Professional Documents

Culture Documents

Effect of Compression Ratio On Bio Diesel

Effect of Compression Ratio On Bio Diesel

Uploaded by

shyleshaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mini-Dungeon - HMD-005 The Temporal Clock TowerDocument5 pagesMini-Dungeon - HMD-005 The Temporal Clock TowerАлексей ЖуравлевNo ratings yet

- City Planning and Neighbourhood Design Case Studies1Document132 pagesCity Planning and Neighbourhood Design Case Studies1shinmiNo ratings yet

- USB TO RS232 Cable For Windows 2000 User's ManualDocument7 pagesUSB TO RS232 Cable For Windows 2000 User's ManualOsvaldo Loyde AlvaradoNo ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Sustainable Building TechnologiesDocument9 pagesSustainable Building TechnologiesprashuboyNo ratings yet

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument61 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDarshan MakwanaNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document13 pages400 Bad Request 400 Bad Request Nginx/1.2.9USAFVOSBNo ratings yet

- Lab Work 1Document2 pagesLab Work 1Adly HakimNo ratings yet

- MUXDocument5 pagesMUXAmit SahaNo ratings yet

- BBA Financial PlanningDocument17 pagesBBA Financial Planningprasad kulkarniNo ratings yet

- HAQ Instructions (ARAMIS) 6-30-09Document16 pagesHAQ Instructions (ARAMIS) 6-30-09nurasyikahNo ratings yet

- GreeceDocument2 pagesGreececopelmnNo ratings yet

- S - 5 1 0 L, S - 5 1 0 R: PioneerDocument4 pagesS - 5 1 0 L, S - 5 1 0 R: PioneermiliindianuNo ratings yet

- Boli Interne Vol I Partea 1Document454 pagesBoli Interne Vol I Partea 1Murariu Diana100% (2)

- Xenforo JsDocument39 pagesXenforo JsjaaritNo ratings yet

- Training Activity Matrix: Training Activities Trainees Facilities/Tools/Equip Venue Date RemarksDocument3 pagesTraining Activity Matrix: Training Activities Trainees Facilities/Tools/Equip Venue Date RemarksCharleneNo ratings yet

- Power Electronic Unit For Field-Mounting (Contrac) EBN853, EBN861Document44 pagesPower Electronic Unit For Field-Mounting (Contrac) EBN853, EBN861Sad LiveNo ratings yet

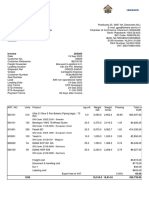

- Invoice 203265: GN Code: 3923.2100 - SwedenDocument2 pagesInvoice 203265: GN Code: 3923.2100 - SwedenArturo RiveroNo ratings yet

- Fan TRO 2830Document106 pagesFan TRO 2830dwr234100% (4)

- William Stallings Computer Organization and Architecture 9 EditionDocument28 pagesWilliam Stallings Computer Organization and Architecture 9 EditionAnggi Riza Amirullah SidhartaNo ratings yet

- Porsche Engineering Magazine 2016/2Document50 pagesPorsche Engineering Magazine 2016/2wattafillingNo ratings yet

- MP 87.1-2008 Australian New Zealand Certification Scheme For Explosion-Protected Electrical Equipment (ANZExDocument6 pagesMP 87.1-2008 Australian New Zealand Certification Scheme For Explosion-Protected Electrical Equipment (ANZExSAI Global - APACNo ratings yet

- Stolzle Prestige Standards BrochureDocument9 pagesStolzle Prestige Standards BrochureTomi AkingbolagunNo ratings yet

- IGBT MitsubishiDocument4 pagesIGBT Mitsubishimadhuvariar100% (3)

- Kinematics Free Fall SolsDocument5 pagesKinematics Free Fall SolsDean JezerNo ratings yet

- Project On Sales Promotion ParagDocument66 pagesProject On Sales Promotion ParagavnishNo ratings yet

- Neonatal Resuscitation. Advances in Training and PracticeDocument10 pagesNeonatal Resuscitation. Advances in Training and PracticeFer45No ratings yet

- Embragues y Frenos - P-1960-CDocument4 pagesEmbragues y Frenos - P-1960-Cdéborah_rosalesNo ratings yet

- James L GordonDocument1 pageJames L Gordonpapan_5069No ratings yet

- PR 2001219Document10 pagesPR 2001219Amr Mohamed GalalNo ratings yet

Effect of Compression Ratio On Bio Diesel

Effect of Compression Ratio On Bio Diesel

Uploaded by

shyleshaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Compression Ratio On Bio Diesel

Effect of Compression Ratio On Bio Diesel

Uploaded by

shyleshaCopyright:

Available Formats

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012)

An Experimental Analysis of Diesel Engine Using Biofuel at Varying Compression Ratio

Sejal Narendra Patel1, Ravindra Kirar2

2

M.Tech Scholar, PCST Bhopal, M.P.,INDIA. Assistant Professor, Mechanical Engg. Department, PCST, Bhopal, M.P.,INDIA. From the combustion analysis, it was found that ignition delay was shorter for neat rapeseed oil and its blends tested compared to that of standard.4The brake specific fuel consumption (BSFC) and exhaust gas temperature(EGT) increased, whereas brake thermal T 8: : T trend for these parameters was observed with increase in the compression ratio (CR) and advancement of injection timing (IT). The BSFC of B100 and its blends with high speed diesel reduced, whereas BTE and EGT increased with the increase in load for the range of CR and IT tested. The differences of BTEs between HSD and B100 were also not statistically significant at engine settings of R IT R IT T u u used on the Ricardo engine at these settings without affecting the performance obtained using high speed diesel (HSD)5. Performance with regard to fuel consumption (BSFC), brake thermal efficiency (BTHE) and emissions of CO, CO2, HC, NOx and Smoke opacity with jatropha methyl ester (JME) as fuel. Comparison of performance and emission was done for different values of compression ratio along with injection pressure to find best possible combination for operating engine with JME. It is found that the combined increase of compression ratio and injection pressure increases the BTHE and reduces BSFC while having lower emissions. For small sized direct injection constant speed engines used for agricultural applications (3.5 kW), the optimum combination was found as CR of 18 with IP of 250 bar.6 II. EXPERIMENTAL WORK 2 .1 Plan of the experiments: The main aim of the experimentation is to check feasibility of biodiesel in C.I. engine fuelled with diesel-biodiesel blends with more fractions and 100% biodiesel. The experimental work under this project consists of two parts, initial experimental work to analyse the effect of different compression ratio on engine performance and emission in second phase, optimizing work for finding the optimum diesel-biodiesel blend.

Abstract - This paper presents an experimental analysis of performance and emission characteristic of diesel-biodiesel blend use in single cylinder, aspirated with varying compression ration i.e, 14,16,18. using biodiesel diesel blends i.e. B10, B20, B30, B40, B60, B80 and pure biodiesel with load variation from ano load to full load and compared with base cases i.e. engine using diesel as a fuel. The parameters which studied are in performance brake power, brake specific fuel consumption and brake thermal efficiency, in emission carbon monoxide, carbon dioxide, nitrogen oxide and unburned hydrocarbon of diesel engine. It was observed that out of three compression ratios i.e. 14, 16 and 18, compression ratio 18 results of brake thermal efficiency, brake specific fuel consumption and brake power as better results and emission for it was also lower except nitrogen oxide. In diesel-biodiesel blend , B20 having a better performance out of all combination of test fuel and emission of carbon monoxide (CO), carbon dioxide (CO2), unburned hydro carbon (HC) and oxides of nitrogen (NOx) decrease. Keywords -Biodiesel, Emission, Jetrophaoil, Performance Varying compression ratio.

I. INTRODUCTION In India, total consumption of crude oil was 103,44 million tonnnes (MT) in2000-2001and 160.03MT in 200910,whereas production was 32.43MT in200-01and33.69MT in2009-10.Thus increment in production is only 3.7%as compared to increment in computation of 35.36%1.Transportation and agricultural sectors are major consumers of fossil fuel and biggest contributors to environmental pollution. Current price of vegetable oil worldwide is nearly competitive with petroleum based fuels. Vegetable oils have a favorable output-input ratio of their production.2 Use of bio-diesel in a conventional diesel engine results in substantial reduction in unburned hydrocarbon (UBHC), carbon monoxide (CO), particulate matters (PM) emission and oxide of nitrogen (NOx) 3. The measured CO emissions of B5 and B100 fuels were found to be 9% and 32% lower than that of the diesel fuel, respectively. The BSFC of biodiesel at the maximum torque and rated power conditions were found to be 8.5% and 8% higher than that of the diesel fuel, respectively.

385

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012) For entire project work, different parameters are varying among their respective range. The variable parameters are fuel, compression ratio and the load condition. Table 3.1 shows all the combination for all the variable parameters. The main parameter is fuel composition. The experiments were carried out with 100% diesel. Diesel-biodiesel blends (B10, B20, B30, B40, B60 and B80) and 100% biodiesel. Also other parameter i.e. loads and compression ratio also varied as mention in Table 3.1 during experimentation. With all the combinations of different load, test fuel and compassion ratio the total number of experiments were 120. Generation of base line performance data from the C.I engine fuelled by diesel, Compare different Dieselbiodiesel blends and 100% biodiesel data with base line data for various load.

Figure 1 Schematic diagram of experimental setup

F1 & F2 - Flow sensor for fuel and air W - Load sensor N - Engine speed sensor PT - Cylinder pressure & Injection pressure sensor T1-6 - Temperature sensors

Table I Variable Parameter in Experiment

Fuel Compression Ratio Load (%)

Pure Diesel, B10, B20, B30, B40, B60, B80, Pure Biodiesel 14, 16, 18 0, 25, 50, 75, 100

Table II Engine Specification

Engine

1 cylinder, 4 stroke, water cooled, stroke 110 mm, bore 87.5 mm. Diesel mode: Power 3.5 KW , CR range 12:1-18:1 , Speed 1500 rpm , Injection variation 0-25 Deg BTDC Type eddy current, water cooled, with loading unit

Dynamometer

Calorimeter Rotameter

Type Pipe in pipe Engine cooling 40-400 LPH; Calorimeter 25-250 LPH

386

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012)

Piezo sensor Combustion: Range 5000 PSI, with low noise cable Diesel line: Range 5000 PSI, with low noise cable Resolution 1 Deg, Speed 5500 RPM with TDC pulse. Type RTD, PT100 and Thermocouple, Type K

Crank angle sensor Temperature sensor

Load sensor Fuel tank Software

Load cell, type strain gauge, range 0-50 Kg Capacity 15 lit, Type: Duel compartment with fuel metering pipe of glass

In figure 1. Schematic diagram of experimental setup is shown. The setup consists of single cylinder, four stroke, Multi-fuel, research engine connected to eddy current type dynamometer. In both modes the compression ratio can be varied without stopping the engine and without altering the combustion chamber geometry by specially designed tilting cylinder block arrangement. Instruments are provided to interface airflow, fuel flow, temperatures and load measurements. Rota meter are provided for cooling water and calorimeter water flow measurement. A battery, starter and battery charger is provided for engine electric start arrangement. Lab view based Engine Performance Analysis k performance evaluation. In Table II the detailed specification of engine is given. 2..2Gas analyzer specifications: Fig.2 shows the exhaust gas analyzer which was used during experiments to find out exhaust gas like carbon monoxide, carbon dioxide, nitrogen oxide and unburned hydrocarbons. The model of u T AVL L Instrument was able to give results of emission gases on the screen. In table 3 the measurement data of instrument is given.

Table III Measurement Data: Emission Parameters Carbon Monoxide (CO) Unburned Hydrocarbons (HC) Carbon Dioxide (CO2) Nitrogen Oxide (NOx) Measurement 0-10% vol. 0-20000 ppm 0-20% vol. 0-5000 ppm Properties

Figure 2 Gas analyzer

Table IV Comparison of Biodiesel and Diesel properties Diesel 825.0 2.10 42235 40 48 Biodiesel 870 2.80 36844 138 52

387

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012) III. RESULT & DISCUSSION

POWER OUTPUT

The brake power distribution is shown in Figures3.1 for diesel and diesel-biodiesel blends. The values of brake power at compression ratio 18 full load for B0, B10, B20, B30, B40, B60, B80 and B100 were 3.35kW, 3.30kW, 3.43kW, 3.37kW, 3.18kW, 3.24kW, 3.14kW and 3.08kW respectively. The brake power is higher for B20 and beyond that as percentage of biodiesel increases the value of biodiesel decreases. the values of brake power for the entire blends for three compression ratio is plotted. By the It is observed from the figure that there is no considerable effect on brake power. The nature of brake power increase with the increase in load. The brake power distribution is shown in Figures 3.2 for diesel and biodiesel at compression ratio 18. At every load it was observed from the figure that brake power is with diesel compare to biodiesel. The brake power of an engine increases significantly with load. At full load the brake power of biodiesel was comparatively 8.05 % and at part load (50% load) it was 8.27% lesser than diesel because of the higher viscosity and density of the biodiesel.

Figure 3.2 Effect of Compression Ratio on BP for all Diesel-Biodiesel Blends

BRAKE THERMAL EFFICIENCY (BTE)

Figure 3.1 Effect of Compression Ratio18 on BP for all Diesel-Biodiesel Blends

The effect of compression ratio on brake thermal efficiency is shown for all the different diesel biodiesel blends. It can be observed that as compression ratio increase brake thermal efficiency was considerably increased for all the blends. This is because as higher compression ratio the combustion was much better compare to lower compression ratio (Fig.4.2). The brake thermal efficiency distribution is shown in Figures 4.1 for diesel and biodiesel at compression ratio 18. At every load we got higher efficiency with diesel compare to biodiesel. The brake thermal efficiency of an engine increases significantly with load. At full load the brake thermal efficiency of biodiesel 8.29 % lower than diesel and at 50% part load it was 5.28% lesser than diesel. This happened because of the lower calorific value of the biodiesel.

388

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012)

Figure 4.2 Effect of Compression Ratio 18 on BTE for all DieselBiodiesel Blends

Figure 5.1 Effect of Compression Ratio on BSFCfor all Diesel-Biodiesel Blends

Figure 4.1 Effect of Compression Ratio on BTE for all Diesel-Biodiesel Blends

BRAKE SPECIFIC FUEL CONSUMPTION

Figure 5.2 Effect of Compression Ratio 18 on BSFC for all DieselBiodiesel Blends

Fig. 5.2 shows the effect of blend on brake specific fuel consumption. The value of brake specific fuel consumption on compression ratio at full load for B20, B30, B40, B60, B80 and B100 was 0.32kg/kWh, 0.33kg.kWh, 0.34kg.kWh,

389

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012) 0.36kg.kWh, 0.38kg.kWh and 0.40kg.kWh respectively. Such a high value of BSFC for the blends, especially for B80 and B100 may be attributed to the poor combustion characteristics of this blends.

Carbon Monoxide (CO)

Figure 8 Effect of Compression Ratio 18 on NOX for Diesel-Biodiesel

Fig. 6: Comparison of Emission of CO for Pure Diesel and Pure Biodiesel

The comparison of emission of carbon monoxide for diesel and biodiesel is shown. At entire load range of including 100% biodiesel had lesser emission of carbon monoxide than diesel. This decrease may be because of higher oxygen content in biodiesel which causes the complete combustion.

Unburned Hydro Carbons (HC)

Shows comparison of nitrogen oxide emission for diesel and biodiesel at compression ratio 18. The emission of nitrogen oxide for diesel and biodiesel 1093ppm and 960ppm.The emission of nitrogen oxide decreases for biodiesel at full load condition but slightly increase at part load condition. During combustion chemical reaction which made nitrogen oxide were takes place at higher temperature. The exhaust gas temperature remains almost same for all the blends.

Carbon Dioxide (CO2)

Comparison of emission of unburned hydrocarbon of diesel and biodiesel is shown. The emission of biodiesel was considerably less compare to diesel. At compression ratio 18 the emission of hydrocarbon of diesel and biodiesel were 38 ppm and 19 ppm respectively. The higher cetane number of biodiesel and oxygen availability of fuel is responsible for this decrease.

The carbon dioxide emission distribution is shown in Figures 4.8(a) for diesel and biodiesel at compression ratio 18. At every load we got lower emission with biodiesel compare to diesel. The carbon dioxide emission of an engine increases significantly with load. At full load the carbon dioxide emission of diesel and biodiesel was 3.6%vol. and 2.6%vol. respectively. At higher compression ratio the combustion was much better compare to lower compression ratio. IV. CONCLUSION Calorific value of Biodiesel is less (36844 kJ/kg) as compare to diesel (42235kJ/kg). Decrease in calorific value results in higher consumption of fuel for biodiesel-diesel blend and pure biodiesel as compare to diesel .Biodiesel is more viscous (2.80cSt) as compare to diesel (2.10cSt).For higher blends of biodiesel, the modification in injection system of engine may be required due to increase in viscosity of fuel. From performance and emission test analysis, it is found that when compression ratio increases brake thermal efficiency (BTHE) increases and brake specific fuel consumption (BSFC) decreases. The results of

Figure 7 Effect of Compression Ratio 18 on HC for Diesel-Biodiesel

Nitrogen Oxide (NOx)

390

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 10, October 2012) brake power remains unaffected by changing compression ratio. In emission parameters with the increment in compression ratio emission of carbon monoxide (CO), unburned hydrocarbons (HC) and carbon dioxide (CO2) was found to be decrease. Emission of nitrogen oxide (NOx) was increases considerably with the compression ratio increases. This was due to better combustion characteristics with increase in compression ratio. In exhaust gas analysis for diesel and B20 emission of carbon monoxide was 0.036%vol. and 0.030%vol., emission of carbon dioxide was 3.6%vol. and 3.1%vol., emission of unburned hydrocarbon was 38ppm and 36ppm, emission of nitrogen oxide was 1093ppm and 1031ppm. Acknowledgment Author thanks SAL INSTITUTE OF TECHNOLOGY AND ENGINEERING REASERCH. For permition to research project on their diesel test ring and also thanks to Khushbu R & D centre for help to testing the bio diesel REFERENCES

[1] J. B. Heywood, Internal combustion engine fundamentals. New York: McGraw Hill, 5 ed., 1988.

[ 2] A. Murugesan , C. Umarani , R. Subramanian , N. Nedunchezhian Bio-diesel as an alternative fuel for diesel enginesA review Renewable and Sustainable Energy Reviews 13, pp. 653662, 2009. [3] k u ukk u 3099-310, 2010. [4] N. Stalin J P u P karanja biodiesel blendin A and Applied Sciences, pp. 32-34, 2007. R 2008. [6] S. Jindal, B.P. Nandwana, N.S R VV x investigation of the effect of compression ratio and injection pressure in a direct injection diesel engine running on Jatropha A T 448, 2010. P Fu 87 6 92666, u J u I Fu 89

[5]

391

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mini-Dungeon - HMD-005 The Temporal Clock TowerDocument5 pagesMini-Dungeon - HMD-005 The Temporal Clock TowerАлексей ЖуравлевNo ratings yet

- City Planning and Neighbourhood Design Case Studies1Document132 pagesCity Planning and Neighbourhood Design Case Studies1shinmiNo ratings yet

- USB TO RS232 Cable For Windows 2000 User's ManualDocument7 pagesUSB TO RS232 Cable For Windows 2000 User's ManualOsvaldo Loyde AlvaradoNo ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Sustainable Building TechnologiesDocument9 pagesSustainable Building TechnologiesprashuboyNo ratings yet

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument61 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDarshan MakwanaNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document13 pages400 Bad Request 400 Bad Request Nginx/1.2.9USAFVOSBNo ratings yet

- Lab Work 1Document2 pagesLab Work 1Adly HakimNo ratings yet

- MUXDocument5 pagesMUXAmit SahaNo ratings yet

- BBA Financial PlanningDocument17 pagesBBA Financial Planningprasad kulkarniNo ratings yet

- HAQ Instructions (ARAMIS) 6-30-09Document16 pagesHAQ Instructions (ARAMIS) 6-30-09nurasyikahNo ratings yet

- GreeceDocument2 pagesGreececopelmnNo ratings yet

- S - 5 1 0 L, S - 5 1 0 R: PioneerDocument4 pagesS - 5 1 0 L, S - 5 1 0 R: PioneermiliindianuNo ratings yet

- Boli Interne Vol I Partea 1Document454 pagesBoli Interne Vol I Partea 1Murariu Diana100% (2)

- Xenforo JsDocument39 pagesXenforo JsjaaritNo ratings yet

- Training Activity Matrix: Training Activities Trainees Facilities/Tools/Equip Venue Date RemarksDocument3 pagesTraining Activity Matrix: Training Activities Trainees Facilities/Tools/Equip Venue Date RemarksCharleneNo ratings yet

- Power Electronic Unit For Field-Mounting (Contrac) EBN853, EBN861Document44 pagesPower Electronic Unit For Field-Mounting (Contrac) EBN853, EBN861Sad LiveNo ratings yet

- Invoice 203265: GN Code: 3923.2100 - SwedenDocument2 pagesInvoice 203265: GN Code: 3923.2100 - SwedenArturo RiveroNo ratings yet

- Fan TRO 2830Document106 pagesFan TRO 2830dwr234100% (4)

- William Stallings Computer Organization and Architecture 9 EditionDocument28 pagesWilliam Stallings Computer Organization and Architecture 9 EditionAnggi Riza Amirullah SidhartaNo ratings yet

- Porsche Engineering Magazine 2016/2Document50 pagesPorsche Engineering Magazine 2016/2wattafillingNo ratings yet

- MP 87.1-2008 Australian New Zealand Certification Scheme For Explosion-Protected Electrical Equipment (ANZExDocument6 pagesMP 87.1-2008 Australian New Zealand Certification Scheme For Explosion-Protected Electrical Equipment (ANZExSAI Global - APACNo ratings yet

- Stolzle Prestige Standards BrochureDocument9 pagesStolzle Prestige Standards BrochureTomi AkingbolagunNo ratings yet

- IGBT MitsubishiDocument4 pagesIGBT Mitsubishimadhuvariar100% (3)

- Kinematics Free Fall SolsDocument5 pagesKinematics Free Fall SolsDean JezerNo ratings yet

- Project On Sales Promotion ParagDocument66 pagesProject On Sales Promotion ParagavnishNo ratings yet

- Neonatal Resuscitation. Advances in Training and PracticeDocument10 pagesNeonatal Resuscitation. Advances in Training and PracticeFer45No ratings yet

- Embragues y Frenos - P-1960-CDocument4 pagesEmbragues y Frenos - P-1960-Cdéborah_rosalesNo ratings yet

- James L GordonDocument1 pageJames L Gordonpapan_5069No ratings yet

- PR 2001219Document10 pagesPR 2001219Amr Mohamed GalalNo ratings yet