Professional Documents

Culture Documents

Indicator Posts To Pressure Mains

Indicator Posts To Pressure Mains

Uploaded by

ganmosesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indicator Posts To Pressure Mains

Indicator Posts To Pressure Mains

Uploaded by

ganmosesCopyright:

Available Formats

Project R999/1: Extension of Business Bay Canal Phase 1 - Sheikh Zayed Road Bridges Dubai Sewerage and Drainage

Master Plan Standard Specifications

Volume 2 Part III

The protective wrapping tape shall be open-weave cotton or synthetic fibre or woven glass fibre coated on both sides with an even coat of petrolatum (petroleum jelly) containing a filler. The tape and paste shall be suitable for use in the prevailing climatic soils pumped liquid and ground water conditions. Before wrapping with tape the item to be encased shall be enclosed with an approved mastic or inert putty-like filler which shall be moulded by hand so as to provide a smooth surface for the tape. The tape shall be tightly spirally wrapped with 25 mm overlaps so as to enclose the whole of the item and a minimum of 150 mm of pipe length on each side. The enclosure shall be firmly pressed out to prevent air being trapped under the wrapping. 4.4.13 Indicator Posts to Pressure Mains Where pressure mains pass through open ground, not adjacent to roads, or where the danger of accidental breakage by excavation is evident, the Engineer may instruct the erection of indicator posts of an approved design. Details of the indicator post construction and spacing shall be shown on the drawings or be directed by the Engineer. The depth, location and size of the pressure main shall be detailed in Arabic and English, to an approved design, on an engraved plastic or noncorrodible plate attached to the post. In addition at all air valve chambers, the Contractor shall erect indicator signs on posts, to an approved design, at locations described to him by the Engineer. 4.4.14 Enclosing Granular or Stone Surround with Geotextile Filter Fabric All slotted pipes and pipes laid beneath the permanent groundwater level the granular bedding material shall be laid on and enclosed within a geotextile filter fabric. Filter fabric used for subsurface drainage works shall consist of long-chain synthetic polymer fibers composed of at least 85 percent by mass polyoiefins, polyesters, or polyamids. They shall be formed into a network such that the filaments or yarns retain dimensional stability relative to each other, including selvedges. The fabric shall be stabilised against ultra-violet light, inert to commonly uncounted chemicals and chemical properties of the in-situ soil and water, and it shall conform to the following minimum requirements:

August 2013

Tender Documents

Page 4/25

Project R999/1: Extension of Business Bay Canal Phase 1 - Sheikh Zayed Road Bridges Dubai Sewerage and Drainage Master Plan Standard Specifications

Volume 2 Part III

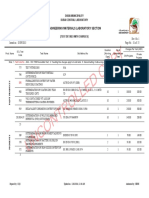

Table 4-8. Requirements for Geotextile Fabric for Subsurface Drainage Property Grab Strength (N) Puncture Strength (N) Burst Strength (Kpa) Trapezoid Tear (N) Permeability (M/S) Apparent Opening Size (Mm) Ultraviolet Degradation (Percent Retained Strength) Test Method ASTM D 4632 ASTM D 4833 ASTM D 3786 ASTM D 4533 ASTM D 4491 ASTM D 4751 ASTM D 4355 Min. Requirements 800 355 2000 220 10-4 0.6 70 @ 150 H

Where filter fabric is used to enclose granular or stone pipe surrounds, the fabric will be placed on the prepared trench formation and carefully supported during pipe laying operations. When the pipe has been laid complete with surround to the correct level the filter fabric shall be closed over the top of the surround by forming a 'lap' of minimum width 500 mm. All membrane joints shall be overlapped a minimum of 500 mm. Care shall be taken not to puncture or damage the membrane in any way during installation or during backfilling of the trench. Fabric damaged or displaced before or during installation or during placement of overlaying aggregate material shall be replaced or repaired to the satisfaction of the Engineer at the Contractor's expense. During periods of shipment and storage, the fabric shall be maintained wrapped in a heavy-duty protective covering and protected from direct sunlight, ultra-violet rays and temperatures greater than 60oC. 4.4.15 Underground Services Warning Tapes Service protection tapes shall be installed above all sewage, drainage and irrigation pipelines and pressure mains constructed or exposed under this contract excluding individual service connections. For pipelines with the top of the pipe barrel more than 900 mm below finished surface level the tape shall be placed over the centreline of the pipeline at 600 mm below finished surface level during backfilling and compaction operations. For pipelines with less than 900 mm cover to the top of the pipe barrel the tape shall be placed over the centreline of the pipe at 300 mm above the top of the pipe barrel during backfilling, compaction and reinstatement operations. The tape shall be continuous over pipelines and at joints between tapes from separate rolls the joint shall be lapped a minimum of one metre.

August 2013

Tender Documents

Page 4/26

You might also like

- Proceedings: Editors: Dr. Armen Amirkhanian, P.E. Eleanor Skelton, P.EDocument726 pagesProceedings: Editors: Dr. Armen Amirkhanian, P.E. Eleanor Skelton, P.EAlalea KiaNo ratings yet

- Iso 6361 2 1990 en PDFDocument8 pagesIso 6361 2 1990 en PDFganmoses0% (1)

- CIDA-SBD2 and 4Document6 pagesCIDA-SBD2 and 4RASIKA NATH60% (5)

- C4-1 Lecture 1 - Intro Lecture Big PictureDocument67 pagesC4-1 Lecture 1 - Intro Lecture Big Pictureelidstone@hotmail.comNo ratings yet

- West-Araya Extended AbstractDocument4 pagesWest-Araya Extended AbstractJoe ColomboNo ratings yet

- Design of SumpDocument7 pagesDesign of SumpRASSAL KARIMNo ratings yet

- Matc FileDocument1,176 pagesMatc Filevineet57No ratings yet

- (A) Tropical Koppen Climate ClassificationDocument22 pages(A) Tropical Koppen Climate ClassificationCandid GuyNo ratings yet

- A Project On Construction of Pile FoundationDocument36 pagesA Project On Construction of Pile FoundationUsama SaeedNo ratings yet

- Details of Readymix Concrete SuppliersDocument2 pagesDetails of Readymix Concrete SuppliersaflalNo ratings yet

- Sodic Soils ByMarcusDocument40 pagesSodic Soils ByMarcusWenhao WangNo ratings yet

- GeotechDesignManual 001Document93 pagesGeotechDesignManual 001rasputin0780803494No ratings yet

- Tropical ClimateDocument27 pagesTropical ClimateHarshitha V100% (1)

- Drainage PanelDocument4 pagesDrainage Panelconstruct404No ratings yet

- Systematic Approach To Planning Monitoring Program Using Geotechnical InstrumentationDocument19 pagesSystematic Approach To Planning Monitoring Program Using Geotechnical InstrumentationKristina LanggunaNo ratings yet

- GeotextileDocument10 pagesGeotextileAnwar ParvesNo ratings yet

- Construction On Soft Soil1Document80 pagesConstruction On Soft Soil1BluebelgianNo ratings yet

- Evaluation of Sub-Soil Geotechnical Properties For Shallow Foundation and Pavement Design in LASPOTECH, Ikorodu Campus, Lagos State, NigeriaDocument8 pagesEvaluation of Sub-Soil Geotechnical Properties For Shallow Foundation and Pavement Design in LASPOTECH, Ikorodu Campus, Lagos State, NigeriaInternational Organization of Scientific Research (IOSR)No ratings yet

- Usman Bellow 0311Document64 pagesUsman Bellow 0311Abdullahi MuhammadNo ratings yet

- Intelligent Compaction For Asphalt MaterialsDocument6 pagesIntelligent Compaction For Asphalt MaterialsHussain ElarabiNo ratings yet

- Site InvestigationsDocument452 pagesSite InvestigationsgaddargaddarNo ratings yet

- Sec-A, Iqbal Boulevard, Phase-Ii, Dha, Islamabad: Geotechnical Site InvestigationDocument21 pagesSec-A, Iqbal Boulevard, Phase-Ii, Dha, Islamabad: Geotechnical Site InvestigationShakir UllahNo ratings yet

- Road Note 06Document32 pagesRoad Note 06hessian123No ratings yet

- GEO PRODUCTS Design - Soil Stabilization - SHORTDocument45 pagesGEO PRODUCTS Design - Soil Stabilization - SHORTLuis Fernando Sandoval CasasNo ratings yet

- Specifications of The Application of Class Concrete Paving BlocksDocument10 pagesSpecifications of The Application of Class Concrete Paving BlockshonneyValadasNo ratings yet

- 2019 CE6420 GI Soil ConfinementDocument28 pages2019 CE6420 GI Soil ConfinementJayashree ArumugamNo ratings yet

- Concrete Pavement OverlaysDocument69 pagesConcrete Pavement OverlaysSunil BoseNo ratings yet

- Types of GeosyntheticsDocument97 pagesTypes of GeosyntheticsJOE G PHILIP CENo ratings yet

- Geoflex Vinyl Sheet Pile System Brochure (Geotechnics BV, 2005)Document6 pagesGeoflex Vinyl Sheet Pile System Brochure (Geotechnics BV, 2005)sandycastleNo ratings yet

- Noise Pollution and Its Control at Construction SiteDocument14 pagesNoise Pollution and Its Control at Construction SiteAbhishek KadianNo ratings yet

- Verticale Drainage en V0Document5 pagesVerticale Drainage en V0Mārcis JankaitisNo ratings yet

- Types of GeosyntheticsDocument8 pagesTypes of Geosyntheticsvadlamani7No ratings yet

- Soil Improvement TechniquesDocument4 pagesSoil Improvement Techniqueshabib malikNo ratings yet

- 1 What Is LevelingDocument19 pages1 What Is LevelingAbduraman Isa100% (1)

- Soil Stabilization in Pavement StructuresDocument168 pagesSoil Stabilization in Pavement Structuresmaria DiazNo ratings yet

- HBM PlatformsDocument43 pagesHBM PlatformsAlexandru IonescuNo ratings yet

- Coir Geotextiles Are Eco Friendly and Economical Solution For Soil ErosionDocument6 pagesCoir Geotextiles Are Eco Friendly and Economical Solution For Soil ErosionKrishna PrasadNo ratings yet

- Retaining Walls 0113Document16 pagesRetaining Walls 0113sossaifjmNo ratings yet

- Syed Mazhar PHD Qualifying Exam PaperDocument3 pagesSyed Mazhar PHD Qualifying Exam PaperVinayaka RamNo ratings yet

- Brochure Terram Geosynthetics 2015 GEOCELLDocument44 pagesBrochure Terram Geosynthetics 2015 GEOCELLsonic8981No ratings yet

- CE6503 Highway Materials Lec7Document110 pagesCE6503 Highway Materials Lec7AhmedNo ratings yet

- Mix Design 8 2Document6 pagesMix Design 8 2Eulogio JameroNo ratings yet

- Final ProposalDocument23 pagesFinal Proposalpriyanshu pathakNo ratings yet

- CIV 4100 Assignment No3Document13 pagesCIV 4100 Assignment No3tamooseNo ratings yet

- ECMDS 5.0 Design ManualDocument24 pagesECMDS 5.0 Design Manualthedevilsdue9420No ratings yet

- A Road Building Opportunity PURE - CRETE - Eng - 02252011Document48 pagesA Road Building Opportunity PURE - CRETE - Eng - 02252011PAYLEUNo ratings yet

- Basic Rules of Concrete Mix DesignDocument2 pagesBasic Rules of Concrete Mix DesignBijaya RaulaNo ratings yet

- M40Document6 pagesM40dandragutescuNo ratings yet

- ECG524-Topic 2a-Asphaltic Concrete Pavement DesignDocument68 pagesECG524-Topic 2a-Asphaltic Concrete Pavement DesignAdika Azwan100% (1)

- DM Reinforced Earth WallDocument76 pagesDM Reinforced Earth Wallbkswain2003No ratings yet

- Water Proofing Manual: BasementDocument5 pagesWater Proofing Manual: Basementannayya.chandrashekar Civil EngineerNo ratings yet

- Module 5 Erosion & Sediment Control: Prepared byDocument54 pagesModule 5 Erosion & Sediment Control: Prepared byГригорий ЛевашовNo ratings yet

- Mechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersDocument11 pagesMechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersCristianAMejiaNo ratings yet

- ID - Brochure - EROSION CONTROL FOR DAM & CUT SLOPEDocument20 pagesID - Brochure - EROSION CONTROL FOR DAM & CUT SLOPEiqbalNo ratings yet

- Dynamic Compaction DCDocument4 pagesDynamic Compaction DCDewa Gede Wahyu WidiarthaNo ratings yet

- ProctorCompactionTestforMaximumDryDensity 001Document23 pagesProctorCompactionTestforMaximumDryDensity 001Raheel ADNANNo ratings yet

- Chemical StabilizationDocument63 pagesChemical Stabilizationanahita_63100% (1)

- Nilex Fabriform BrochureDocument4 pagesNilex Fabriform BrochureApurba haldarNo ratings yet

- 5 Metfloor Installation GuideDocument9 pages5 Metfloor Installation GuideTùng Hì100% (1)

- Macro & Mini PilesDocument1 pageMacro & Mini PilesAnonymous JZFSB3D0% (1)

- Fosroc GeotexDocument3 pagesFosroc GeotexBalasubramanian AnanthNo ratings yet

- MebraDrain GeosyntheticDocument5 pagesMebraDrain GeosyntheticAndika Satria AgusNo ratings yet

- A Guide On Geodetic Survey and MonitoringDocument25 pagesA Guide On Geodetic Survey and MonitoringEncardio RiteNo ratings yet

- Stone ColumnDocument8 pagesStone ColumnBilal Ahmed BarbhuiyaNo ratings yet

- ADWEA STD Specifications For Warning TapeDocument1 pageADWEA STD Specifications For Warning TapeMubashar IslamNo ratings yet

- Road Geometric Design Manual PDFDocument690 pagesRoad Geometric Design Manual PDFganmosesNo ratings yet

- Heavy PlatesDocument41 pagesHeavy PlatesganmosesNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesNo ratings yet

- Epoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidDocument4 pagesEpoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidganmosesNo ratings yet

- DCL Test ChargesDocument1 pageDCL Test ChargesganmosesNo ratings yet

- Underpass DWGDocument1 pageUnderpass DWGganmosesNo ratings yet

- Nitomortar FC PDFDocument2 pagesNitomortar FC PDFganmosesNo ratings yet

- Cement Stablize - StudyDocument21 pagesCement Stablize - StudyganmosesNo ratings yet

- Crosshole Sonic LoggingDocument2 pagesCrosshole Sonic LoggingganmosesNo ratings yet

- BOQ - Finishing - Wall FInishes PDFDocument2 pagesBOQ - Finishing - Wall FInishes PDFThean ThoeurnNo ratings yet

- QCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCDocument20 pagesQCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCTrần TùngNo ratings yet

- AttachmentDocument11 pagesAttachmentShamas TabraizNo ratings yet

- BT5 Precast RSWDocument13 pagesBT5 Precast RSWRyan Rey ClaurNo ratings yet

- Is 6735 1994Document14 pagesIs 6735 1994sarath6725No ratings yet

- 2-Assignment 3 Reuse of Treated WastewaterDocument2 pages2-Assignment 3 Reuse of Treated Wastewatermona aminNo ratings yet

- Material - Wood PresentationDocument49 pagesMaterial - Wood PresentationsrishtiNo ratings yet

- Nterior PaintingDocument23 pagesNterior PaintingJaysonT.BautistaNo ratings yet

- Transmission Fill Tube - Gauge, SightDocument3 pagesTransmission Fill Tube - Gauge, SightJESUSNo ratings yet

- Escarmosa Nielvilyn G. Feasibility Study Beaming Beginnings PreschoolDocument10 pagesEscarmosa Nielvilyn G. Feasibility Study Beaming Beginnings PreschoolKHRISSYL ANN SOLIDONo ratings yet

- Summary ReportDocument204 pagesSummary Reporteffan f gultomNo ratings yet

- Urban Development (Kabul)Document31 pagesUrban Development (Kabul)Jama 'Figo' MustafaNo ratings yet

- Flygt JP 4715 EnglishDocument2 pagesFlygt JP 4715 EnglishMohammed SaadNo ratings yet

- CD 361 Weathering Steel For Highway Structures-WebDocument19 pagesCD 361 Weathering Steel For Highway Structures-WebAbinashNo ratings yet

- Addendum Screw Thread TypesDocument3 pagesAddendum Screw Thread Typeskanha15102003No ratings yet

- Silenciadores ParkerDocument2 pagesSilenciadores ParkerDaniel MarNo ratings yet

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDocument4 pagesStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127No ratings yet

- LCP LYCORPANEL SpecificationDocument2 pagesLCP LYCORPANEL SpecificationGarfieldNo ratings yet

- Irene UbaywwDocument11 pagesIrene Ubaywwskdelacruz.djdengrNo ratings yet

- ASME Ch17 p001-068 1 9-5-08 PDFDocument68 pagesASME Ch17 p001-068 1 9-5-08 PDFJames RobsonNo ratings yet

- Efficiency Analysis On High Rise BuildingsDocument13 pagesEfficiency Analysis On High Rise BuildingsRizwan DogerNo ratings yet

- Irjet V4i7516 PDFDocument7 pagesIrjet V4i7516 PDFRajat MohanNo ratings yet

- IW216437 - 4477-BWO Barossa Lifting Report - REV03 (STAAD PRO)Document45 pagesIW216437 - 4477-BWO Barossa Lifting Report - REV03 (STAAD PRO)Thao TaoNo ratings yet

- TS68Document52 pagesTS68finandariefNo ratings yet

- Castle Builder Vol 4 TowersDocument21 pagesCastle Builder Vol 4 TowersClay Liford100% (1)