Professional Documents

Culture Documents

Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & Gas

Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & Gas

Uploaded by

Carlos Tarquino0 ratings0% found this document useful (0 votes)

54 views12 pagesThe document provides installation, operation and maintenance instructions for a Mooney Slam Shut valve or Mooney Flowgrid Slam Shut valve. The slam shut valve is an automatic emergency shutoff device designed for use with a pressure reducing regulator. It consists of a valve body with a bleed plate and cover mounted on top and a slam shut actuator assembly mounted on the bottom. The slam shut valve is available in configurations for over pressure protection only, under pressure protection only, or over and under pressure protection.

Original Description:

Original Title

+Mooney_Flwgrd_SlamShut_1in_iom_manual_0612

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides installation, operation and maintenance instructions for a Mooney Slam Shut valve or Mooney Flowgrid Slam Shut valve. The slam shut valve is an automatic emergency shutoff device designed for use with a pressure reducing regulator. It consists of a valve body with a bleed plate and cover mounted on top and a slam shut actuator assembly mounted on the bottom. The slam shut valve is available in configurations for over pressure protection only, under pressure protection only, or over and under pressure protection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

54 views12 pagesMooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & Gas

Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & Gas

Uploaded by

Carlos TarquinoThe document provides installation, operation and maintenance instructions for a Mooney Slam Shut valve or Mooney Flowgrid Slam Shut valve. The slam shut valve is an automatic emergency shutoff device designed for use with a pressure reducing regulator. It consists of a valve body with a bleed plate and cover mounted on top and a slam shut actuator assembly mounted on the bottom. The slam shut valve is available in configurations for over pressure protection only, under pressure protection only, or over and under pressure protection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

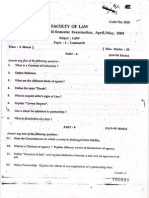

You are on page 1of 12

Table of Contents

Product Description ........................................................................... 1

Materials of Construction ............................................................... 2

Specifications ....................................................................................... 2

Valve Markings .................................................................................... 3

Nameplate Information ................................................................... 3

Principles of Operation .................................................................... 4

Hydrostatic Testing ........................................................................... 4

Installation ............................................................................................. 4

Setup ........................................................................................................ 5

Testing ..................................................................................................... 5

Startup and Operation ..................................................................... 6

Maintenance ........................................................................................ 7

GE Oil & Gas

Mooney

*

Flowgrid

*

Slam Shut

*

1 inch Valve

Installation/Operation/Maintenance Manual

imagination at work

Piping Schematics ........................................................................... 10

Troubleshooting ............................................................................... 12

Product Support .............................................................................. 12

Warranty ............................................................................................. 12

Product Description

The slam shut valve is an easy to maintain automatic

emergency shutoff device. The slam shut is designed

for use with a pressure reducing regulator to provide

secondary downstream pressure protection.

The device is designed to shut off the flow of gas

when the sense or downstream pressure in the

system either exceeds or drops below the set point

pressures. It can be used as a stand alone device or

integrated with the one inch Flowgrid regulator. The

one inch Mooney Slam Shut valve consists of a valve

body with a bleed plate and cover mounted on top,

and a Slam Shut actuator assembly mounted on the

bottom of the body. The one inch Mooney Flowgrid

Slam Shut also has a throttle plate, diaphragm, and

main spring.

Scope

This manual provides the installation, operation, and

maintenance for the Mooney Slam Shut valve (Slam

Shut only) and the Mooney Flowgrid Slam Shut valve

(Slam Shut and Flowgrid combined). The Mooney Slam

Shut or Mooney Flowgrid Slam Shut

can be supplied in

three configurations; (1) over pressure protection only,

(2) under pressure protection only, and (3) over and

under pressure protection.

Instructions for the Flowgrid regulator and Pilot are

found in separate IOM manuals.

2

Materials of Construction

Valve Body, Bleed

Plate & Spring Case

Carbon Steel (WCB)

Throttle Plate 17-4 PH or A515

Slam Shut Seat SST

Slam Shut Seal Nitrile

Flowgrid Diaphragm Nitrile or Viton

Flowgrid Spring SST

Slam Shut Housing,

Slam Shut Spring

Cases

Aluminum

Spring Cover Aluminum

Rotating Shaft SST

Main Shaft Guide Delrin

End Cap Lexan

Plug Seal Nitrile

O-Rings Nitrile

Specifications

Sizes 1 NPT & SWE

1.25 NPT & SWE

Types Stand Alone or Integrated into

Flowgrid

Pressure Protection Standard: Over

Optional: Over and/or Under

Temperature* -20F to 150F

(-29C to 65C)

Maximum Operating

Inlet Pressure

740 psig

(50 Bar)

Operating Sense

Pressure

5 to 450 psig

(.35 Bar to 31 Bar)

Response Time < .25 seconds

* EN14382 restricts the minimum temperature to -4 F (-20 C).

Spring Color

Spring Range Accuracy

(% of Set Point) **

psig Bar

Red 5 - 10 0.35 - 0.7 10

Silver 10 - 40 0.7 - 3 5

Blue 40 - 90 3 - 6 2.5

Purple 90 - 175 6 - 12 2.5

Black 175 - 250 12 - 17 2.5

White/Green 250 - 450 17 - 31 2.5

Over Pressure Set Point Ranges

Spring Color

Spring Range Accuracy

(% of Set Point) **

psig Bar

Red 5 - 10 0.35 -0.7 2.5

Silver 10 - 40 0.7 - 3 2.5

Blue 40 - 90 3 - 6 2.5

Purple 90 - 175 6 - 12 1.0

Black 175 - 250 12 - 17 1.0

White/Green 250 - 450 17 - 31 1.0

Under Pressure Set Point Ranges

** Preliminary AG Data, Testing per EN 14382

Excellent performance and accuracy across a large

pressure range by changing only the spring

External visual indicator to show when the unit is

tripped

Easy to reset; only three caps need to be removed for

complete reset

High cycle applications; only one wear component

No pressure differential requirements for full shutoff

Spring Case Vent Chamber may to pressurized for

remote trip or remote change of setpoint

The Slam Shut can be provided in one of three

different actuator assemblies; (1) Overpressure

protection only, (2) Underpressure protection only, or

(3) Overpressure and Underpressure protection.

The one inch Mooney Slam Shut has several unique

features such as:

Easy to maintain; only two bolts required to remove

entire Slam Shut assembly

Resistant to sticking due to freezing water or debris

in pipeline

Well contained moving mechanical parts resistant

to vibration effects

7

5

6

3

2

1

8

4

8

3

Figure 1 Valve Markings

Figure 2 Slam Shut Nameplate

Valve Markings

Nameplate Information

Flowgrid Nameplate information, see the Flowgrid IOM.

1. American National Standards Institute (ANSI)

pressure class rating of the valve.

2. Indication that the valve has been hydrostatically

tested according to code requirements.

3. The serial number is stamped on the spring

case, bleed plate, valve body, & throttle plate

on Flowgrid regulators with integral slam shuts.

On stand alone slam shuts the serial number is

stamped on the cover, bleed plate, and valve

body.

Item Definition

NITRILE The Slam Shut has all nitrile soft goods.

VITON The Slam Shut has nitrile static seals and

viton dynamic seals and diaphragms.

MAX INLET Maximum inlet pressure PSIG/BAR

MIN OUTLET Minimum difference in inlet and down-

stream pressure required for the Slam Shut

to operate.

OP. TEMP. Operation Temperature range

4. The Slam Shut Nameplate location.

5. The Flowgrid Nameplate location.

6. The flow direction is marked on the spring case

or cover (INLET and/or a flow arrow). Proper

alignment assures that the diaphragm guide on

the Spring Case is aligned toward outlet side of

the valve on regulators.

7. The % Capacity tag indicates the capacity of the

throttle plate (100%, 75%, 50%, & 35%) in the

valve.

8. The springcase nameplate indicating the pressure

range for each color spring.

Series 41

Over/Under Pressure Protection

RED

PLATED

BLUE

PURPLE

BLACK*

GREEN*

* Adjusting Screw Spacer Required

5-10 psi (0.35-0.7 bar)

10-40 psi (0.7-3 bar)

40-90 psi (3-6 bar)

90-175 psi (6-12 bar)

175-200 psi (12-17 bar)

250-450 psi (17-31 bar)

Figure 3 Valve Markings Nameplate

4

WARNING

Principals of Operation

During normal operation in the untripped condition,

the plug is retracted into the fully open position. The

downstream pressure is monitored by the Overpressure

and/or Underpressure sensing diaphragms. If an

overpressure or underpressure condition occurs, the

sensing diaphragms will move the trip shaft, causing the

valve to trip completely closed. After the Slam Shut has

tripped, the valve must be reset manually.

Hydrostatic Testing

All slam shut Stand Alone valves and slam shut valves

integrated into Flowgrid valves are hydrostatically tested at

the factory prior to shipment according to ISA-S75.19-1989

and MSS-SP-61 standards.

If it is necessary to retest the valve, the slam shut valve

may be hydrotested without any modifications. If a

FlowGrid regulator is integrated into the slam shut, care

should be taken to not damage the diaphragm. Refer to

the Flowgrid IOM.

Installation

Personal injury, equipment damage, or leakage due

to explosion of accumulated gas or bursting of

pressure containing parts may result if the Slam

Shut is over pressured or is installed where service

conditions could exceed the limits given in the

specification of this manual or on the nameplate, or

where conditions exceed any ratings of the adjacent

piping or piping connections. Verify the limitations of

the Flowgrid regulator, Slam Shut valve and pilot to

ensure none of the devices are over pressured.

To avoid such injury or damage, provide pressure

relieving or pressure limiting devices as required by

applicable codes to prevent service conditions

from exceeding those limits. Additionally, physical

damage to the regulator could result in damage

such as breaking the pilot (if supplied) off the main

valve, causing personal injury and/or property

damage due to explosion of accumulated gas.

To avoid such injury and damage, install the Slam

Shut and Regulator in a safe location.

NOTE: The Slam Shut maybe supplied as a stand

alone unit or integrated into a Flowgrid regulator

with filters, restrictors and pilots. This procedure

covers the installation of the slam shut and may

refer to components not ordered with the slam

shut. Consult the proper IOM for the installation of

Flowgrid regulator, filters, restrictors and pilots.

1. PERSONNEL: Installation of the slam shut valve

and/or Flowgrid regulator should be made by

qualified personnel familiar with high pressure

piping and pilot operated regulators.

2. PRIOR INSPECTION: Inspect the Slam Shut valve,

regulator, pilot, and tubing for any damage that

might have occurred in shipping. Make sure the

body, pilot lines, and inlet piping are clear and

free from foreign material.

3. ORIENTATION: Stand alone Slam Shuts must

be installed up stream of the pressure regulator

to provide secondary protection. The Slam Shut

valve or Slam Shut integrated into a Flowgrid

regulator may be installed in any position, the

best position being one that provides easiest

access for the Slam Shut, pilot adjustment and

maintenance.

4. SCREWED END VALVES: Apply pipe compound

to the male threads starting one or two threads

back from the end prior to assembling the joint.

5. FLANGED END VALVES: Use suitable line gaskets

and standard bolting practices with flanged

bodies. A criss-cross pattern of incrementally

tightening the line bolts is recommended.

6. WELD END BODIES: Before welding a butt weld

and/or a socket weld valve body, disassemble

the valve. On stand alone Slam Shuts remove the

bonnet, Slam Shut body assembly and all O-rings.

On Slam Shuts integrated into Flowgrid valves;

remove the Slam Shut body assembly, Spring

Case and all trim parts including diaphragm

and O-rings. Reassemble the valve (refer to

the MAINTENANCE section of this manual for

Disassembly and Assembly procedures) and

pressurize to check for leaks prior to putting the

valve in service.

7. Slam Shut SENSE LINE: Install a 3/8 inch OD

tube from the sense port to a port on the pipe

line located 8 to 10 pipe diameters minimum of

straight pipe downstream of the final regulator in

the run. The sense port is located on the down-

stream side of the controller and latch module

just above the Slam Shut label.

NOTE: The sense line connection should be away

from areas of turbulence (such as valves, reducers,

and elbows) and should have a full opening into

the pipe free from burrs, drill peels, and weld slag.

Shutoff valves are not required in the control

line(s), but if installed, they should be of the full

opening type.

8. INLET PRESSURE LINES: All pilots or other devices

requiring a supply of inlet pressure that can

result in a flow of gas downstream of the Slam

Shut must be connected to the center port (port

inlet) on the Slam Shut body assembly. A shut

off valve may be installed in the sense line to

prevent the Slam Shut valve from closing during

setup of regulators and other equipment and to

aid in setting up the Slam Shut valve.

5

WARNING

Connection of any device such as a pilot to the inlet

port on the valve body can result in the flow of gas

downstream of the Slam Shut canceling the secondary

downstream pressure protection of the slam shut.

This may result in personal injury, death, equipment

damage, and/or bursting of pressure containing

parts and/or leakage of gas resulting in explosion of

accumulated gas.

9. VENT VALVES AND GAUGE CONNECTIONS: Vent

valves and gauge connections are recommended

in the inlet and outlet piping to the slam shut

and downstream regulator. These are a great

convenience during start up, maintenance, and

operation.

10. TOKEN RELIEF VALVES: Installation of a token relief

valve in the line downstream of the slam shut is

recommended. The relief valve should be set to

open before the slam shut valve is set to close.

Minor over pressure problems such as gas thermal

expansion or seat leakage due to dirt moving

through the system will be handled by the relief

valve, while maintaining a supply of gas to the

customers. Major malfunctions of the regulator

beyond the flow capacity of the token relief will

activate the slam shut valve.

Setup

Changing the Trip Set Point

1. Remove the Adjusting Screw Cap

2. Turn the Adjusting Screw with a 9/16 wrench

to change the set point. Turning clockwise will

increase the setpoint pressure, turning counter-

clockwise will decrease the setpoint pressure.

Resetting the Slam Shut (See Figure 4)

1. Close the Upstream and Downstream Block Valves.

2. Remove the bleed cap, reset cap, and clear bottom

cap.

3. Inside of the cavity labeled bleed, push and hold

the pin with a screwdriver. This will cause the

pressure upstream of the valve to bypass the

shutoff device into the downstream piping, causing

the pressure across the plug to equalize.

4. If an Underpressure feature is being used, the line

pressure must be 20% or more above the setpoint

before resetting the valve. If an Overpressure

feature is being used, the line pressure must be

20% or more below the setpoint before resetting

the valve.

5. Where the clear cap was previously located, find

the shaft with a hole through it. Insert a screw-

driver into the hole and, using the screwdriver as a

handle, pull the shaft into the reset position.

6. With the shaft held in the reset position, push the

reset pin. The trip mechanism will then snap into

place.

7. Replace the bleed cap, reset cap, and clear bottom

cap. (Make sure the reset pin remains in the reset

hole)

8. Open the Upstream and Downstream block valves.

Testing Slam Shut Shutoff

During all Slam Shut shutoff tests, if a Flowgrid pressure

regulator is combined with the Slam Shut, the Flowgrid

must be in the open position. There are two options to

force the regulator open; (1) install a ball valve in the

inlet tubing to the restrictor and close the valve to open

the Flowgrid, or (2) disconnect and vent the inlet and

outlet tubing.

Shutoff Test

Overpressure Protection Only (See Figure 5)

1. Close upstream and downstream block valves and

vent line pressure on inlet and outlet sides.

2. Disconnect the Slam Shut Sense Line and plug the

tubing connection in the piping.

3. Connect a pressurized bottle into the Slam Shut

Sense Line and introduce pressure above the

Overpressure Set Point. The Slam Shut will trip

closed.

4. Disconnect the bottle and re-install the Sense Line

tubing.

5. Open the upstream block valve and monitor the

downstream piping for any leakage.

6. Go through the Resetting the Slam Shut procedure

for Slam Shut reset.

Alternate Shutoff Test #1

Overpressure Protection Only (See Figure 6)

1. Must have a ball valve installed in the Slam Shut

Sense Line & a tee between the ball valve and the

Slam Shut.

2. Close the Slam Shut Sense Line and vent the tubing.

3. Connect a pressurized bottle into the tee, and

introduce pressure above the Overpressure Set

Point. The Slam Shut will trip closed.

4. Disconnect the bottle and plug the tee.

5. Open the Slam Shut Sense Line ball valve.

6. Check the downstream piping for any leakage.

7. Go through the Resetting the Slam Shut procedure

for Slam Shut reset.

Alternate Shutoff Test #2

Overpressure Protection Only

1. Inlet and Outlet pipelines must have pressure.

2. Remove the adjustment screw cap on the

Overpressure Unit.

6

3. Slightly loosen the nut on the adjusting screw. Do

not change the location of the nut on the screw.

4. Turn the adjustment screw counter-clockwise until

the Slam Shut trips closed.

5. Close the downstream block valve.

6. Vent the downstream piping and monitor the

downstream piping for any leakage.

7. Turn the adjusting screw clockwise until the nut

contacts the spring case. Tighten the nut.

8. Go through the Resetting the Slam Shut procedure

for Slam Shut reset.

Shutoff Test Any unit with Underpressure

Protection

1. Close upstream and downstream block valves and

vent line pressure on inlet and outlet sides. Slam

Shut should trip closed when venting.

2. Slightly open the upstream block valve, introducing

line pressure, and monitor the downstream piping

for any leakage.

3. Go through the Resetting the Slam Shut procedure

for Slam Shut reset.

Alternate Shutoff Test #3 Any unit with

Underpressure Protection (See Figure 7)

1. Must have a ball valve installed in the Slam Shut

Sense Line.

2. Close the Slam Shut Sense Line ball valve and vent

the tubing. Slam Shut will then trip closed.

3. Re-connect the tubing and open the sense line ball

valve.

4. Close the downstream block valve and vent the

downstream piping, and monitor the downstream

piping for any leakage.

5. Go through the Resetting the Slam Shut procedure

for Slam Shut reset.

Testing Regulator Shutoff with Integrated Slam Shut

When testing for regulator shutoff (lockup), the Slam

Shut must be in the open position during the shutoff

test. Follow the procedures below to ensure that the

Slam Shut remains in the open position. Refer to the

Flowgrid IOM for regulator shutoff procedures.

For the Overpressure Protection Only version of the

Slam Shut:

1. Close the upstream and downstream block valves

and vent the line pressure

2. If the Slam Shut is not already in the open position,

follow the Resetting the Slam Shut procedure to

open the Slam Shut.

For any Slam Shut version with Underpressure

Protection:

1. Close the upstream and downstream block valves

and vent the line pressure.

2. Connect a pressurized bottle into the Slam Shut

Sense Port and apply a constant pressure above

the Underpressure set point (and below the

Overpressure set point if applicable). (See Figure 5).

3. Follow the Resetting the Slam Shut procedure to

open the Slam Shut.

Startup and Operation

With Mooney Flowgrid Slam Shut units, it is recom-

mended that the Overpressure Protection adjustment

screw be turned fully in (clockwise) & the Underpressure

Protection adjustment screw be turned fully out

(counter-clockwise), prior to setting the Flowgrid

regulator. Follow the steps from the Flowgrid regulator

IOM for regulator Startup and Operation. For Slam Shut

Startup and Operation, follow the steps below:

Establish Set Point for Overpressure Protection Unit:

1. Close the upstream and downstream block valves

and vent the line pressure.

2. Verify that the Overpressure Protection adjust-

ment screw is turned fully in (clockwise) and the

Underpressure Protection (if applicable) is turned

fully out (counter-clockwise).

3. Connect a pressurized bottle into the Slam Shut

Sense Port and apply the desired Set Point pressure.

(See Figure 2).

4. Turn the adjustment screw out (counter-clockwise)

slowly until the Slam Shut trips closed.

5. Disconnect the pressurized bottle and re-connect

the Slam Shut Sense Line.

6. Follow the Resetting the Slam Shut procedure to

open the Slam Shut.

Establish Set Point for Underpressure Protection Unit:

1. Close the upstream and downstream block valves

and vent the line pressure.

2. Verify that the Underpressure Protection is turned

fully out (counter-clockwise).

3. Connect a pressurized bottle into the Slam Shut

Sense Port and apply the desired Set Point pressure.

4. Turn the adjustment screw in (clockwise) slowly until

the Slam Shut trips closed.

5. Disconnect the pressurized bottle and re-connect

the Slam Shut Sense Line.

6. Follow the Resetting the Slam Shut procedure to

open the Slam Shut.

Figure 4 Figure 5

Figure 6 Figure 7

7

Replacement of Seals in Overpressure Assembly

1. Turn adjusting

screw counter

clockwise until

fully removed.

Maintenance

The slam shut parts are subject to normal wear and must be inspected and replaced as they become worn. The

frequency of the inspection and replacement of the parts depends on the severity of the service conditions and/

or the applicable government requirements.

Inspect all parts for wear and damage. Replace all worn and damaged parts as necessary. Replace all seals

when tearing down and rebuilding the slam shut vale assembly.

WARNING

Before disassembly make sure the Slam Shut and

optional integrated regulator have been isolated

by closing upstream and downstream block valves.

Safely release the pressure in the lines. Failure to

complete these steps may result in personal injury

and property damage.

8

5. Inspect and/or Replace the following seals

Sense diaphragm (Re-install dry)

Pin o-ring (Re-install with Parker Super O-Lube)

Lower seal plate o-ring (Re-install with Lubriplate 105)

Upper seal plate o-ring (Re-install with Lubriplate 105)

Inspect and/or replace the rotator shaft part for

excessive wear (Re-install dry)

Replacement of Seals in Main Shaft Assembly

1. Disconnect the slam shut sense line from the

actuator block.

2. Use 5/16 allen

wrench to remove

two cap screws

from the actuator

block.

4. Use socket

wrench to remove

Insert assembly.

5. Use a paper clip to remove insert O-ring.(take care

not to scratch).

6 Inspect and/or Replace the following seals

Sense diaphragm (Re-install dry)

Pin O-ring (Use a paper clip or similar tool to

remove O-ring. Take care not to scratch the part

during removal) (Re-install with Parker Super

O-Lube)

Insert O-ring (Re-install with Lubriplate 105)

Replacement of Seals in Underpressure Assembly

1. Turn adjusting screw

2. Use 1/2 wrench to remove four cap screws from

spring case with Low Trip labeled on the actuator

block.

3. Use 9/16 wrench to remove nut from diaphragm

assembly.

4. Use head of trip pin to remove the seal plate.

(Take care not to scratch the trip pin).

2. Use 1/2 wrench to remove four cap screws from

spring case with High Trip labeled on the actuator

block.

3. Use 9/16 wrench

to remove nut from

diaphragm assembly.

9

3. Pull the actuator

assembly out of

the main body.

4. Pull the main shaft assembly out of the actuator

block.

5. Use a 5/32 allen wrench to remove the plug

screw.

6. Unscrew the reset shaft, and the assembly will

then separate.

7. Inspect and/or Replace the following seals

Plug Seal (Re-install dry)

Spring Cover O-ring (Re-install with Lubriplate 105)

Spring Plate O-ring (Re-install with Lubriplate 105)

Shaft O-ring (Re-install with Lubriplate 105

Replacement of Seals in Equalizer (bleed) Assembly

1. Use a 7/8 wrench to remove the bleed cap and

assembly

3. Remove the parts from the body.

4. Inspect and/or Replace the following seals

Body Seals (Qty 2) (Re-install dry)

Slam Shut Seat O-ring (Re-install with Lubriplate 105)

Diaphragm (if applicable) (Re-install dry)

NOTE: Replacing the seals in the Overpressure

Assembly, Underpressure Assembly, or Main Shaft

Assembly may be done with the slam shut actuator

block removed from the body. The body does not need

to be removed from the pipeline when servicing the

Slam Shut or Flowgrid.

2. Inspect and/or Replace the following seals

Cap o-ring (Re-install with Lubriplate 105)

Stem O-ring (Re-install with Lubriplate 105)

Orifice o-ring (Re-install with Lubriplate 105)

Plug & Stem (Re-install dry)

Replacement of Seals in Slam Shut Seat Assembly

(and FlowGrid if applicable)

1. Disconnect the connecting tubing and accessories

(if applicable)

2. Use 13/16 wrench to remove the four cap screws

on the top plate.

Figure 8 - Stand Alone Slam Shut

Underpressure

protection drive

Overpressure

protection drive

Slam Shut

Sense Line

Slam Shut

Sense Line

Inlet

Flowgrid

Sense Line

Outlet

Figure 9 - Pressure reducing Flowgrid with Slam Shut

downstream overpressure protection

Figure 10 - Pressure reducing Flowgrid with Slam Shut downstream

underpressure protection

Slam Shut

Sense Line

Flowgrid

Sense Line

Outlet

Inlet

Piping Schematic

10

Figure 12 - Standby Monitor with Slam Shut under 60 psid

Figure 13 - Working Monitor with Slam Shut (4 bar)

Figure 11 - Standby Monitor with Slam Shut over 60 psid (4 bar)

Inlet

Flowgrid

Sense Line

Outlet

Slam Shut

Sense Line

Outlet

Outlet

Inlet

Flowgrid

Sense Line

Slam Shut

Sense Line

Inlet

Outlet

Outlet

Slam Shut

Sense Line

Inlet

Flowgrid

Sense Line

Flowgrid Sense LIne Monitor

11

Product Support

Local support is available through our manufactures representative and distributor network. Contact the

factory or refer to our web site for your support representative contact information. Factory support is

available from 8:00 AM to 4:30 PM MST Monday through Friday. Limited after hours support is also available.

Complete product specifications, parts lists, and flow calculation software is available on our web site.

www.ge.com/energy +1 801-487-2225 USA.

Limited Warranty

Seller warrants that Products shall be delivered free from defects in material, workmanship and title and that Services shall be performed in a competent,

diligent manner in accordance with any mutually agreed specifications. The warranty for Products shall expire one (1) year from first use or eighteen (18)

months from delivery, whichever occurs first, except that software is warranted for ninety (90) days from delivery. The warranty for Services shall expire one

(1) year after performance of the Service, except that software-related Services are warranted for ninety (90) days. If Products or Services do not meet the

above warranties, Buyer shall promptly notify Seller in writing prior to expiration of the warranty period. Seller shall (i) at its option, repair or replace defective

Products and (ii) re-perform defective Services. If despite Sellers reasonable efforts, a non-conforming Product cannot be repaired or replaced, or non-

conforming Services cannot be re-performed, Seller shall refund or credit monies paid by Buyer for such non-conforming Products and Services. Warranty

repair, replacement or re-performance by Seller shall not extend or renew the applicable warranty period. Buyer shall obtain Sellers agreement on the

specifications of any tests it plans to conduct to determine whether a non-conformance exists. Buyer shall bear the costs of access for Sellers remedial

warranty efforts (including removal and replacement of systems, structures or other parts of Buyers facility), de-installation, decontamination, re-installation

and transportation of defective Products to Seller and back to Buyer. The warranties and remedies are conditioned upon (a) proper storage, installation,

use, operation, and maintenance of Products, (b) Buyer keeping accurate and complete records of operation and maintenance during the warranty period

and providing Seller access to those records, and (c) modification or repair of Products or Services only as authorized by Seller in writing. Failure to meet

any such conditions renders the warranty null and void. Seller is not responsible for normal wear and tear. The above sets forth the exclusive remedies for

all claims based on failure of or defect in Products or Services, regardless of when the failure or defect arises, and whether a claim, however described, is

based on contract, warranty, indemnity, tort/extra-contractual liability (including negligence), strict liability or otherwise. The warranties provided above

are exclusive and are in lieu of all other warranties, conditions and guarantees whether written, oral, implied or statutory. NO IMPLIED OR STATUTORY

WARRANTY, OR WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLIES.

Troubleshooting

Problem Likely Cause

Fails Shutoff Test (leaks from upstream

to downstream piping)

Damaged Plug Seal

Damaged Seat

Damaged Seat O-Ring

Damaged Body Seal

Porosity in Body Casting

Damaged sealing surface

Service conditions too cold for plug

seal

Fails External Leakage Test Damaged Spring Cover O-ring

Damaged Body Seal

Damaged Sensing Diaphragm

Damaged Flowgrid Diaphragm

Damaged Upper Seal Plate O-ring

Damaged sealing surface

Damaged Sense Port Adapter

O-ring

Fails External Leakage Test out of

Bleed Assembly

Damaged Bleed Cap O-ring

Damaged Bleed Stem O-ring

Damaged Sealing Surface

Vents gas out of Slam Shut Actuator

Body Vent Port

Damaged Sensing Diaphragm

Rubber damaged on diaphragm

assembly nut

Nut on diaphragm assembly not

properly tightened

Damaged Sealing Surface

Fails to Reset Damaged Main Shaft external

threads

Reset Shaft not properly

tightened onto Main Shaft

Main Shaft not properly tightened

onto Plug

Reset Pin missing

Rotator Shaft excessively worn or

damaged

Fails to Trip Closed Rotator Shaft damaged

Excessive internal icing

GEA 20048 Mooney 1 Slam Shut IOM Manual

Rev 06.2012

GE Oil & Gas

2822 S. 1030 West

Salt Lake City, UT 84119

P: +1 801.487.2225

F: +1 801.487.2587

mooney.inquiries@ge.com

Visit us online at:www.ge.com/energy

2012 General Electric Company

All Rights Reserved

*Denotes trademarks of

General Electric Company

You might also like

- HL2-90 Compressor Instr ManualDocument12 pagesHL2-90 Compressor Instr ManualCosmin Iulian100% (3)

- Backup-Script RAW-Mangle-Queue Tree-Simple QueueDocument3 pagesBackup-Script RAW-Mangle-Queue Tree-Simple Queueismanto hamani100% (2)

- Status Note On Collective Investment Schemes - 1326177032722-ADocument225 pagesStatus Note On Collective Investment Schemes - 1326177032722-AVivek Agrawal67% (3)

- RP10Document3 pagesRP10PireyiNo ratings yet

- RTHC Svn02c enDocument16 pagesRTHC Svn02c enRicardo100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- EFM Family Brochure PDFDocument4 pagesEFM Family Brochure PDFCarlos TarquinoNo ratings yet

- Catalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgDocument20 pagesCatalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgluis_d_mNo ratings yet

- D 101550 X 012Document24 pagesD 101550 X 012Norberto SotoNo ratings yet

- Convertidor Neumatico Y695ADocument8 pagesConvertidor Neumatico Y695AALBERTONo ratings yet

- 390 InstructionsDocument48 pages390 InstructionsemaanazeemNo ratings yet

- Manual Regulators Man Slamshut 2-4inchDocument20 pagesManual Regulators Man Slamshut 2-4inchDelfin Rosanieto TapiaNo ratings yet

- Fisherr GX Control Valve and Actuator System: Scope of ManualDocument68 pagesFisherr GX Control Valve and Actuator System: Scope of Manualابزار دقیقNo ratings yet

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pages52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNo ratings yet

- Control Valve Norriseal - Series2200 O&MDocument16 pagesControl Valve Norriseal - Series2200 O&MJairo AlonsoNo ratings yet

- Fisher Design ETR ValveDocument24 pagesFisher Design ETR ValveTanuTiganuNo ratings yet

- Conver 6358Document8 pagesConver 6358ALBERTONo ratings yet

- Instalación y Mantenimiento de Válvulas RotativasDocument4 pagesInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraNo ratings yet

- BPRVDocument18 pagesBPRVPatel UsamaNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- HM and HM34 Inverted Bucket Steam TrapsDocument12 pagesHM and HM34 Inverted Bucket Steam TrapsJuan ZamoraNo ratings yet

- 3-5400 SERIES Safety Relief Valves: Instruction ManualDocument16 pages3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanNo ratings yet

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftNo ratings yet

- Butterfly Valve User ManualDocument10 pagesButterfly Valve User ManualEduardoAscencioNo ratings yet

- 67C and 67CF Series: Installation Guide English - December 2003Document2 pages67C and 67CF Series: Installation Guide English - December 2003mpendletonNo ratings yet

- SolenoidDocument2 pagesSolenoidStelios KonstantinidesNo ratings yet

- G4 Iom PDFDocument16 pagesG4 Iom PDFgullenariNo ratings yet

- Convertidor Mechanical S108KDocument8 pagesConvertidor Mechanical S108KALBERTONo ratings yet

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 pagesOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonNo ratings yet

- Pressure Reducing Regulator FISHER Manual Serie 64Document8 pagesPressure Reducing Regulator FISHER Manual Serie 64Billy Isea DenaroNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- 727 PosrvDocument7 pages727 Posrvtxlucky80No ratings yet

- HDPH436vikingheavypump (German)Document17 pagesHDPH436vikingheavypump (German)Hector_Cornejo_5673No ratings yet

- Stop and Check ValvesDocument24 pagesStop and Check ValvesRahul PatilNo ratings yet

- D 100394 X 012Document52 pagesD 100394 X 012Preyas SuvarnaNo ratings yet

- Installation Instructions: Dry Gas Dual Cartridge Canister Seal For Mixers and AgitatorsDocument8 pagesInstallation Instructions: Dry Gas Dual Cartridge Canister Seal For Mixers and AgitatorsDima ArfNo ratings yet

- +FlowgridSlamShut Bro - 111Document8 pages+FlowgridSlamShut Bro - 111Carlos TarquinoNo ratings yet

- Safety Relief Valves Operation ManualDocument21 pagesSafety Relief Valves Operation ManualSumit JadhavNo ratings yet

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocument20 pagesFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNo ratings yet

- Válve Relay Air Starters CAT E WaukeshaDocument8 pagesVálve Relay Air Starters CAT E WaukeshaJonatas Barbaglio Gomes PereiraNo ratings yet

- LPG Pump IOM LGL2 LGL3 PDFDocument12 pagesLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- 30RB 21siDocument76 pages30RB 21sixavierxo50% (2)

- 1zua5492-505 - Gas Detector Relay Model 11 and 12Document16 pages1zua5492-505 - Gas Detector Relay Model 11 and 12Hau Phung VanNo ratings yet

- Before Installation, These Instructions Must Be Fully Read and UnderstoodDocument1 pageBefore Installation, These Instructions Must Be Fully Read and Understoodtilakthakar1No ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- IOM Manual For CAMAROON Ball ValvesDocument20 pagesIOM Manual For CAMAROON Ball ValvesSathish Kumar Pt100% (2)

- Breathing Air Distribution System Technical Rescue Cart Instruction Manual - EN PDFDocument30 pagesBreathing Air Distribution System Technical Rescue Cart Instruction Manual - EN PDFSERGIONo ratings yet

- Amico Regulador de Manifold Planos PDFDocument52 pagesAmico Regulador de Manifold Planos PDFLopez ClaudioNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Febco DCD and DC 850 856 870 and 876Document12 pagesFebco DCD and DC 850 856 870 and 876Brandon TrocNo ratings yet

- Oper - 69NT40-511-345 To-399Document121 pagesOper - 69NT40-511-345 To-399cloviskrellingNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- Section 4 - Gas Regulation Low PressureDocument12 pagesSection 4 - Gas Regulation Low PressurehammamiNo ratings yet

- Models 69NT40-511-300 To 309, 69NT40-511-311 To 399Document117 pagesModels 69NT40-511-300 To 309, 69NT40-511-311 To 399cloviskrelling100% (2)

- 67CF Series Installation Sheet PDFDocument4 pages67CF Series Installation Sheet PDFARMANDONo ratings yet

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- 19 Series - Safety Valve: Installation, Operation, & MaintenanceDocument6 pages19 Series - Safety Valve: Installation, Operation, & MaintenanceADAN CESSANo ratings yet

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARNo ratings yet

- HD 102 Alarm Valve Model ADocument9 pagesHD 102 Alarm Valve Model AjabbanNo ratings yet

- In-Line Hydraulic TesterDocument5 pagesIn-Line Hydraulic TesterMasterrNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- SIL Explained: Fluid Power Actuators and Control SystemsDocument8 pagesSIL Explained: Fluid Power Actuators and Control Systemsprihartono_diasNo ratings yet

- IATD April 2015 Packaging - Solutions - LoRes PDFDocument48 pagesIATD April 2015 Packaging - Solutions - LoRes PDFCarlos TarquinoNo ratings yet

- Modern Leak Detection Modern Leak Detection Technologies TechnologiesDocument45 pagesModern Leak Detection Modern Leak Detection Technologies TechnologiesCarlos TarquinoNo ratings yet

- ++flow Calculation For Gases PDFDocument1 page++flow Calculation For Gases PDFCarlos TarquinoNo ratings yet

- Fundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyDocument6 pagesFundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyCarlos TarquinoNo ratings yet

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoNo ratings yet

- 0428 1700 Methane Leak Detection and Measurement Technologies Heath PDFDocument23 pages0428 1700 Methane Leak Detection and Measurement Technologies Heath PDFCarlos TarquinoNo ratings yet

- 43 430 UF Final PDFDocument4 pages43 430 UF Final PDFCarlos TarquinoNo ratings yet

- Slab056d PDFDocument64 pagesSlab056d PDFCarlos TarquinoNo ratings yet

- User's Manual: 1-800-HEATH-USDocument35 pagesUser's Manual: 1-800-HEATH-USCarlos TarquinoNo ratings yet

- Comparison of Various Short Range Wireless Communication Technologies With NFCDocument5 pagesComparison of Various Short Range Wireless Communication Technologies With NFCCarlos TarquinoNo ratings yet

- Paradigms of Public AdministrationDocument7 pagesParadigms of Public AdministrationannNo ratings yet

- PL17 Accelerate MySQL Apache Ignite 4656Document35 pagesPL17 Accelerate MySQL Apache Ignite 4656Kishor pNo ratings yet

- The Principles of InvestmentDocument29 pagesThe Principles of InvestmentsimilikitiawokwokNo ratings yet

- IJAIR Volume 9 Issue 2 (IX) April - June 2022Document289 pagesIJAIR Volume 9 Issue 2 (IX) April - June 2022Rupali BhardwajNo ratings yet

- Train Schedule Hyderabad StationDocument5 pagesTrain Schedule Hyderabad Stationnitin guptaNo ratings yet

- Strategic Leadership Primer PDFDocument75 pagesStrategic Leadership Primer PDFAbdul Jabbar100% (1)

- SpaceCAD Model Rocket SoftwareDocument7 pagesSpaceCAD Model Rocket Softwareheric19886445No ratings yet

- Cloud Computing Lab ManualDocument57 pagesCloud Computing Lab ManualAdvithNo ratings yet

- Digital Microwave Communication PrinciplesDocument113 pagesDigital Microwave Communication PrinciplesMustaf MohamedNo ratings yet

- 2nd Sem Previous Yr. Question Papers (5 Subjects)Document44 pages2nd Sem Previous Yr. Question Papers (5 Subjects)Muhammed Muktar0% (1)

- 15 27.10.2020 Machine Learning Johan Van Middelaar TNODocument13 pages15 27.10.2020 Machine Learning Johan Van Middelaar TNOShahzadNo ratings yet

- Steering StandardDocument7 pagesSteering StandardAbinash KumarNo ratings yet

- Colder Catalog 27-30 PMC ConnectorsDocument4 pagesColder Catalog 27-30 PMC ConnectorsDENNIZNo ratings yet

- SPE 26515 Overbalance Perforating and Stimulation Method For WellsDocument10 pagesSPE 26515 Overbalance Perforating and Stimulation Method For WellsSebastián PavónNo ratings yet

- Rules/Terms of ServiceDocument8 pagesRules/Terms of ServiceBaptiste THEVENOTNo ratings yet

- Ted Nelson - Computer Lib - Dream Machine PDFDocument132 pagesTed Nelson - Computer Lib - Dream Machine PDFgmtinwinslienl12No ratings yet

- Lecture Week 4: Algorithm ComplexityDocument34 pagesLecture Week 4: Algorithm ComplexityMaham uroojNo ratings yet

- Asus LaptopDocument118 pagesAsus Laptopanu johnNo ratings yet

- Cement Ceramic HR NumbersDocument8 pagesCement Ceramic HR NumbersCorrosion FactoryNo ratings yet

- Lesson Plan Spark Plug Removal & ReplacementDocument4 pagesLesson Plan Spark Plug Removal & ReplacementVon MoreNo ratings yet

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDocument17 pages15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- 1.EE 563 SyllabusDocument3 pages1.EE 563 SyllabusMohammad Reza RajatiNo ratings yet

- ABB Price Book 764Document1 pageABB Price Book 764EliasNo ratings yet

- B1 (2016) : D B I: Natef Task Sheet - Section A.5 D.3,6,8,10 P-1 ISC Rake NspectionDocument1 pageB1 (2016) : D B I: Natef Task Sheet - Section A.5 D.3,6,8,10 P-1 ISC Rake Nspectionabul hussainNo ratings yet

- Initial Environmental Examination: Section No. 1: Jalalabad-Kunar 220 KV Double Circuit Transmission Line ProjectDocument129 pagesInitial Environmental Examination: Section No. 1: Jalalabad-Kunar 220 KV Double Circuit Transmission Line ProjectfazailNo ratings yet

- Introduction To The Study of GlobalizationDocument47 pagesIntroduction To The Study of GlobalizationRyan Jule CruzNo ratings yet

- Aonla Cultivation Is Profitable SereddyDocument3 pagesAonla Cultivation Is Profitable SereddyDr.Eswara Reddy SiddareddyNo ratings yet

- This Map Should Only Be Used As A Guide. Refer To Individual Timetables For Detailed Information On Fare/zone BoundariesDocument1 pageThis Map Should Only Be Used As A Guide. Refer To Individual Timetables For Detailed Information On Fare/zone BoundarieslerplataNo ratings yet