesFinite Element Modeling of Concrete Beams Prestressed With External TendonsviniciusltNo ratings yet

- Torsion of Open and Closed Thin-WalledLaminated Composite SectionsDocument28 pagesTorsion of Open and Closed Thin-WalledLaminated Composite SectionsFlmkaneNo ratings yet

- Theoretical and Numerical Stability Analyses ofDocument28 pagesTheoretical and Numerical Stability Analyses ofsaber javidNo ratings yet

- Studies To Minimize The Effects of Bond Slipage in Extreior Joints of RC Ductile Moment Resisting Frames PDFDocument8 pagesStudies To Minimize The Effects of Bond Slipage in Extreior Joints of RC Ductile Moment Resisting Frames PDFrjtcostaNo ratings yet

- 571-Article Text PDF-4626-1-10-20130303Document12 pages571-Article Text PDF-4626-1-10-20130303CESAR ARMANDO JOSIMAR DEL CID JUAREZNo ratings yet

- Secondary Bending Joint PDFDocument19 pagesSecondary Bending Joint PDFPhilippeWojtowiczNo ratings yet

- Modeling and Analysis of Discretely Supported Thin-Walled Silo Shells With Stringer Stiffeners at The SupportsDocument8 pagesModeling and Analysis of Discretely Supported Thin-Walled Silo Shells With Stringer Stiffeners at The SupportsAnonymous wWOWz9UnWNo ratings yet

- Metals: Bidirectional Response of Weak-Axis End-Plate Moment Connections: Numerical ApproachDocument18 pagesMetals: Bidirectional Response of Weak-Axis End-Plate Moment Connections: Numerical ApproachRicardo Muñiz DelgadoNo ratings yet

- Archives of Civil Engineering, LX, 4, 2014 DOI: 10.2478/ace-2014-0029Document20 pagesArchives of Civil Engineering, LX, 4, 2014 DOI: 10.2478/ace-2014-0029MichelSagnoNo ratings yet

- A Study of R.C.C. Beam-Column Connection Subjected To PDFDocument7 pagesA Study of R.C.C. Beam-Column Connection Subjected To PDFInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Behavior of Beams With Dowel ActionDocument5 pagesBehavior of Beams With Dowel ActioncustomerxNo ratings yet

- 547 002 PDFDocument19 pages547 002 PDFLikhon BiswasNo ratings yet

- Curved I-Girder Design: Esign TheDocument19 pagesCurved I-Girder Design: Esign TheLikhon BiswasNo ratings yet

- Final Term Paper SubmissionDocument5 pagesFinal Term Paper SubmissionKandousi YassineNo ratings yet

- Nonlinear Buckling Behaviours of Thin-Walled Functionally Graded Open Section BeamsDocument11 pagesNonlinear Buckling Behaviours of Thin-Walled Functionally Graded Open Section Beamsdjoumana ahmiediNo ratings yet

- Stability of Corrugated Expansion BellowsDocument21 pagesStability of Corrugated Expansion Bellowsnutan zambreNo ratings yet

- Web Buckling in Castellated Beams: A. A. Aglan, R. G. RedwoodDocument14 pagesWeb Buckling in Castellated Beams: A. A. Aglan, R. G. RedwoodmokhtazulNo ratings yet

- Numerical Analysis of Steel-Reinforced Concrete Composite GirdersDocument12 pagesNumerical Analysis of Steel-Reinforced Concrete Composite GirdersSeifeldin Ali MarzoukNo ratings yet

- Dynamic Analysis and Response of Semirigid Flames: E. M. LuiDocument11 pagesDynamic Analysis and Response of Semirigid Flames: E. M. LuikhaledmegahedNo ratings yet

- Bracing of Steel-Concrete Composite Bridge During ConstructionDocument10 pagesBracing of Steel-Concrete Composite Bridge During Constructionparvaneh.eNo ratings yet

- Buckling Behavior of Curved Composite Beams With Different Elastic Response in Tension and CompressionDocument10 pagesBuckling Behavior of Curved Composite Beams With Different Elastic Response in Tension and CompressionFox_oNe_7No ratings yet

- Assessment of The Out-Of-plane Imperfections of A Steel Tied Arch BridgeDocument8 pagesAssessment of The Out-Of-plane Imperfections of A Steel Tied Arch BridgeDhimas Surya NegaraNo ratings yet

- AUEJ - Volume 13 - Issue 49 - Pages 1392-1403Document13 pagesAUEJ - Volume 13 - Issue 49 - Pages 1392-1403محمد حسن محمد حسنNo ratings yet

- Journal of Petroleum Science and Engineering: Youhong Sun, Yongping Yu, Baochang LiuDocument9 pagesJournal of Petroleum Science and Engineering: Youhong Sun, Yongping Yu, Baochang LiuEzequiel AbrilNo ratings yet

- Analytical Model For Beams On Elastic Foundations Considering The Coupling of HorizontalDocument12 pagesAnalytical Model For Beams On Elastic Foundations Considering The Coupling of HorizontalPrantik Adhar SamantaNo ratings yet

- Trindade Wolter Sampaio 2005 JSVDocument22 pagesTrindade Wolter Sampaio 2005 JSVhlsmonteiroNo ratings yet

- Civil Engg - Ijcseierd - Experimental and Analytical Study On The Dynamic Behavior of Frames Under Relative Displacement Between Support PointsDocument10 pagesCivil Engg - Ijcseierd - Experimental and Analytical Study On The Dynamic Behavior of Frames Under Relative Displacement Between Support PointsTJPRC PublicationsNo ratings yet

- Cracks As Important Constituents of Strut and Tie ModelsDocument20 pagesCracks As Important Constituents of Strut and Tie ModelsBrandon LevineNo ratings yet

- Building Frame Bridge Bent Structural WallDocument9 pagesBuilding Frame Bridge Bent Structural WallpmergosNo ratings yet

- Strength Analysis Modelling of FlexibleDocument19 pagesStrength Analysis Modelling of Flexiblexinlin.cppNo ratings yet

- OnZeroStiffness PDFDocument24 pagesOnZeroStiffness PDFAvinash KumarNo ratings yet

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsDocument6 pagesCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- Operating Bolt Load Calculation in Joints of Complex Elastic StructuresDocument8 pagesOperating Bolt Load Calculation in Joints of Complex Elastic Structuresdf_campos3353No ratings yet

- Shear-Flexible Element With Warping For Thin-Walled Open BeamsDocument19 pagesShear-Flexible Element With Warping For Thin-Walled Open BeamsnevinkoshyNo ratings yet

- Shapes of A Suspended Curly Hair: Week Ending 14 FEBRUARY 2014Document5 pagesShapes of A Suspended Curly Hair: Week Ending 14 FEBRUARY 2014MaingotNo ratings yet

- Plastic Collapse of General Frames: Mcivor, A. S. Wineman WangDocument14 pagesPlastic Collapse of General Frames: Mcivor, A. S. Wineman WangMohamed N AboudNo ratings yet

- 2821 6440 1 PB PDFDocument11 pages2821 6440 1 PB PDFsaulolmNo ratings yet

- DownloadDocument14 pagesDownloadGladimir GrigolettiNo ratings yet

- Nonlinear and Time-Dependent Analysis of Continuous Unbonded Pre-Stressed BeamDocument11 pagesNonlinear and Time-Dependent Analysis of Continuous Unbonded Pre-Stressed BeamPhạm Tiến ĐạtNo ratings yet

- Shi 1989Document16 pagesShi 1989Sai GowthamNo ratings yet

- Buckling and Design of Columns With Intermediate Elastic Torsional RestraintDocument14 pagesBuckling and Design of Columns With Intermediate Elastic Torsional Restraintfahmi aballiNo ratings yet

- Performance of Base-Plate Connections of Steel Storage Pallet RacksDocument10 pagesPerformance of Base-Plate Connections of Steel Storage Pallet RacksAlan GironNo ratings yet

- 1988 Finite Element Analysis of Stability of Thin-Walled Beams of Open SectionDocument15 pages1988 Finite Element Analysis of Stability of Thin-Walled Beams of Open SectionHussein M. H. Al-KhafajiNo ratings yet

- Corrugated Web BeamDocument4 pagesCorrugated Web BeamNegin MalekiNo ratings yet

- Application of Nonlinear Concrete Model PDFDocument7 pagesApplication of Nonlinear Concrete Model PDFOat GTNo ratings yet

- Ductility Analysis of Prestressed Concrete Beams With Unbonded TendonsDocument9 pagesDuctility Analysis of Prestressed Concrete Beams With Unbonded TendonsvenkatesanjsNo ratings yet

- BSHV Elastica Follower 2007Document6 pagesBSHV Elastica Follower 2007AmenNo ratings yet

- Elastic Analysis O F Spatial Shear Wall Systems With Flexible BasesDocument18 pagesElastic Analysis O F Spatial Shear Wall Systems With Flexible Basessanh137No ratings yet

- (Jonsson & Ramonas, 2012) - Flange Curling in Cold Formed ProfilesDocument11 pages(Jonsson & Ramonas, 2012) - Flange Curling in Cold Formed Profileschristos032No ratings yet

- Li 2002Document14 pagesLi 2002fahmi aballiNo ratings yet

- Experimental Force Identification by Using Natural OptimizationDocument9 pagesExperimental Force Identification by Using Natural OptimizationbrucemlsNo ratings yet

- 273 10Document52 pages273 10Dr Axel ChangNo ratings yet

- Theoretical Study For Bond Between Reinforcement Steel and ConcreteDocument10 pagesTheoretical Study For Bond Between Reinforcement Steel and ConcreteSulaim Al KautsarNo ratings yet

- Articulo Dispacion Victor CeballosDocument20 pagesArticulo Dispacion Victor CeballosVictor CeballosNo ratings yet

- Buckling and Vibration of Stiffened PlatesDocument11 pagesBuckling and Vibration of Stiffened Platesغازي اللجيNo ratings yet

- A Parametric Survey of The Influence of The Semi-Rigid Connections On The Shakedown of Elasto-Plastic FramesDocument9 pagesA Parametric Survey of The Influence of The Semi-Rigid Connections On The Shakedown of Elasto-Plastic FramesAmine OsmaniNo ratings yet

- 1 s2.0 S0143974X1931404X MainDocument10 pages1 s2.0 S0143974X1931404X MainHugNitNo ratings yet

- Hyperbolic Structures: Shukhov's Lattice Towers - Forerunners of Modern Lightweight ConstructionFrom EverandHyperbolic Structures: Shukhov's Lattice Towers - Forerunners of Modern Lightweight ConstructionNo ratings yet

- Stresses Around A Circular Hole: KKK KK K 4 9 4 9Document1 pageStresses Around A Circular Hole: KKK KK K 4 9 4 9Pasc Oana JianinaNo ratings yet

- Comparative Study On Reinforced Masonry With Polymer GridsDocument6 pagesComparative Study On Reinforced Masonry With Polymer GridsPasc Oana JianinaNo ratings yet

- Tensar PPT Biaxial GridsDocument20 pagesTensar PPT Biaxial GridsPasc Oana JianinaNo ratings yet

- The Analysis of The Transient Dynamic Response of Elastic Thin-Walled Beams of Open Section Via The Ray MethodDocument13 pagesThe Analysis of The Transient Dynamic Response of Elastic Thin-Walled Beams of Open Section Via The Ray MethodPasc Oana JianinaNo ratings yet

- GBT-based Analysis of Tapered Thin-Walled Members: Recent DevelopmentsDocument12 pagesGBT-based Analysis of Tapered Thin-Walled Members: Recent DevelopmentsPasc Oana JianinaNo ratings yet

- ASP Onnee Project ReportDocument29 pagesASP Onnee Project ReportPasc Oana JianinaNo ratings yet

- Prof - Tamura July19 APSS2010 Wind-Universitatea TokyoDocument156 pagesProf - Tamura July19 APSS2010 Wind-Universitatea TokyoPasc Oana JianinaNo ratings yet

- Isla VerdeDocument3 pagesIsla VerdeEdjey Luis F. MatinongNo ratings yet

- Management Consulting 101 So, You Might Want To Be A ConsultantDocument58 pagesManagement Consulting 101 So, You Might Want To Be A ConsultantTrisha PanditNo ratings yet

- Unit 5 Group Behavior & Group Dynamics, Team EffectivenessDocument67 pagesUnit 5 Group Behavior & Group Dynamics, Team Effectivenesspratikyaul100% (3)

- 5) Asymemtric - GRACHDocument34 pages5) Asymemtric - GRACHDunsScotoNo ratings yet

- Devex 2018 Introduction To Reservoir SimulationDocument52 pagesDevex 2018 Introduction To Reservoir SimulationKonul AlizadehNo ratings yet

- HieuTQ Asm2 529 PDFDocument16 pagesHieuTQ Asm2 529 PDFQuân ShellNo ratings yet

- Industry 4.0. German Standardization RoadmapDocument77 pagesIndustry 4.0. German Standardization Roadmapmihai.banicaNo ratings yet

- A Geographic Information SystemDocument5 pagesA Geographic Information SystemVikneswaran Gunahlan NeshNo ratings yet

- Simple Random SamplingDocument59 pagesSimple Random SamplingAlyssandra N.No ratings yet

- JEDI Course Notes Intro1 MasterDocumentDocument244 pagesJEDI Course Notes Intro1 MasterDocumentMarkQuindozaNo ratings yet

- Fundamentals of Physics, 8th Edition Halliday, Resnick, WalkerDocument5 pagesFundamentals of Physics, 8th Edition Halliday, Resnick, Walkerabhishekkumar1996No ratings yet

- 9 Class Holiday HomeworkDocument5 pages9 Class Holiday HomeworksavageitgirlNo ratings yet

- Fluidewell ProfileDocument12 pagesFluidewell ProfileChaudhary AsadullahNo ratings yet

- Learning Theory by BanduraDocument5 pagesLearning Theory by BanduraOnwuka FrancisNo ratings yet

- StaffDocument4 pagesStaffBianca RadutaNo ratings yet

- Survey Questions AwarenessDocument4 pagesSurvey Questions Awarenesszoey zaraNo ratings yet

- Michael Heinrich - Invaders From Marx: On The Uses of Marxian Theory, and The Difficulties of A Contemporary ReadingDocument8 pagesMichael Heinrich - Invaders From Marx: On The Uses of Marxian Theory, and The Difficulties of A Contemporary ReadingStipe Ćurković100% (1)

- PYRAMIDOLOGYDocument92 pagesPYRAMIDOLOGYverdiblue100% (2)

- AdvertisementDocument1 pageAdvertisementSachin KhandekarNo ratings yet

- ProspectusDocument51 pagesProspectusalext1985No ratings yet

- Parking Issuu PDFDocument132 pagesParking Issuu PDFRicardo FajardoNo ratings yet

- Corrosion Raccords Proform 2018 PDFDocument34 pagesCorrosion Raccords Proform 2018 PDFDiegoNo ratings yet

- Android: Multimedia, Animation and Graphics: Syllabus: Playing Audio, Playing Video, Rotate AnimationDocument7 pagesAndroid: Multimedia, Animation and Graphics: Syllabus: Playing Audio, Playing Video, Rotate AnimationvisheshNo ratings yet

- Outlook For The Next Framework Programme: 29 January 2018, Radisson Blu, BrusselsDocument2 pagesOutlook For The Next Framework Programme: 29 January 2018, Radisson Blu, BrusselsAndrea StavrouNo ratings yet

- Balancing of Redox Reactions - 1Document2 pagesBalancing of Redox Reactions - 1Anonymous vRpzQ2BL0% (1)

Acee 2010-2 Ce W - Wuwer R - Walentynski

Acee 2010-2 Ce W - Wuwer R - Walentynski

Uploaded by

Pasc Oana JianinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acee 2010-2 Ce W - Wuwer R - Walentynski

Acee 2010-2 Ce W - Wuwer R - Walentynski

Uploaded by

Pasc Oana JianinaCopyright:

Available Formats

1.

INTRODUCTION

For several recent years a crucial demand for thin-

walled structures made of cold-formed profiles has

been observed. Many overseas companies erected in

Poland hundreds of buildings according to their struc-

tural system solutions; this was described in Ref. [1].

The rich assortment of thin-walled cross-sections

offered by Polish metallurgic factories can encourage

development of an own structural system with joints

enabling a reliable and quick assembly on the con-

struction site. These requirements are satisfied by

blind bolts BOM R16-6, diameter 13.6 mm [2].

They permit to join walls of a thickness 3.06.0 mm

with open or semi-open economic closed cross-section

profiles.

The aim of the investigations is an attempt to recog-

ANALYSIS OF A LAP-JOINT IN A THIN-WALLED STRUCTURE

UNDER COMBINED BENDING AND SHEARING LOAD

Walter WUWER

a

, Ryszard WALENTYSKI

b

a

Associate Prof.; Faculty of Civil Engineering, The Silesian University of Technology, Akademicka 5, 44-100 Gliwice, Poland

E-mail address: Walter.Wuwer@polsl.pl

b

Associate Prof.; Faculty of Civil Engineering, The Silesian University of Technology, Akademicka 5, 44-100 Gliwice, Poland

E-mail address: Ryszard.Walentynski@polsl.pl

Received: 20.01.2010 ; Revised: 01.03.2010; Accepted: 15.04.2010

Abs t r a c t

Basing on an experimentally verified mathematical nonlinear model describing the statical behavior of an arbitrary joint of

thin-walled profiles a numerical analysis of a five-blind-bolt lap-joint has been carried out. Diagrams of three cases of limit

curves: I limit load bearing capacity, II limit displacements and III limit of the mathematical model have been plot-

ted. Additionally, two limit surfaces of the joint have been presented. The main aim of the contribution is an analysis of the

mutual influence of the shearing force and the moment on the corresponding rigidities. To show this, the interaction rela-

tions between rotation, transverse and axial rigidities have been expressed in terms of rigidity reduction coefficients. Their

diagrams are presented in form of contour plots. The analysis has been carried out for different angles of the direction of

the shearing force. Contour plots of displacements and the corresponding forces are shown for selected bolts, too. It has

been shown that the coefficients of rigidity reduction are not sensitive to changes of the angle of transverse forces direction,

whereas some forces in the bolts change considerably with this angle.

St r e s z c z e ni e

Bazujc na dowiadczalnie zweryfikowanym nieliniowym modelu opisujcym statyczne zachowanie si dowolnego

poczenia cienkociennych profili przeprowadzono numeryczn analiz poczenia zakadkowego na pi cznikw.

Zostay narysowane wykresy trzech przypadkw krzywych granicznych: I granicy nonoci, II granicy przemieszcze

i III granicy modelu matematycznego. Gwnym celem pracy jest analiza wzajemnego wpywu siy cinajcej i momentu

na odpowiadajce sztywnoci. Aby to pokaza, relacje interakcyjne pomidzy obrotem, a sztywnociami poprzecznymi

i osiowymi zostay wyraone poprzez wspczynniki redukcji sztywnoci. Zostay one pokazane w postaci map konturowych,

Te analizy zostay przeprowadzone dla rnych ktw kierunku siy cinajcej. Dla wybranych cznikw przestawiono te

mapy konturowe przemieszcze i odpowiadajcych im si. Pokazano, e wspczynniki redukcji sztywnoci nie s wraliwe

na zmiany kta kierunkowego si poprzecznych, natomiast niektre siy w cznikach zmieniaj si istotnie wraz z tym

ktem.

Ke y wor ds : Nonlinear; Lap-joint; Limit state; Thin-walled; Interaction; Blind bolt; Lightweight; Rigidity reduction.

2/ 2010 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 71

A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T

The Si l esi an Uni ver si t y of Technol ogy No. 2/ 2010

W . W u w e r , R . W a l e n t y s k i

nize behavior of blind-bolt joint in thin-walled struc-

tures. A mathematical model of the joint has been

proposed and experimentally verified. General gov-

erning equations of an arbitrary multi-bolt joint

loaded with a moment and shearing force has been

formulated in Refs [3, 4, 5, 6]. Constitutive relations

in the form of exponential function have been evalu-

ated by a function of nonlinear regression, according

to regulations quoted in [7].

Mathematical model has been implemented within

the system Mathematica [8], by Walentyski R. and

verified experimentally, [4], by Wuwer W. A good

coincidence between numerical and experimental

data has been observed in [9].

According to the proposed model, which has been

verified experimentally, we can estimate the load

capacity and rigidity of an arbitrary joint, and to

develop limit curves and limit surfaces of displace-

ments and the load capacity for an arbitrary systemof

loads. Previously we should evaluate the parameters

of a constitutive relation. This can be done by an

experiment developed according to [7].

Contemporary computer systems for numerical

analyses based on the Finite Element Method, for

example Robot Millennium, permit also nonlinear

releases of bars. They enable us to compute bar struc-

tures with flexible nodes. The values of three rigidi-

ties in the joint, depending on rotation and two

orthogonal displacements occurring between con-

nected walls of cold-formed profiles have a crucial

influence on the internal forces and vertical and hor-

izontal deflection, as shown in [9]. The function in the

computer system does not take into account the

interaction between three instantaneous rigidities.

They allow only to define, for example, the rotation

rigidity as a function of the moment. The shearing

force has been neglected.

We have developed a proposal of evaluating the

rigidities of flexible nodes. The rigidities depend on

three parameters of degradation

M

,

H

and

V

.

These parameters take only into account variations

of the global plastic destruction of the corresponding

force. For example,

M

is a function of momentum.

The introduced coefficients

M

,

H

and

V

take into

account the mutual influence of forces on the rigidi-

ties. For example,

M

depends on the moment and

the components of the shearing force.

The paper is illustrated by contour and parametric

plots of some displacement, the corresponding forces

in blind bolts, the coefficients

M

,

H

and

V

, the limit

curves and limit surfaces.

This paper is a further development of the results

presented in [13].

2. PROBLEM DESCRIPTION

2.1. Physical model

We will deal in this paper with a joint that is present-

ed in Fig. 1. The 5-blind-bolt joint is loaded with the

moment M and the transverse W sloped at the angle

W

to the vertical axis y. Due to the symmetry of the

joint the practical analysis can be reduced to the

angle

W

e (u,45).

It can be proved that in this case the most saddled

bolt is the fourth one, Fig. 1. Figure 2 illustrates an

analysis for 3 angles

W

e (u,90) showing that this

bolt always takes over most of the load.

It is also easily visible that the fifth bolt does not take

part in the bearing of the moment.

2.2. System of equations for a 5-blind-bolt joint

A general systemof governing equations is presented

in the dissertation [4]. For the considered problem

the system of equations has been expanded, and we

have the following equations:

3 equations of equilibrium

72 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 2/ 2010

0

2

4

4

3

3

2

2

1

1

5

5

4

4

3

3

2

2

1

1

|

|

.

|

\

|

+

|

|

.

|

\

|

+ + + +

o o o o

|

o o o o o

S S S S r S S S S S

v V , (1)

0

2

4

4

3

3

2

2

1

1

5

5

4

4

3

3

2

2

1

1

|

|

.

|

\

|

+

|

|

.

|

\

|

+ + + +

o o o o

|

o o o o o

S S S S r S S S S S

u H , (2)

Figure 1.

Scheme of a five-blind-bolt joint loaded with the bending

moment Mand the shearing force Winclined at the angle

W

to the axis y

ANALYSI S OF A L AP- JOI NT I N A THI N- WALLED STRUCTURE UNDER COMBI NED BENDI NG AND SHEARI NG LOAD

5 geometrical equations

constitutive equation 1

where:

S

i

forces in blind bolts,

i

mutual displacement of joined profile walls in

the direction of the forces Si,

u mutual horizontal displacement of the walls in

the joint,

C

I

V

I

L

E

N

G

I

N

E

E

R

I

N

G

e

2/ 2010 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 73

Figure 2.

Extreme cases of loading of a five-blind-bolt joint with the forces M and W; a)

W

= 0, b)

W

= /4, c)

W

= /2

c

a b c

. 0 2

2

4

4

3

3

2

2

1

1

4

4

3

3

2

2

1

1

4

4

3

3

2

2

1

1

|

|

.

|

\

|

+ + +

|

|

.

|

\

|

+

+

|

|

.

|

\

|

+ +

o o o o

|

o o o o

o o o o

S S S S

r

S S S S

v

S S S S

u

r

M

(3)

0

2 2

2 2

1

|

.

|

\

|

+ + |

.

|

\

|

| |

o

r

v

r

u ,

(4)

0

2 2

2 2

2

|

.

|

\

|

+ |

.

|

\

|

| |

o

r

v

r

u ,

(5)

0

2 2

2 2

3

|

.

|

\

|

+ |

.

|

\

|

+

| |

o

r

v

r

u ,

(6)

0

2 2

2 2

4

|

.

|

\

|

+ + |

.

|

\

|

+

| |

o

r

v

r

u ,

(7)

0

2 2

5

v u .

(8)

i s

b

s i

e a S

1 ,

(9)

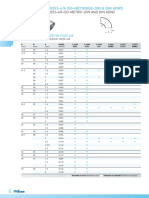

Figure 3.

Relation S

1

-

L+E

when walls 5.0 mm thick are joined in five test elements I

W . W u w e r , R . W a l e n t y s k i

v mutual vertical displacement of the walls in the

joint,

mutual rotation displacement of the walls in the

joint,

r radius, see Fig. 1,

H horizontal component of the shearing force

V vertical component of the shearing force

M moment, see Fig. 1.

The parameters a

s

and b

s

in the constitutive relation,

Eqn 9, have been evaluated by nonlinear regression

from experimental data, see Fig. 3.

2.3. Symbolic computation

The systemof equation (1-9) can be reduced to a sys-

tem of three equations with unknown values of the

displacements u, v and . This was done by applying

the computer system Mathematica. Due to the com-

plicated form of the equations the system is not pre-

sented in this paper.

74 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 2/ 2010

Figure 4.

Boundary curves I, II and III of a five-blind-bolt joint loaded with the forces M and W, related to the third case of the boundary state

concerning four cases of loading: a) when

W

= 0, b) when

W

= 15, c) when

W

= 30, d) when

W

= 45

ANALYSI S OF A L AP- JOI NT I N A THI N- WALLED STRUCTURE UNDER COMBI NED BENDI NG AND SHEARI NG LOAD

3. NUMERICAL ANALYSIS OF A LAP-

JOINT

The obtained system of the free nonlinear algebraic

equation has been solved for the given data of forces.

The algorithm was implemented within the

Mathematica system.

3.1. Limit states

The solution is limited with regard to the domain of

the shearing force W and moment M. These limita-

tions have a different origin. The first limitation is due

to the fact that the maximumforce in any blind bolt of

the joint cannot exceed the design value. Statistically

it was in the considered case estimated as:

This value of force implies that the mutual displace-

ment of the profile walls

L+E,d

= 209.3 10

-2

mm, see

Fig. 1. The first limit state can be regarded as an engi-

neering one.

The second limit state comes fromthe limitation quot-

ed in [7] concerning the value of the characteristic

load-bearing capacity of the blind bolt. It has been

stated that values of the obtained forces cannot be

taken into account when the mutual displacement of

the joint exceeds: max(

i

)<

gr

3.0 mm; that implies

that the characteristic value of the bolt load capacity is

This value was used as a basis for the estimation of

the first limit state in the statistical way and the sec-

ond limit state of the blind-bolt joint. This limit state

can be regarded as a physical one.

The mathematical model presented in point 2.2 is

limited by the domain connected with the fact that

the constitutive equation (9) has a horizontal asymp-

tote. It implies that the force in any bolt may not

cross the limit:

This limit state can be regarded as a mathematical

one.

In the analysis of the problem we can distinguish two

special cases. The first one when the joint is loaded

with the shearing force only, M 0. In that case the

shearing force is taken to be uniform in all five bolts,

so the limit value can be evaluated exactly:

The second special case is observed when the joint is

loaded only with the moment, W 0 . The moment

concerns only bolts 1-4, and its limit state value can

be assessed exactly

Symbol X in eqs (13) and (14) stands for I, II and III,

depending on the limit state.

According to these statements the limit curves have

been evaluated for 4 different angles of the direction

of the force W. Figure 4 presents 3 limit curves. The

lowest light-grey line refers to the first limit state I,

Eqn 10. The second line dark-grey line refers to the

second limit state, Eqn 11. The highest curve (black)

refers to the third limit state, Eqn 12. The domain of

each diagramis normalized to the dimensionless area

(u,1) (u,1).

The variation of the curves is small with regard to the

angle. Nevertheless, it can be noticed that the limit

curves in Fig. 4a embrace the largest areas, whereas in

Fig. 4d the smallest ones. This leads to the conclusion

that it is more favourable if the direction of the shear-

ing force coincides with the direction of the axes x or y

(see Fig. 2a or 2c), than if it has a sloping direction (see

Fig. 2b). It should be taken into account while design-

ing the connections, as far as possible of course.

Figure 5 presents two limit surfaces of the considered

5-blind-bolt joint. The inner surface represents the

first limit state, the outer one represents the third

limit state. The surfaces have three planes of symme-

try but they are not surfaces of revolution

(cf. Figs 4a-d), which shows meridians of these sur-

faces.

C

I

V

I

L

E

N

G

I

N

E

E

R

I

N

G

e

2/ 2010 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 75

c

kN P S S

d

I

i

6 . 48 max

lim

.

(10)

kN S P S

II

av m i

85 . 55 max

lim ,

.

(11)

kN a P S S

s destr

III

i

58 . 58 max

lim

.

(12)

X X

S W

lim

5 .

(13)

X X

S r M

lim

4 . (14)

Figure 5.

Boundary surfaces of the calculated load-carrying capacity

I and of the destructive load-carrying capacity III of a five-

blind-bolt joint

W . W u w e r , R . W a l e n t y s k i

3.2. Solution of the problem

The system of equation has been solved for different

values of the angle

W

, Fig. 1. This angle changes the

direction of the shearing force fromvertical, Fig 2a to

sloping, Fig 2b. Figures 6 and 7 show diagrams of the

mutual displacement and forces in the bolt No. 1.

Comparing these diagrams we see that variations of

the angle do not influence these functions much.

The situation is different in case of bolt No. 2 (see

Fig. 1). Figures 8 and 9 show that the mutual dis-

placement and forces in the bolt No. 2 are highly sen-

sitive to variations of the angle

W

. The black colour

in the upper right-hand corner represents the area

outside the mathematical domain of the model. This

remark refers also to further diagrams in this paper.

Performing the analysis according to the proposed

model we can design properly further experiments,

predict the behaviour of the joint, estimate the

destruction load and calibrate the load path.

4. RIGIDITY OF THE JOINT

The solution of the system permits to estimate the

rigidity of the joint, as has been mentioned in the

introduction to the computer analysis of structures

with flexible nodes. The rigidity of the joint is accord-

ing to the proposed nonlinear model a function of all

load components [4]. Usually built-in procedures in

finite element systems, for example RoboBAT prod-

ucts, allow to subordinate rigidities only to the corre-

sponding forces, for example rotation rigidity is a

function of the momentum only. We can show that

our model enables us to take into account three

forces. It is done by introducing reduction coeffi-

cients of rigidity.

76 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 2/ 2010

Figure 6.

Contour maps of displacements 1 occurring between the

walls of the bind bolt No. 1: a) when

W

= 0, b) when

W

=

15, c) when

W

= 30, d) when

W

= 45

a

b

c

d

ANALYSI S OF A L AP- JOI NT I N A THI N- WALLED STRUCTURE UNDER COMBI NED BENDI NG AND SHEARI NG LOAD

C

I

V

I

L

E

N

G

I

N

E

E

R

I

N

G

e

2/ 2010 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 77

Figure 7.

Contour maps the forces S1 affecting respectively the blind

bolt No. 1: a) when

W

= 0, b) when

W

= 15, c) when

W

= 30, d) when

W

= 45

a

b

c

d

Figure 8.

Contour maps of displacements 2 occurring between the

walls of the bind bolt No. 2: a) when

W

= 0, b) when

W

= 15, c) when

W

= 30, d) when

W

= 45

a

b

c

d

c

W . W u w e r , R . W a l e n t y s k i

We distinguish three instantaneous rigidities of the joint.

In the considered case of a 5-blind-bolt joint we have:

instantaneous rigidity of vertical displacement

instantaneous rigidity of horizontal displacement

instantaneous rigidity of rotation

The initial rigidity is a constant value

This rigidity is reduced by a function called the para-

meter of the degradation of rigidity. These parame-

ters are computed as follows:

5. REDUCTION COEFFICIENTS OF

RIGIDITY

5.1. Definition

Since each parameter of rigidity degradation depends

only on one component of force, we introduce reduc-

tion coefficients of rigidity.

where:

v(V,0,0) vertical displacement in the joint comput-

ed for exclusive action of the vertical force V,

v(V,H,M) total vertical displacement computed for

the mutual action of forces H, V and moment M,

u(0,H,0) horizontal displacement in the joint com-

puted for the exclusive action of the horizontal force H,

u(V,H,M) total horizontal displacement computed

for the mutual action of the forces H, V and moment

M,

78 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 2/ 2010

Figure 9.

Contour maps of forces S2 affecting respectively the blind

bolt No. 2: a) when

W

= 0, b) when

W

= 15, c) when

W

= 30, d) when

W

= 45

a

b

c

d

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(15)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(16)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(17)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(18)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III

s

M

M

b

M

e

(19)

III

s

W

V

b

V

e

(20)

III

s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(19)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III

s

M

M

b

M

e

(19)

III

s

W

V

b

V

e

(20)

III

s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(20)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III

s

M

M

b

M

e

(19)

III

s

W

V

b

V

e

(20)

III

s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(21)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(22)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(23)

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III s

M

M

b

M

e

(19)

III s

W

V

b

V

e

(20)

III s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

(24)

ANALYSI S OF A L AP- JOI NT I N A THI N- WALLED STRUCTURE UNDER COMBI NED BENDI NG AND SHEARI NG LOAD

C

I

V

I

L

E

N

G

I

N

E

E

R

I

N

G

e

2/ 2010 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 79

Figure 10.

Contour maps of coefficients of reduction M for III case of

the boundary state: when

W

= 0, b) when

W

= 15, c)

when

W

= 30, d) when

W

= 45

a

b

c

d

a

b

c

d

Figure 11.

Contour maps of coefficients of reduction V for III case of

the boundary state: when

W

= 0, b) when

W

= 15, c)

when

W

= 30, d) when

W

= 45

c

W . W u w e r , R . W a l e n t y s k i

(0,0,M) angle of rotation in the joint computed

for the exclusive action of the moment M,

(V,H,M) total angle of rotation computed for the

mutual action of the forces H, V and moment M.

Reduction coefficients of rigidity have been comput-

ed for the considered 5-blind-bolt joint. Their dia-

grams are shown in Figs 10, 11 and 12. The diagrams

in Figs 10 and 11 have been prepared for four differ-

ent values of the angle

W

, see Fig. 1. They present

the function of

M

and

V

, respectively. Figure 12 pre-

sents the function

H

for one selected angle. The dia-

grams are plotted in the dimensionless domain.

5.2. Sensitivity analysis

Analyzing the diagram of the functions

M

and

V

(cf.

Figs 10 and 12), we see that they are not very sensi-

tive to variations of the angle

W

. Comparing Figs 11d

and 12 we can state that the function

H

is almost

identical to

V

.

5.3. Analysis of significance and example

Analyzing these functions we see that the reduction

of rigidities caused by the mutual influence of forces

can be considerable. Let us consider a joint loaded

with the shearing force (Eqn 13):

and the moment (Eqn 14):

In the first case let us assume that the shearing force

is sloped to wards the vertical axis at the angle

W

= 45 (see Figs 1 and 2b).

We can check, that the pair W/W

III

= 0.4 and

M/M

III

=0.4 lies within the area limited by the first

limit curve (see Fig. 4d), so it is allowable from the

engineering point of view.

We get the following forces in the blind bolts Fig. 1:

S

1

S

3

= 34.94 kN (see Fig. 7d), S

2

= 1.20 kN (see

Fig. 9d) and S

4

= 42.34 kN < S

I

48.6 kN (see Eqn

10). It is worth noting that the bolt No. 2 is almost

unloaded.

For the considered case we obtain the following val-

ues of the coefficients of reduction of rigidities:

M

=

0.784 (compare Fig. 10),

V

H

= 0.810 (compare

Figs 11 and 12).

In the second case we assume that the shearing acts

along the vertical axis,

W

= 0 (see Figs 1 and 2a).

We can check, that the pair W/W

III

= 0.4 and

M/M

III

=0.4 lies within the area limited by the first

limit curve (see Fig 4a).

We get the following forces in the blind bolts (Fig. 1):

S

1

S

4

= 40.40 kN (see Fig. 7a), S

2

S

3

= 22.51 kN

(see Fig. 9a).

For the considered case we obtain the following val-

ues of the rigidities reduction coefficients:

M

= 0.794

(cf. Fig. 10a),

V

= 0.820 (cf. Fig. 11a). The coeffi-

cient

H

is indeterminate when

W

= 0, since the dis-

placement u u (cf. Fig. 2a).

We can see that the reduction of rigidity is significant

and therefore the mutual influence of forces should

be taken into account.

6. CONCLUSIONS AND FINAL RE -

MARKS

Experimentally verified nonlinear mathematical

model presented in this paper can be used in the

design and verification of multi-blind joints.

This verification can be supported by the limit curves,

limit surfaces and diagrams presented in the paper.

They can also be useful in the further design of exper-

imental verification.

Provided analysis of rigidity shows that forces exert a

mutual influence on instantaneous rigidities. The

introduced and analyzed coefficients of rigidity

reduction may be helpful.

Provided formulas for rigidity have already been

applied in numerical analyze of 2D structures of thin-

walled structures with flexible nodes, within the

80 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 2/ 2010

Figure 12.

Contour maps of coefficients of reduction H for III case of

the boundary state when

W

= 45

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III

s

M

M

b

M

e

(19)

III

s

W

V

b

V

e

(20)

III

s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

2

V V

S

ri

V

rt

K K u = 1 5 (15)

H H

S

ri

H

rt

K K u = 1 5 (16)

M M

S

ri

M

rt

K r K u = 1 4

2

(17)

s s i i

S

ri

b a S K

i

= c = 0 o

(18)

III

s

M

M

b

M

e

(19)

III

s

W

V

b

V

e

(20)

III

s

W

H

b

H

e

(21)

( ) M H V v

V v

V

, ,

0 , 0 ,

= u (22)

( ) M H V u

H u

H

, ,

0 , , 0

= u (23)

( ) M H V

M

M

, ,

, 0 , 0

|

u = (24)

kN W W

III

2 . 117 58 . 58 5 4 . 0 4 . 0 =

kN M M

III

155 . 5 58 . 58 055 . 0 4 4 . 0 4 . 0 =

ANALYSI S OF A L AP- JOI NT I N A THI N- WALLED STRUCTURE UNDER COMBI NED BENDI NG AND SHEARI NG LOAD

Finite Element computer system [10]. Such an analy-

sis requires an iterative approach, but has been suc-

cessful. It has also been shown that the reductions of

rigidities influence significantly displacements and

internal forces.

Provided analysis can also be used in the further

development of national and European design codes

[11], [12].

REFERENCES

[1] Wuwer W.; Prba oceny podatnoci wzw w sys-

temach konstrukcyjnych z ksztatownikw gitych

(Test of evaluation of flexibility of nodes in the struc-

tural systems made of cold-formed sections).

Inynieria i Budownictwo, No. 10, 2002, p.573-577 (in

Polish)

[2] Technical Certificate of the Institute of Civil

Engineering, No. AT-15-3487/99, Warszawa 1999,

Bolts of produced by Huck

[3] Wuwer W.; Investigations and calculation of lap-joints

with special blind bolts. Polish Academy of Sciences,

Archives of Civil Engineering, Volume LI, Issue 2.

Warszawa 2005, p.253-280

[4] Wuwer W.; Podatne poczenia na sworznie jednos-

tronne w prtowych konstrukcjach cienkociennych

(Flexible joints with blind bolts in thin-walled bar

constructions). Zeszyty Naukowe Politechniki

Slskiej Nr 1710, z. 105 (Scientific Fascicles of the

Silesian University of Technology), Gliwice 2006 (in

Polish)

[5] Wuwer W.; Experimental verification of the method

of calculation lap-joints in thin-walled constructions.

Archives of Civil Engineering, Polish Academy of

Sciences, Warszawa, LIII, 4, 2007, p.663-681

[6] Wuwer W.; The behaviour and design of lap-joints in

thin-walled bar constructions. Advanced Steel

Construction, an International Journal, Editors;

China; Asian-Pacific & African The Hong Kong

Institute of Steel Construction, USA, Italy; Vol.4,

Number 1, March 2008, p.59-83

[7] Recommendations for Steel Constructions, ECCS-

TC7, The Design and Testing of Connections in Steel

Sheeting and Sections. Constrado, 21/1990

[8] Wolfram S.; The Mathematica Book, 5

th

edition,

Wolfram Media, Champaign, 2003

[9] Walentyski R., Wuwer W.; Eccentrically loaded lap-

joints of thin-walled sections, Conference; New

Trends in Statics and Dynamics of Buildings, Faculty

of Civil Engineering STU, Bratislava, Slovakia, 2004,

Proceedings, p.297-302

[10] Wuwer W. and Kowolik B.; Rigidity of the quoin in the

frame of sheet-metal sections. In proceedings of the

Symposium on the Durability of materials and build-

ing structures. Poland, Kamie lski, July, 2005

[11] PN-EN 1993-1-3, Eurokod 3, Projektowanie kon-

strukcji stalowych, Cz 1-3; Reguy oglne. Reguy

uzupeniajce dla konstrukcji z ksztatownikw I

blach profilowanych na zimno. (Design of steel struc-

tures Part 1-3: General rules. Supplementary rules

for cold formed thin gauge members and sheeting)

[12] PN-B-03207: 2002. Konstrukcje stalowe. Konstrukcje

z ksztatownikw i blach profilowanych na zimno.

Projektowanie i wykonanie. (Steel Structures.

Constructions of section and cold-formed sheet-

metal. Design and realization); Polish standard

[13] W. Wuwer, R. Walentyski; Interaction relations in the

model of the lap joint of thin walled structure under

complex load state. In Lightweight Stricture in Civil

Engineering, Micropublisher, Warsaw, 2005

C

I

V

I

L

E

N

G

I

N

E

E

R

I

N

G

c

e

2/ 2010 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 81

W . W u w e r , R . W a l e n t y s k i

82 A R C H I T E C T U R E C I V I L E N G I N E E R I N G E N V I R O N M E N T 2/ 2010

You might also like

- Stories For Good MannersDocument55 pagesStories For Good Mannersሃይማኖት ኬሜቶNo ratings yet

- On Bending Stiffness of Composite TubesDocument7 pagesOn Bending Stiffness of Composite TubesJeremy WilliamsNo ratings yet

- Committed StiffnessDocument15 pagesCommitted StiffnessMarco Gaetani d'AragonaNo ratings yet

- Notes On The Linear Analysis of Thin-Walled BeamsDocument76 pagesNotes On The Linear Analysis of Thin-Walled BeamsPasc Oana JianinaNo ratings yet

- Library Hub and School Library Action Plan: Areas Objectives Activities Persons Involved Time Line Expected OutcomeDocument4 pagesLibrary Hub and School Library Action Plan: Areas Objectives Activities Persons Involved Time Line Expected OutcomeKaren dale Doble100% (4)

- EpidemiologyDocument58 pagesEpidemiologyrebecca100% (4)

- Crowd Psychology - WikipediaDocument8 pagesCrowd Psychology - WikipediaD BNo ratings yet

- Finite Element Modeling of Concrete Beams Prestressed With External TendonsDocument8 pagesFinite Element Modeling of Concrete Beams Prestressed With External TendonsviniciusltNo ratings yet

- Torsion of Open and Closed Thin-WalledLaminated Composite SectionsDocument28 pagesTorsion of Open and Closed Thin-WalledLaminated Composite SectionsFlmkaneNo ratings yet

- Theoretical and Numerical Stability Analyses ofDocument28 pagesTheoretical and Numerical Stability Analyses ofsaber javidNo ratings yet

- Studies To Minimize The Effects of Bond Slipage in Extreior Joints of RC Ductile Moment Resisting Frames PDFDocument8 pagesStudies To Minimize The Effects of Bond Slipage in Extreior Joints of RC Ductile Moment Resisting Frames PDFrjtcostaNo ratings yet

- 571-Article Text PDF-4626-1-10-20130303Document12 pages571-Article Text PDF-4626-1-10-20130303CESAR ARMANDO JOSIMAR DEL CID JUAREZNo ratings yet

- Secondary Bending Joint PDFDocument19 pagesSecondary Bending Joint PDFPhilippeWojtowiczNo ratings yet

- Modeling and Analysis of Discretely Supported Thin-Walled Silo Shells With Stringer Stiffeners at The SupportsDocument8 pagesModeling and Analysis of Discretely Supported Thin-Walled Silo Shells With Stringer Stiffeners at The SupportsAnonymous wWOWz9UnWNo ratings yet

- Metals: Bidirectional Response of Weak-Axis End-Plate Moment Connections: Numerical ApproachDocument18 pagesMetals: Bidirectional Response of Weak-Axis End-Plate Moment Connections: Numerical ApproachRicardo Muñiz DelgadoNo ratings yet

- Archives of Civil Engineering, LX, 4, 2014 DOI: 10.2478/ace-2014-0029Document20 pagesArchives of Civil Engineering, LX, 4, 2014 DOI: 10.2478/ace-2014-0029MichelSagnoNo ratings yet

- A Study of R.C.C. Beam-Column Connection Subjected To PDFDocument7 pagesA Study of R.C.C. Beam-Column Connection Subjected To PDFInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Behavior of Beams With Dowel ActionDocument5 pagesBehavior of Beams With Dowel ActioncustomerxNo ratings yet

- 547 002 PDFDocument19 pages547 002 PDFLikhon BiswasNo ratings yet

- Curved I-Girder Design: Esign TheDocument19 pagesCurved I-Girder Design: Esign TheLikhon BiswasNo ratings yet

- Final Term Paper SubmissionDocument5 pagesFinal Term Paper SubmissionKandousi YassineNo ratings yet

- Nonlinear Buckling Behaviours of Thin-Walled Functionally Graded Open Section BeamsDocument11 pagesNonlinear Buckling Behaviours of Thin-Walled Functionally Graded Open Section Beamsdjoumana ahmiediNo ratings yet

- Stability of Corrugated Expansion BellowsDocument21 pagesStability of Corrugated Expansion Bellowsnutan zambreNo ratings yet

- Web Buckling in Castellated Beams: A. A. Aglan, R. G. RedwoodDocument14 pagesWeb Buckling in Castellated Beams: A. A. Aglan, R. G. RedwoodmokhtazulNo ratings yet

- Numerical Analysis of Steel-Reinforced Concrete Composite GirdersDocument12 pagesNumerical Analysis of Steel-Reinforced Concrete Composite GirdersSeifeldin Ali MarzoukNo ratings yet

- Dynamic Analysis and Response of Semirigid Flames: E. M. LuiDocument11 pagesDynamic Analysis and Response of Semirigid Flames: E. M. LuikhaledmegahedNo ratings yet

- Bracing of Steel-Concrete Composite Bridge During ConstructionDocument10 pagesBracing of Steel-Concrete Composite Bridge During Constructionparvaneh.eNo ratings yet

- Buckling Behavior of Curved Composite Beams With Different Elastic Response in Tension and CompressionDocument10 pagesBuckling Behavior of Curved Composite Beams With Different Elastic Response in Tension and CompressionFox_oNe_7No ratings yet

- Assessment of The Out-Of-plane Imperfections of A Steel Tied Arch BridgeDocument8 pagesAssessment of The Out-Of-plane Imperfections of A Steel Tied Arch BridgeDhimas Surya NegaraNo ratings yet

- AUEJ - Volume 13 - Issue 49 - Pages 1392-1403Document13 pagesAUEJ - Volume 13 - Issue 49 - Pages 1392-1403محمد حسن محمد حسنNo ratings yet

- Journal of Petroleum Science and Engineering: Youhong Sun, Yongping Yu, Baochang LiuDocument9 pagesJournal of Petroleum Science and Engineering: Youhong Sun, Yongping Yu, Baochang LiuEzequiel AbrilNo ratings yet

- Analytical Model For Beams On Elastic Foundations Considering The Coupling of HorizontalDocument12 pagesAnalytical Model For Beams On Elastic Foundations Considering The Coupling of HorizontalPrantik Adhar SamantaNo ratings yet

- Trindade Wolter Sampaio 2005 JSVDocument22 pagesTrindade Wolter Sampaio 2005 JSVhlsmonteiroNo ratings yet

- Civil Engg - Ijcseierd - Experimental and Analytical Study On The Dynamic Behavior of Frames Under Relative Displacement Between Support PointsDocument10 pagesCivil Engg - Ijcseierd - Experimental and Analytical Study On The Dynamic Behavior of Frames Under Relative Displacement Between Support PointsTJPRC PublicationsNo ratings yet

- Cracks As Important Constituents of Strut and Tie ModelsDocument20 pagesCracks As Important Constituents of Strut and Tie ModelsBrandon LevineNo ratings yet

- Building Frame Bridge Bent Structural WallDocument9 pagesBuilding Frame Bridge Bent Structural WallpmergosNo ratings yet

- Strength Analysis Modelling of FlexibleDocument19 pagesStrength Analysis Modelling of Flexiblexinlin.cppNo ratings yet

- OnZeroStiffness PDFDocument24 pagesOnZeroStiffness PDFAvinash KumarNo ratings yet

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsDocument6 pagesCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- Operating Bolt Load Calculation in Joints of Complex Elastic StructuresDocument8 pagesOperating Bolt Load Calculation in Joints of Complex Elastic Structuresdf_campos3353No ratings yet

- Shear-Flexible Element With Warping For Thin-Walled Open BeamsDocument19 pagesShear-Flexible Element With Warping For Thin-Walled Open BeamsnevinkoshyNo ratings yet

- Shapes of A Suspended Curly Hair: Week Ending 14 FEBRUARY 2014Document5 pagesShapes of A Suspended Curly Hair: Week Ending 14 FEBRUARY 2014MaingotNo ratings yet

- Plastic Collapse of General Frames: Mcivor, A. S. Wineman WangDocument14 pagesPlastic Collapse of General Frames: Mcivor, A. S. Wineman WangMohamed N AboudNo ratings yet

- 2821 6440 1 PB PDFDocument11 pages2821 6440 1 PB PDFsaulolmNo ratings yet

- DownloadDocument14 pagesDownloadGladimir GrigolettiNo ratings yet

- Nonlinear and Time-Dependent Analysis of Continuous Unbonded Pre-Stressed BeamDocument11 pagesNonlinear and Time-Dependent Analysis of Continuous Unbonded Pre-Stressed BeamPhạm Tiến ĐạtNo ratings yet

- Shi 1989Document16 pagesShi 1989Sai GowthamNo ratings yet

- Buckling and Design of Columns With Intermediate Elastic Torsional RestraintDocument14 pagesBuckling and Design of Columns With Intermediate Elastic Torsional Restraintfahmi aballiNo ratings yet

- Performance of Base-Plate Connections of Steel Storage Pallet RacksDocument10 pagesPerformance of Base-Plate Connections of Steel Storage Pallet RacksAlan GironNo ratings yet

- 1988 Finite Element Analysis of Stability of Thin-Walled Beams of Open SectionDocument15 pages1988 Finite Element Analysis of Stability of Thin-Walled Beams of Open SectionHussein M. H. Al-KhafajiNo ratings yet

- Corrugated Web BeamDocument4 pagesCorrugated Web BeamNegin MalekiNo ratings yet

- Application of Nonlinear Concrete Model PDFDocument7 pagesApplication of Nonlinear Concrete Model PDFOat GTNo ratings yet

- Ductility Analysis of Prestressed Concrete Beams With Unbonded TendonsDocument9 pagesDuctility Analysis of Prestressed Concrete Beams With Unbonded TendonsvenkatesanjsNo ratings yet

- BSHV Elastica Follower 2007Document6 pagesBSHV Elastica Follower 2007AmenNo ratings yet

- Elastic Analysis O F Spatial Shear Wall Systems With Flexible BasesDocument18 pagesElastic Analysis O F Spatial Shear Wall Systems With Flexible Basessanh137No ratings yet

- (Jonsson & Ramonas, 2012) - Flange Curling in Cold Formed ProfilesDocument11 pages(Jonsson & Ramonas, 2012) - Flange Curling in Cold Formed Profileschristos032No ratings yet

- Li 2002Document14 pagesLi 2002fahmi aballiNo ratings yet

- Experimental Force Identification by Using Natural OptimizationDocument9 pagesExperimental Force Identification by Using Natural OptimizationbrucemlsNo ratings yet

- 273 10Document52 pages273 10Dr Axel ChangNo ratings yet

- Theoretical Study For Bond Between Reinforcement Steel and ConcreteDocument10 pagesTheoretical Study For Bond Between Reinforcement Steel and ConcreteSulaim Al KautsarNo ratings yet

- Articulo Dispacion Victor CeballosDocument20 pagesArticulo Dispacion Victor CeballosVictor CeballosNo ratings yet

- Buckling and Vibration of Stiffened PlatesDocument11 pagesBuckling and Vibration of Stiffened Platesغازي اللجيNo ratings yet

- A Parametric Survey of The Influence of The Semi-Rigid Connections On The Shakedown of Elasto-Plastic FramesDocument9 pagesA Parametric Survey of The Influence of The Semi-Rigid Connections On The Shakedown of Elasto-Plastic FramesAmine OsmaniNo ratings yet

- 1 s2.0 S0143974X1931404X MainDocument10 pages1 s2.0 S0143974X1931404X MainHugNitNo ratings yet

- Hyperbolic Structures: Shukhov's Lattice Towers - Forerunners of Modern Lightweight ConstructionFrom EverandHyperbolic Structures: Shukhov's Lattice Towers - Forerunners of Modern Lightweight ConstructionNo ratings yet

- Stresses Around A Circular Hole: KKK KK K 4 9 4 9Document1 pageStresses Around A Circular Hole: KKK KK K 4 9 4 9Pasc Oana JianinaNo ratings yet

- Comparative Study On Reinforced Masonry With Polymer GridsDocument6 pagesComparative Study On Reinforced Masonry With Polymer GridsPasc Oana JianinaNo ratings yet

- Tensar PPT Biaxial GridsDocument20 pagesTensar PPT Biaxial GridsPasc Oana JianinaNo ratings yet

- The Analysis of The Transient Dynamic Response of Elastic Thin-Walled Beams of Open Section Via The Ray MethodDocument13 pagesThe Analysis of The Transient Dynamic Response of Elastic Thin-Walled Beams of Open Section Via The Ray MethodPasc Oana JianinaNo ratings yet

- GBT-based Analysis of Tapered Thin-Walled Members: Recent DevelopmentsDocument12 pagesGBT-based Analysis of Tapered Thin-Walled Members: Recent DevelopmentsPasc Oana JianinaNo ratings yet

- ASP Onnee Project ReportDocument29 pagesASP Onnee Project ReportPasc Oana JianinaNo ratings yet

- Prof - Tamura July19 APSS2010 Wind-Universitatea TokyoDocument156 pagesProf - Tamura July19 APSS2010 Wind-Universitatea TokyoPasc Oana JianinaNo ratings yet

- Isla VerdeDocument3 pagesIsla VerdeEdjey Luis F. MatinongNo ratings yet

- Management Consulting 101 So, You Might Want To Be A ConsultantDocument58 pagesManagement Consulting 101 So, You Might Want To Be A ConsultantTrisha PanditNo ratings yet

- Unit 5 Group Behavior & Group Dynamics, Team EffectivenessDocument67 pagesUnit 5 Group Behavior & Group Dynamics, Team Effectivenesspratikyaul100% (3)

- 5) Asymemtric - GRACHDocument34 pages5) Asymemtric - GRACHDunsScotoNo ratings yet

- Devex 2018 Introduction To Reservoir SimulationDocument52 pagesDevex 2018 Introduction To Reservoir SimulationKonul AlizadehNo ratings yet

- HieuTQ Asm2 529 PDFDocument16 pagesHieuTQ Asm2 529 PDFQuân ShellNo ratings yet

- Industry 4.0. German Standardization RoadmapDocument77 pagesIndustry 4.0. German Standardization Roadmapmihai.banicaNo ratings yet

- A Geographic Information SystemDocument5 pagesA Geographic Information SystemVikneswaran Gunahlan NeshNo ratings yet

- Simple Random SamplingDocument59 pagesSimple Random SamplingAlyssandra N.No ratings yet

- JEDI Course Notes Intro1 MasterDocumentDocument244 pagesJEDI Course Notes Intro1 MasterDocumentMarkQuindozaNo ratings yet

- Fundamentals of Physics, 8th Edition Halliday, Resnick, WalkerDocument5 pagesFundamentals of Physics, 8th Edition Halliday, Resnick, Walkerabhishekkumar1996No ratings yet

- 9 Class Holiday HomeworkDocument5 pages9 Class Holiday HomeworksavageitgirlNo ratings yet

- Fluidewell ProfileDocument12 pagesFluidewell ProfileChaudhary AsadullahNo ratings yet

- Learning Theory by BanduraDocument5 pagesLearning Theory by BanduraOnwuka FrancisNo ratings yet

- StaffDocument4 pagesStaffBianca RadutaNo ratings yet

- Survey Questions AwarenessDocument4 pagesSurvey Questions Awarenesszoey zaraNo ratings yet

- Michael Heinrich - Invaders From Marx: On The Uses of Marxian Theory, and The Difficulties of A Contemporary ReadingDocument8 pagesMichael Heinrich - Invaders From Marx: On The Uses of Marxian Theory, and The Difficulties of A Contemporary ReadingStipe Ćurković100% (1)

- PYRAMIDOLOGYDocument92 pagesPYRAMIDOLOGYverdiblue100% (2)

- AdvertisementDocument1 pageAdvertisementSachin KhandekarNo ratings yet

- ProspectusDocument51 pagesProspectusalext1985No ratings yet

- Parking Issuu PDFDocument132 pagesParking Issuu PDFRicardo FajardoNo ratings yet

- Corrosion Raccords Proform 2018 PDFDocument34 pagesCorrosion Raccords Proform 2018 PDFDiegoNo ratings yet

- Android: Multimedia, Animation and Graphics: Syllabus: Playing Audio, Playing Video, Rotate AnimationDocument7 pagesAndroid: Multimedia, Animation and Graphics: Syllabus: Playing Audio, Playing Video, Rotate AnimationvisheshNo ratings yet

- Outlook For The Next Framework Programme: 29 January 2018, Radisson Blu, BrusselsDocument2 pagesOutlook For The Next Framework Programme: 29 January 2018, Radisson Blu, BrusselsAndrea StavrouNo ratings yet

- Balancing of Redox Reactions - 1Document2 pagesBalancing of Redox Reactions - 1Anonymous vRpzQ2BL0% (1)