Professional Documents

Culture Documents

Alivio Cartucho - C010

Alivio Cartucho - C010

Uploaded by

DANIZACHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alivio Cartucho - C010

Alivio Cartucho - C010

Uploaded by

DANIZACHCopyright:

Available Formats

www.atos.

com

Cartridge pressure relief valves type SP-CART

screw-in mounting

Table C010-10/E

SP-CART are direct operated pressure

relief valves for screw-in mounting.

They are used to limit the max pressure

in the hydraulic systems or to protect

part of the circuit from overpressure.

They are available in six sizes for diffe-

rent flow and pressure range.

The cartridge execution is specifically

designed to reduce the dimension of

blocks and manifolds, without penali-

zing the functional characteristics.

The following safety options are availa-

ble with factory preset regulation, not

adjustable (lead sealed regulation):

/RS conformi ng to the Machi ne

Directive (2006/42/CE). The factory

preset regul ati on requi red by the

costumer corresponds to the valves

cracking pressure.

/PED certified by ConCert according to

PED Directive (97/23/CE). The valves

are factory set at the pressure level

required by the costumer with a flow

trough the valve as shown in section 6.

For thi s versi on, the P/Q l i mi ts are

shown in section 9.

Max flow: 150 l/min.

Max pressure: 350 bar,

400 bar for SP-CART-ARE-20

Screw-in

relief cartridges

1

C010

Size:

M-3 = G1/2 (1)

M-4 = M14x1

M-5 = M20x1,5

M-6 = M33x1,5 (1)

ARE-15= M32x1,5

ARE-20= M35x1,5 (1)

MODEL CODE

SP-CART M-5/***

SP-CART M-6/***/PED

/RS

Max pressure setting:

see section 3for available setting

(1) Available also in stainless steel execution, see technical table E135

(2) Standard execution of SP-CART M-4 and SP-CART ARE-20 provides the reduced leakage feature, then the /R is always present in the valve model code

(3) For handwheel and knob features, see sections 10 , 11 .For their availability, see section 5

Synthetic fluid

WG= water glycol

PE = phosphate ester

Only for RS, PED options:

280 = factory pressure setting to be defined depending to the

customer requirement (example 280 = 280 bar)

SP-CART M-6 350 / /PED /* ** /*

Options, see section 5 for options availability and combination:

/R = reduced leakage for special application (standard code for SP-CART M-4 and SP-CART ARE-20) (2)

/RS = as /R, plus conforming to 2006/42/CE

/PED= as /R, plus certified by ConCert according to 97/23/CE

/F = fixed pressure setting

Only for standard and /R option (3):

/V = regulating handwheel

/VF = regulating knob

/VS = regulating knob with safety locking

Series number

2 HYDRAULIC SYMBOLS

SP-CART

SP-CART **/R

SP-CART **/RS

SP-CART **/PED

SP-CART **/F

Nameplate only

for /PED option

X

X

X

X

Assembly position Any position

Ambient temperature -20C + 70C

Fluid Hydraulic oil as per DIN 51524...535; for other fluids see section 1

Recommended viscosity 15100 mm

2

/s at 40C (ISO VG 15100)

Fluid contamination class ISO 19/16, achieved with in line filters at 25 m value and 25 75 (recommended)

Fluid temperature -20C +60C (standard and /WG seals) -20C +80C (/PE seals)

4 MAIN CHARACTERISTICS OF CARTRIDGE PRESSURE RELIEF VALVES

Option

Valve model SP-CART M-3 SP-CART M-5 SP-CART M-6

/V

/RS

/PED

/VF

/F

SP-CART ARE-15

SP-CART ARE-20

/VS

/R

STANDARD

5 OPTIONS AVAILABILITY

6 SETTING OF VALVES WITH /PED OPTION

/RV

/RVF

/RVS

Combinated

option

(1)

(1) /RV = reduced leakage and regulating handwheel

/RVF = reduced leakage and regulating knob

/RVS = reduced leakage and regulating knob with safety lock

3 HYDRAULIC CHARACTERISTICS

Valve model SP-CART M-3 SP-CART M-5 SP-CART M-6

/F

/R

/RS

/F

/R

/RS

/PED

/PED

SP-CART ARE-15

/RS, /PED, /F

SP-CART ARE-20

STANDARD

STANDARD

STANDARD

Max

pressure

setting

[bar]

Pressure

range

[bar]

Max flow [l/min]

(1)

(1)

(1)

(1) The values correspond to the min and max regulation of the valves craking pressure.

SP-CART M-4

2,5

2,5

/50

/210

/100

/350

/50

/210

/100

/350

450 6100

7210 8350

450 6100

7210 8350

35

/100 /210

/350

25100 100210

210350

50

/50 /100 /210

/250 /350

250 3100 5210

8350 7250

40

/50

/220

/100

/210 /350

/270

/330 /350

250

200250

3100

10210 15350

250290

290350 310370

25100 100210

210350

/100 /210

/350

60

250 3100

15350

/50 /100

/210 /350

75

/200

/150

130170

200

/75

/250

/150

/350

/250

/190

/280

/230

2575 75150

150250 150350

170210

250

210250

280

/15 /50 /75

/150 /250

100

/15 /50 /75

/150 /250 /350

215 350 475

8150 8250

215 350 475

8150 8250

80350

120

150

/50 /100 /210

/315 /400

350 5100 6210

8315 10400

/100 /210

/315 /400

25100 100210

210315 315400

SP-CART M-4

VALVE MODEL

FLOW FOR FACTORY PRESSURE SETTING

(l/min)

SP-CART M-3 1

SP-CART M-4 1

SP-CART M-5 20

SP-CART M-6 30

SP-CART ARE-15 50

SP-CART ARE-20 50

STANDARD

15

15

/100 /210

/350

/100 /210

/350

6100 7210

8350

6100 7210

8350

210260 260300

300370

8210

/220 /270

/350

The /PED valves are factory set at the pressure level required by the

costumer (every 1 bar) at the following flow shown in the table.

The set pressure is marked on the valve nameplate, see section 6.1

6.1 EXAMPLE OF NAMEPLATE FOR /PED OPTION

Notified body reference number

Valve code

SP-CART ARE -15/250/PED/190

Set pressure

Max working pressure

XXXX

/250 /280

/200

/130 /180

250 280

200

130 180

/250 /280

/200

/150 /180

250 280

200

150 180

7 REGULATED PRESSURE VERSUS FLOW DIAGRAMS (based on mineral oil ISO VG 46 at 50C)

SP-CART M-3

Min. regulated pressure

SP-CART M-5

Min. regulated pressure

SP-CART M-5 **/F

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-6 **/F

SP-CART M-6 **/RS

SP-CART ARE-15

Min. regulated pressure

SP-CART ARE-15 **/F

SP-CART ARE-15 **/RS

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-6

Min. regulated pressure

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART ARE-20 **/R

Min. regulated pressure

C010

SP-CART M-4 **/R

Min. regulated pressure

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-4 **/RS

8 REGULATED PRESSURE VERSUS FLOW DIAGRAMS (based on mineral oil ISO VG 46 at 50C)

9 PERMITTED WORKING RANGES shaded area (based on mineral oil ISO VG 46 at 50C)

SP-CART M-3 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-5 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART ARE-15 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-6 **/PED

SP-CART M-3 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-5 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART ARE-15 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-6 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART ARE-20 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART ARE-20 **/PED

SP-CART M-4 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

SP-CART M-4 **/PED

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Flow [l/min]

30 Nm

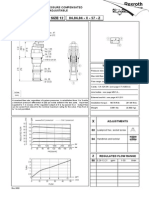

10 CAVITY AND DIMENSIONS FOR SP-CART M-3, M-4 AND M-5 [mm]

SP-CART M-3

SP-CART M-5

C010

SP-CART M-4

25 Nm

Option /PED

Option /F

Option /PED

Option /PED Option /V

Cavity drawing not in scale

with the cartridge

Standard

Standard

Standard

60 Nm

X

X

X

X

X

X

X

X

X

X

X

X

11 CAVITY AND DIMENSIONS FOR SP-CART M-6, SP-CART ARE-15 AND ARE-20 [mm]

Option /V

SP-CART ARE-15

04/09

65 Nm

Option /V

SP-CART ARE-20

140 Nm

Option /RS

/PED

Option /VF

/VS

Option /V

SP-CART M-6

55 Nm

Option /F

55 Nm

Option /RS

/PED

Option /VF

/VS

Option /RS

/PED

65 Nm

Option /F

Standard

Standard

Standard

Nameplate only

for /PED option

Nameplate only

for /PED option

Nameplate only

for /PED option

X

X

X

X

X

X

X

X

X

X

X

X

You might also like

- Manual HaskelDocument30 pagesManual HaskelMarcos Rodrigues Dos Santos100% (1)

- FP15 Interface Valve PDFDocument10 pagesFP15 Interface Valve PDFMargaret Daugherty0% (1)

- 2020-RoadmapDocument23 pages2020-RoadmapRezky RizaldiNo ratings yet

- MONUSCO Part 2 Schedules Final (To Be Taken Printout As Is Where Is)Document39 pagesMONUSCO Part 2 Schedules Final (To Be Taken Printout As Is Where Is)Uppiliappan GopalanNo ratings yet

- Pressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsDocument4 pagesPressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsmfbayatNo ratings yet

- Hawe Rapid RangeDocument16 pagesHawe Rapid RangecinbrekNo ratings yet

- Universal: Flow Monitor Installation and Maintenance Instructions For Vane and Piston Style Variable Area Flow MonitorsDocument40 pagesUniversal: Flow Monitor Installation and Maintenance Instructions For Vane and Piston Style Variable Area Flow Monitors4lk0nNo ratings yet

- Valvulas XT PDFDocument4 pagesValvulas XT PDFIsidro Gomez GarciaNo ratings yet

- E5174 10 12 10 - Rbe 1 - 8 3 - 4Document4 pagesE5174 10 12 10 - Rbe 1 - 8 3 - 4romekgzp0% (1)

- Atos HidraulicaDocument8 pagesAtos HidraulicaFabinhoTowerNo ratings yet

- Hose Burst Valve PDFDocument4 pagesHose Burst Valve PDFnikhil nagannavarNo ratings yet

- Vivoil P enDocument90 pagesVivoil P enHorea CordunianuNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Re26892 2003-02Document10 pagesRe26892 2003-02DANIZACHNo ratings yet

- PN03CL1S01Document4 pagesPN03CL1S01Amreusit SaschimbnumeleNo ratings yet

- Ec 0301Document25 pagesEc 0301Silvio RomanNo ratings yet

- Re 10460Document20 pagesRe 10460Ahmed Abd ElhakeemNo ratings yet

- E5174 RbeDocument4 pagesE5174 RbeVinod YbNo ratings yet

- Check d180 - HR KRDocument4 pagesCheck d180 - HR KRDANIZACHNo ratings yet

- S RV CalculatorDocument4 pagesS RV CalculatorRahul PatilNo ratings yet

- Yukenmodularvalves Yuken CatDocument140 pagesYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Parker Catálogo de Válvulas ProporcionalesDocument62 pagesParker Catálogo de Válvulas ProporcionalesJuan Ignacio d'Valle IIINo ratings yet

- Fil+Reg+Lub: D A E D A EDocument14 pagesFil+Reg+Lub: D A E D A EIrwin ParedesNo ratings yet

- Dongguan Suncenter Fluid Control Equipment Co., LTDDocument10 pagesDongguan Suncenter Fluid Control Equipment Co., LTDJeisson Daza100% (1)

- Hi-Force Hydrostatic PDFDocument6 pagesHi-Force Hydrostatic PDFWong Chung MengNo ratings yet

- Proportional Valves: Catalog HY15-3502/USDocument62 pagesProportional Valves: Catalog HY15-3502/USPartsGopher.comNo ratings yet

- R Pilot - BWBPSHLDocument2 pagesR Pilot - BWBPSHLalvipin0010% (1)

- RegulatorDocument6 pagesRegulatorFlorin GoiaNo ratings yet

- F500Document4 pagesF500back1949No ratings yet

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerDocument8 pages02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988No ratings yet

- Air Preparation ProductsDocument6 pagesAir Preparation ProductssenamotoNo ratings yet

- Tecumseh Quick Select Guide - CompressorsDocument12 pagesTecumseh Quick Select Guide - Compressorsسامح الجاسم100% (1)

- R07-200 RNKG PDFDocument4 pagesR07-200 RNKG PDFAlexandre EmmerickNo ratings yet

- D 103077 X 012Document40 pagesD 103077 X 012Jediael JuniorNo ratings yet

- MS 01 141Document8 pagesMS 01 141arlumNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Check en Linea - c406Document2 pagesCheck en Linea - c406DANIZACHNo ratings yet

- Flowserve Lined Flush BottomDocument32 pagesFlowserve Lined Flush BottomDevdatt WaghuleNo ratings yet

- Nupro Relief ValvesDocument8 pagesNupro Relief Valvesgeverett2765No ratings yet

- Rexroht PumpDocument45 pagesRexroht PumpmanualdeutsNo ratings yet

- Class 1CJ1S01 (Pip PN01CJ1S01 - 2007)Document4 pagesClass 1CJ1S01 (Pip PN01CJ1S01 - 2007)Zvonko BešlićNo ratings yet

- DM931 Variable Orifice Double Regulating Valve: PN16 Cast Iron Balancing Valve (VODRV), Flanged To BSEN 1092-2Document10 pagesDM931 Variable Orifice Double Regulating Valve: PN16 Cast Iron Balancing Valve (VODRV), Flanged To BSEN 1092-2Mohamed AdelNo ratings yet

- Hermetic CAN&CNFDocument20 pagesHermetic CAN&CNFkikechuNo ratings yet

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- 3105 B 26Document3 pages3105 B 26ParIs MoRanNo ratings yet

- 3 Way Unimizer ValvesDocument3 pages3 Way Unimizer ValvesSunil PawarNo ratings yet

- Chemguard Ratio Flow ControllerDocument3 pagesChemguard Ratio Flow Controllerergo proxyNo ratings yet

- Alivio - d120 - HM - KMDocument4 pagesAlivio - d120 - HM - KMDANIZACHNo ratings yet

- 399ADocument24 pages399ADana Mera100% (2)

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stNo ratings yet

- Scanwill Pressure IntensifierDocument12 pagesScanwill Pressure IntensifierÁlvaro Conti FilhoNo ratings yet

- 83 Wilo Star Rs TCH PodaciDocument3 pages83 Wilo Star Rs TCH PodacilajosmolNo ratings yet

- About Axial Displacement Pump A4VSoDocument68 pagesAbout Axial Displacement Pump A4VSomrkadu_61No ratings yet

- Krilna Rexroth 1pv2v3Document8 pagesKrilna Rexroth 1pv2v3ado_22No ratings yet

- Λιπαντήρες αέρος PDFDocument21 pagesΛιπαντήρες αέρος PDFPeter SakeNo ratings yet

- SDM 141 eDocument28 pagesSDM 141 eseaqu3stNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Valvula de Acc Manual - E150Document4 pagesValvula de Acc Manual - E150DANIZACHNo ratings yet

- 305 TransmissionDocument2 pages305 TransmissionDANIZACHNo ratings yet

- Pump Polaris SeriesDocument47 pagesPump Polaris SeriesDANIZACHNo ratings yet

- Valvula Tn10 - Dke E025Document4 pagesValvula Tn10 - Dke E025DANIZACHNo ratings yet

- Check en Linea - c406Document2 pagesCheck en Linea - c406DANIZACHNo ratings yet

- Check d180 - HR KRDocument4 pagesCheck d180 - HR KRDANIZACHNo ratings yet

- En - b1 - 070 PATINES LINEALESDocument2 pagesEn - b1 - 070 PATINES LINEALESDANIZACHNo ratings yet

- Catalogo Componentes 2007Document39 pagesCatalogo Componentes 2007DANIZACHNo ratings yet

- Cilindros Hidráulicos de Simple y Doble Efecto Single and Double Acting Hydraulic CylindersDocument1 pageCilindros Hidráulicos de Simple y Doble Efecto Single and Double Acting Hydraulic CylindersDANIZACHNo ratings yet

- Pump Magnun SeriesDocument63 pagesPump Magnun SeriesDANIZACHNo ratings yet

- Divisor Pld-02-T-ADocument20 pagesDivisor Pld-02-T-ADANIZACHNo ratings yet

- Pump KappaDocument112 pagesPump KappaDANIZACHNo ratings yet

- 4 - Way Directional Control Valve "HPV4": FeaturesDocument2 pages4 - Way Directional Control Valve "HPV4": FeaturesDANIZACHNo ratings yet

- TF4 Mar 20 06Document6 pagesTF4 Mar 20 06DANIZACHNo ratings yet

- Basic Training: Motors, Gears & DrivesDocument80 pagesBasic Training: Motors, Gears & DrivesDANIZACH50% (2)

- Re26892 2003-02Document10 pagesRe26892 2003-02DANIZACHNo ratings yet

- Reductores - d140 - HG KGDocument4 pagesReductores - d140 - HG KGDANIZACHNo ratings yet

- 742Document52 pages742DANIZACHNo ratings yet

- H&P Reprints 2009Document4 pagesH&P Reprints 2009DANIZACHNo ratings yet

- Breathers Mar 20 06Document8 pagesBreathers Mar 20 06DANIZACHNo ratings yet

- 040404X57ZDocument1 page040404X57ZDANIZACHNo ratings yet

- Valvula de Asiento - Dloh E041Document4 pagesValvula de Asiento - Dloh E041DANIZACHNo ratings yet

- Filter Cart Modelo SCFCDocument1 pageFilter Cart Modelo SCFCDANIZACHNo ratings yet

- Flow Control Valves QV-06: Pressure Compensated, Two Way, ISO 4401 Size 06Document2 pagesFlow Control Valves QV-06: Pressure Compensated, Two Way, ISO 4401 Size 06DANIZACHNo ratings yet

- Industry Analysis of Two Wheeler MarketDocument109 pagesIndustry Analysis of Two Wheeler MarketGautam100% (1)

- 3 ASSI DairyPracticesCouncil11!06!2014Document53 pages3 ASSI DairyPracticesCouncil11!06!2014Jacques BlueqNo ratings yet

- Unit 2. Software Process Primitives and Process Management FrameworksDocument83 pagesUnit 2. Software Process Primitives and Process Management FrameworksEfrain Sanjay AdhikaryNo ratings yet

- Haccp 1Document43 pagesHaccp 1Prashant popatNo ratings yet

- Spectra Encryption User GuideDocument100 pagesSpectra Encryption User GuideMarcos Vinicius SilvaNo ratings yet

- RFQ - Residential Commons (1!25!10 Issue)Document15 pagesRFQ - Residential Commons (1!25!10 Issue)loristahl8340No ratings yet

- Setting Up Cost Accounting in Fusion: Source SystemsDocument35 pagesSetting Up Cost Accounting in Fusion: Source SystemsShiva KumarNo ratings yet

- How To Make Your Own Knives - Jim Mayes (S)Document185 pagesHow To Make Your Own Knives - Jim Mayes (S)karnizsdjuro83% (12)

- Cot C Brochure PepDocument8 pagesCot C Brochure Pepswaggeroni yololo100% (1)

- Company Name & Add. Executive Name Product Name: S.N. Office NoDocument47 pagesCompany Name & Add. Executive Name Product Name: S.N. Office NoSargam NigamNo ratings yet

- Manual NI myDAQDocument15 pagesManual NI myDAQAlejandro CastelNo ratings yet

- Secrets To More Effective Electrical Estimating EC&MDocument30 pagesSecrets To More Effective Electrical Estimating EC&MHakeem AzmaNo ratings yet

- Data Sheet 15-5PH-AMS5659Document2 pagesData Sheet 15-5PH-AMS5659沈家麒No ratings yet

- A New Approach To Diagnosing and Managing Projects: Introducing The Project Complexity ModelDocument8 pagesA New Approach To Diagnosing and Managing Projects: Introducing The Project Complexity ModelDIVINE123456789No ratings yet

- Project Cost Estimating Manual Third Edition PDFDocument83 pagesProject Cost Estimating Manual Third Edition PDFYanning LiNo ratings yet

- TNEP Energy Transformed Lecture 1.4Document21 pagesTNEP Energy Transformed Lecture 1.4Thiago Hagui Dos SantosNo ratings yet

- Arkema Catalogue 13.09.22Document10 pagesArkema Catalogue 13.09.22rynianNo ratings yet

- PB OnliteDocument276 pagesPB OnliteIoana BacanciosNo ratings yet

- Tang Minh Phat - Project ProfileDocument21 pagesTang Minh Phat - Project Profiledominhdung263168No ratings yet

- Mining Frequent Itemsets Using Apriori AlgorithmDocument5 pagesMining Frequent Itemsets Using Apriori AlgorithmseventhsensegroupNo ratings yet

- Paper Airplane Building Machine Paper Airplane LauncherDocument49 pagesPaper Airplane Building Machine Paper Airplane LauncherozarNo ratings yet

- Job DeskDocument19 pagesJob DeskPandi IndraNo ratings yet

- Catalogo Miller Safety Cat132016Document80 pagesCatalogo Miller Safety Cat132016Jimy BarronNo ratings yet

- Water Supply Law Lao 2009Document25 pagesWater Supply Law Lao 2009Siharath PhoummixayNo ratings yet

- WC B2B Business ModelsDocument19 pagesWC B2B Business ModelsAbhishek Kumar100% (1)

- Wartsila Annual Report 2008 En.Document144 pagesWartsila Annual Report 2008 En.Uhrin ImreNo ratings yet

- ACP Inventor PDFDocument2 pagesACP Inventor PDFAlejandro GonzalezNo ratings yet

- Sandeep ResumeDocument3 pagesSandeep ResumeTarun AluguriNo ratings yet