Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

78 views2009 Annual Survey Report and Appendices-Phase I

2009 Annual Survey Report and Appendices-Phase I

Uploaded by

toddflyThis annual survey report summarizes cathodic protection testing of reservoirs, pipelines, and BART stations in Hayward, California. Most reservoirs were receiving adequate protection. The Hesperian Aqueduct pipeline received adequate protection at most test stations but half could not be accessed. The Industrial/Valle Vista pipelines met criteria at some stations but half were not tested. Testing of the 42-inch Wastewater and portions of the West Winton pipelines was inconclusive. Soil testing indicated moderate to high corrosion risk for the Mission and West Winton pipelines. No functioning BART stations were located to assess stray current. Remedial actions were recommended.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- EOT Crane Power & Control DiagramDocument4 pagesEOT Crane Power & Control DiagramMuhammad Rizwan KhanNo ratings yet

- En 1838 Emergency LightingDocument12 pagesEn 1838 Emergency LightingAna Jorgacevic100% (2)

- Control To Temp EquipmentDocument84 pagesControl To Temp EquipmentSteven FlynnNo ratings yet

- Mine Haul Road ManualDocument136 pagesMine Haul Road Manualfbtura100% (12)

- IS Barrier - IECEx - CML - 17.0015XDocument14 pagesIS Barrier - IECEx - CML - 17.0015XU.K.No ratings yet

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocument21 pagesMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNo ratings yet

- Exp 2 Calibration of Pressure GaugeDocument7 pagesExp 2 Calibration of Pressure GaugeSaid Ahmed AliNo ratings yet

- JGDCL Doc Electronic Odorizer 09-10-2017Document21 pagesJGDCL Doc Electronic Odorizer 09-10-2017bmanojkumar16No ratings yet

- 2885 5-2012Document8 pages2885 5-2012toddfly33% (3)

- Sensornet Oct 2017-DAS-NASDocument13 pagesSensornet Oct 2017-DAS-NASListyo SurantoNo ratings yet

- KhairulDocument244 pagesKhairulAyie KhairiNo ratings yet

- Shell DTS PrimerDocument97 pagesShell DTS PrimershatalinNo ratings yet

- General Works To Support Pipeline-Non Pipeline Activities-Tmg OkDocument5 pagesGeneral Works To Support Pipeline-Non Pipeline Activities-Tmg Okarif rhNo ratings yet

- Fat Sat SitDocument17 pagesFat Sat SitYaye Ndew ThiaoNo ratings yet

- Geo InstallationDocument78 pagesGeo InstallationUdin DzonoNo ratings yet

- SATR-J-6503 - Rev 0 PDFDocument5 pagesSATR-J-6503 - Rev 0 PDFAdel KlkNo ratings yet

- Cathodic Protection Cable Installation-Tmg OkDocument4 pagesCathodic Protection Cable Installation-Tmg Okarif rhNo ratings yet

- Appendix 3 Cable Management and Route PlanningDocument5 pagesAppendix 3 Cable Management and Route Planningkaushikray06No ratings yet

- Fotech Power System Monitoring 160919 SLDocument49 pagesFotech Power System Monitoring 160919 SLGia Bảo LưuNo ratings yet

- Orifice FlowMeterDocument12 pagesOrifice FlowMetersanggul elli noraNo ratings yet

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- Data Sheet For Earthing and Lightning Protection SystemsDocument3 pagesData Sheet For Earthing and Lightning Protection SystemsNael SwedanNo ratings yet

- Desmoke System p.155-173Document19 pagesDesmoke System p.155-173Just RysdanNo ratings yet

- NG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedDocument16 pagesNG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedFolarin AyodejiNo ratings yet

- Pig Signaller PDFDocument2 pagesPig Signaller PDFMargaret DaughertyNo ratings yet

- Exhibit C - Testing and Acceptance - 201210191417400204Document3 pagesExhibit C - Testing and Acceptance - 201210191417400204Yousif_AbdalhalimNo ratings yet

- Technologies ListDocument121 pagesTechnologies ListrasthoenNo ratings yet

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDocument3 pagesEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNo ratings yet

- ACG Phase1 ESIA EngDocument1,175 pagesACG Phase1 ESIA EngEzzadin BabanNo ratings yet

- Commissioning Guide - (V200R008C02 01, NGN)Document148 pagesCommissioning Guide - (V200R008C02 01, NGN)Catherine HiginoNo ratings yet

- Alfanar Low Voltage Control Cables CatalogDocument52 pagesAlfanar Low Voltage Control Cables CatalogAhmed H. HassanNo ratings yet

- Sat TR General (Rev. 0 2009)Document3 pagesSat TR General (Rev. 0 2009)Abhinav SinhaNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Oil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudyDocument8 pagesOil and Gas Offshore Pipeline Leak Detection System: A Feasibility StudycbqucbquNo ratings yet

- Galvanic Anode System DesignDocument10 pagesGalvanic Anode System DesignilublessingNo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- Servo Gauge TI00452G08EN06.14Document41 pagesServo Gauge TI00452G08EN06.14jeduardo2325No ratings yet

- ANSI American National Standard For Roadway Lighting Equipment Internal Labeling of LuminairesDocument2 pagesANSI American National Standard For Roadway Lighting Equipment Internal Labeling of LuminairesricardoNo ratings yet

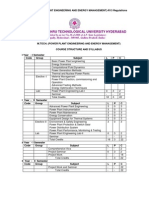

- Power Plant Engineering and Energy Management 2Document22 pagesPower Plant Engineering and Energy Management 2RAPRATSINNo ratings yet

- Decommissioning IPFDocument2 pagesDecommissioning IPFDuraisamy DevarajNo ratings yet

- Apnedix 4 - Method Statement For Loop TestDocument11 pagesApnedix 4 - Method Statement For Loop TestShahid IqbalNo ratings yet

- MZ-000-CCX-HS-PRO-00011 Control of Hazardous Energy Procedure Rev 0Document63 pagesMZ-000-CCX-HS-PRO-00011 Control of Hazardous Energy Procedure Rev 0Abílio Júnior MubaiNo ratings yet

- 2005 13 ISO 3171 Allocation Sampling For Challenging Tie Ins and Low RVP Production Hydrocarbons Jiskoot Jiskoot LTDDocument11 pages2005 13 ISO 3171 Allocation Sampling For Challenging Tie Ins and Low RVP Production Hydrocarbons Jiskoot Jiskoot LTDGustav MolMedNo ratings yet

- Subsea Production Control Systems: 1 ForewordDocument25 pagesSubsea Production Control Systems: 1 ForewordBSFNo ratings yet

- Egp ReportDocument109 pagesEgp ReportvyshnapramodNo ratings yet

- 01-01-1865-D ELDS Technical Manual Iss13Document221 pages01-01-1865-D ELDS Technical Manual Iss13Alberyt099No ratings yet

- Monitoring and ManagementDocument24 pagesMonitoring and ManagementShakirNo ratings yet

- Natural Gas Transmission SystemDocument11 pagesNatural Gas Transmission SystemoonthaiNo ratings yet

- 60.35-001 - 1994 Pressure GuagesDocument3 pages60.35-001 - 1994 Pressure GuagespradeepNo ratings yet

- cv5788987 FileDocument5 pagescv5788987 FileAbdul SaquibNo ratings yet

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Document138 pagesOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- OV 141113 FDS JR Comments - Revision - 1Document56 pagesOV 141113 FDS JR Comments - Revision - 1wqs_19No ratings yet

- Procedure For Safety Certification and Technical Clearance of Metro Systems (With CS No Upto 3) PDFDocument58 pagesProcedure For Safety Certification and Technical Clearance of Metro Systems (With CS No Upto 3) PDFMayank SharmaNo ratings yet

- Approved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XDocument2 pagesApproved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XP Sandana NaraNo ratings yet

- Iecex Certificate of ConformityDocument3 pagesIecex Certificate of Conformitymlutfima100% (1)

- 3500-25 Enhanced Keyphasor Module Datasheet - 141532Document10 pages3500-25 Enhanced Keyphasor Module Datasheet - 141532Ali HadiNo ratings yet

- Fundamentals of Flow MeterDocument12 pagesFundamentals of Flow Meteralan_yaobin8409No ratings yet

- Danalyzer GC MAN 3 9000 744 700XA PDFDocument204 pagesDanalyzer GC MAN 3 9000 744 700XA PDFFercho MNo ratings yet

- SATR-J-6601 Rev 0 PDFDocument4 pagesSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- IntrvwDocument67 pagesIntrvwER Balram YadavNo ratings yet

- Cathodic Protection For Storage Tanks and Buried PipingDocument62 pagesCathodic Protection For Storage Tanks and Buried PipingBalakumar100% (1)

- Cathodic Protection For On-Ground Storage Tanks and Buried PipingDocument62 pagesCathodic Protection For On-Ground Storage Tanks and Buried PipingBhaiJan59100% (1)

- Nelson River Pole 2 Mercury Arc Valve ReplacementDocument6 pagesNelson River Pole 2 Mercury Arc Valve Replacementtkdrt2166No ratings yet

- Operator Qualification History & Milestones: I. The MandateDocument9 pagesOperator Qualification History & Milestones: I. The MandatetoddflyNo ratings yet

- Pipeeiber PDFDocument31 pagesPipeeiber PDFtoddflyNo ratings yet

- 30B20StainlessSteelTapping SleeveDocument4 pages30B20StainlessSteelTapping SleevetoddflyNo ratings yet

- Asme 2010 Ebooks PDFDocument2 pagesAsme 2010 Ebooks PDFtoddflyNo ratings yet

- Gas Pipeline Pig PDFDocument13 pagesGas Pipeline Pig PDFtoddfly100% (1)

- Dictionary of WeldingDocument57 pagesDictionary of WeldingtoddflyNo ratings yet

- Ipc04 0395Document6 pagesIpc04 0395toddflyNo ratings yet

- Hose PDFDocument1 pageHose PDFankurNo ratings yet

- TABLEROSDocument56 pagesTABLEROSDaniel ChavezNo ratings yet

- Acer All in One - 13045-1Document55 pagesAcer All in One - 13045-1prasetyo elmoNo ratings yet

- Mockup PortofolioDocument5 pagesMockup PortofolioGUSTI AHMAD HAFI A1317025No ratings yet

- MK4 Elastomeric BearingsDocument12 pagesMK4 Elastomeric BearingsyhszaNo ratings yet

- Methods of SpreadingDocument10 pagesMethods of Spreadingarunkadve67% (3)

- Omar CVDocument2 pagesOmar CVomarNo ratings yet

- Gebrauchsanweisung 20 Kaltlicht-Fontäne D-LIGHT P Instruction Manual 20 Cold Light Fountain D-LIGHT P Manual de Instrucciones 20 Fuente de Luz Fría D-LIGHT PDocument68 pagesGebrauchsanweisung 20 Kaltlicht-Fontäne D-LIGHT P Instruction Manual 20 Cold Light Fountain D-LIGHT P Manual de Instrucciones 20 Fuente de Luz Fría D-LIGHT PersinNo ratings yet

- Datasheet - ECOSY M 6530CDN PDFDocument2 pagesDatasheet - ECOSY M 6530CDN PDFEdi PurnomoNo ratings yet

- Dana Spicer Drive Axles: Differential Lockout Inter AxleDocument4 pagesDana Spicer Drive Axles: Differential Lockout Inter AxleJj MtNo ratings yet

- ElcometerDocument228 pagesElcometerMohammedMudassirNo ratings yet

- FCB UnO v1 0 2 UserGuideDocument30 pagesFCB UnO v1 0 2 UserGuideMoontraneNo ratings yet

- HwcompatDocument470 pagesHwcompatEstefannyCanoTorresNo ratings yet

- Pcie Simulation Analysis1 (Xilinux)Document66 pagesPcie Simulation Analysis1 (Xilinux)Somasekhar ChepuriNo ratings yet

- Airence Virtual Keyboard Mapper Plugin Manual v1.1Document9 pagesAirence Virtual Keyboard Mapper Plugin Manual v1.1metropoliszagrebNo ratings yet

- Screw ELgiDocument13 pagesScrew ELgitakhtenoorNo ratings yet

- CQI and SNRDocument9 pagesCQI and SNRamit_tomar_amitNo ratings yet

- NorsokDocument133 pagesNorsokNuzuliana EnuzNo ratings yet

- Bang Gia PVC BMDocument1 pageBang Gia PVC BMCuong Hoang100% (1)

- AD43 Ansi Bifma X5.4Document20 pagesAD43 Ansi Bifma X5.4medical services100% (1)

- Assignment: Software Devolpment Life CycleDocument10 pagesAssignment: Software Devolpment Life Cyclejiten100% (1)

- Iso TS 19218-1-2011Document22 pagesIso TS 19218-1-2011Ragul VinothNo ratings yet

- Exel Spring Reel IomDocument12 pagesExel Spring Reel IomstephenNo ratings yet

- WWW - Solerpalau.ro Docs Catalogo General en 357 367 CMB CMT Fid5630 PDFDocument11 pagesWWW - Solerpalau.ro Docs Catalogo General en 357 367 CMB CMT Fid5630 PDFEsteban GalarceNo ratings yet

- I-Et-3010.2d-1200-200-P4x-004 - Requeriments For Piping SupportDocument31 pagesI-Et-3010.2d-1200-200-P4x-004 - Requeriments For Piping SupportRodger SenaNo ratings yet

- Iologik E1200 Series QIG v4 PDFDocument2 pagesIologik E1200 Series QIG v4 PDFIlic MiroslavNo ratings yet

- Two Way Radio CommunicationsDocument2 pagesTwo Way Radio Communicationsabross36No ratings yet

2009 Annual Survey Report and Appendices-Phase I

2009 Annual Survey Report and Appendices-Phase I

Uploaded by

toddfly0 ratings0% found this document useful (0 votes)

78 views82 pagesThis annual survey report summarizes cathodic protection testing of reservoirs, pipelines, and BART stations in Hayward, California. Most reservoirs were receiving adequate protection. The Hesperian Aqueduct pipeline received adequate protection at most test stations but half could not be accessed. The Industrial/Valle Vista pipelines met criteria at some stations but half were not tested. Testing of the 42-inch Wastewater and portions of the West Winton pipelines was inconclusive. Soil testing indicated moderate to high corrosion risk for the Mission and West Winton pipelines. No functioning BART stations were located to assess stray current. Remedial actions were recommended.

Original Description:

Original Title

2009 Annual Survey Report and Appendices-Phase I[1]

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis annual survey report summarizes cathodic protection testing of reservoirs, pipelines, and BART stations in Hayward, California. Most reservoirs were receiving adequate protection. The Hesperian Aqueduct pipeline received adequate protection at most test stations but half could not be accessed. The Industrial/Valle Vista pipelines met criteria at some stations but half were not tested. Testing of the 42-inch Wastewater and portions of the West Winton pipelines was inconclusive. Soil testing indicated moderate to high corrosion risk for the Mission and West Winton pipelines. No functioning BART stations were located to assess stray current. Remedial actions were recommended.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

78 views82 pages2009 Annual Survey Report and Appendices-Phase I

2009 Annual Survey Report and Appendices-Phase I

Uploaded by

toddflyThis annual survey report summarizes cathodic protection testing of reservoirs, pipelines, and BART stations in Hayward, California. Most reservoirs were receiving adequate protection. The Hesperian Aqueduct pipeline received adequate protection at most test stations but half could not be accessed. The Industrial/Valle Vista pipelines met criteria at some stations but half were not tested. Testing of the 42-inch Wastewater and portions of the West Winton pipelines was inconclusive. Soil testing indicated moderate to high corrosion risk for the Mission and West Winton pipelines. No functioning BART stations were located to assess stray current. Remedial actions were recommended.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 82

5349.

02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final)

FINAL REPORT

ANNUAL CATHODIC PROTECTION SYSTEM SURVEY

2009

PROJECT 623-7041

CITY OF HAYWARD

RESERVOIRS, PIPELINES, AND BART LINE CURRENT MONITORING

STATIONS

HAYWARD, CA

PREPARED FOR:

CITY OF HAYWARD

777 B STREET

HAYWARD, CA 94541-5007

PREPARED BY:

CORRPRO

2799 MILLER STREET

SAN LEANDRO, CA 94577

(510) 614-8800

September 2009

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final)

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final)

TABLE OF CONTENTS

SUMMARY................................................................................................................................... 1

SYSTEM DESCRIPTIONS......................................................................................................... 3

TEST PROCEDURES.................................................................................................................. 6

CRITERIA..................................................................................................................................... 8

RESULTS AND CONCLUSIONS .............................................................................................. 9

RECOMMENDATIONS............................................................................................................ 13

APPENDICES

Appendix 1 Reservoir Data Rectifier, Anode bed, and Potential Data

Appendix 2 Pipelines Rectifier and Groundbed Data

Appendix 3 Pipelines Potential Survey Data

Appendix 4 West Winton Pipeline Soil Resistivity and Chemical Analysis Data

Appendix 5 Mission Pipeline Soil Resistivity and Chemical Analysis Data

Appendix 6 GPS Data

Appendix 7 Photographs

Appendix 8 Criterion NACE Standard SP0388-2007

Appendix 9 Criterion NACE Standard RP0196-2004

Appendix 10 Criterion NACE Standard SP0169-2007

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 1

SUMMARY

During the months of February through J uly 2009, Corrpro conducted the annual cathodic

protection system (CPS) survey on the reservoirs, pipelines, and BART line current monitoring

stations for the City of Hayward. The structures inspected during the survey were:

750 Highland Reservoir

1000 Highland Reservoir

1285 Highland Reservoir

1530 Highland East Reservoir

Garin Hill Reservoir

South Walpert Reservoir

Hesperian Aqueduct North (33-inch)

Hesperian Aqueduct South (43-inch)

Industrial Pipeline

Valle Vista Pipeline

42-inch Wastewater Treatment Plant Pipeline

West Winton 30-inch Aqueduct

2,000-foot ductile-iron pipeline (DIP) section of West Winton 30-inch Aqueduct

Mission Boulevard 24-inch Aqueduct

BART Line Current Monitoring Stations at:

- J ackson Street 12-Inch Water Main at Silvia Street

- Western Boulevard 8-Inch located between Peralta Street and Simon

- South Meter Vault 40-Feet South of the BART substation in the BART

Southern Alameda Yard Test Station

The survey consisted of determining the level of cathodic protection currently being maintained

on the structures and, if possible, adjusting the cathodic protection (CP) systems to meet NACE

International criteria for cathodic protection.

Based on the data obtained during the survey, all the reservoirs (except Garin Hill, which was

not internally accessible at the time of testing and has a non-functioning rectifier) are currently

receiving adequate cathodic protection.

The Hesperian Aqueduct pipeline is receiving adequate cathodic protection at the majority of the

test stations tested; however, approximately half of the pipeline test stations could not be located

or accessed for testing, and seven (7) of the twelve (12) rectifiers associated with the system are

not functional at this time, due to varying degrees of damage to the rectifiers and/or anode wells.

The Industrial/Valle Vista pipelines are meeting the -850 mV NACE criteria for cathodic

protection at a few of the test stations, but only about half of the test stations were able to be

located and/or tested. Also, two (2) of the six (6) rectifiers are not functional.

The 42-inch Wastewater Treatment Plant pipeline cathodic protection system components could

not be located and contact to the pipeline could not be made; therefore, the status of cathodic

protection on the pipeline could not be evaluated.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 2

Contact points at accessible appurtenances for the DIP portion of the West Winton pipeline

could not be confirmed to be continuous to the carrier pipe, therefore current requirement and

electrical continuity testing was inconclusive. The soil resistivity testing for the West Winton

pipeline and the Mission Pipeline indicated moderately-corrosive to corrosive soil. Thus,

installation of cathodic protection systems should be considered for preventing external

corrosion of the Mission Pipeline and the DIP section of the West Winton Pipeline, thereby

extending the service life of these pipelines.

No functioning BART line current monitoring stations were located; therefore, the status of stray

current at those locations remains unknown.

Remedial items, as required for overall improvement and maintenance of the CP systems, are

provided in the Conclusions and Recommendations sections of this report.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 3

SYSTEM DESCRIPTIONS

RESERVOIRS

750 Highland Reservoir

The 750 Highland Reservoir is a 161.75-foot diameter, 32-foot high aboveground storage tank

(AST) of welded-steel plate construction. The cathodic protection system installed for internal

corrosion control of the AST consists of one (1) cathodic protection rectifier powering twenty-

eight (28) platinized-niobium impressed-current wire anodes. Also, one (1) permanent

copper/copper-sulfate reference electrode is installed in the tank for CP monitoring.

1000 Highland Reservoir

The 1000 Highland Reservoir is a 70-foot diameter, 35-foot high aboveground storage tank of

welded-steel plate construction. The cathodic protection system installed for internal corrosion

control of the AST consists of one (1) cathodic protection rectifier powering twenty-eight (28)

platinized-niobium impressed-current wire anodes. Also, one (1) permanent copper/copper-

sulfate reference electrode is installed in the tank.

1285 Highland Reservoir

The 1285 Highland Reservoir is a 105-foot diameter, 35-foot high aboveground storage tank of

welded-steel plate construction. The cathodic protection system installed for internal corrosion

control of the AST consists of a galvanic system with ten (10) magnesium rod anodes connected

to the tank through a rheostat for current output adjustment. Also, one (1) permanent

copper/copper-sulfate reference electrode is installed in the tank.

1530 Highland East Reservoir

The 1530 Highland East Reservoir is a 128-foot diameter, 35-foot high aboveground storage

tank of welded-steel plate construction. The cathodic protection system installed for internal

corrosion control of the AST consists of a galvanic system with sixteen (16) magnesium rod

anodes connected to the tank through a rheostat for current output adjustment. Also, one (1)

permanent copper/copper-sulfate reference electrode is installed in the tank.

Garin Hill Reservoir

The new Garin Hill Reservoir (previous tank replaced in 2006/7) is an 80-foot diameter, 35-foot

high aboveground storage tank of welded-steel plate construction. The cathodic protection

system installed for internal corrosion control of the AST consists of one (1) cathodic protection

rectifier powering nine (9) platinized-niobium impressed-current wire anodes. Also, one (1)

permanent copper/copper-sulfate reference electrode is installed in the tank.

South Walpert Reservoir

The Walpert Reservoir is a 166-foot diameter, 41-foot high aboveground storage tank of welded-

steel plate construction. The cathodic protection system installed for internal corrosion control of

the AST consists of one (1) cathodic protection rectifier powering thirty-six (36) platinized-

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 4

niobium impressed-current wire anodes. Also, one (1) permanent copper/copper-sulfate

reference electrode is installed in the tank.

PIPELINES

Hesperian Aqueduct

The Hesperian Aqueduct consists of two sections of cement-mortar lined and coated, welded-

steel pipeline (MLCWSP) water main. The two sections (North and South) are electrically

isolated from each other by an inline isolation flange at Industrial Parkway.

Hesperian North consists of 12,500 feet of 33-inch diameter pipe and runs along Hesperian

Boulevard (in Hayward) from the Skywest Pump Station to Industrial Parkway.

Hesperian South consists of 40,000 feet of 42-inch diameter pipe and runs along Hesperian

Boulevard and then Union City Boulevard from Industrial Boulevard (at the Industrial Aqueduct

tee) down to the Newark Slough at Thornton Avenue in Newark.

The cathodic protection system installed for the Hesperian North pipeline consists of four (4)

rectifiers and associated anode wells (Skywest, West Street, Depot Court, and Oliver Drive). The

cathodic protection system installed for the Hesperian South pipeline consists of eight (8)

rectifiers with associated anode wells (Pepsi, Union Sanitary, Silvertide Drive, Delores Drive,

Melissa and Winslow, Alameda Creek, Bettencourt and Braidburn, and Hickory and Thornton).

Industrial and Valle Vista Pipelines

The Industrial Aqueduct consists of approximately 13,964 feet of 24-inch diameter welded-steel

water main. The pipeline runs along Industrial Parkway from Hesperian Boulevard (a butterfly

valve tee connecting to the 42-Inch Hesperian Aqueduct) to Mission Boulevard (an insulating

joint tee into the Mission Aqueduct).

The Valle Vista Sewage Force Main consists of 11,350 feet of 27-inch diameter concrete

cylinder pipe with welded joints. The pipeline runs along Industrial Parkway, Arden Road, and

Baumberg Court from the Valle Vista Pump Station (east of Highway 880) to a junction at a

concrete vault (Weir Box) on Baumberg Court.

The cathodic protection system originally designed and installed for the Valle Vista and

Industrial pipelines consists of six (6) rectifiers and associated anode wells distributed along the

pipelines (Mission, Taylor, Ruus Road, Hopkins, Well B, and Baumberg Court).

42-Inch Wastewater Treatment Plant (WWTP) Pipeline

The 42-Inch diameter WWTP pipeline originally consisted of approximately 800 feet of 42-inch

diameter mortar MLCWSP within the plant. The pipeline ran from the Fluid Bed Reactor

(currently the Aeration Blower Building) through a valve vault north of the Final Clarifier

(currently the Aeration Tanks) to the Outfall J unction Box (no longer exists). The pipeline then

changed to a 12-inch MLCWSP from the Outfall J unction Box to the Equalization Pond J unction

Box, and then a 45-inch diameter pipe MLCWSP from there to a tie-in to a 48-inch reinforced

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 5

concrete pipe (RCP). According to WWTP personnel, the pipeline no longer goes to the Outfall

J unction Box, but goes directly west from the valve vault to a newly built control shed.

The cathodic protection system originally installed for the pipeline consisted of five (5) anode

junction boxes connecting pipe structure wires to multiple 60-pound anodes via potentiometers.

(See drawing East Bay Dischargers Authority, Water Quality Management Program Phase 1,

Hayward Secondary Treatment Facilities Unit No. 2, Cathodic Protection, 12/81, by

Kennedy/J enks Engineers)

West Winton Aqueduct

The West Winton Aqueduct reportedly consists of 2,000 feet of 30-inch diameter ductile iron

pipeline (DIP) and 9,088 feet of 30-inch diameter asbestos cement pipeline (ACP). The pipeline

runs primarily along West Winton Avenue from just east of Hesperian Boulevard to the

intersection of Francisco Street and Mission Boulevard.

The DIP section of the West Winton Aqueduct pipeline does not currently have any cathodic

protection systems installed.

Mission Boulevard Aqueduct

The Mission Boulevard 24-inch Aqueduct reportedly consists of approximately 10.7 miles of 24-

inch diameter concrete-cylinder pipeline built in 1956. The pipeline runs primarily along

Mission Boulevard from a turnout northwest of Mission Boulevard and Callery Court in

Hayward to Mission Boulevard and East Las Palmas Avenue in Fremont.

The Mission Boulevard Aqueduct does not currently have any cathodic protection systems

installed.

B. A. R. T. MONITORING TEST STATIONS

BART monitoring test stations were originally installed to monitor the stray current, if any,

present on City of Hayward pipelines caused by BART lines in the vicinities of each of the test

stations. The original locations of the three known test stations are:

- J ackson Street 12-Inch Water Main at Silvia Street

- Western Boulevard 8-Inch located between Peralta Street and Simon

- South Meter Vault 40-Feet South of the BART substation in the BART

Southern Alameda Yard Test Station

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 6

TEST PROCEDURES

Test station locations surveyed by Corrpro were located using drawings and assistance provided

by City of Hayward personnel. The following test procedures were used during the annual

cathodic protection system survey:

RESERVOIRS

An internal tank-to-water potential survey of each tank was conducted. The potentials were

measured with respect to a portable copper-copper-sulfate reference electrode (CSE) to

incremental immersion depths at the man-way and the monitoring ports at each tank, as

equipped.

Potentials were measured with the cathodic protection system energized (On) and temporarily

interrupted (Instant-Off) in manual mode, at the lowest tap set position possible while still

closely matching the current output exhibited during potential control operation. On and

Instant-Off structure potentials at the permanent reference electrodes were measured in

automatic and manual control modes.

Each cathodic protection rectifier was adjusted, as required, based on a field analysis of the

measurement data, and restored to automatic operation. Rectifier output and tank-to-water

potential survey data collected during the survey of the reservoirs is included with the reservoir

potential data in Appendix 1.

PIPELINES

All pipe-to-soil potential measurements were made using a high-impedance digital multimeter

and a portable copper/copper-sulfate reference electrode (CSE). Connections to the pipe for the

potential tests were made at test station cables or by directly contacting the pipe, where possible.

Anode currents were documented by measuring the voltage drop across the calibrated shunt

within the test station or anode junction box and then calculating the current using Ohms law.

Energized pipe-to-soil potentials were measured at each test location with the cathodic

protection current applied (rectifier ON or anodes connected) and with the cathodic protection

current momentarily interrupted (rectifier OFF or anodes disconnected). Geosynchronous current

interrupters were utilized to simultaneously interrupt the current at all rectifiers affecting each

section while testing.

Rectifier output survey data collected during the survey of the pipelines is included in Appendix

2. Potential survey data collected for the pipelines is included in Appendix 3. The electrical

continuity and current requirement data are included in Appendix 4. The soil resistivity data

collected is included in Appendix 5. GPS coordinates for each test station and rectifier are listed

in Appendix 6. Photographs of test stations and rectifiers are included in Appendix 7.

A soil corrosivity analysis was conducted on the West Winton and Mission pipeline alignments

to develop corrosion control recommendations. Soil resistivities along each pipeline were

calculated from measurements made at representative locations along the pipelines utilizing a

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 7

Megger DET2/2 digital soil resistance meter and the ASTM G-57 Wenner Four-Pin Method.

Measurements were taken in 5-foot increments up to 15-feet spacing. Where possible,

measurements were taken in both the longitudinal and transverse directions at each location.

Additionally, representative soil samples collected by Corrpro from five (5) locations along the

West Winton pipeline and six (6) locations along the Mission pipeline alignment were subjected

to chemical analysis to determine corrosivity. The samples were collected from depths of zero to

2 feet. Corrpro evaluated the soil chemical analysis information to determine the soil corrosive

properties and to determine appropriate corrosion control measures.

The soil resistivity values indicate the relative capability of the soil at each location to carry

electrical current and is generally recognized as the most significant soil characteristic with

regard to corrosivity of the soil. Areas of low soil resistivity are more corrosive than areas of

higher resistivity. Soil resistivity can also change dramatically with moisture content. Soil,

which has a high resistivity when it is dry, can have substantially lower resistivity when wet or

saturated depending on such factors as pH and chemical content.

The degree of corrosion experienced in the low resistivity area is usually governed by the lowest

measured resistivity. A relatively simple soil resistivity survey will indicate, with a high degree

of accuracy, all areas likely to be actively corroding in accordance with the following guide:

Soil Resistivity (ohm-cm) Degree of Corrosivity

0 500 Very corrosive

501 2,000 Corrosive

2,001 10,000 Moderately corrosive

10,001 30,000 Mildly corrosive

Above 30,000 Negligible

Tests were also conducted to determine the electrical continuity and cathodic protection current

requirement of the DIP portion of the West Winton pipeline using the current attenuation

method. Attempts were made to impress cathodic protection current onto the respective

pipeline(s) and then obtain pipe-to-soil potential measurements along the pipeline with the CP

current momentarily interrupted. Where an Instant OFF of 100 millivolts or more negative

than the original (Static) pipe-to-soil potential was observed at test locations, the pipeline was

deemed electrically continuous and the associated current output was deemed the minimum

current required to achieve cathodic protection of the pipe at that location. Otherwise, the

pipeline section was considered electrically discontinuous.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 8

CRITERIA

NACE International has established criteria for cathodically protected reservoirs and pipelines.

The criteria for reservoirs are set forth in Section 6 of the NACE Standards SP0388-2007 and

RP0196-2004, and were applied to determine the adequacy of cathodic protection of the

specified structures. Where NACE Criterion 6.2.1 and 6.2.2, and 6.3.1 and 6.3.2, respectively,

are met, adequate internal cathodic protection of the reservoirs is indicated. Applicable portions

of the referenced standards are included in Appendix 8 and 9.

The criteria for pipelines are set forth in Section 6 of the NACE Standard SP0169-2007, and

were applied to determine the adequacy of cathodic protection of the specified structures. Where

NACE Criterion 6.2.2.1.1, 6.2.2.1.2, or 6.2.2.1.3 are met, adequate cathodic protection of the

pipelines is indicated. Applicable portions of the referenced standard are included in Appendix

10.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 9

RESULTS AND CONCLUSIONS

RESERVOIRS

Tank-to-water potential test data for the reservoirs (see Appendix 1) indicates that the all

reservoirs tested meet NACE criteria (RP0388 and RP0196) for cathodic protection. However,

access to the Garin Reservoir roof was not made available and testing was not possible.

Also, the rectifier for the Garin Hill Reservoir cathodic protection system is obsolete and not

functional and needs to be replaced with a modern cathodic protection rectifier. Therefore, it is

assumed that the tank does not currently meet NACE criteria for cathodic protection.

PIPELINES

Hesperian Aqueduct

RECTIFIERS

Skywest:

- The rectifier is in good working order and is operating correctly.

West Street:

- The rectifier cabinet doors lower hinge has failed and requires repair/replacement.

- The rectifier ammeter has failed and requires replacement.

Depot Court:

- The rectifier ammeter has failed and requires replacement.

Oliver Drive:

- The rectifier cabinet doors lower hinge has failed and requires repair/replacement.

- The rectifier is not outputting any current and requires troubleshooting to determine

the cause. Reportedly, the anode and/or structure wires may have been damaged by

past construction activity in the area.

Pepsi:

- The rectifier is not outputting any current.

- The rectifier enclosure is damaged and vandalized and requires replacement.

- All wires associated with the rectifier have been cut and are missing and the rectifier

has been gutted.

- There is no AC power available at the rectifier location. The City is reportedly

waiting on PG&E to supply AC power to the location.

- The location requires a new rectifier. The new rectifier will require an AC or DC

power source to be supplied at the location.

Union Sanitary:

- The rectifier is not outputting any current and requires troubleshooting to determine

the cause.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 10

- The rectifier cabinet doors lower hinge has failed and requires repair/replacement.

Silvertide:

- The rectifier is not outputting any current.

- There is no AC power available at the rectifier location. The City is reportedly

waiting on PG&E to supply AC power to the location.

Delores Drive:

- No access was provided to the rectifier.

- According to City of Hayward personnel, there is no AC power available at the

rectifier location. The City is reportedly waiting on PG&E to supply AC power to the

location.

Melissa and Winslow:

- The rectifier is not outputting any current.

- There is no AC power available at the rectifier location. The City is reportedly

waiting on PG&E to supply AC power to the location. AC power lines were

reportedly cut during construction activity in the area.

- The rectifier cabinet is bent and rusting and requires repair/replacement.

- The anode wells flush-to-grade Christy box is buried.

Alameda Creek:

- The rectifier cabinet doors lower hinge has failed and requires repair/replacement.

- The anode wells flush-to-grade Christy G-4 box lid is missing and requires

replacement.

Bettencourt and Braidburn:

- The rectifier ammeter has failed and requires replacement.

Hickory and Thornton:

- The rectifier is not outputting any current.

- There is no AC power available at the rectifier location. The City is reportedly

waiting on PG&E to supply AC power to the location.

All other rectifiers are in good working condition and are operating properly.

TEST STATIONS

Well B RFT:

- Pipe-to-soil potentials are not meeting -850 mV Instant-Off NACE criteria for

cathodic protection. Depolarized pipe-to-soil potentials are needed to determine the

cathodic protection status of the pipe at this location.

ETS 36, ETS 28, ETS 23R, ETS 22R, ETS 22R, 17R, 16R, 13, 11, (OL)-5R, 5, 4R, 3(OL)-3R,

and F2:

- These test stations could not be located.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 11

Industrial and Valle Vista Pipelines

RECTIFIERS

Ruus Road:

- The rectifier was reportedly destroyed by a car accident.

- The anode wires and a structure lead wire were found in a flush-to-grade Christy box

in the sidewalk. Measurements taken on the anode wires suggest anode lead wires are

still electrically continuous to the individual anodes. However, the structure lead was

found to be broken. The severed end of the remaining structure wire is underground

approximately 2-feet east of the Christy box.

- The rectifier and structure wire should be replaced. Replacement of the anode well

should also be considered, since the actual condition of the buried anode lead wires is

unknown.

Hopkins:

- The rectifier is not outputting any current and requires troubleshooting to determine

the cause.

- AC is present at the rectifier.

- The rectifiers AC disconnect enclosure cover is not weatherproof and should be

replaced.

TEST STATIONS

W534+59:

- This test station could not be located. It appears that the test stations G-5 box may

only be paved over.

W498+21, W463+95, W462+50, S123+34, S140+99:

- These test stations could not be located.

W463+65 RFT (Ruus Road Rectifier):

- See previous Rectifiers section.

S204+25 (Post-mounted):

- Test lead wires and test station conduit are missing and require replacement.

Hopkins RFT (Hopkins Rectifier), W426+12 (West), S168+93, S112+94:

- Pipe-to-Soil potentials are not meeting -850 mV Instant-Off NACE criteria for

cathodic protection. Depolarized pipe-to-soil potentials are needed to determine the

cathodic protection status of the pipe at this location.

Wastewater Treatment Plant 42-Inch Pipeline

- The five (5) anode junction boxes originally installed for the pipeline were not able to

be located and no cathodic protection measurements were able to be taken. Therefore,

no conclusions pertaining to the cathodic protection status of the pipeline can be

made.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 12

West Winton Pipeline

Soil Corrosivity Testing:

- Soil resistivity and chemical analysis measurements along the pipeline indicate that

the soil in the area of the pipeline is moderately-corrosive to corrosive. Thus,

cathodic protection should be considered for extending the service life of the pipeline.

Current Requirement and Electrical Continuity Testing:

- Current requirement and electrical continuity testing of the DIP section of the

pipeline was inconclusive.

- Contact to the carrier pipe could not be confirmed at any of the appurtenances

(valves, etc.) identified as possible contact locations. Tests conducted at these

locations indicated that most or all of the appurtenances are most likely electrically

isolated from the carrier pipe.

- Installation of pipe test leads (at approximately three locations) along the DIP section

of the pipeline is required for current requirement, electrical continuity, and corrosion

monitoring testing.

Mission Boulevard 24-Inch Aqueduct

Soil Corrosivity Testing:

- Soil resistivity and chemical analysis measurements along the pipeline indicate that

the soil in the area of the pipeline is moderately-corrosive to corrosive. Thus,

cathodic protection should be considered for extending the service life of the pipeline.

BART Line Current Monitoring Stations

J ackson Street 12-Inch Water Main at Silvia Street:

- This test station enclosure has been knocked off its concrete footing and gutted. Only

AC power wires and the enclosure are left. The concrete footing is also damaged.

Western Boulevard 8-Inch located between Peralta Street and Simon:

- This test station could not be located.

South Meter Vault 40-Feet South of the BART substation in the BART Southern

Alameda Yard Test Station:

- This test station could not be located.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 13

RECOMMENDATIONS

Continue to maintain and operate the ICCP system rectifiers at the present output settings.

Operating voltage and current output should be read from the rectifier panel meter(s) and

recorded monthly. Report to Corrpro any variance in excess of 20% compared to the values

recorded during this survey.

Institute a program to conduct annual cathodic protection surveys for all structures addressed in

this report.

It is also recommended that the following items be addressed:

RESERVOIRS

Garin Hill Reservoir

Conduct a cathodic protection design survey to determine the cathodic protection status of the

Garin Hill Reservoir and to determine the size and type of cathodic protection rectifier required

to replace the existing, non-functioning rectifier. Based on the design survey, it may be

determined that the anodes also need to be replaced.

PIPELINES

Hesperian Aqueduct

RECTIFIERS

West Street:

- Repair or replace the rectifier cabinet doors lower hinge, door, or the whole

enclosure.

- Replace the rectifier ammeter.

Depot Court:

- Replace the rectifier ammeter.

Oliver Drive:

- Repair or replace the rectifier cabinet doors lower hinge, door, or the whole

enclosure.

- Troubleshoot the rectifier to determine why it has no current output.

- Energize the anode and structure wires with a test rectifier to determine if they are

functional.

Pepsi:

- Install a new rectifier and anode well at this location. Consider a solar-powered

system if AC power is not able to be provided.

Union Sanitary:

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 14

- Troubleshoot the rectifier to determine why it has no current output.

- Repair or replace the rectifier cabinet doors lower hinge, door, or the whole

enclosure.

Silvertide:

- Troubleshoot the rectifier to determine why it has no current output.

- Consider a solar-power supply, if AC power is not able to be provided.

Delores Drive:

- Provide access to this rectifier to facilitate inspection.

- Consider a solar-power supply, if AC power is not able to be provided.

Melissa and Winslow:

- Troubleshoot the rectifier to determine why it has no current output.

- Consider a solar-power supply, if AC power is not able to be provided.

- Repair or replace the rectifier cabinet.

- Locate and raise to grade the anode wells flush-to-grade Christy box.

Alameda Creek:

- Repair or replace the rectifier cabinet doors lower hinge, door, or the whole

enclosure.

- Replace the lid for the anode wells flush-to-grade Christy G-4 box.

Bettencourt and Braidburn:

- Replace the rectifier ammeter.

Hickory and Thornton:

- Troubleshoot the rectifier to determine why it has no current output.

- Consider a solar-power supply, if AC power is not able to be provided.

TEST STATIONS

Well B RFT:

- Collect depolarized pipe-to-soil potentials to determine the cathodic protection status

of the pipe at this location. This will involve turning the rectifier(s) off for a period of

time and then monitoring the pipe-to-soil potentials.

ETS 36, ETS 28, ETS 23R, ETS 22R, ETS 22R, 17R, 16R, 13, 11, (OL)-5R, 5, 4R, 3(OL)-3R,

and F2:

- Locate or replace these test stations, if feasible.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 15

Industrial and Valle Vista Pipelines

RECTIFIERS

Ruus Road:

- Replace the rectifier and structure wire.

- If economically feasible, install a new anode well, since the functionality of the

buried anode lead wires cannot be guaranteed, and operation of the rectifier with

damaged anode lead wires will result in failed anode lead wires.

Hopkins:

- Troubleshoot the rectifier to determine why it has no current output.

- Replace the rectifiers AC disconnect enclosure cover.

TEST STATIONS

W534+59, W498+21, W463+95, W462+50, S123+34, S140+99:

- Locate or replace these test stations, if feasible.

W463+65 RFT (Ruus Road Rectifier):

- See Ruus Road rectifier recommendations.

S204+25 (Post-mounted):

- Replace test lead wires and test station conduit.

Hopkins RFT (Hopkins Rectifier), W426+12 (West), S168+93, S112+94:

- Collect depolarized pipe-to-soil potentials to determine the cathodic protection status

of the pipe at this location.

Wastewater Treatment Plant 42-Inch Pipeline

- Locate or replace the missing anode junction boxes originally installed for the

pipeline, for proper cathodic protection monitoring.

West Winton Pipeline

- Install corrosion monitoring test stations (3 each) along the DIP section of the

pipeline to conduct current requirement, electrical continuity, and corrosion

monitoring testing, and to determine the next step in providing cathodic protection to

the pipeline. The test stations should be installed at both ends and near the middle of

the DIP section. A corrosion inspection is also recommended when the pipe is

excavated for installation of the test stations.

5349.02 City of Hayward (Proj 623-7041) 2009 Annual Survey Report (Final) Page 16

Mission Pipeline

- Install corrosion monitoring test stations along the pipeline at 1-mile intervals

(approximately 11 total) to conduct current requirement, electrical continuity, and

corrosion monitoring testing, and to determine the next step in providing cathodic

protection to the pipeline. A corrosion inspection is also recommended when the pipe

is excavated for installation of the test stations.

BART LINE CURRENT MONITORING STATIONS

J ackson Street 12-Inch Water Main at Silvia Street:

- Install a new Current Monitoring Station at this location.

Western Boulevard 8-Inch located between Peralta Street and Simon:

- Locate or replace this test station.

South Meter Vault 40-Feet South of the BART substation in the BART Southern

Alameda Yard Test Station:

- Locate or replace this test station.

APPENDICES

APPENDIX 1

CITY OF HAYWARD

PROJECT NO. 623-7041

RESERVOIRS

HAYWARD, CA

RECTIFIER AND POTENTIAL DATA

MARCH 2009

NAME / ID: 750 Highland Reservoir

LOCATION:

MANUFACTURER:

MODEL: CTAYSA 40-12D

SERIAL NO.

TYPE/FEATURES: Automatic potential-controlled.

A.C. INPUT:

D.C. OUTPUT:

SHUNT: 15 A / 50 mV

ANODE SYSTEM:

Date Status Setting Volts Amps Auto/Man On I-Off Set Actual By Remarks

3/11/09 AF A-4 9.2 1.9 Auto 1099 1000 1080 1080 GDM Portable Meter

3/11/09 AT A-4 9.2 2.0 Manual 1477 1152 1080 1080 GDM Portable Meter

3/11/09 AL A-4 9.2 2.0 Auto 1477 1152 1080 1080 GDM Portable Meter

TANK-TO-WATER POTENTIALS (-mV to Portable CSE)

Depth (Ft.) On I-Off

0 (22/28) 2595 1050

5 2467 1054

10 2128 1037

15 1792 1023

20 1554 1004

22 1492 1000

Notes:

1. Status: AF =As Found, AT =As Tested, AL =As Left

2. Pot. =Potential

3. CSE =Copper/Copper-Sulfate Reference Electrode.

4. Depth of tank-to-water potentials measured from surface of water.

6 Tank was about 90% full.

DC Output

0.063-inch diameter platinized niobium wire anodes (28) with #14 HMW/PE anode lead wire.

Goodall

82H1109

40 Volts, 12 Amps

Pot. Meas. (-mV) Pot. Meas. (-mV)

5349.02 City of Hayward (Proj 623-7041) APP 1 - Reservoir Data (Final) Page 1 of 6

APPENDIX 1

CITY OF HAYWARD

PROJECT NO. 623-7041

RESERVOIRS

HAYWARD, CA

RECTIFIER AND POTENTIAL DATA

MARCH 2009

NAME / ID: 1000 Highland Reservoir

LOCATION:

MANUFACTURER:

MODEL: CTAYSA 40-4D

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 2.2 Amps, 1 Phase

D.C. OUTPUT:

SHUNT: 5 A / 50 mV

ANODE SYSTEM:

Date Status Setting Volts Amps Auto/Man Pot. Meas. (V) Pot. Set (V) By Remarks

3/12/09 AF A-3 3.5 0.1 Auto 1.16 0.84 BM Panel Meters

3/12/09 AT A-3 4.5 0.2 Man 0.908 0.88 BM Portable Meter

3/12/09 AL A-3 4.5 0.2 Auto 1.21 0.85 BM Portable Meter

3/12/09 AL A-3 4.0 0.2 Auto 1.18 0.88 BM Panel Meters

TANK-TO-WATER POTENTIALS (-mV to Portable CSE)

Depth (Ft.) On I-Off

0 (23/30) 2756 1051

5 2630 1090

10 2590 1040

15 2390 1006

20 2390 1018

25 2240 1049

Notes:

1. Status: AF =As Found, AT =As Tested, AL =As Left

2. Pot. =Potential

3. CSE =Copper/Copper-Sulfate Reference Electrode.

4. Depth of tank-to-water potentials measured from surface of water.

6 Tank was about 80% full.

DC Output

Goodall

82H1110

40 Volts, 4 Amps

0.063-inch diameter platinized niobium wire anodes (28) with #14 HMW/PE anode lead wire.

5349.02 City of Hayward (Proj 623-7041) APP 1 - Reservoir Data (Final) Page 2 of 6

APPENDIX 1

CITY OF HAYWARD

PROJECT NO. 623-7041

RESERVOIRS

HAYWARD, CA

RECTIFIER AND POTENTIAL DATA

MARCH 2009

NAME / ID: 1285 Highland Reservoir

LOCATION:

MANUFACTURER:

MODEL: A7-P-0020 (Anode junction box).

SERIAL NO.

TYPE/FEATURES: Galvanic System

SHUNT: 2 A / 200 mV

ANODE SYSTEM:

REMARKS:

Date Status % Volts Amperes On I-Off By Remarks

3/11/09 AF 19 N/A 0.0 1.168 0.954 GDM Panel Meters

3/11/09 AF 19 1.354* 0.2 1.176 0.966 GDM Portable Meter

3/11/09 AT 19 4.8 0.4 2.365 1.5 GDM Portable Meter

3/11/09 AL 19 4.8 0.4 1.05 - GDM Portable Meter

TANK-TO-WATER POTENTIALS (-mV to Portable CSE)

Depth (Ft.) On I-Off

0 (28/32) 1198 991

5 1195 988

10 1193 993

15 1191 994

20 1189 995

25 1188 982

28 1186 1000

Notes:

1. Status: AF =As Found, AT =As Tested, AL =As Left

2. Pot. =Potential

3. CSE =Copper/Copper-Sulfate Reference Electrode.

4. Depth of tank-to-water potentials measured from surface of water.

6 Tank was about 90% full.

7. New tank installed in 2005 (replacement for old 1285).

8 * Open circuit anode potential.

DC Output

Ten (10) 2-inch diameter, 10-foot long, 25-pound magnesium rod anodes with #8

HMWPE anode lead and header wires.

Corrpower

C-021700J B

Pot. Meas.

New tank installed in 2005 as a replacement for the original 1285 Highland Reservoir.

5349.02 City of Hayward (Proj 623-7041) APP 1 - Reservoir Data (Final) Page 3 of 6

APPENDIX 1

CITY OF HAYWARD

PROJECT NO. 623-7041

RESERVOIRS

HAYWARD, CA

RECTIFIER AND POTENTIAL DATA

MARCH 2009

NAME / ID: 1530 Highland Reservoir

LOCATION:

MANUFACTURER:

MODEL: C-051930 (Anode J unction Box)

SERIAL NO.

TYPE/FEATURES: Galvanic System

A.C. INPUT: N/A

D.C. OUTPUT:

SHUNT: 2 A / 200 mV

ANODE SYSTEM:

REMARKS:

Date Status % Volts Amperes By Remarks

3/11/09 AF / AL 40 N/A 0.0 GDM Panel Meters

3/11/09 AF / AL 40 N/A 0.2 GDM Portable Meter

TANK-TO-WATER POTENTIALS (-mV to CSE)

To Depth (Ft.) On I-Off

Ref 1 - 1208 986

Ref 2 - 1200 969

Portable 0 (28/32) 1250 1006

Portable 5 1244 1000

Portable 10 242 1000

Portable 15 1238 996

Portable 20 1236 955

Notes:

1. Status: AF =As Found, AT =As Tested, AL =As Left

2. Pot. =Potential

3. CSE =Copper/Copper-Sulfate Reference Electrode.

4. Ref 1, 2 =Permanent CSE, Portable =Portable CSE.

5. Depth of tank-to-water potentials measured from surface of water.

DC Output

Sixteen (16) 2-inch diameter, 10-foot long, 25-pound magnesium

rod anodes with #8 HMWPE anode lead and header wires.

Corrpower

C-021700J B

N/A

5349.02 City of Hayward (Proj 623-7041) APP 1 - Reservoir Data (Final) Page 4 of 6

APPENDIX 1

CITY OF HAYWARD

PROJECT NO. 623-7041

RESERVOIRS

HAYWARD, CA

RECTIFIER AND POTENTIAL DATA

MARCH 2009

NAME / ID: Garrin Reservoir

LOCATION:

MANUFACTURER:

MODEL: 0195

SERIAL NO.

TYPE/FEATURES: Installed by Cathodic Protection Services Waterworks Division (Springfield, NJ ).

A.C. INPUT: 110 Volts, 7 Amps, 1 Phase

D.C. OUTPUT:

SHUNT: N/A

ANODE SYSTEM:

Man. Aux-1 Aux-2

Date Status Setting Volts Amps Auto/Man A-1 Cell A-2 Cell Pot. Set I Set I Ratio I Ratio By Remarks

3/12/09 AF / AL - 0.0 0.0 Manual -2.0 -2.0 0.95 0 0 0 BM Panel Meters

TANK-TO-WATER POTENTIALS (-mV to CSE)

Depth (Ft.) On I-Off

- - -

Notes:

1. Status: AF =As Found, AT =As Tested, AL =As Left

2. Pot. =Potential

3. CSE =Copper/Copper-Sulfate Reference Electrode.

4. Depth of tank-to-water potentials measured from surface of water.

6 No access to the ladder. No static potentials taken.

DC Output

Nine (9) 0.063-inch diameter platinized niobium wire anodes.

Micro-Polatrol

19178

25 Volts, 20 Amps

5349.02 City of Hayward (Proj 623-7041) APP 1 - Reservoir Data (Final) Page 5 of 6

APPENDIX 1

CITY OF HAYWARD

PROJECT NO. 623-7041

RESERVOIRS

HAYWARD, CA

RECTIFIER AND POTENTIAL DATA

MARCH 2009

NAME / ID: South Walpert Reservoir

LOCATION:

MANUFACTURER:

MODEL: CTAYSA 40-12

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT:

D.C. OUTPUT:

SHUNT:

ANODE SYSTEM:

Date Status Setting Volts Amperes Auto/Man On I-Off Pot. Set By Remarks

3/11/09 AF A-3 6.0 0.3 Auto 1.05 - 0.85 GDM Panel Meters

3/11/09 AF A-3 5.9 0.2 Auto 1.05 - 0.85 GDM Portable Meter

3/11/09 AT A-2 4.8 0.4 Man 2.36 1.5 1 GDM Portable Meter

3/11/09 AL A-2 4.8 0.4 Auto 1.05 - 1 GDM Portable Meter

TANK-TO-WATER POTENTIALS (-mV to CSE)

Depth (Ft.) On I-Off

0 (23/30) 2929 1103

5 2900 1115

10 2840 1100

15 2775 1107

20 2712 1114

25 2614 1117

Notes:

1. Status: AF =As Found, AT =As Tested, AL =As Left

2. Pot. =Potential

3. CSE =Copper/Copper-Sulfate Reference Electrode.

4. Depth of tank-to-water potentials measured from surface of water.

6 Tank was about 90% full.

DC Output

Thirty-six (36) 0.063-inch diameter platinized niobium wire anodes.

Goodall

82H1108

40 Volts, 12 Amps

Pot. Meas.

5349.02 City of Hayward (Proj 623-7041) APP 1 - Reservoir Data (Final) Page 6 of 6

NAME: Skywest

LOCATION: Hesperian Blvd. and Skywest Drive (Skywest Pump Station)

MANUFACTURER:

MODEL: CAYSE 30-16 Z88,251,509,1001,1502

SERIAL NO.

TYPE/FEATURES: Tap-Adjusted

A.C. INPUT: 115/230 Volts, 6.91/3.45 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 20 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

GROUNDBED DATA:

REMARKS:

Date Setting Volts Amperes By Remarks

9/4/07 A-1 0.50 0.50 BM As Energized

9/13/07 B-1 7.60 7.32 BM As Adjusted / Left

2/19/09 B-1 7.9 6.0 BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.69

2 1.72

3 0.86

4 1.03

5 1.65

6 1.47

Total 7.42

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

MARCH 2009

DC Output

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

Connection to EBMUD. Connection to SFPUC.

C-061339

30 Volts, 16 Amperes

Five (5) Hi-Silicon Cast Iron Anodes with Coke-Breeze Backfill in a 111' Deep

Well.

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 1 of 18

NAME: West Street (Prev. Hesperian rectifier No.11 in 1997 report.)

LOCATION: Hesperian Blvd. and West Street (North end of Hesperian Pipeline)

MANUFACTURER: Goodall

MODEL: CSAYSA 18-12 DFRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15A / 50 mV (Rectifier), 0.01 Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 C-4 3.4 1.5 On BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.26

2 0.17

3 0.13

4 0.14

5 0.13

6 0.16

7 0.12

8 0.13

9 0.13

10 0.18

Total: 1.55

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

Cabinet door lower hinge broken. Ammeter broken.

83C2357

18 Volts, 12 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 2 of 18

NAME: Depot Court (Prev. Hesperian rectifier No.10 in 1997 report.)

LOCATION: Hesperian Blvd. and Depot Court

MANUFACTURER: Goodall

MODEL: CSAYSA 18-12 DFRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 A-3 2.4 0.8 On BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.11

2 0.07

3 0.05

4 0.07

5 0.08

6 0.08

7 0.09

8 0.00

9 0.10

10 0.10

Total 0.75

DC Output

Ammeter broken.

93C2358

18 Volts, 12 Amperes

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

MARCH 2009

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 3 of 18

NAME: Oliver Drive (Prev. Hesperian rectifier No.9 in 1997 report.)

LOCATION: Hesperian Blvd. and Oliver Drive

MANUFACTURER: Goodall

MODEL: CAYSE 18-12 FRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 A-4 0.5 0.0 On BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.00

2 0.00

3 0.00

4 0.00

5 0.00

Total 0.00

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

83C2153

18 Volts, 12 Amperes

Cabinet has broken lower door hinge. Rectifier Fuse and AC to rectifier are operational.

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 4 of 18

NAME: Pepsi (Prev. Hesperian rectifier No.8 in 1997 report.)

LOCATION: Hesperian Blvd. and South Pepsi Drive (Alameda Flood Control Trench)

MANUFACTURER: Goodall

MODEL: CAYSE 18-12 FRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 - - - - BM As found / As left

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

82C2154

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

18 Volts, 12 Amperes

Enclosure needs replacement. Damaged by construction activity. All wires are cut. New AC power required.

If solar panel utilized, vandalism prevention required. City is waiting on PG&E.

DC Output

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 5 of 18

NAME: Union Sanitary (Prev. Hesperian rectifier No.7 in 1997 report.)

LOCATION: Whipple Road and Benson Road in Union City

MANUFACTURER: Goodall

MODEL: CSAYSA 18-12 FRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS: Cabinet door's lower hinge broken.

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 A-5 5.0 4.1 Off BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.01

2 0.00

3 0.26

4 0.30

5 0.51

6 0.17

7 0.54

8 1.49

9 0.73

10 1.25

Total 5.26

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

83C2148

18 Volts, 12 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 6 of 18

NAME: Silvertide Drive (Prev. Hesperian rectifier No.6 in 1997 report.)

LOCATION: Union City Blvd. and Silvertide Drive in Union City

MANUFACTURER: Goodall

MODEL: CSAYSA 12-12 DFRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 2.2 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV

REMARKS: No AC at rectifier. Waiting on PG&E.

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 B-2 0.6 0.0 Off BM As found / As left

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

83C2152

18 Volts, 12 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 7 of 18

NAME: Delores Drive

LOCATION: Union City Blvd. and Delores Drive in Union City (By Alameda Creek Overpass)

MANUFACTURER:

MODEL:

SERIAL NO.

TYPE/FEATURES:

A.C. INPUT:

D.C. OUTPUT:

SHUNT:

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 - - - - BM No access

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

No key available for access through fence gate.

CITY OF HAYWARD

APPENDIX 2

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 8 of 18

NAME:

LOCATION: Melissa Terrace and Winslow Terrace in Fremont

MANUFACTURER: Goodall

MODEL: CSAYSA 12-12

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 2.2 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV

REMARKS: AC to rectifier cut in street during construction. Rectifier cabinet bent

and rusting. Anode well box buried.

Date Setting Volts Amperes By Remarks

2/18/09 B-5 0.6 0.0 BM As found / As left

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

82C2151

12 Volts, 12 Amperes

Melissa and Winslow (Prev. Hesperian rectifier No.5 in 1997 report.)

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 9 of 18

NAME: Alameda Creek (Prev. Hesperian rectifier No.4 in 1997 report.)

LOCATION: Union City Blvd. at Alameda Creek Trail in Fremont

MANUFACTURER: Goodall

MODEL: CSAYSA 18-12 DFRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 B-1 5.8 3.0 On BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.60

2 0.44

3 0.60

4 0.63

5 0.80

Total 3.07

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

Rectifier cabinet door's lower hinge broken. In high grass. Anode well traffic box lid missing.

83C2356

18 Volts, 12 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 10 of 18

NAME: Bettencourt and Braidburn (Prev. Hesperian rectifier No.2 in 1997 report.)

LOCATION: Bettencourt Street and Braidburn Avenue in Newark

MANUFACTURER: Goodall

MODEL: CSAYSA 18-12 FRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 B-1 5.4 3.9 On BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.92

2 0.73

3 0.65

4 0.63

5 0.93

Total 3.86

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

Ammeter broken.

83C2150

18 Volts, 12 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 11 of 18

NAME: Hickory and Thornton (Prev. Hesperian rectifier No.1 in 1997 report.)

LOCATION: Hickory Street and Thornton Avenue in Newark

MANUFACTURER: Goodall

MODEL: CSAYSA 18-12 FRSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 3.3 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 15 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

2/18/09 A-4 1.2 0.0 On BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.00

2 0.00

3 0.00

4 0.00

5 0.00

Total 0.00

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

HESPERIAN AQUEDUCT PIPELINE (42-INCH AND 33-INCH)

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

No AC supplied by PG&E. Possible solar location.

83C2149

18 Volts, 12 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 12 of 18

NAME: Mission (Prev. Industrial rectifier No.1 in 1997 report.)

LOCATION: Industrial Pkwy. and Mission Blvd.

MANUFACTURER: Corrpower

MODEL: CSAYSA 40-22 AVOZ90, 183

SERIAL NO.

TYPE/FEATURES:

A.C. INPUT: 115/230 Volts, 12.0/6.0 Amperes, 1/3 Phase

D.C. OUTPUT:

SHUNT: 25 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes By Remarks

2/18/09 A-2 3.0 1.4 BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.09

2 0.04

3 0.08

4 0.12

5 0.11

6 0.13

7 0.12

8 0.13

9 0.19

10 0.07

Total 1.08

MARCH 2009

DC Output

Green rectifier enclosure. Negative Test & Drain leads on junction panel.

C-021836

40 Volts, 22 Amperes

APPENDIX 2

RECTIFIER AND GROUNDBED DATA

CITY OF HAYWARD

PROJECT NO. 623-7041

INDUSTRIAL 24-INCH PIPELINE

HAYWARD, CA

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 13 of 18

NAME: Taylor (Prev. Industrial rectifier No.2 in 1997 report.)

LOCATION: Industrial Pkwy. and Taylor Avenue

MANUFACTURER: Corrpower

MODEL:

SERIAL NO.

TYPE/FEATURES: Constant-Potential

A.C. INPUT:

D.C. OUTPUT:

SHUNT: 25 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

ANODE BED:

REMARKS: IR-Free / On-Potential Modes.

Date Setting Volts Amperes Mode Auto/Man Pot. Adjust By Remarks

2/18/09 A-4 3.7 2.0 IR-Free Manual 70% BM As Found / As Left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.23

2 0.31

3 0.27

4 0.06

5 0.16

6 0.12

7 0.22

8 0.12

9 0.23

10 0.25

Total 1.97

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

MARCH 2009

DC Output

One (1) 10-inch diameter, 200-foot deep, vertical anode well with six (6) 1-Inch O.D. by 40-inch long

mixed-metal oxide anodes.

C-061526

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

INDUSTRIAL 24-INCH PIPELINE

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 14 of 18

NAME: Ruus Rd. (Prev. Industrial rectifier No.3 in 1997 report.)

LOCATION: 1,500 feet West of Ruus Road on Industrial Parkway.

MANUFACTURER:

MODEL:

SERIAL NO.

TYPE/FEATURES:

A.C. INPUT:

D.C. OUTPUT:

SHUNT:

REMARKS:

Date Setting Volts Amperes Filter Bypass By Remarks

3/31/09 - - - - BM Only wires in Meter Box

STRUCTURE-TO-SOIL POTENTIALS (-mV) FOR "WATER" CHRISTY BOX WIRES

Wire Size/Color Static Structure Lead

#8 Blk HMW 304 Anode lead?

#8 Blk HMW 233 Anode lead?

#8 Blk HMW 235 Anode lead?

#8 Blk HMW 306 Anode lead?

#8 Blk HMW 307 Anode lead?

#8 Blk HMW 230 Anode lead?

#8 Blk HMW 301 Anode lead?

#8 Blk HMW 260 Anode lead?

#8 Blk HMW 304 Anode lead?

#8 Blk HMW 305 Anode lead?

#2 Blk HMW - Pipe lead?

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

INDUSTRIAL 24-INCH PIPELINE

Rectifier destroyed by car accident years ago. Anode wires and structure wire still present in

2x1-foot "Water" Christy Box located in sidewalk. Structure wire was found to be severed and

was pulled out of the earth and left in the box.

DC Output

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

MARCH 2009

NAME: Hopkins (Prev. Industrial rectifier No.4 in 1997 report.)

LOCATION: Industrial Pkwy. And Hopkins Street

MANUFACTURER: Goodall

MODEL: CPAYSA 24-20 ADEFPSZ

SERIAL NO.

TYPE/FEATURES: Custom

A.C. INPUT: 115 Volts, 6.9 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 25 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes AC Ref (V) Set (V) By Remarks

2/19/09 A-4 1.5 0.0 On 0.15 0 BM As found

2/19/09 A-4 1.5 0.0 Off 0.15 0 BM As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/19/2009

1 0.00

2 0.00

3 0.00

4 0.00

5 0.00

6 0.00

Total: 0.0

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

INDUSTRIAL 24-INCH PIPELINE

DC Output

75A1044

24 Volts, 20 Amperes

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

MARCH 2009

AC disconnect enclosure / cover is not weather proof. Needs to be repaired or replaced. AC present at

AC disconnect. AC to rectifier okay. Old pulse-generator installed.

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 16 of 18

NAME: Well B (Prev. Industrial rectifier No.5 in 1997 report.)

LOCATION: Hesperian Blvd. and Industrial Pkwy. (28475 Hesperian Blvd.)

MANUFACTURER: Integrated Rectifier Technologies, Inc.

MODEL: BMASFS 18-22 DMSY

SERIAL NO.

TYPE/FEATURES:

A.C. INPUT: 115/230 Volts 6.14/3.07 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 25 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS:

Date Setting Volts Amperes By Remarks

2/19/09 C-2 5.4 3.6 BM As found / As left

ANODE CURRENT OUTPUT (Amps):

Anode No. 2/18/09

1 0.47

2 0.49

3 0.19

4 0.00

5 0.60

6 0.22

7 0.46

8 0.34

9 0.25

10 0.77

Total 3.79

PIPELINE CURRENT RETURNS (AMPS):

PIPE ID. 2/18/09

27-Inch FM 2.82

42-Inch W 0.93

Total 3.75

APPENDIX 2

CITY OF HAYWARD

PROJECT NO. 623-7041

INDUSTRIAL 24-INCH PIPELINE

DC Output

MARCH 2009

HAYWARD, CA

RECTIFIER AND GROUNDBED DATA

05R-0799

18 Volts, 22 Amperes

5349.02 City of Hayward (Proj 623-7041) APP 2 - PL Rectifier Data (Final) Page 17 of 18

NAME: Baumberg Court (Prev. Industrial rectifier No.6 in 1997 report.)

LOCATION: End of Baumberg Court (West of Baumberg Avenue)

MANUFACTURER: Goodall

MODEL: CSOYSE 40-28 EGP

SERIAL NO.

TYPE/FEATURES: Custom, Oil-Filled

A.C. INPUT: 115/230 Volts, 15.7/7.7 Amperes, 1 Phase

D.C. OUTPUT:

SHUNT: 50 A / 50 mV (Rectifier), 0.01Ohm (Anode junction box)

REMARKS: